Welding method of stainless steel clad plate

A welding method and composite board technology, applied in welding equipment, welding/welding/cutting items, arc welding equipment, etc., can solve the problems of easy cracks at joints and low welding quality, and achieve high welding efficiency, avoid cracks, The effect of improving the quality of welded joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

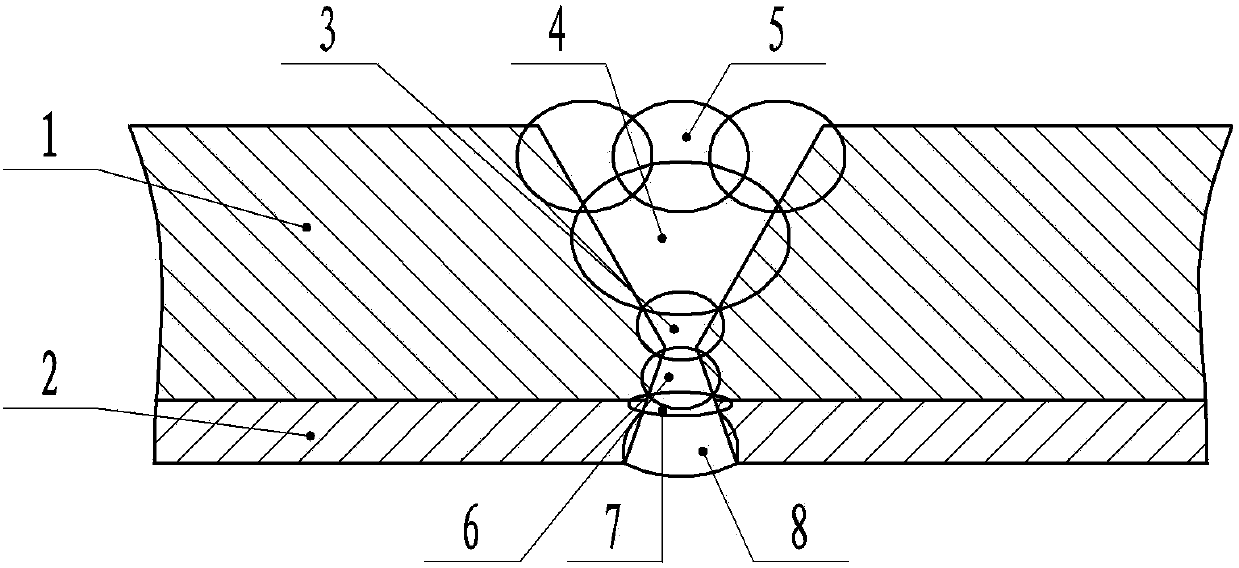

[0017] figure 1 The stainless steel clad plate shown includes a base layer 1 and a clad layer 2, the base layer 1 is Q245R, and the clad layer 2 is 301 stainless steel; when performing welding operations, first remove the surface oxides of the base layer 1 and clad layer 2 of the stainless steel clad plate to be welded ; Then process the groove on the butt end of the treated stainless steel composite plate, the groove is an X-shaped groove, the groove angle is 55°, the root gap of the groove is 1 mm, the joint root is in the base layer, and the joint root to the interface The distance is 1 mm; then, welding the base layer 1, the weld seam of the base layer 1 is composed of the first welding layer 3, the second welding layer 4 and the third welding layer 5 from inside to outside, wherein the third welding layer 5 has multiple The first welding layer 3 and the third welding layer 5 are welded by submerged arc automatic welding, the current intensity of submerged arc automatic we...

Embodiment 2

[0019] The base layer of the stainless steel clad plate in the present embodiment is Q345R, and cladding is 304 stainless steel; When carrying out welding operation, first remove the base layer of the stainless clad plate to be welded and the surface oxide of clad layer; Then the stainless clad plate after processing The butt end of the groove is processed with a groove, the groove is an X-shaped groove, the groove angle is 60°, the root gap of the groove is 2mm, the root of the joint is in the base, and the distance from the root of the joint to the interface is 2 mm; Then, weld the base , the weld of the base layer is composed of the first welding layer, the second welding layer and the third welding layer from the inside to the outside, wherein the third welding layer has multiple weld passes, and the first welding layer and the third welding layer adopt Welding by submerged arc automatic welding, the current intensity of submerged arc automatic welding is 165 amps, the arc ...

Embodiment 3

[0021] The base layer of the stainless steel clad plate in the present embodiment is Q345R, and cladding is 304 stainless steel; When carrying out welding operation, first remove the base layer of the stainless clad plate to be welded and the surface oxide of clad layer; Then the stainless clad plate after processing Groove is processed at the butt joint end, the groove is X-shaped groove, the groove angle is 65°, the root gap of the groove is 3 mm, the root of the joint is in the base, and the distance from the root of the joint to the interface is 2 mm; then, weld the base , the weld of the base layer is composed of the first welding layer, the second welding layer and the third welding layer from the inside to the outside, wherein the third welding layer has multiple weld passes, and the first welding layer and the third welding layer adopt Welding by submerged arc automatic welding, the current intensity of submerged arc automatic welding is 180 amps, the arc voltage is 23 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com