900MPa-level high-performance gas shielded welding wire

A gas shielded welding wire, high-performance technology, used in welding media, welding equipment, welding/cutting media/materials, etc., can solve the problem of low low temperature impact toughness, increased weld metal strength, adverse weld metal crack resistance and low temperature. Toughness requirements and other issues, to achieve good crack resistance and low temperature toughness, the effect of improving toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with embodiment.

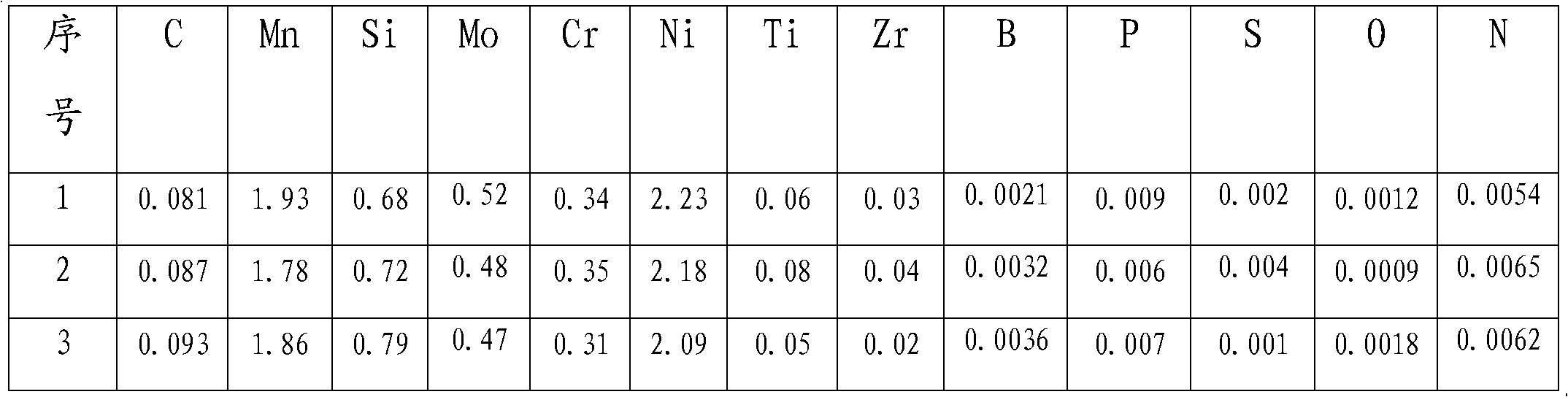

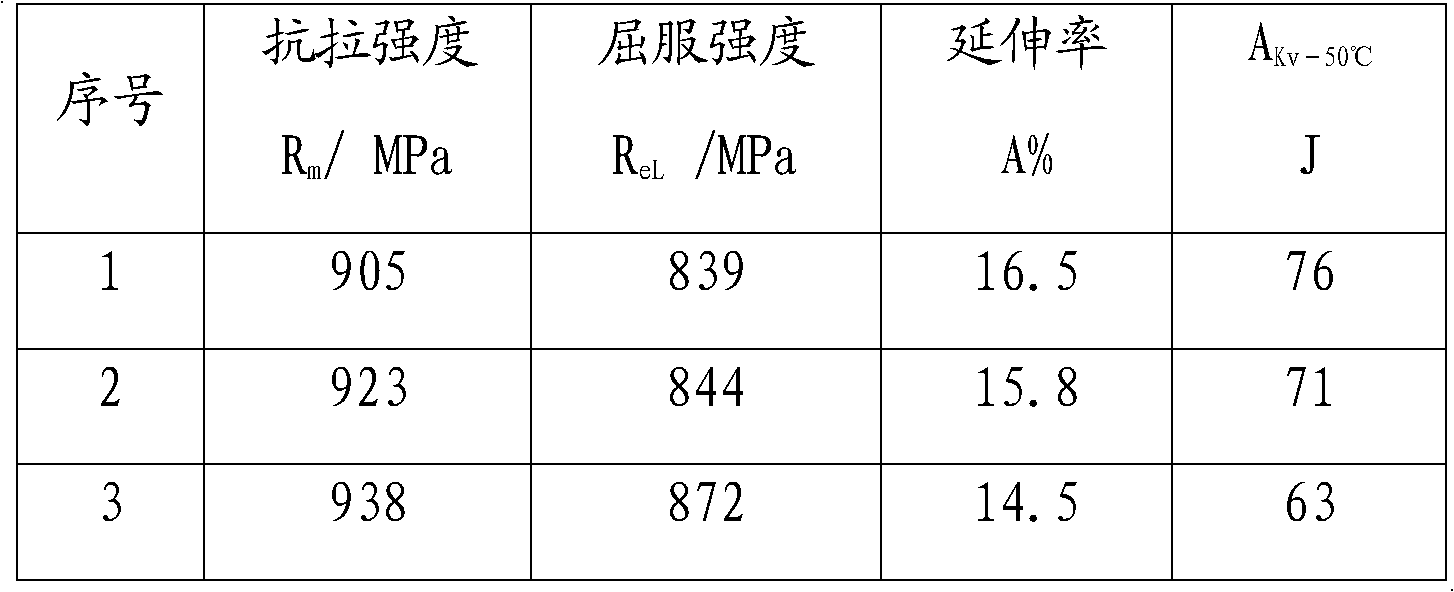

[0015] According to the scope of chemical composition of the present invention, adopt vacuum induction furnace (whether it is a commercially available product, is there any requirement to specification?) to smelt three furnaces of welding wire steel (specific process steps, such as: technical requirements such as temperature and time), after forging , rolling, wire drawing, copper plating and shaft winding, etc., and processed into a finished welding wire with a diameter of 1.2mm. The chemical composition of the welding wire is shown in Table 1. Three kinds of welding wire use Ar+20%CO 2 The mechanical properties of the deposited metal are shown in Table 2.

[0016] The chemical composition (mass percentage, %) of welding wire of table 1 embodiment

[0017]

[0018] The mechanical property of table 2 embodiment welding wire deposited metal

[0019]

[0020] The balance of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com