Novel narrow-gap gas metal arc welding gun

A melting electrode gas, shielded welding technology, applied in welding equipment, electrode characteristics, arc welding equipment, etc., can solve the problems of accidental arcing on the side wall, welding torch cooling, and lack of fusion on the side wall, and achieve good welding quality and welding process. Stable, high welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

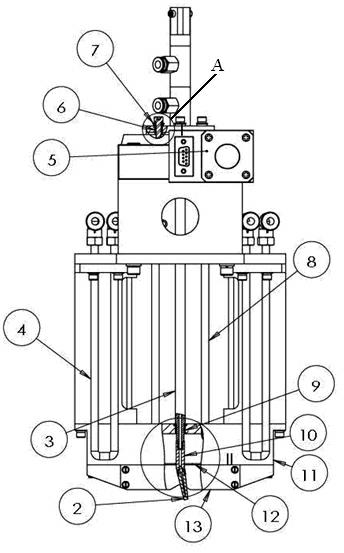

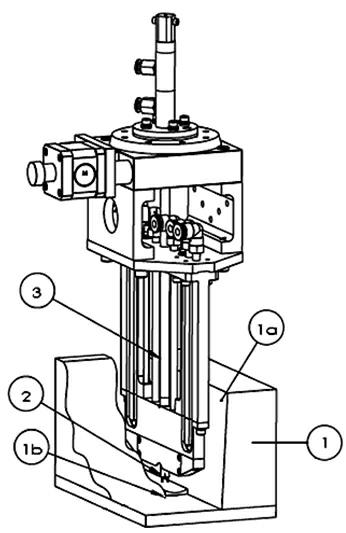

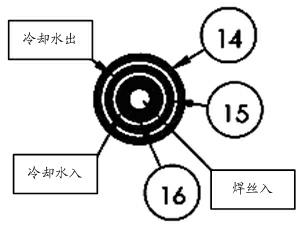

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0032] Theoretically, the heat input of narrow gap metal arc welding (NG-GMAW) is between submerged arc welding and argon tungsten arc welding. Makes NG-GMAW very potential. In recent decades, domestic research investment on narrow-gap gas metal shielded welding has been very large. At the same time, the rapid development of machinery manufacturing and control technology has also provided a good opportunity for the breakthrough of NG-GMAW. The present invention is It came into being under the circumstances of such a great opportunity and market demand.

[0033] The invention provides a novel narrow-gap MIG shielded welding torch. The welding torch is flat overall and can work in a narrow space. At the same time, the thickness of the welding torch can be controlled within 10mm according to the limitation of the actual working environment and the processing level. Su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com