Composite welding method of ultrasound wave and non-melt pole electrical arc

A non-melting electrode, welding method technology, applied in arc welding equipment, welding equipment, vibrating fixtures for electrodes, etc. Controlling and regulating effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

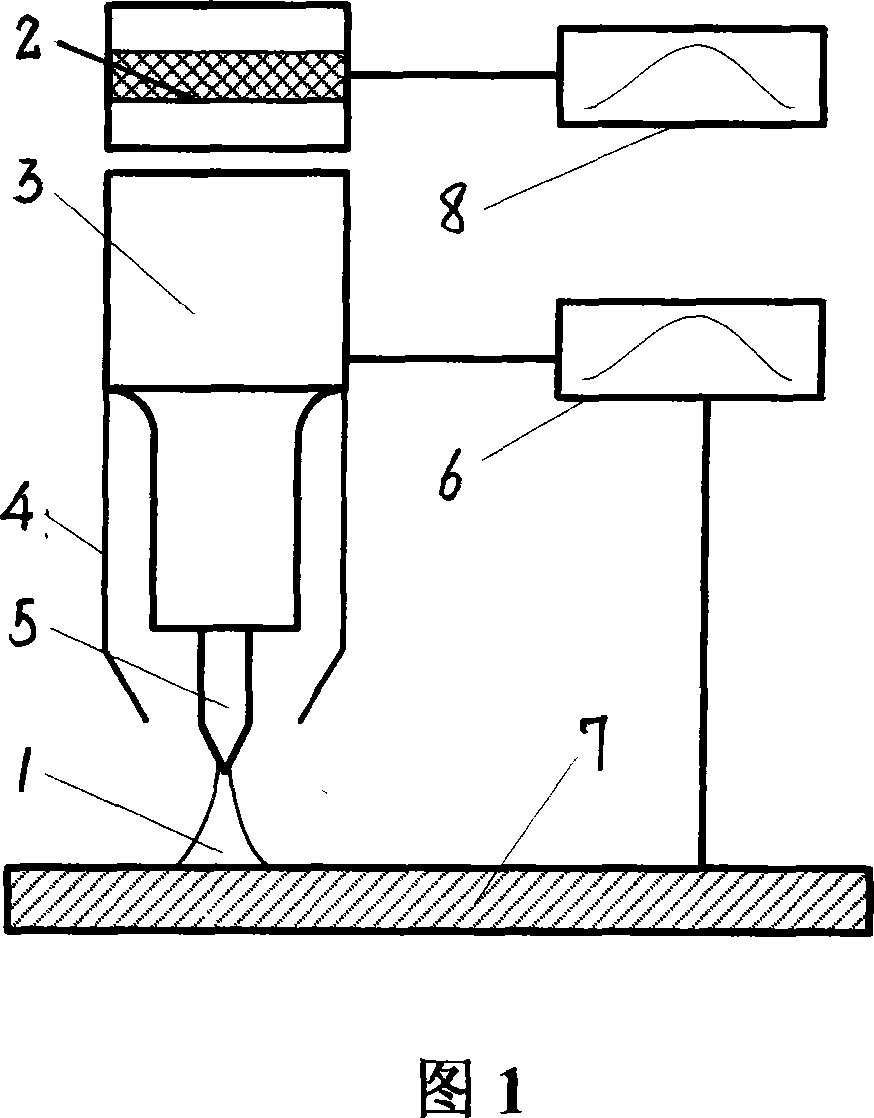

[0017] The high-frequency electrical signal of the ultrasonic power supply is converted into mechanical vibration through the transducer. The mechanical vibration amplitude of the transducer is small, and it is amplified to 30μm-150μm by the horn of the next stage, and finally the vibration is transmitted to the inlay On the electrodes in the horn, as shown in Figure 1. The above-mentioned device can work under the ultrasonic vibration with a frequency of 15kHz to 2MHz, and generate ultrasonic vibration of corresponding frequency on the electrodes. The input power of the ultrasound can be adjusted arbitrarily between 1W and 1000W. Then, the welding is carried out according to the method of ordinary non-melting electrode gas shielded welding. After applying the ultrasound, the welding arc will be compressed by the ultrasound. The arc 7 concentrates energy when processing the workpiece 1, effectively improving the utilization rate of the arc during welding.

[0018] The inventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com