3D metal welding and printing method based on gas metal arc welding and numerical control machining

A technology of melting electrode gas and 3D printing, which is applied in the field of metal welding 3D printing and manufacturing metal parts, which can solve the problems of inability to manufacture high density and high strength, eliminate defects such as internal pores and microcracks, and increase cooling speed , Improve the effect of density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] This example uses ER50-6 solid core welding wire for welding hollow objects with a single wall thickness of 3mm and a size of 80mm×80mm×60mm. The shielding gas uses Ar80%+CO 2 20% mixed gas. One weld on each layer, the height of each weld is 3mm, and the distance between adjacent welds (the upper and lower layers) is 3mm. The lowering height of the working table is 3mm, the surface of the obtained welding sample is well formed, the bonding effect between the upper and lower adjacent welds is better, and there is no obvious boundary in the macroscopic view. The specific welding process parameters are shown in the following table:

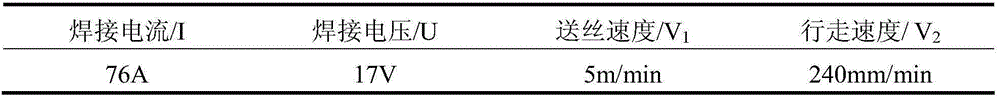

[0024] Process parameters of the bottom 1-4 layers of the sample

[0025]

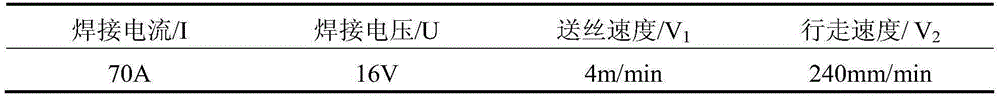

[0026] Process parameters of the middle 5-15 layers of the sample

[0027]

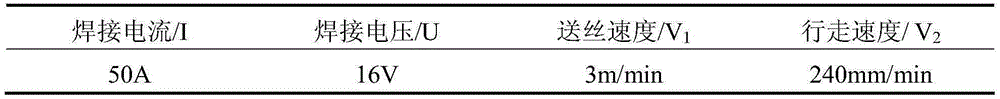

[0028] Process parameters of the top 16-20 layers of the sample

[0029]

[0030] Due to the small size of the sample, it did not meet the requirements of the national standard, and it was not test...

Embodiment 2

[0032] This example uses The ER50-6 welding wire is used for welding hollow samples, the size is 350mm×60mm×45mm. Shielding gas is mixed gas: Ar80%+CO 2 20%. Each layer consists of 5 welds. The width of each weld is w=3mm, and the height h=3mm. The distance between adjacent welds (two meanings: one means adjacent to each other up and down; one means adjacent to left and right) is 3mm. The lowering height of the worktable is 3mm, the surface of the welded sample prepared is well formed, the bonding effect between the two welds is good, and there is no obvious boundary in the macroscopic view. The specific welding process parameters are shown in the following table:

[0033] Process parameters of the bottom 1-5 layers of the sample

[0034]

[0035] Process parameters of the middle 6-8 layers of the sample

[0036]

[0037] Process parameters of the top 9-15 layers of the sample

[0038]

[0039] Sample mechanical performance testing

[0040]

[0041] In short, the present invention ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com