Method for welding pile leg main board pipe

A welding method and the technology of the main side pipe, applied in the direction of welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of slow welding speed and high welding cost, achieve the improvement of welding speed, reduce welding cost, and ensure welding quality requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention comprises the steps:

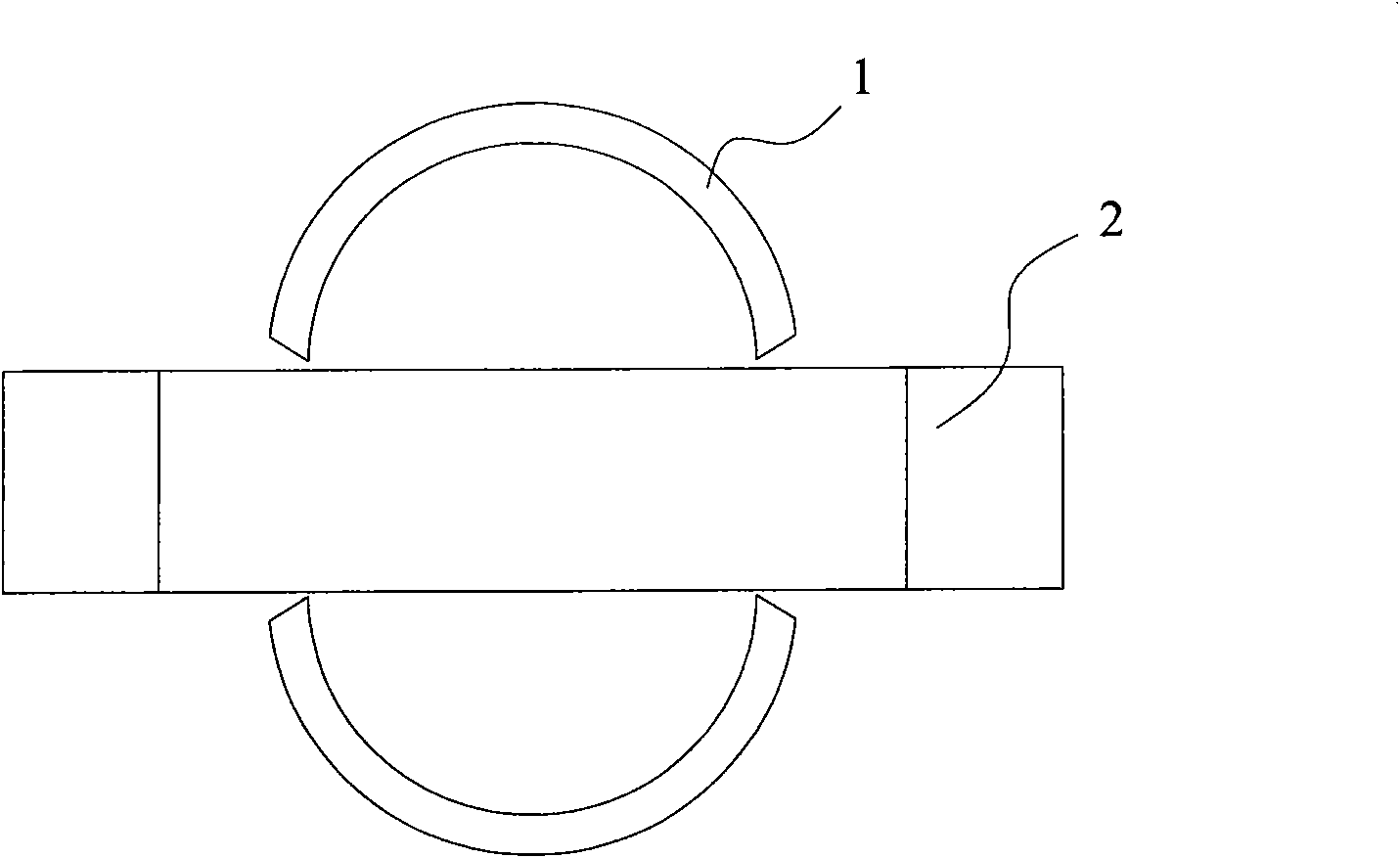

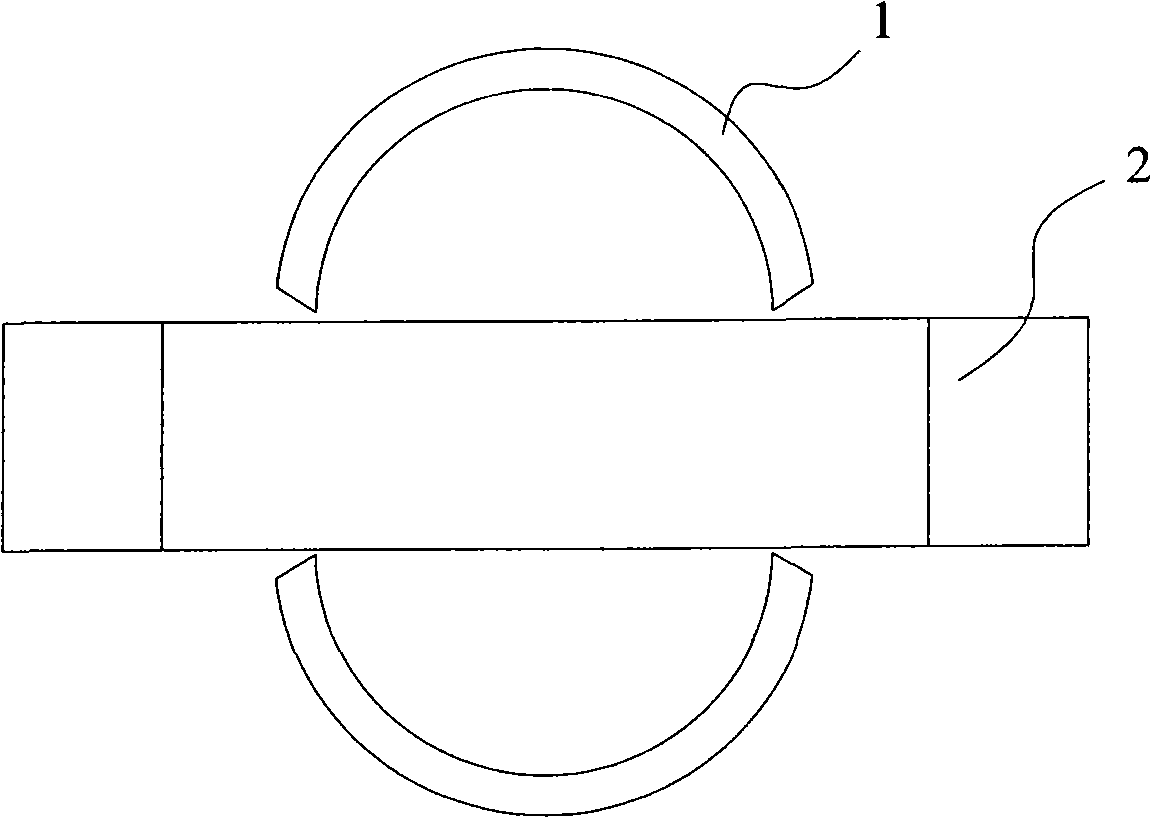

[0014] Step a, such as figure 1 As shown, butt the processed semicircular plate 1 with the rack 2;

[0015] Step b, heating the welding joint to 120-180°C for spot welding, the length of the spot welding is 100-150mm, and the interval is less than 300mm;

[0016] Step c. Preheat the workpiece with an electric heating plate, the workpiece is preheated to 150-180°C, and the preheating range is at least within 80mm around the weld;

[0017] Step d, control the interlayer temperature at 180±10°C, use GMAW gas shielded welding with 1-1.4mm welding wire to seal the bottom, and submerged arc welding to fill the cover with 3-5mm; when welding, the joints between the same semicircular plate and the rack are carried out simultaneously Symmetrical welding to eliminate distortion from the welding process.

[0018] By adopting the welding method combining GMAW gas shielded welding and submerged arc welding, the invention can not only e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com