Ultrasonic welding head applicable to automobile dashboard glass welding

An automobile instrument panel and ultrasonic technology, which is applied in the field of ultrasonic welding heads, can solve the problems of inaccurate welding of instrument panel glass, and achieve the effect of ensuring the accuracy and welding quality requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

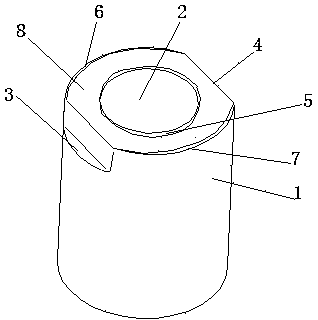

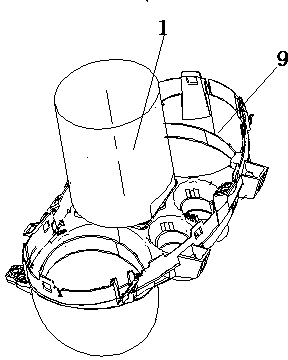

[0012] Embodiment 1: as figure 1 , 2 As shown, an ultrasonic welding head suitable for welding automobile instrument panel glass includes a welding head body 1, and an inner ring welding protrusion arranged on the periphery of the energy diversity hole is provided on the ultrasonic generating surface 8 of the welding head body 1 5. The upper welding protrusion 6 arranged on the upper side of the ultrasonic generating surface 8, the lower welding protrusion 7 arranged on the lower side of the ultrasonic generating surface 8, the welding head body 1 is cylindrical, and the middle part is provided with an energy Diversity hole 2, the energy diversity hole 2 disperses the energy to the welding protrusion, the welding protrusion contacts the welding surface of the workpiece 9, generates ultrasonic waves to weld the glass on the workpiece 9, and has a shape gap on the upper side of the welding head body 3. The shape gap 3 is designed to concentrate the ultrasonic waves converted by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com