Ultrahigh speed double-wire common molten pool gas metal arc welding process for low carbon steel thin plate welding

A welding technology of molten electrode gas and thin plate, applied in welding equipment, manufacturing tools, arc welding equipment, etc., to achieve strong adaptability, reduce welding production costs, improve the flow process of liquid metal and the effect of heat distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

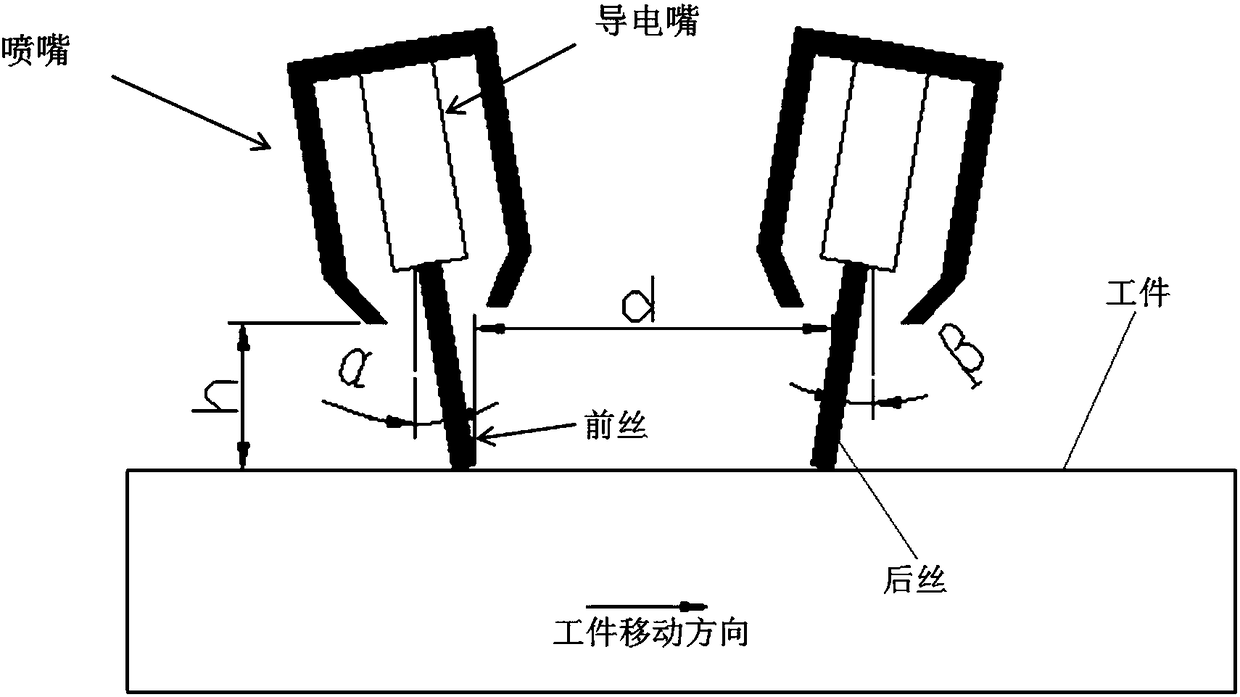

[0042] Such as figure 1 As shown, an ultra-high-speed twin-wire eutectic pool gas shielded welding process for welding low-carbon steel sheets includes the following steps:

[0043] (1) Pretreatment before welding: 2mm thick Q235 is used as the welding workpiece. The workpiece does not need to be grooved, and the butt edge is kept perpendicular to the surface of the workpiece; the area to be welded is ground and derusted, and the grinding width is not less than 20mm;

[0044] (2) Workpiece clamping: Clamp the two workpieces processed in step (1) on a worktable that can move the workpiece at a constant speed at any speed between 0.5 and 4.0m / min, without using a liner; The gap between workpieces is 0.8mm; with ordinary CO 2 Gas shielded welding for tack welding;

[0045] (3) Welding: fix the front welding torch and the rear welding torch on the upper part of the workpiece to be welded in step (2) along the welding direction, the vertical distance between the nozzle of the we...

Embodiment 2

[0060] With 2mm thick Q235 as the welding workpiece, adopt the same welding process and parameters as in Example 1 to test the flow situation of the molten pool in the workpiece welding process, the results are as follows Figure 5 It can be seen that a shallow depression is formed in the molten pool below the front wire arc, and the liquid metal flows backward, but under the forward blowing force of the rear wire arc, the backward flow velocity of the liquid metal decreases , the accumulation of liquid metal between the two welding wires has increased but no obvious liquid local bulge has been formed, while the liquid metal in the tail area of the molten pool is evenly distributed and has good fluidity, without significant depressions, thin liquid layers, and liquid metal in the front of the molten pool. The appearance of a bulge. This is because the rear wire arc with a smaller current exerts a certain hindering effect on the high-speed backward liquid flow at the front of...

Embodiment 3

[0064] An ultra-high-speed twin-wire eutectic pool gas shielded welding process for welding low-carbon steel sheets, comprising the following steps:

[0065] (1) Pretreatment before welding: 1.5mm thick Q235 is used as the welding workpiece. The workpiece does not need to be grooved, and the butt edge is kept perpendicular to the surface of the workpiece; the area of the workpiece to be welded is ground and derusted, and the grinding width is not less than 20mm.

[0066] (2) Workpiece clamping: Clamp the two workpieces processed in step (1) on a worktable that can move at a constant speed at any speed between 0.5 and 4.0m / min, and the gap between the workpieces is 0.5mm; no need to use liner; use ordinary CO 2 Gas shielded welding for tack welding;

[0067] (3) Welding: fix the front welding torch and the rear welding torch on the upper part of the workpiece to be welded in step (2) along the welding direction, the vertical distance between the nozzle of the welding torch ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Plate thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com