Patents

Literature

53results about How to "Appropriate resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

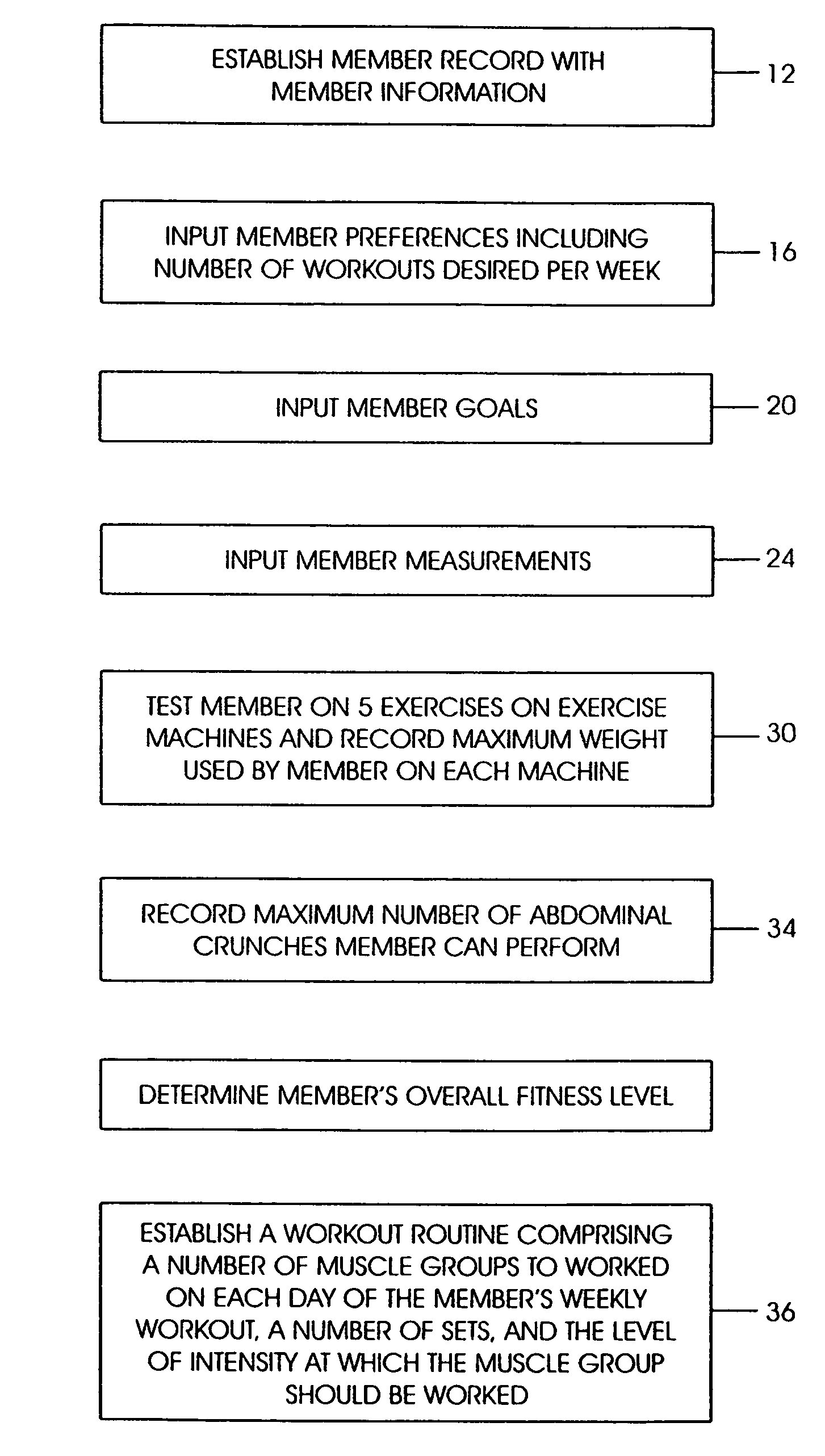

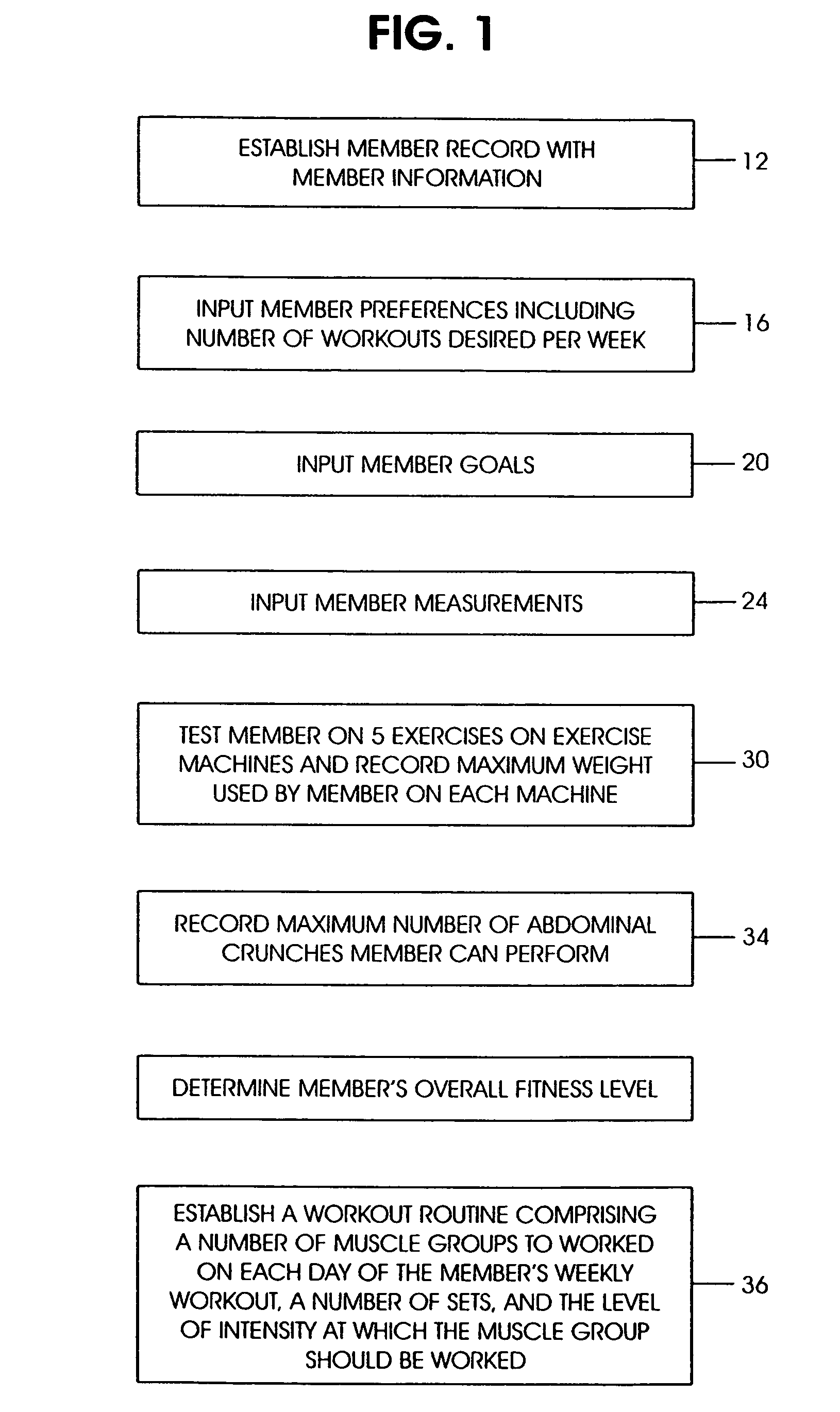

System and method for preparing workouts for a plurality of individuals and monitoring individual compliance

A method of developing a workout comprising a series of exercises and communicating the workout to a user is disclosed that involves identifying a muscle group to use during a workout, selecting an intensity level for exercising the muscle group, selecting an exercise from a plurality of exercises for exercising the muscle group, selecting a routine from a plurality of routines for performing each of the plurality of exercises at the selected intensity level, each of the plurality of routines comprising a number of repetitions, selecting a resistance level related to the maximum resistance the user was able to manipulate on a first exercise machine, selecting a second exercise machine for performing the selected exercise, and displaying a workout comprising an identification of the second exercise machine, a name of an exercise to be performed on the second exercise machine, a resistance level to be used in performing the named exercise on the second exercise machine, and information relating to the number of repetitions and sets to be performed. A system for carrying out the method is also disclosed.

Owner:ACTIV TRAX

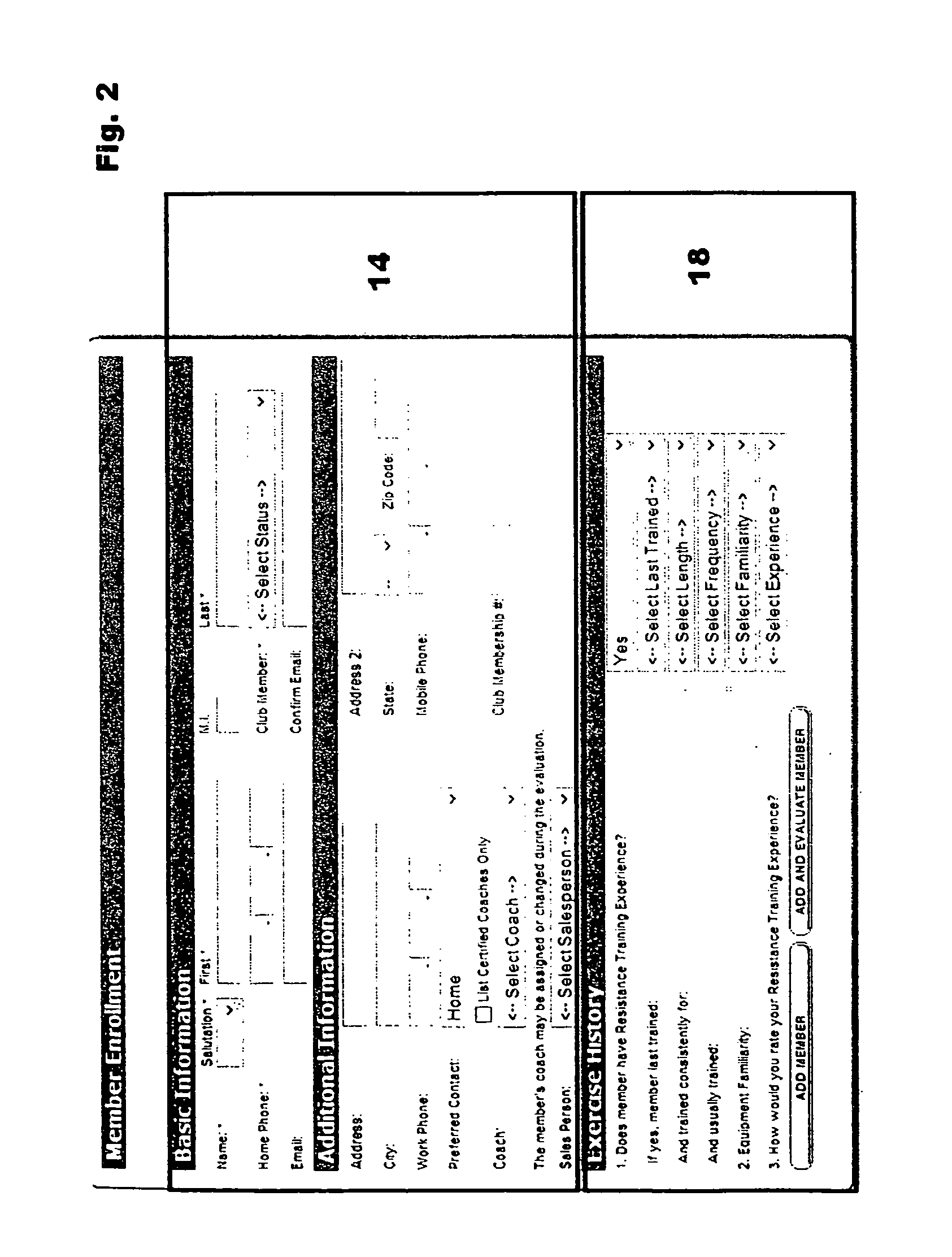

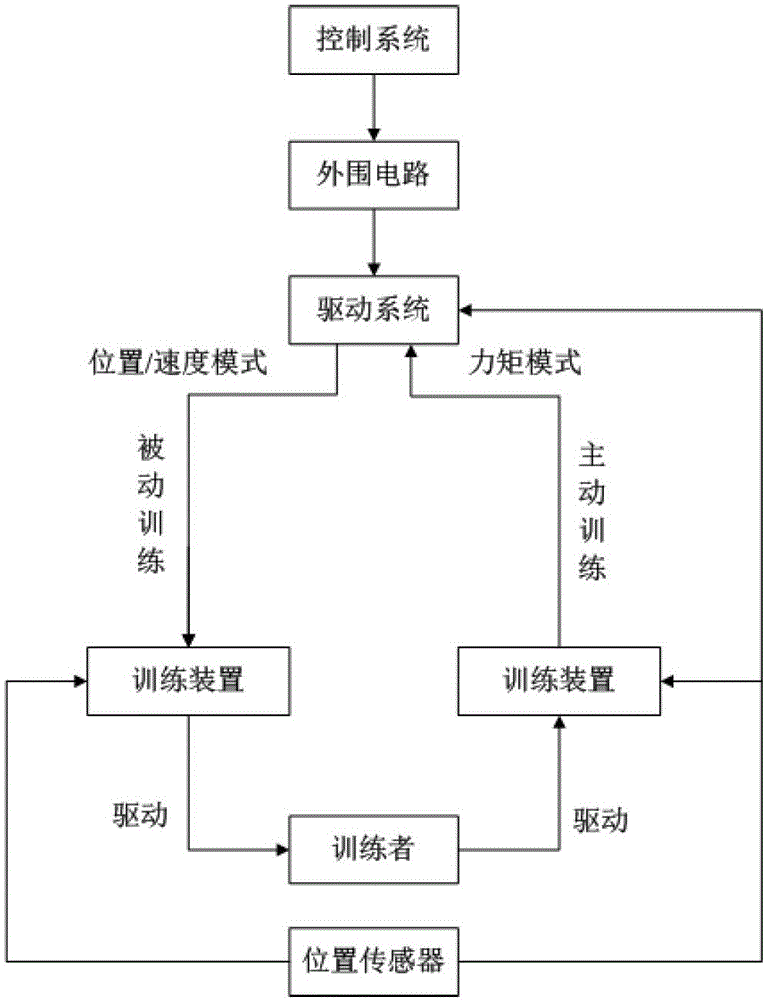

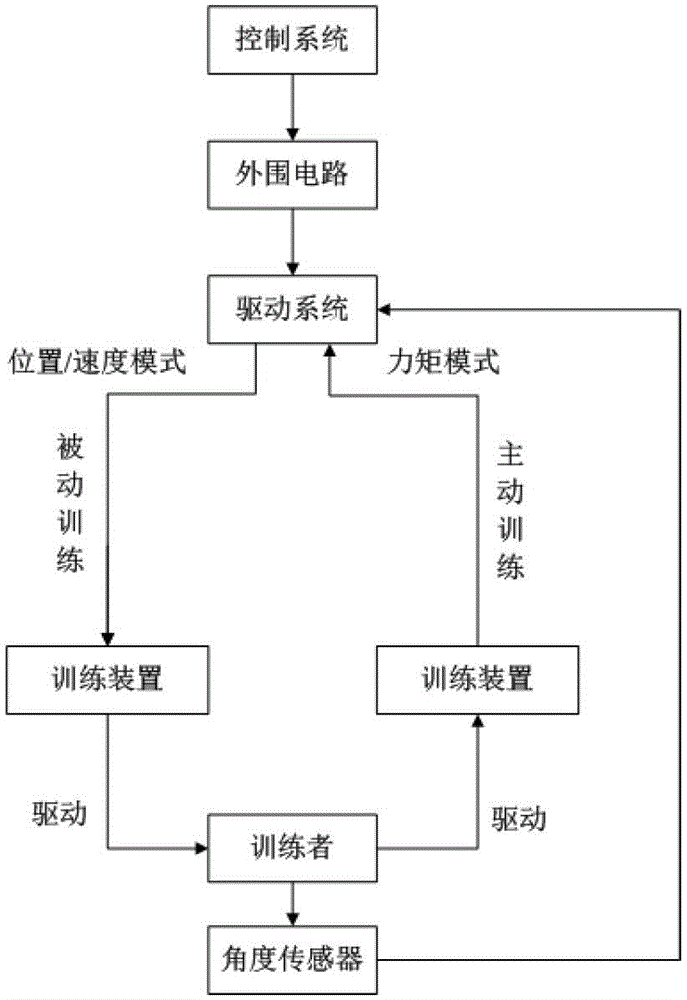

Active and passive realizing method of healthy exercise trainer

ActiveCN103142383ASensitive resistance changesSoft resistanceChiropractic devicesMuscle exercising devicesTime switchingPhysical exercise

The invention discloses an active and passive realizing method of a healthy exercise trainer. When a trainer is in passive training, a control motor is in either a position mode or a speed mode, and upper and lower limbs are driven to exercise to finish the passive training through a training device; when the trainer is in active training, the upper and lower limbs of the trainer exert strength, the motor is set to be in a torque mode, and the motor is driven to rotate through the training device; and the trainer is in assisted training, a working mode of the motor is a combination of the torque mode and the position mode or the speed mode in the different time periods, the active and passive trainings can be achieved through the real-time switching of the control motor between the position mode or the speed mode and the torque mode. According to the active and passive realizing method of the healthy exercise trainer, the initiatives of the trainers who take part in the training can be improved, and either body builders or patients can autonomously regulate the training mode, speed and intensity according to their own physical conditions and physical abilities, so that the active and passive realizing method of the healthy exercise trainer can be suitable for the healthy training of different recovery stages and different psychologic statuses.

Owner:WUHU TIANREN INTELLIGENT MACHINERY

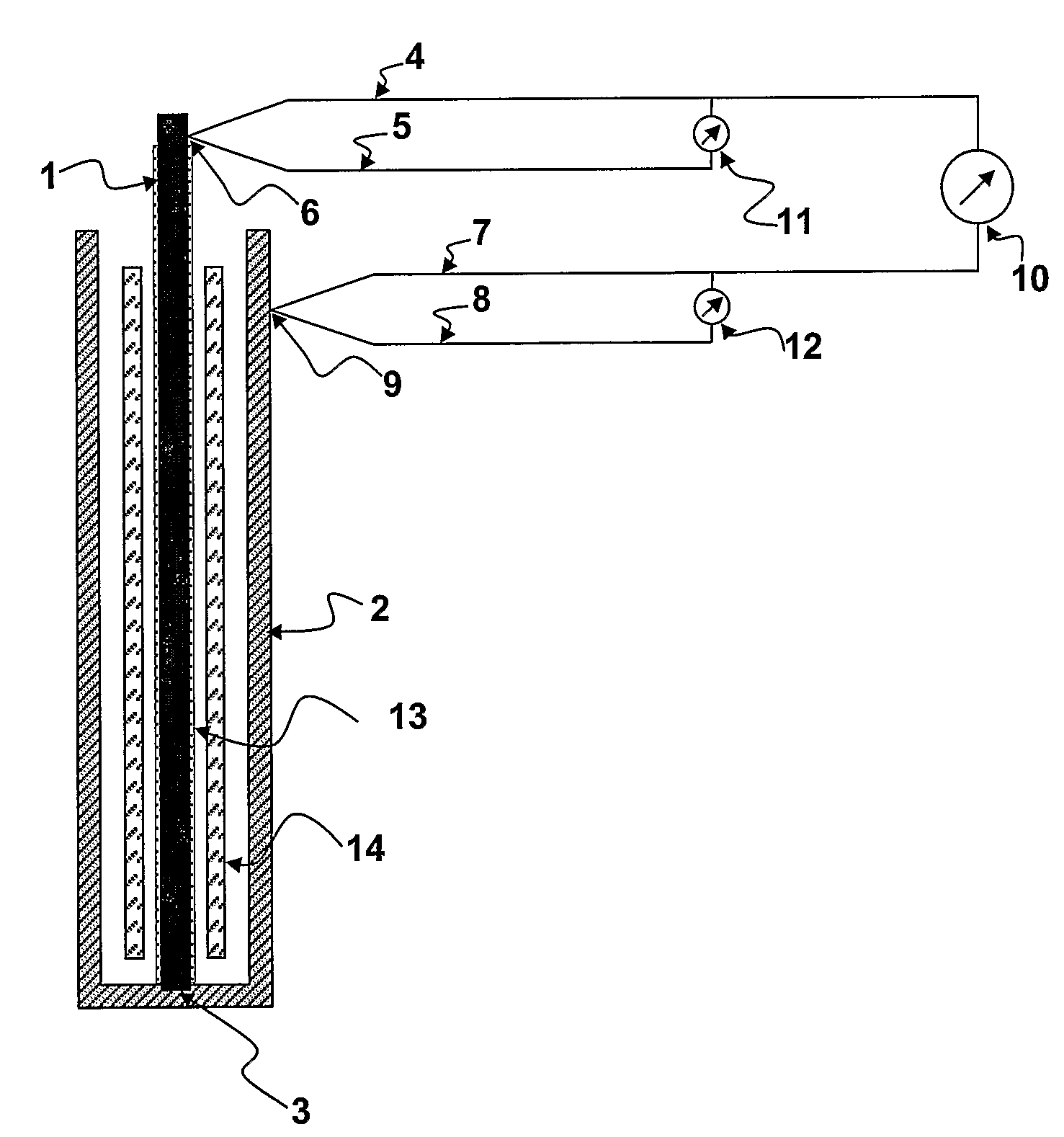

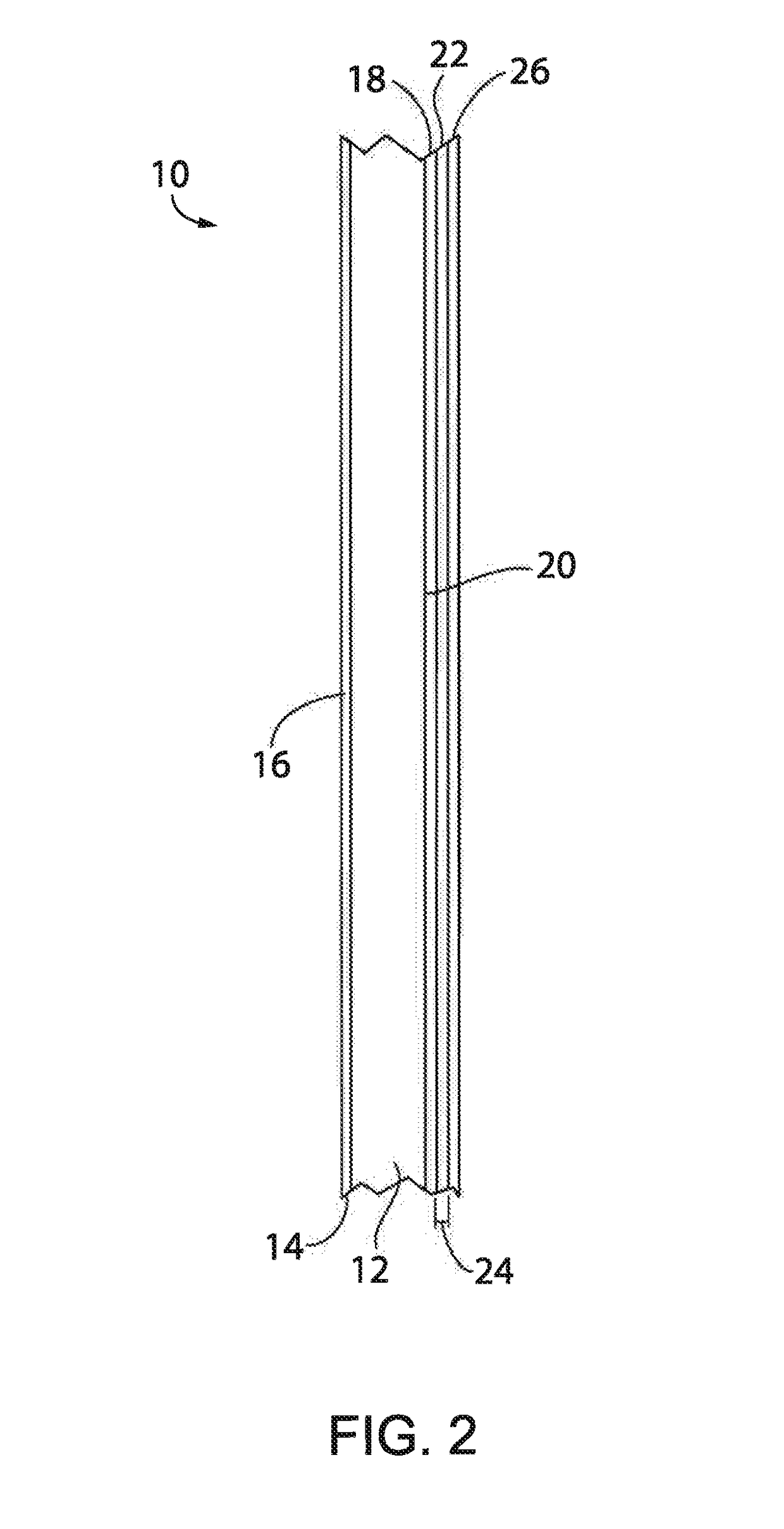

Moisture sensor for monitoring an access to a patient and method of producing the moisture sensor

ActiveUS9629964B2Low production costSimplify connectivity issuesDetection of fluid at leakage pointOther blood circulation devicesElectrical conductorEngineering

A moisture sensor for monitoring an access to a patient for a system by which, via a flexible line, a liquid is fed to and / or out from a patient, for monitoring the vascular access in extra-corporeal blood treatment or for monitoring a central venous catheter for acute dialysis, and a method of producing a moisture sensor are described. The moisture sensor has a substrate material with an electrically conductive structure having conductor paths arranged at a distance from one another and connected together across a terminating resistor. The terminating resistor is an electrically conductive film which is applied in a section of the substrate material on which are formed electrical contacting regions for connecting the terminating resistor to the conductor paths, such that an external terminating resistor is not required and the moisture sensor can be produced easily in large numbers complete with the terminating resistor.

Owner:FRESENIUS MEDICAL CARE DEUTSCHLAND GMBH

Topcoat

InactiveUS20100310882A1Preventing generation of squeak noiseSoftness and flexibility and smoothness and slick touchSynthetic resin layered productsPretreated surfacesCross-linkEmulsion

This invention provides a natural leather having a coating film as a topcoat layer that can suppress and prevent the occurrence of an uncomfortable squeak noise and, at the same time, has softer feeling, soft and smooth feeling, and slick feeling, a composition for the formation of a coating film on a natural leather, and a process for producing a natural leather. The natural leather comprises, as a topcoat layer, a coating film comprising 48 to 55% by weight of a two-component aliphatic polyurethane, 3 to 7% by weight of silica fine particles, 23 to 37% by weight of a cross-linking agent, and 7 to 13% by weight of a silicone touch agent (the total of the components being 100% by weight), wherein, in the coating film as the topcoat layer, the two-component aliphatic polyurethane contains 12 to 25% by weight, based on the solid content, of a polyurethane resin matting agent, or wherein, in the coating film as the topcoat layer, the two-component aliphatic polyurethane is contained in an amount of 51 to 55% by weight based on the solid content and further contains 6 to 10% by weight, based on the solid content, of a two-component aliphatic polyurethane / acryl emulsion.

Owner:MIDORI HOKUYO CO LTD

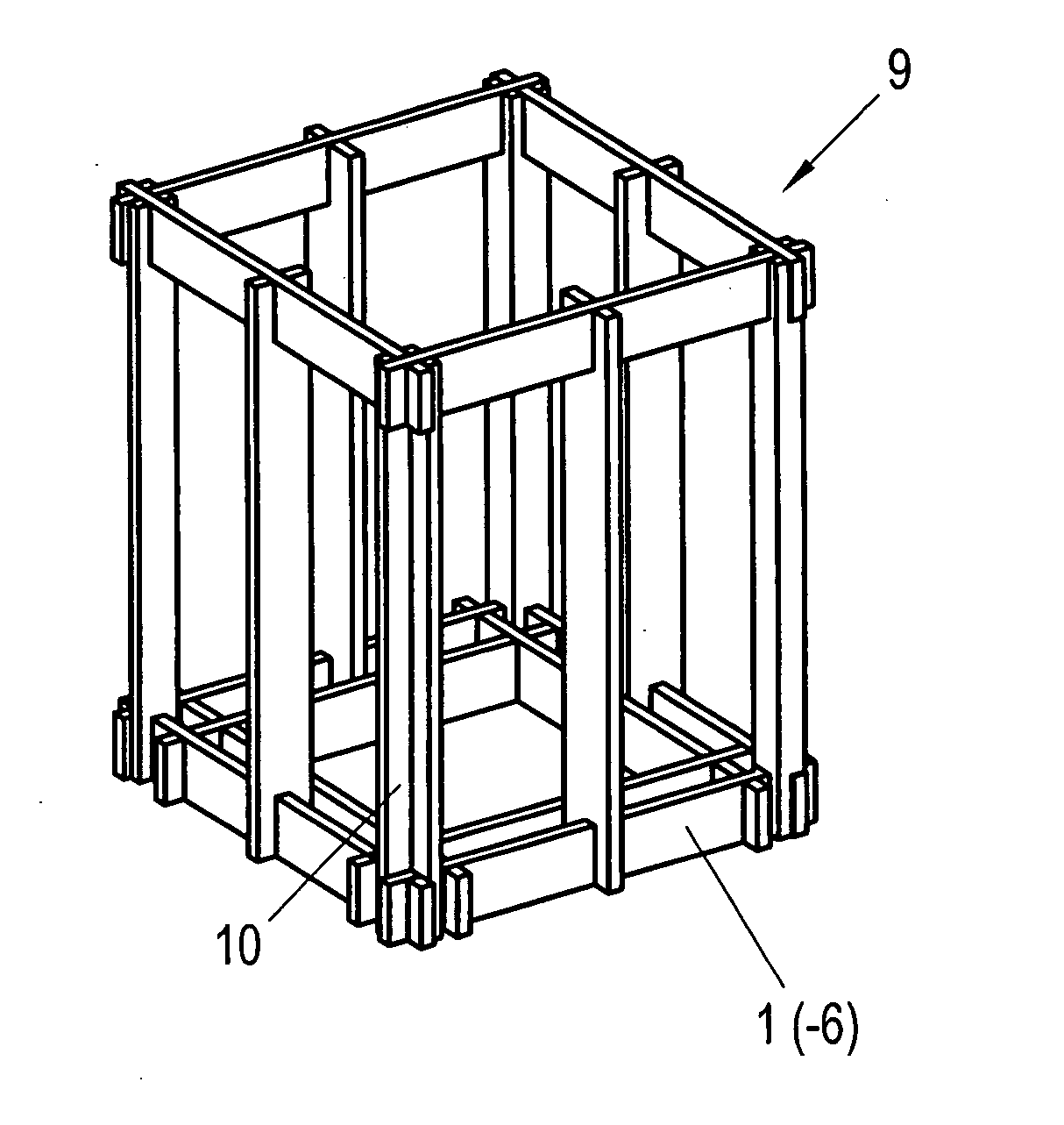

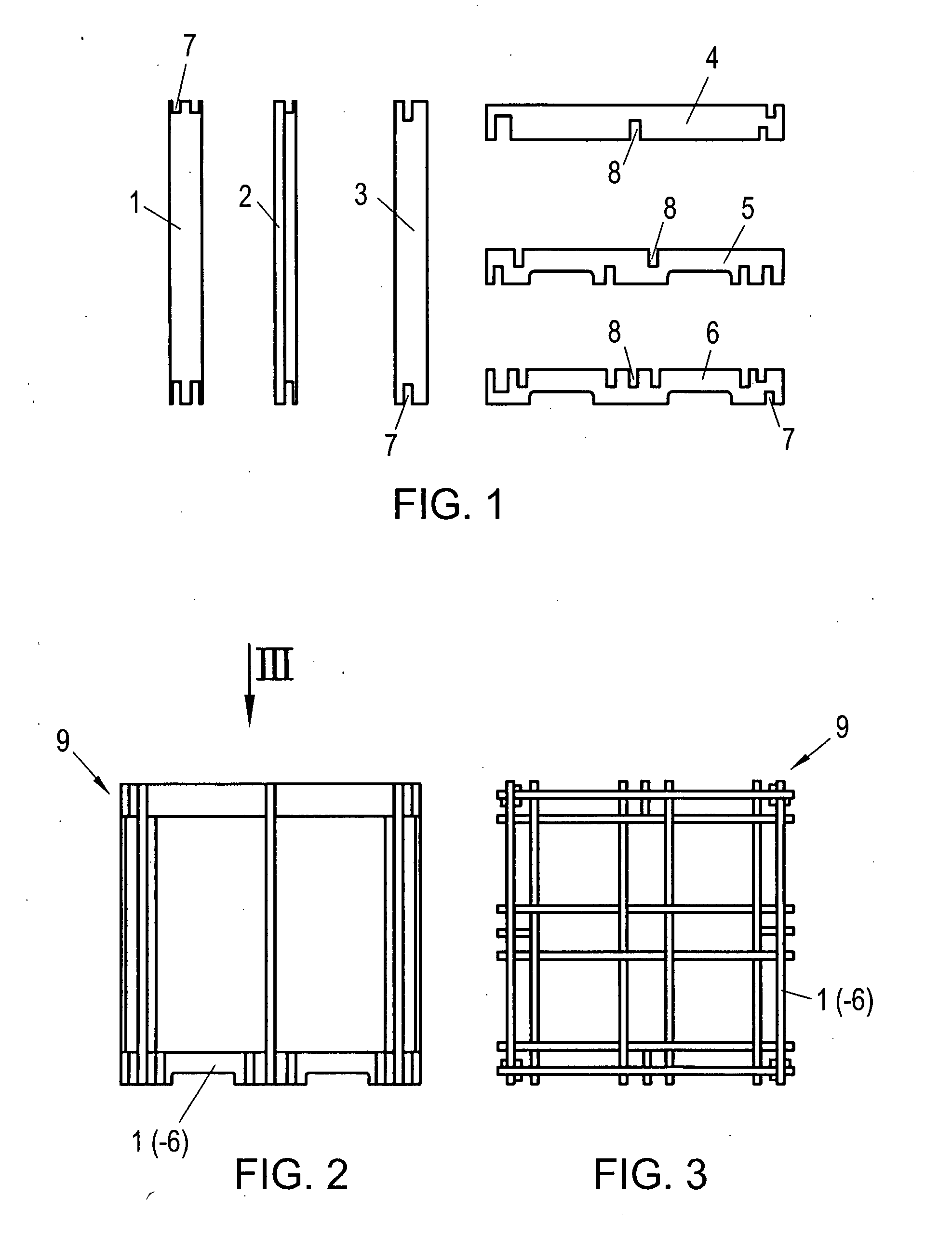

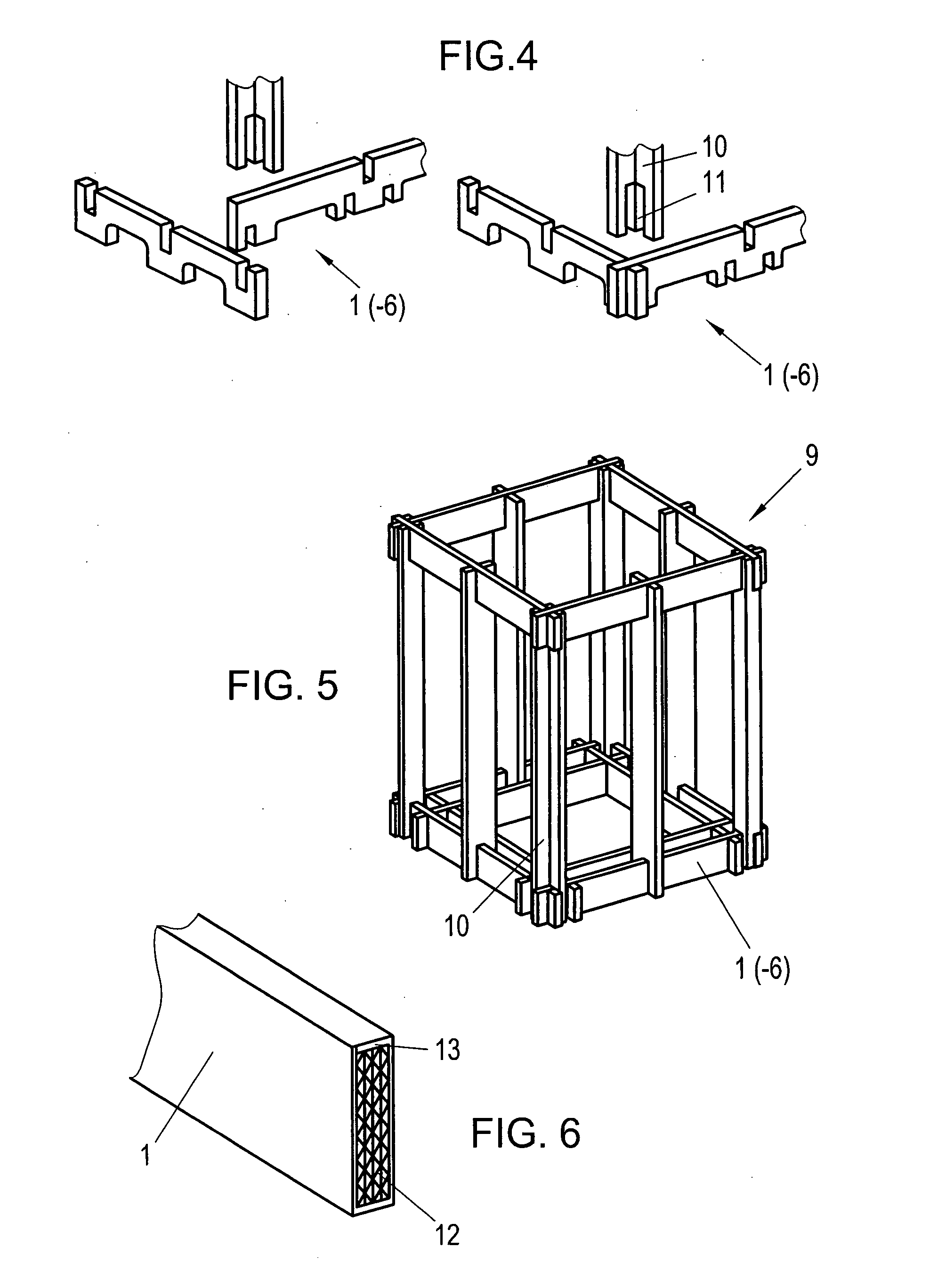

Three-dimensional frame structure or support structure for transporting and/or storing and object and method for the production thereof

The invention relates to a three-dimensional frame structure or support structure (9) for transporting and / or storing at least one object, which has a multitude of support elements (1-6, 10), which are or can be joined to one another and extend at least along the outer edges of the frame structure or support structure (9) while defining it. The invention provides that each support element (1-6, 10) is made of a multilayered composite of tightly packed sheets or boards (12) made of a corrugated paper or cardboard material, particularly corrugated board. The invention also relates to a method for easily and rapidly producing a three-dimensional frame structure or support structure of the aforementioned type.

Owner:UNIPAL INT LTD CO

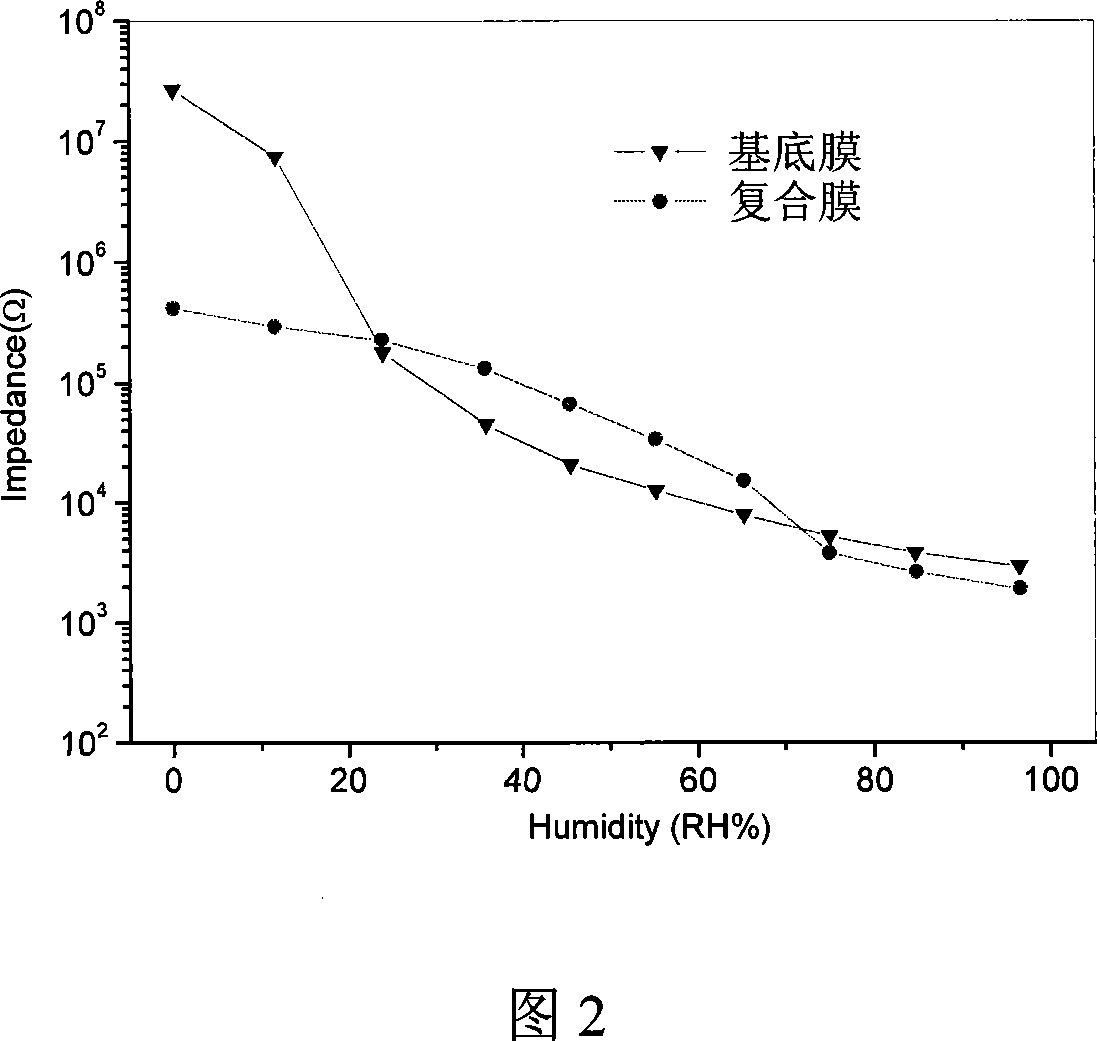

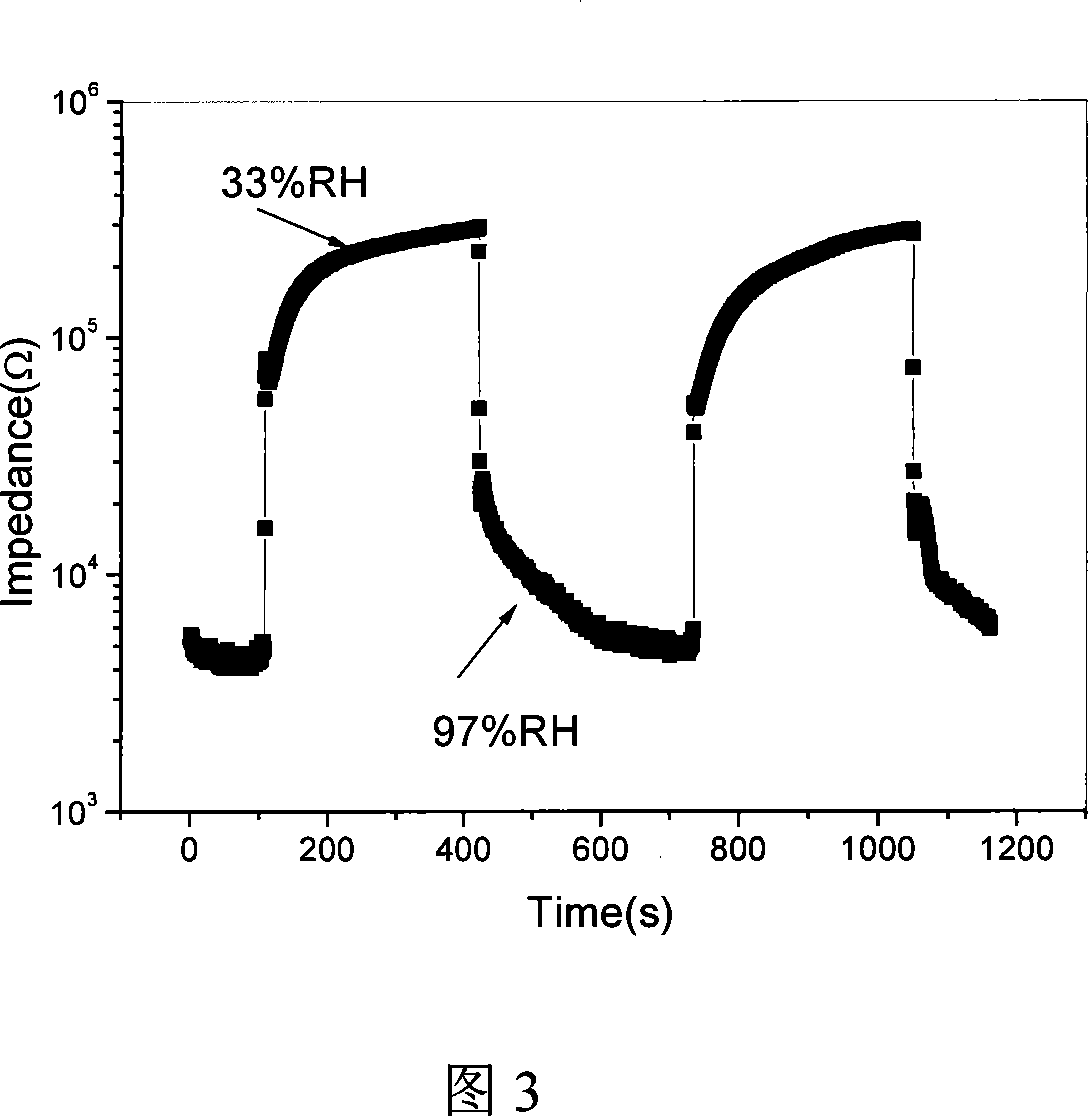

Polyelectrolyte / intrinsic conducting polymer composite humidity sensor and its production method

InactiveCN101078704AHigh humidity sensitivityAppropriate resistanceMaterial resistanceCross-linkPolyelectrolyte

The invention discloses a humidity sensor of combination of polyelectrolyte and intrinsic conducting polymer and the fabricating method. It adopts glass ceramic as substrate and multiple pairs of interdigital golden electrodes are set on it. Humidity film of combination of poly 4-vinypyridine with cross-linking quaternary amination and polypyrole is coated on surface of glass ceramic and interdigital golden electrode. The invention is provided with simple preparing process and low cost. It is suitable for mass production especially. Prepared humidity sensors are all provided with moderate resistance, high sensitivity, good linearity, quick response, good recurrence, strong stability and measuring in room temperature so on in wide humidity range, especially in circumstance with middle-low humidity (0-60%). It can be applied in production process of industry and agriculture, storage and accurate measurement and control for circumstance humidity when air circumstance is monitored.

Owner:ZHEJIANG UNIV

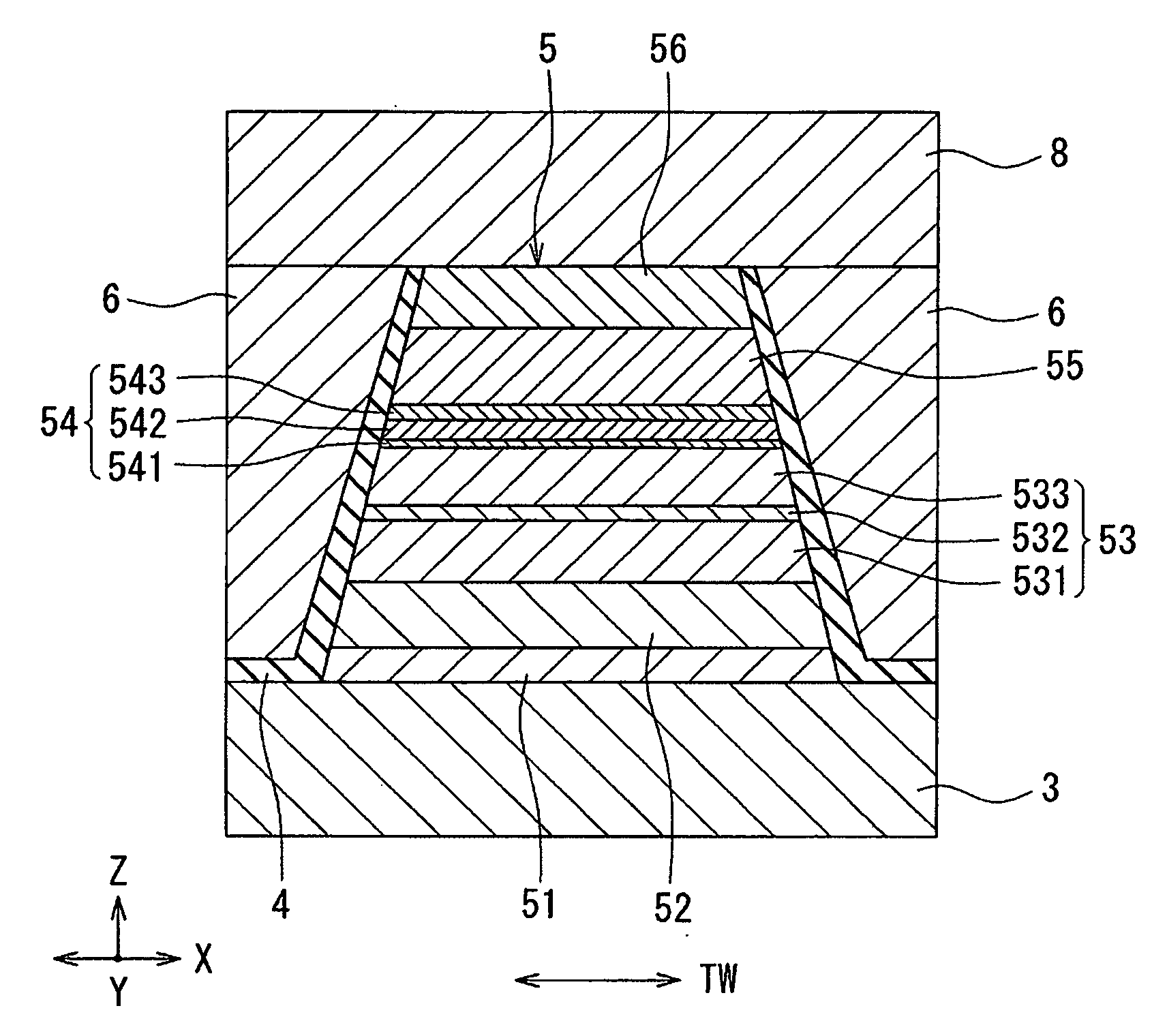

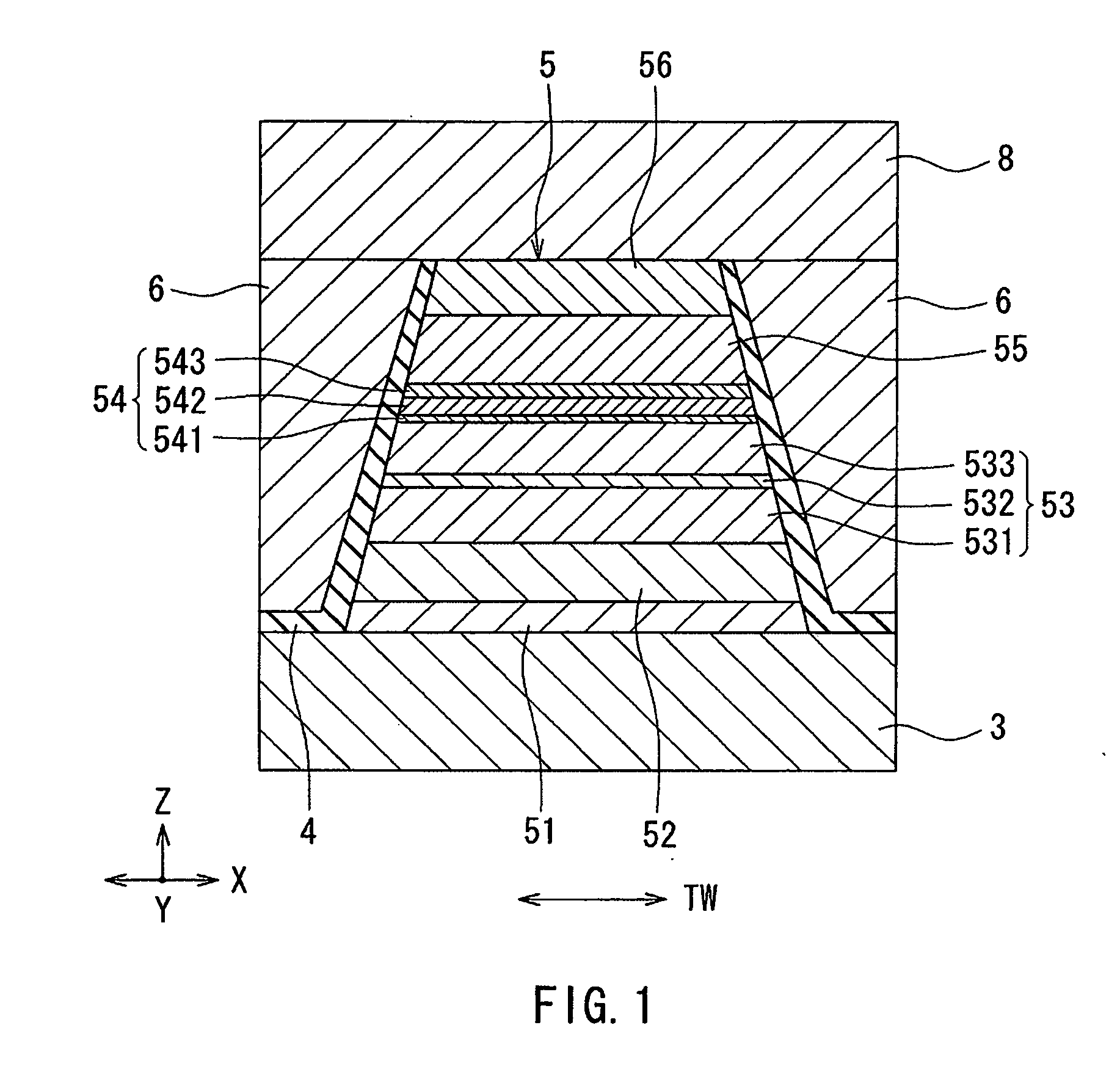

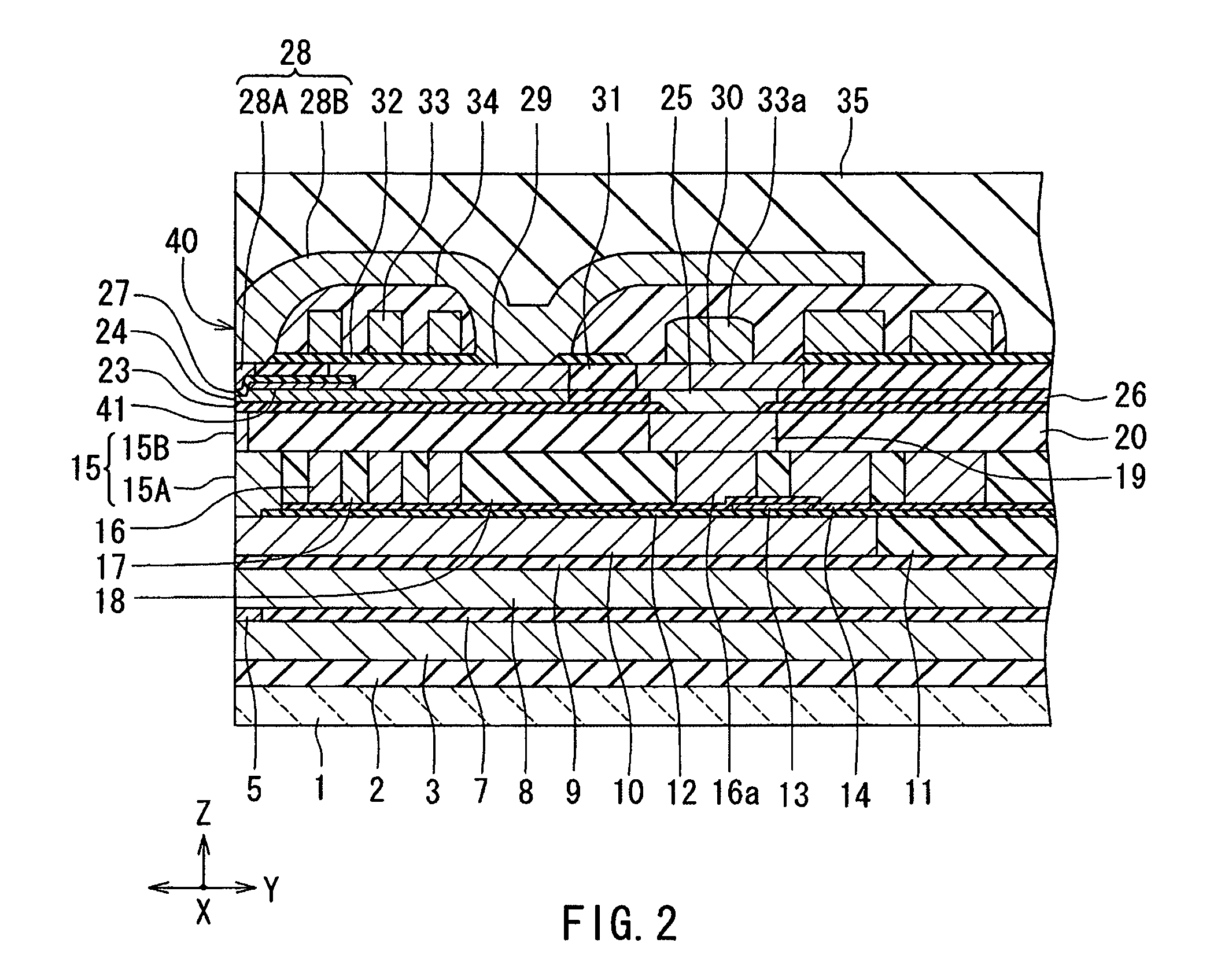

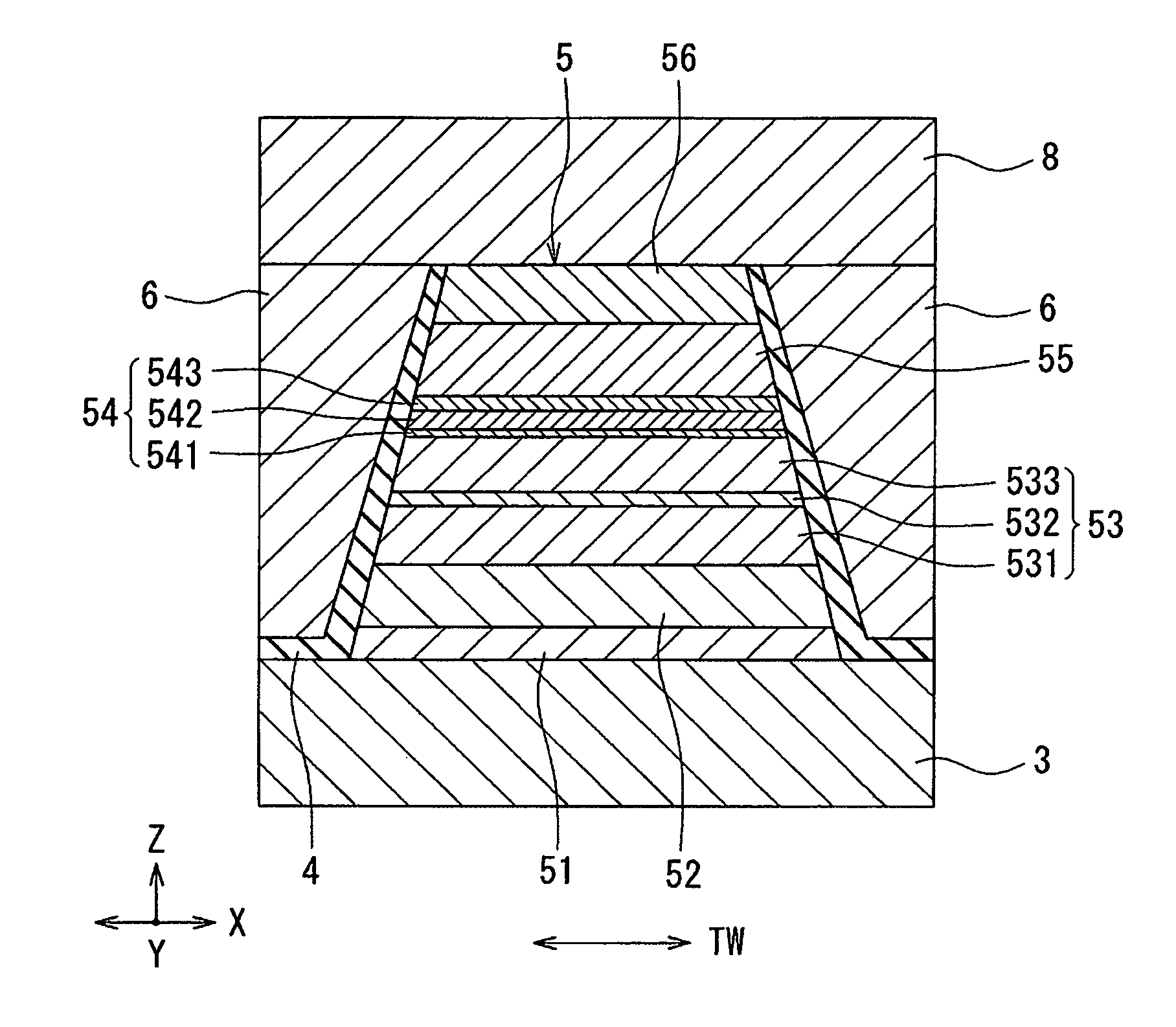

CPP-Type Magnetoresistive Element Including Spacer Layer

ActiveUS20120002330A1Raise the ratioAppropriate resistanceNanomagnetismNanoinformaticsSemiconductorMetal

An MR element includes a first ferromagnetic layer, a second ferromagnetic layer, and a spacer layer disposed between the first and second ferromagnetic layers. The spacer layer includes a nonmagnetic metal layer, a first oxide semiconductor layer, and a second oxide semiconductor layer that are stacked in this order. The nonmagnetic metal layer is made of Cu, and has a thickness in the range of 0.3 to 1.5 nm. The first oxide semiconductor layer is made of a Ga oxide semiconductor, and has a thickness in the range of 0.5 to 2.0 nm. The second oxide semiconductor layer is made of a Zn oxide semiconductor, and has a thickness in the range of 0.1 to 1.0 nm.

Owner:TDK CORPARATION

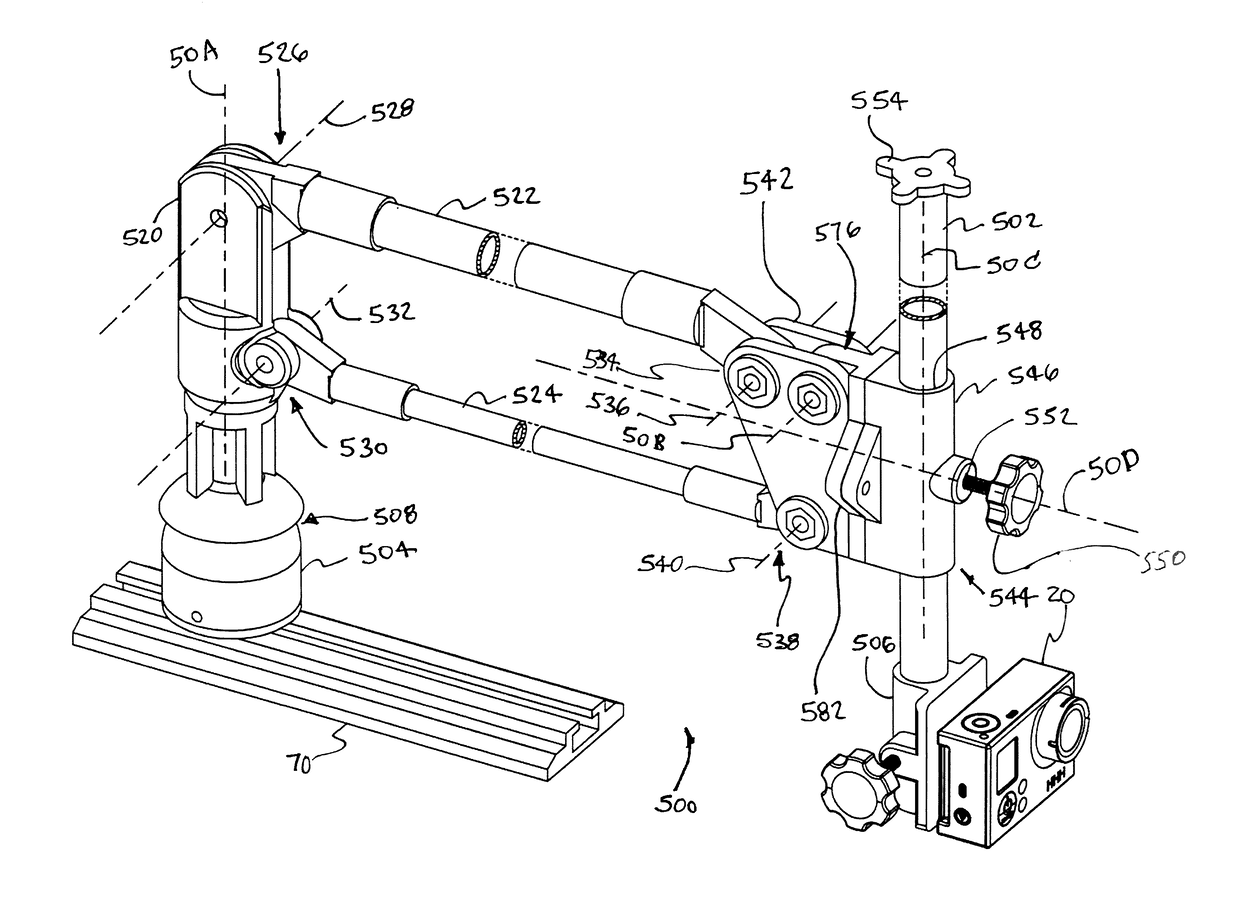

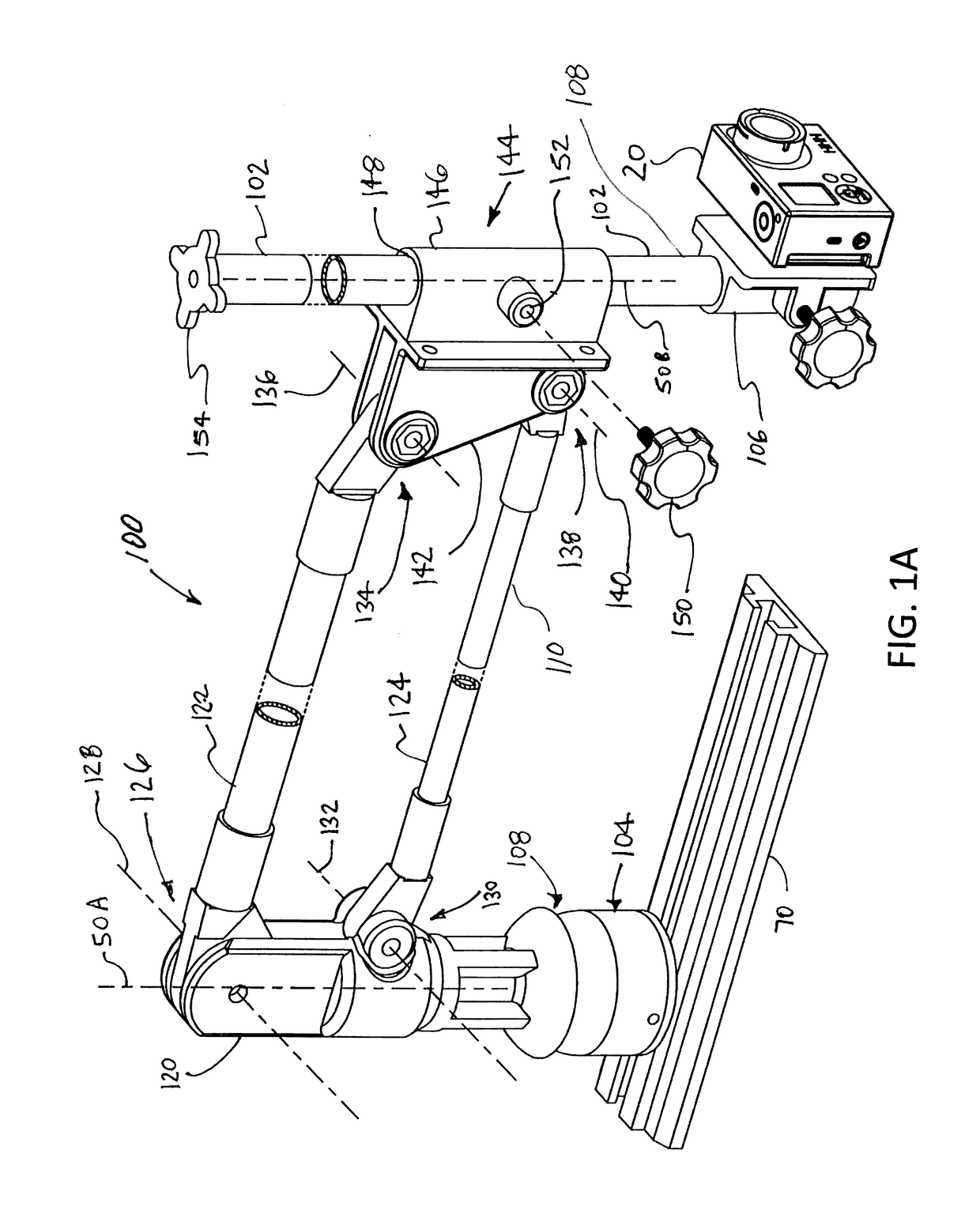

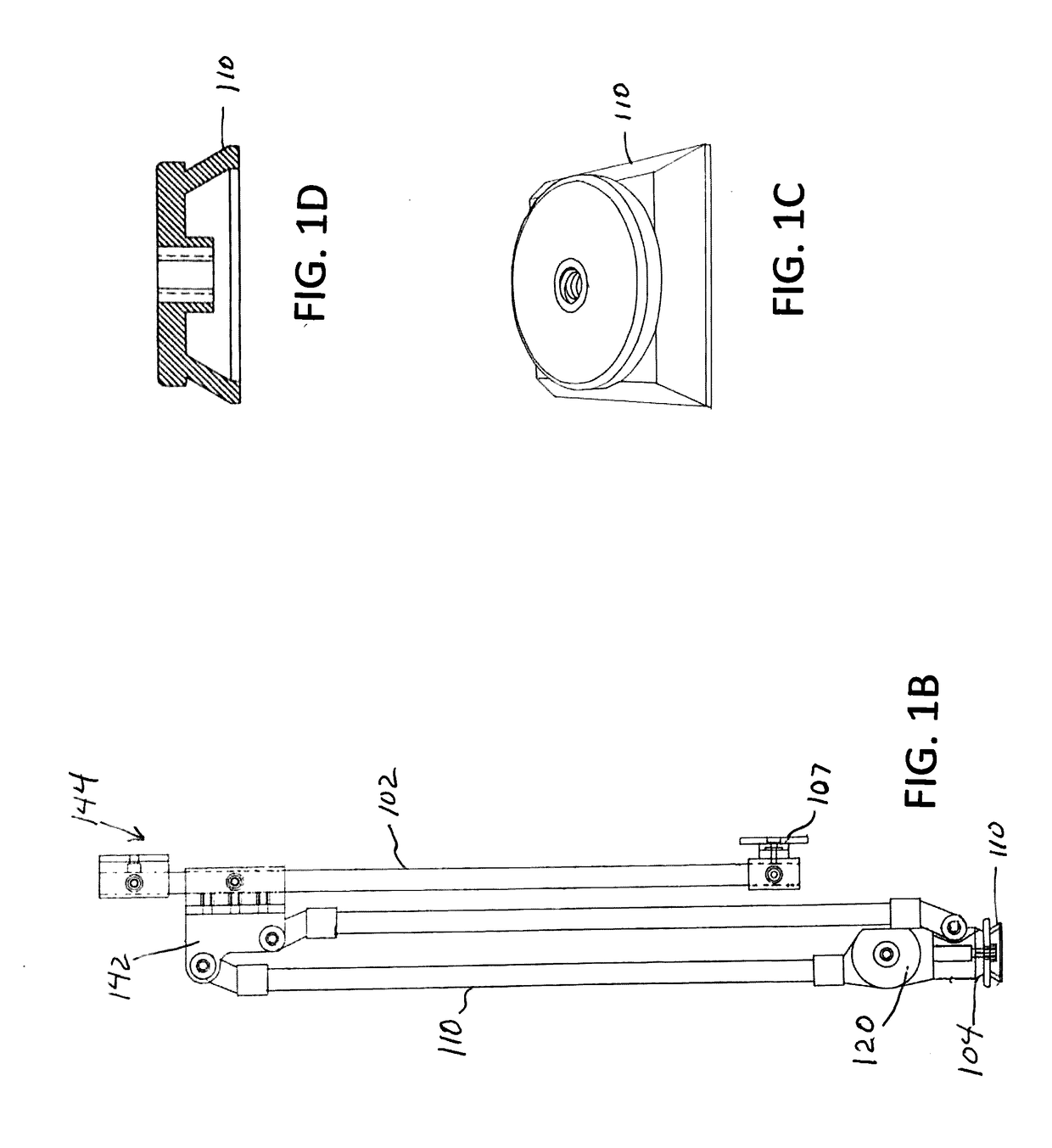

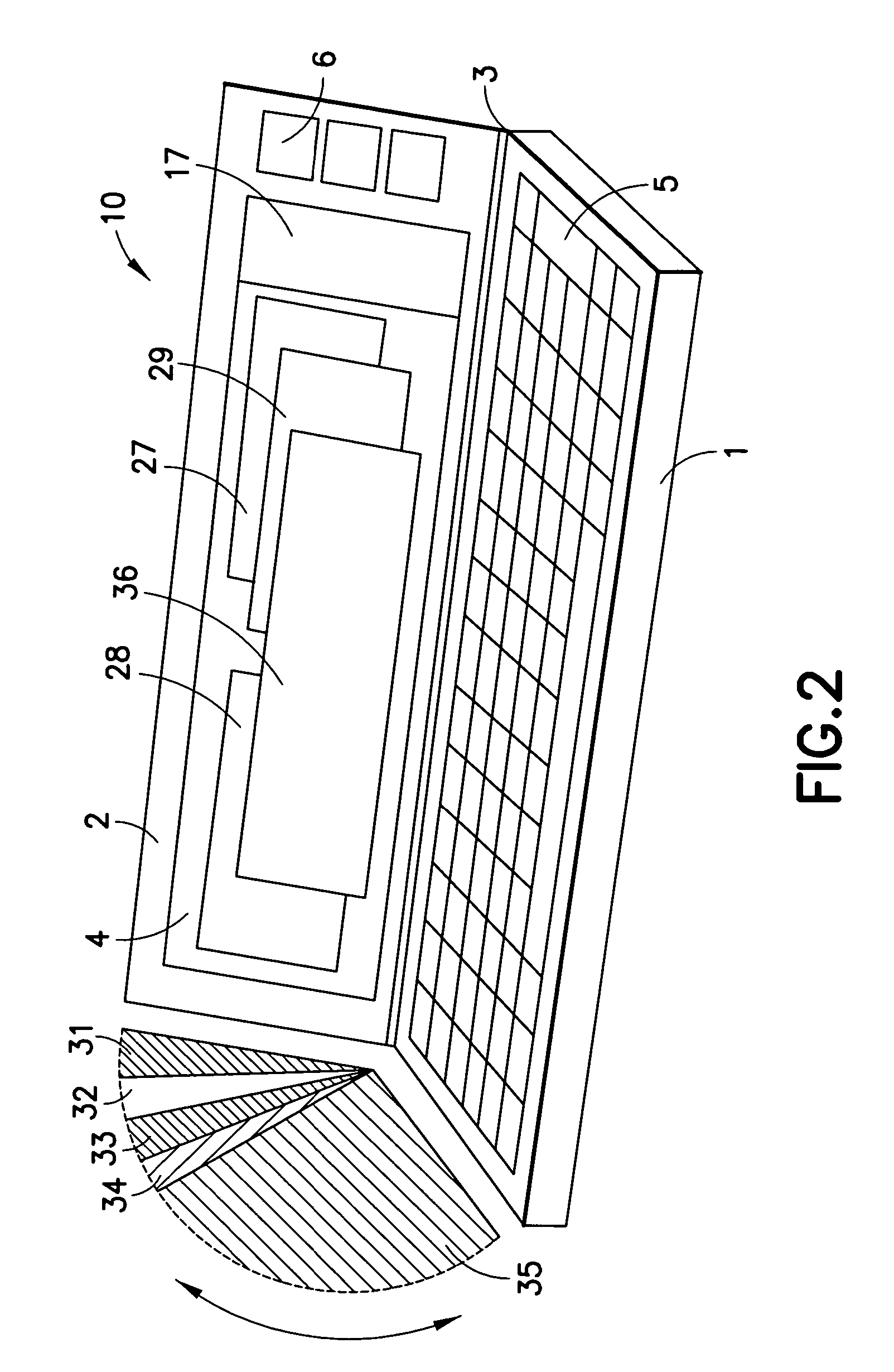

Camera positioning and orienting apparatus

InactiveUS20170150018A1Easy to adjustIncrease coefficient of frictionTelevision system detailsColor television detailsUnintended MovementEngineering

A camera stand comprises a base portion that may seat on or be suitably anchored on a floor surface, boat, dock, table, rail, vehicle, or other support structure. A horizontally and vertically adjustable linkage extends from the base portion and has the camera positioned at an end of the linkage. Means are provided for keeping the camera at a specific angle from horizontal as the adjustable linkage moves the camera about. Means are provided to provide joints in the linkage that have suitable resistance to unintended movement by gravity, wind or other forces and for which resistance to unintended movement is readily adjustable.

Owner:LUOMA EUGENE H

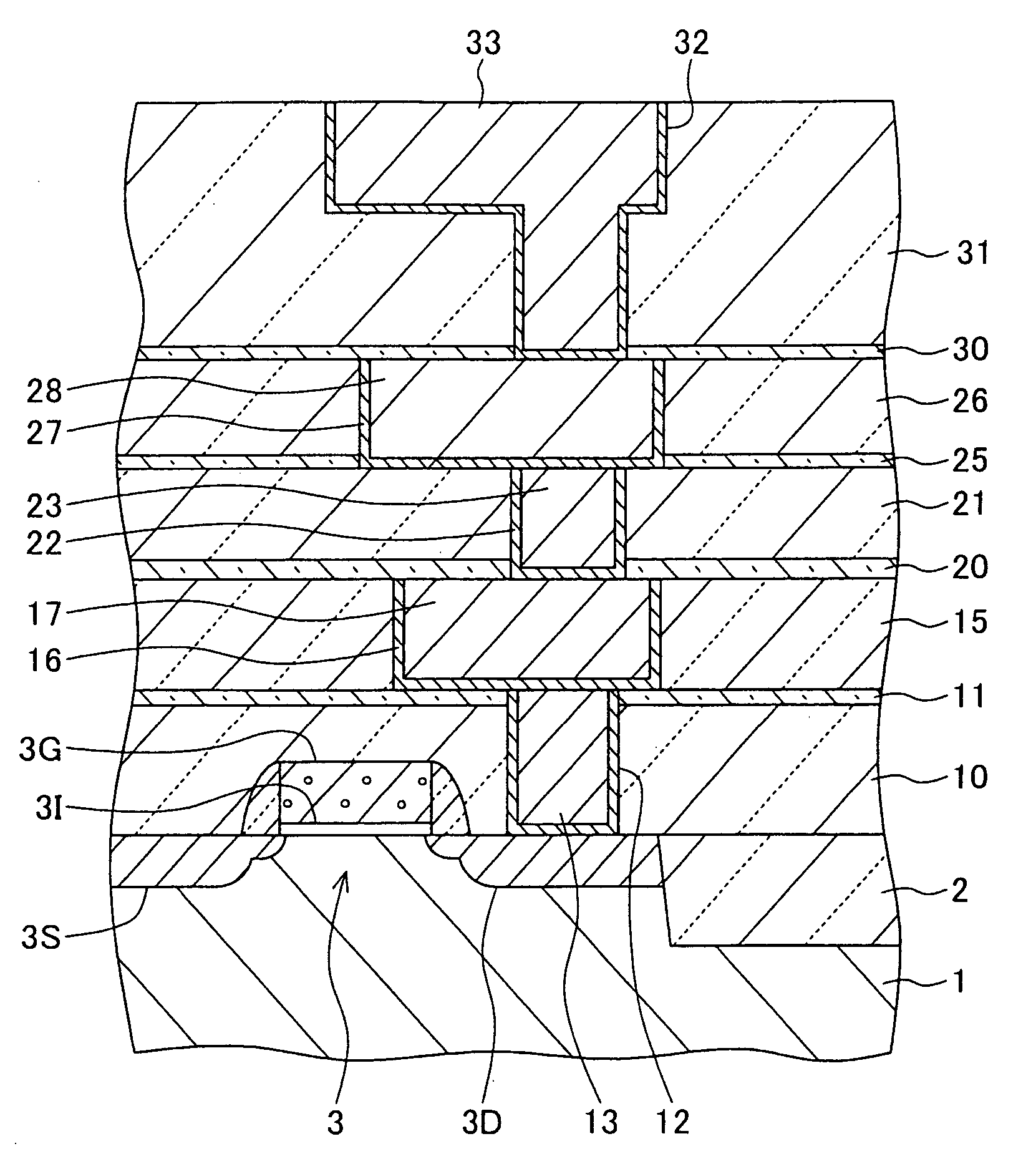

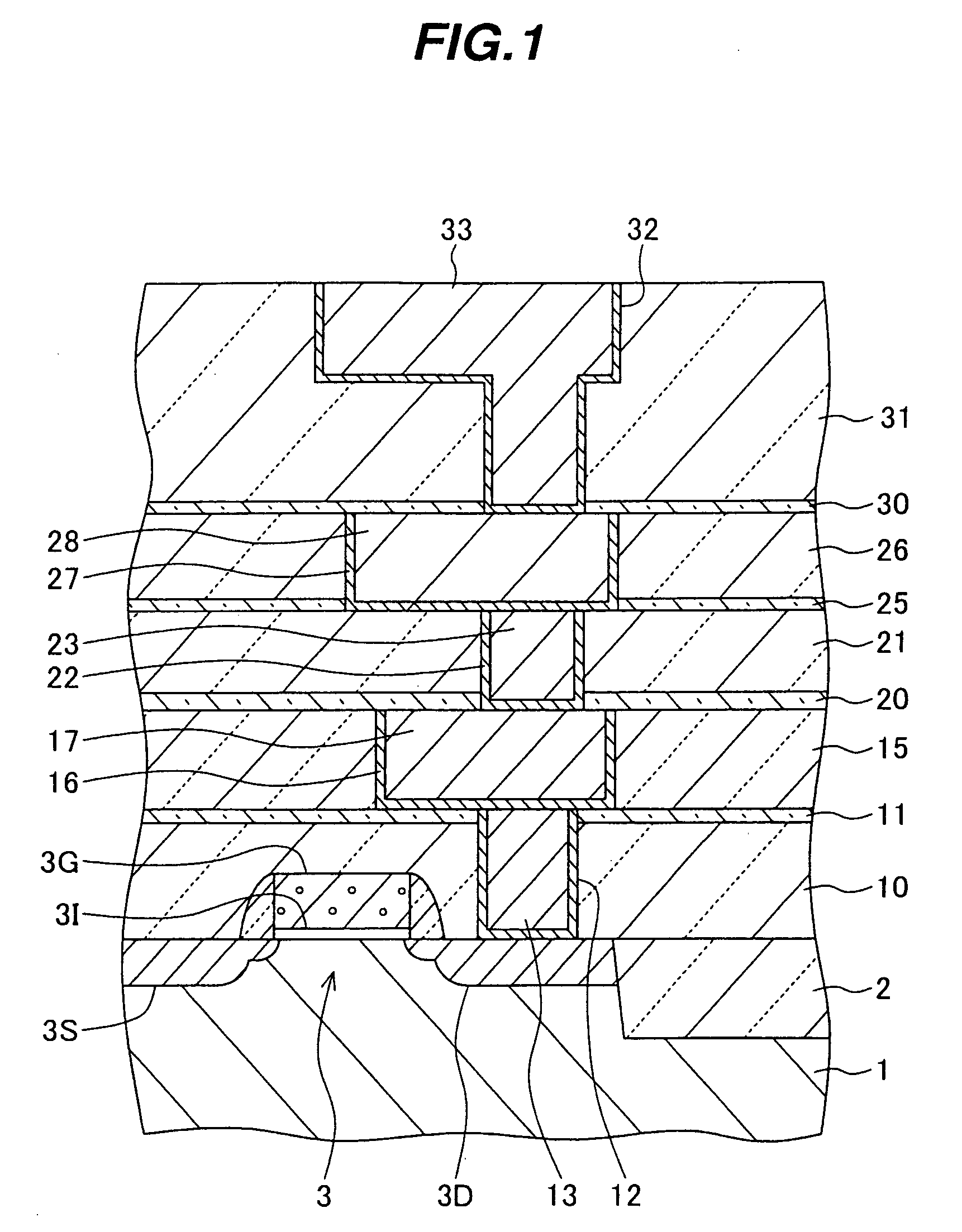

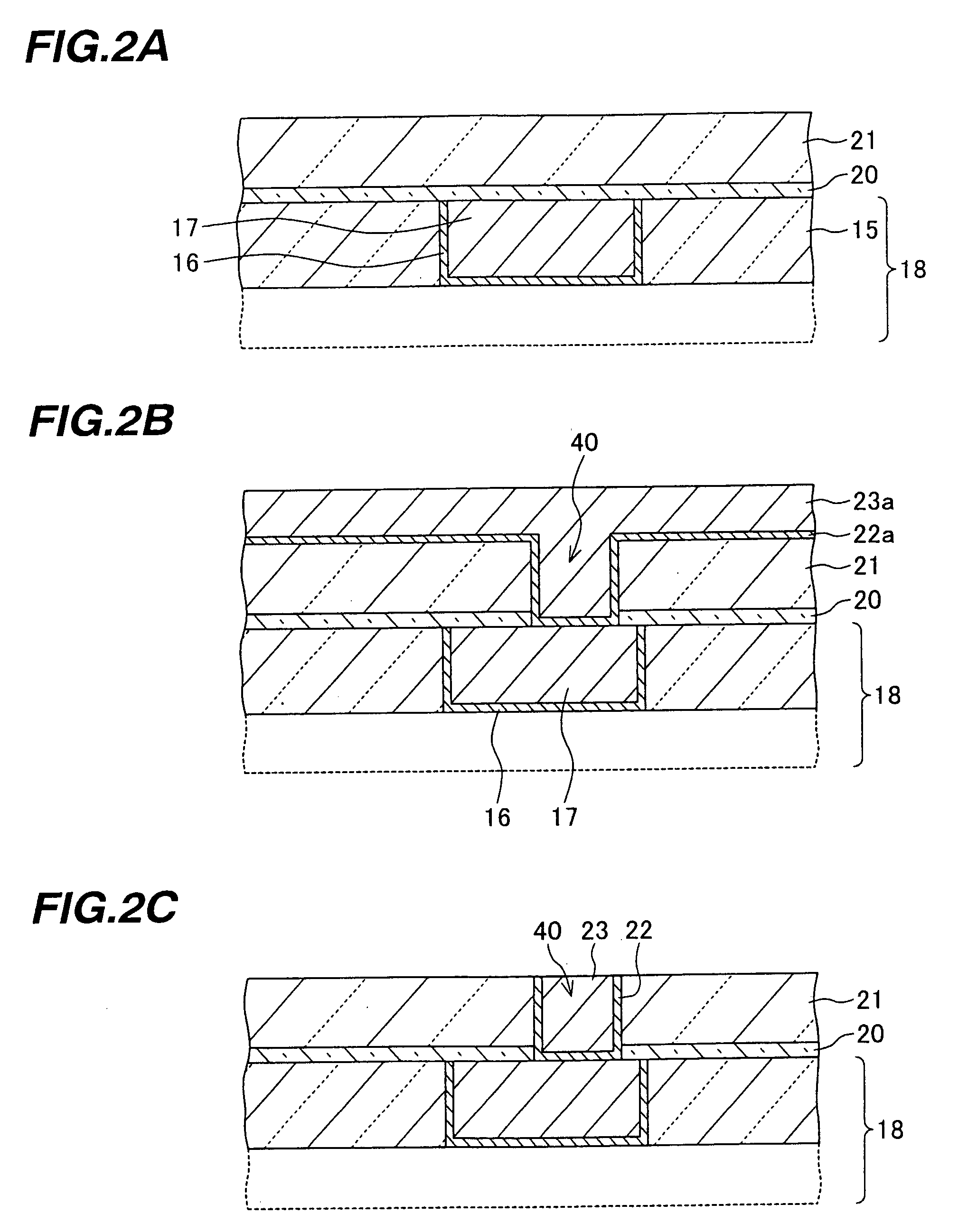

Semiconductor device having copper wiring and its manufacture method

ActiveUS20060012046A1Sufficient stressmigrationImproved resistance to electromigrationSemiconductor/solid-state device detailsSolid-state devicesDevice materialSulfur

A first interlayer insulating film made of insulting material is formed over an underlying substrate. A via hole is formed through the first interlayer insulating film. A conductive plug made of copper or alloy mainly consisting of copper is filled in the via hole. A second interlayer insulating film made of insulating material is formed over the first interlayer insulating film. A wiring groove is formed in the second interlayer insulating film, passing over the conductive plug and exposing the upper surface of the conductive plug. A wiring made of copper or alloy mainly consisting of copper is filled in the wiring groove. The total atom concentration of carbon, oxygen, nitrogen, sulfur and chlorine in the conductive plug is lower than the total atom concentration of carbon, oxygen, nitrogen, sulfur and chlorine in the wiring.

Owner:FUJITSU LTD

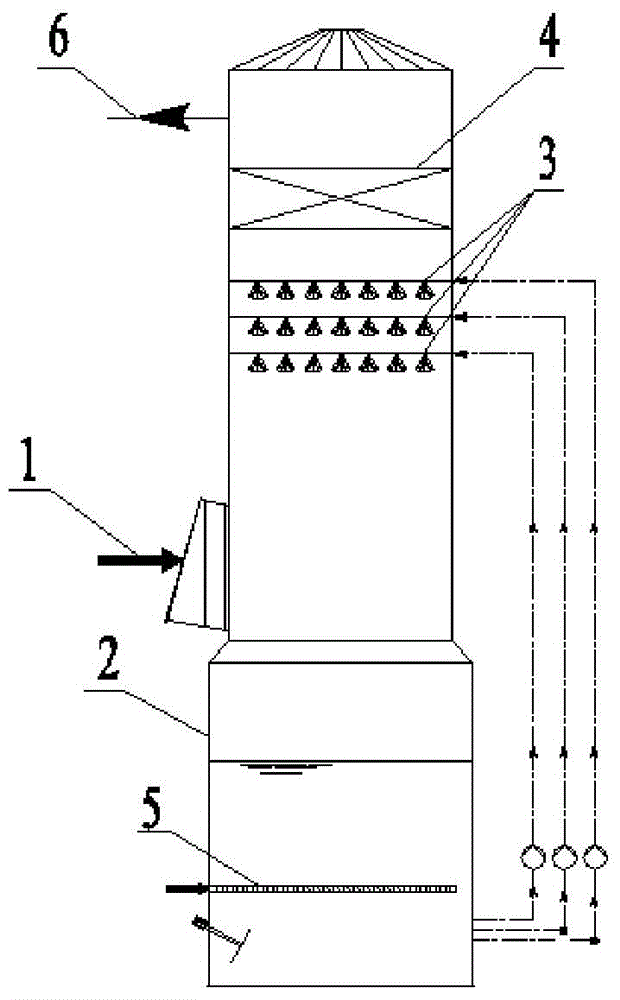

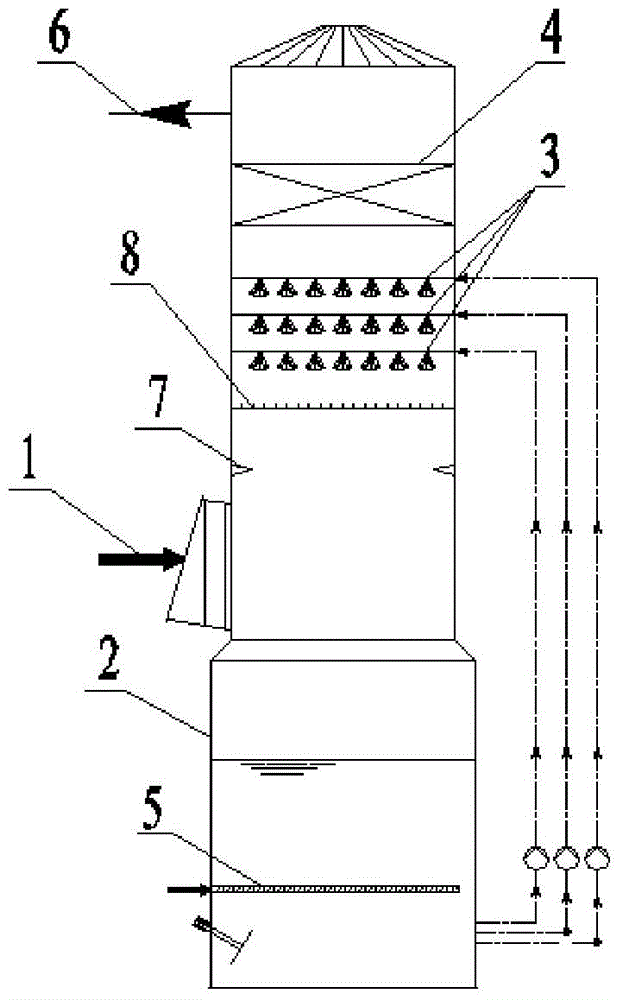

Mass transfer enhancing high-efficiency desulfurization absorption tower

InactiveCN104785084AImprove distribution uniformityImprove contact effectCombination devicesUsing liquid separation agentPollutantMass transfer

The invention relates to a mass transfer enhancing high-efficiency desulfurization absorption tower comprising a tower body; the tower body is provided with a flue gas inlet and a flue gas outlet, the tower body is internally provided with spray layers, a mist eliminator and an aerator pipe, the tower body is internally provided with at least one layer of sieve plate, the internal wall of the tower body is also provided with a gas-liquid reditribution reinforcement ring, and the gas-liquid reditribution reinforcement ring is located below the sieve plate and above the flue gas inlet. A function of the non-overflow sieve plate comprises that a liquid holding layer with stable height can be formed above the sieve plate and has the effects of improving gas-liquid distribution uniformity in the desulfurization absorption tower and enhancing the gas-liquid mass transfer effect; the gas-liquid reditribution reinforcement ring has the functions of improving flow field uniformity, preventing side wall flue gas from escaping and improving the gas-liquid contact area; through scientific combination of the sieve plate and the gas-liquid reditribution reinforcement ring, the gas-liquid mass transfer effect in the absorption tower can be effectively enhanced, the removal efficiency of SO2 pollutants is improved, the desulfurization efficiency can reach more than 99%, and the requirement of SO2 ultra-low emission is met.

Owner:ZHEJIANG UNIV

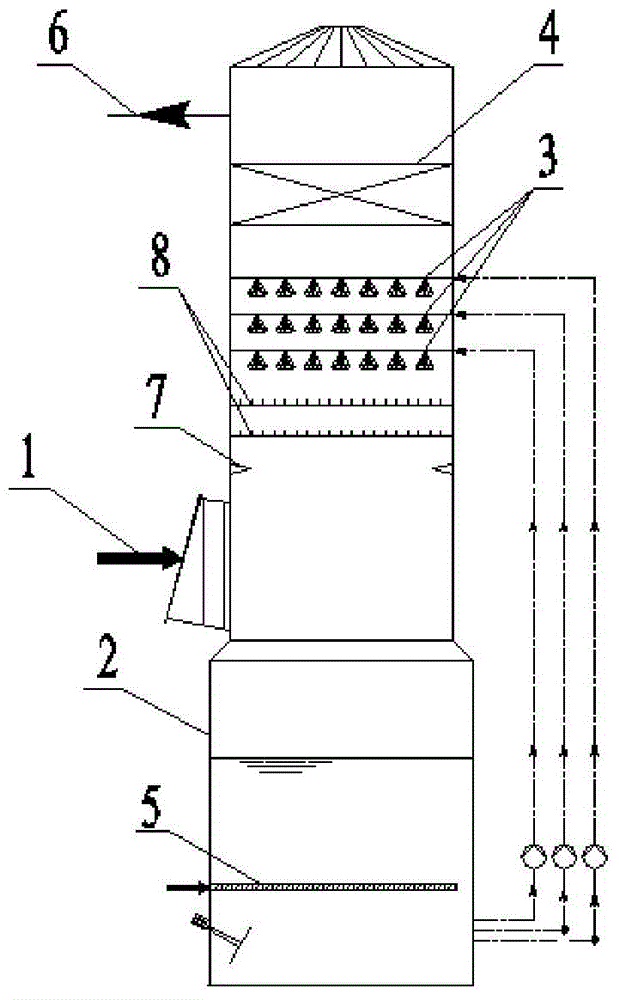

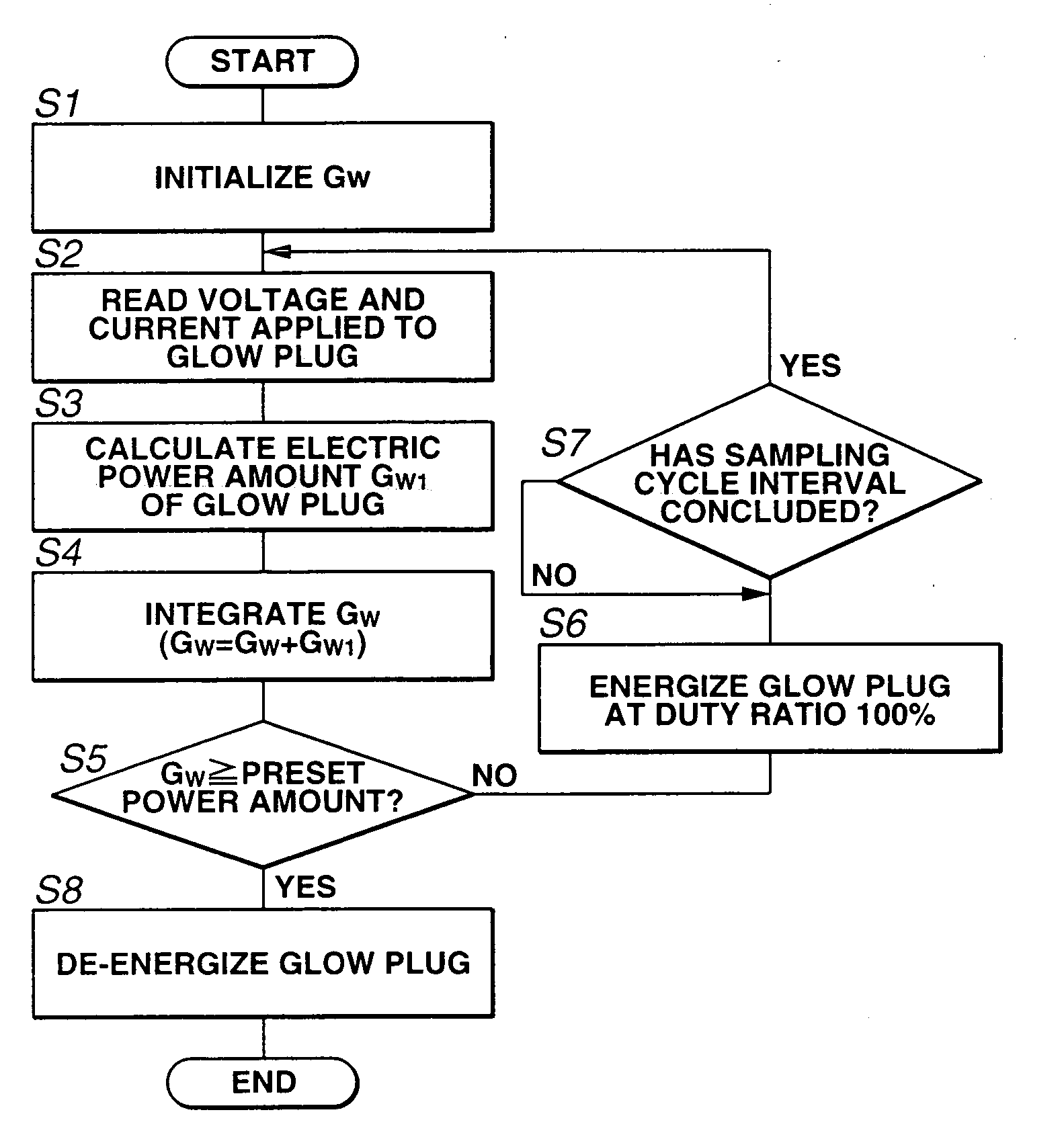

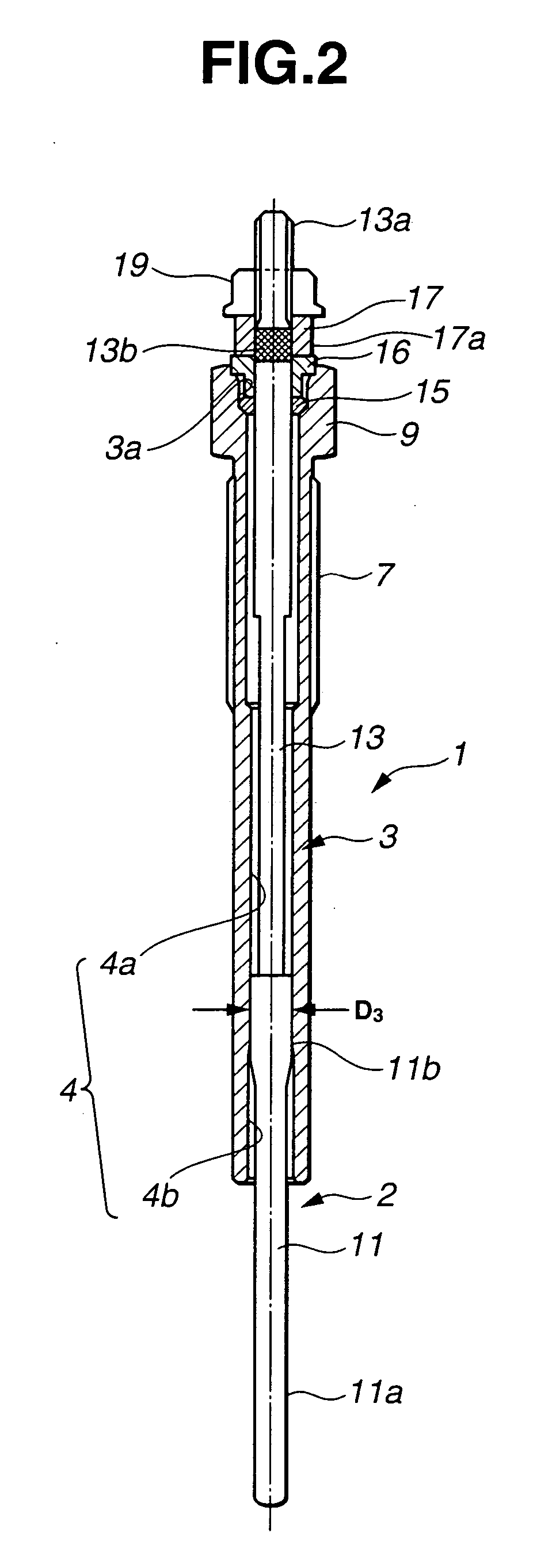

Controller of glow plug and glow plug

InactiveUS20060049163A1Stable maintenanceConvenient ArrangementElectrical controlIncandescent ignitionElectrical resistance and conductanceCombustion chamber

There is provided a control device for a glow plug, capable of controlling the energization of a resistance heater of the glow plug by a resistance control process while attaining good resistance control response under cooling of the heater by fuel injection and combustion gas and thereby stably controlling the amount of heat generated by the heater. The resistance heater includes a resistive heating element having a ratio of electrical resistance R1000 at 1000° C. to electrical resistance R20 at 20° C. of 6 or larger, and the glow plug is mounted with at least part of the resistive heating element being protrudingly located in an engine combustion chamber. Under such a condition, the control device controls energization of the resistance heater in a steady control mode to adjust electrical power supplied to the resistance heater in such a manner as to keep a resistance of the heater within a predetermined range.

Owner:NGK SPARK PLUG CO LTD

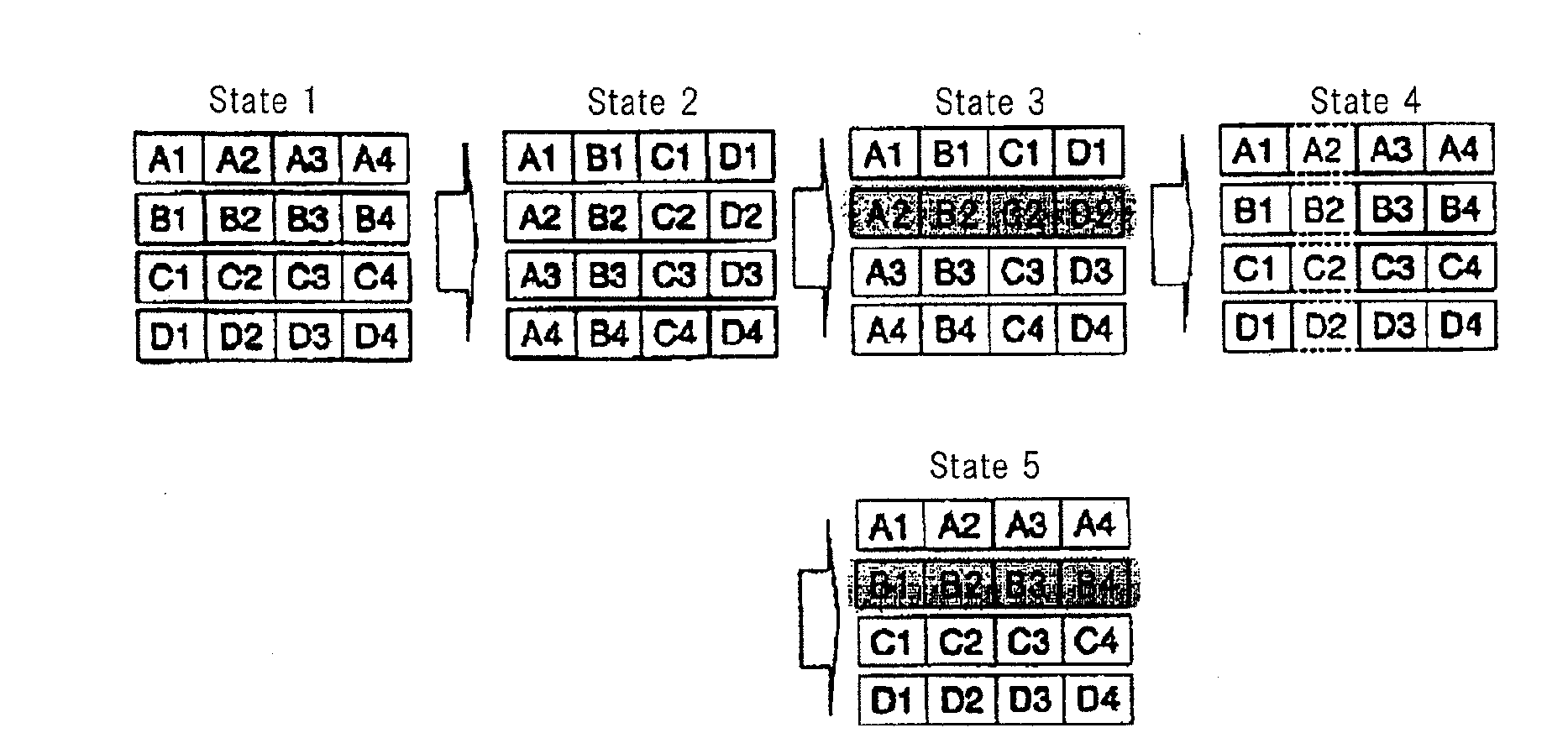

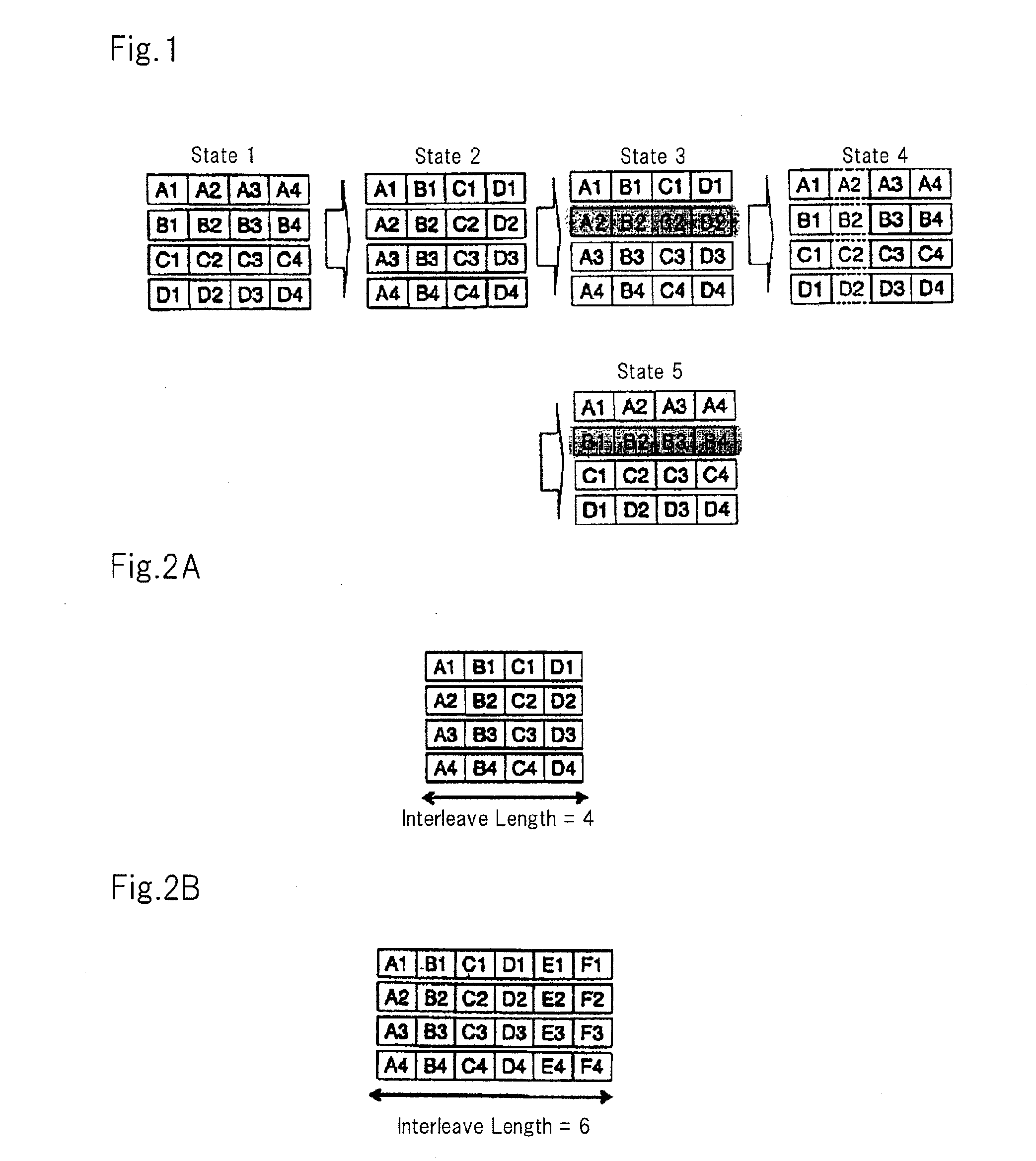

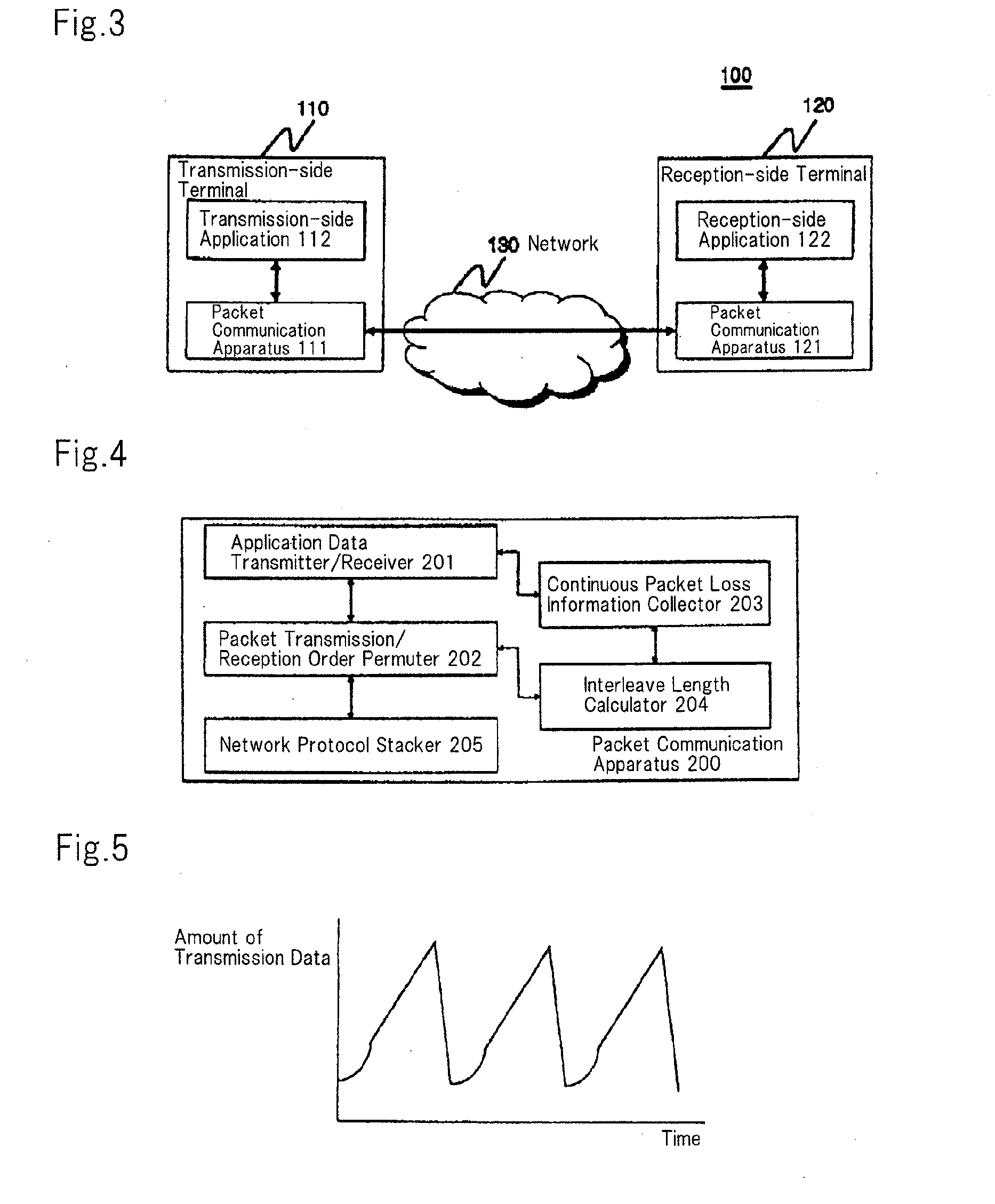

Communication apparatus and method

InactiveUS20090310498A1Packet lossAppropriate resistanceTransmission systemsFrequency-division multiplex detailsPacket lossCommunication device

A packetizer sectionalizes data to be transmitted into predetermined units and packetizes them into packets. A permuter permutes the order of the packets created by the packetizer based on a designated interleave length and sends out the packets to a network. A continuous loss information collector collects information on continuous packet loss occurring on the network. An interleave length determiner determines an interleave length based on the information on continuous packet loss, collected by the continuous loss information collector and designates the interleave length for the permuter.

Owner:NEC CORP

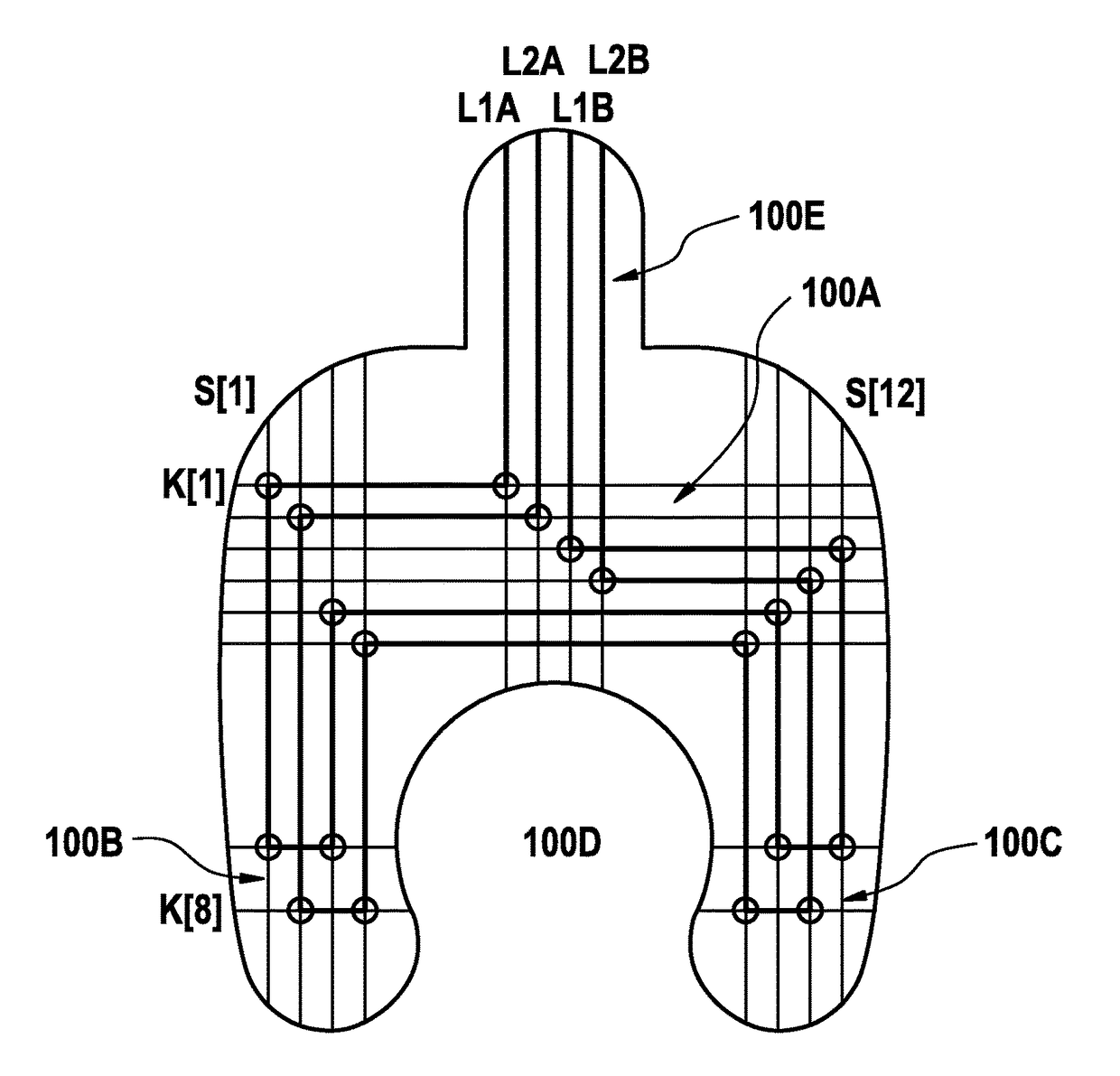

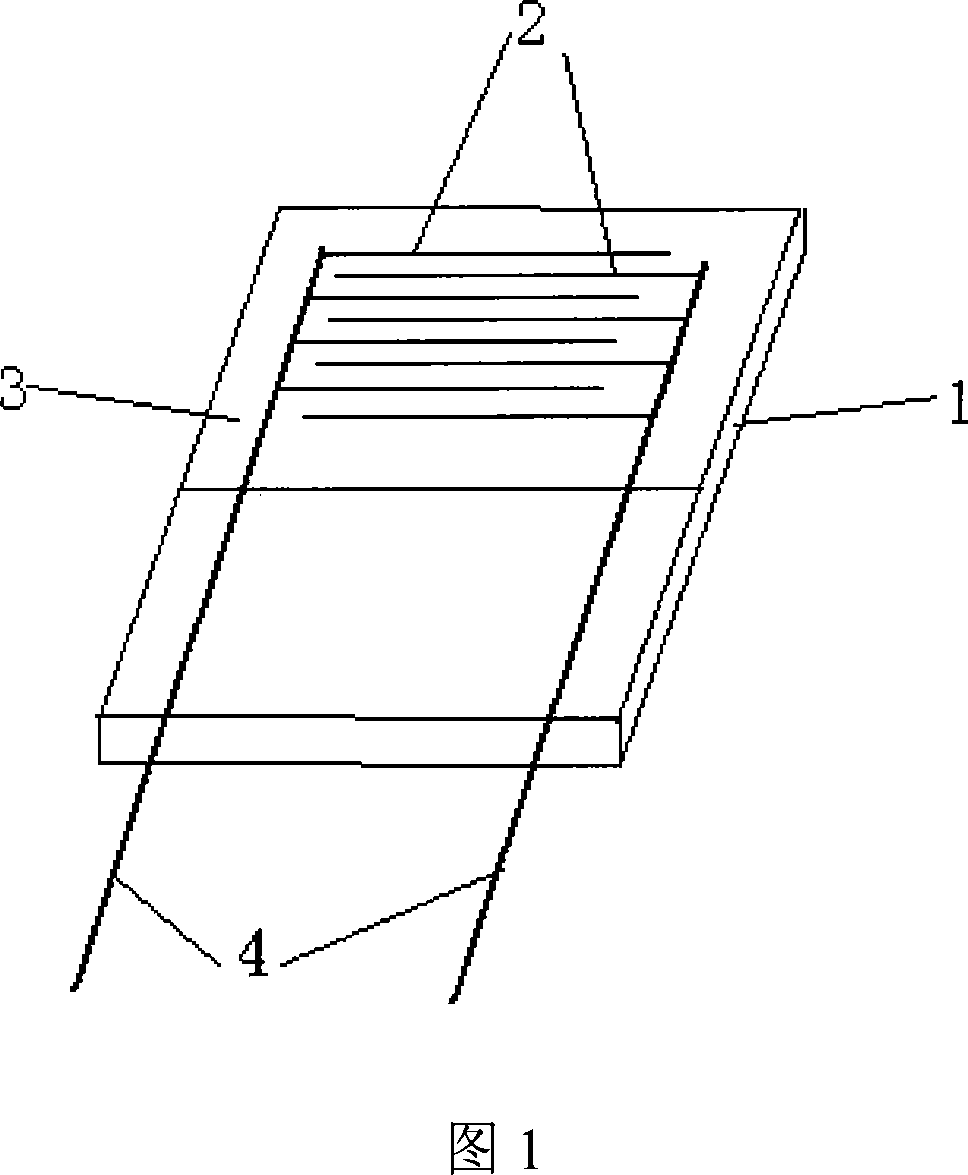

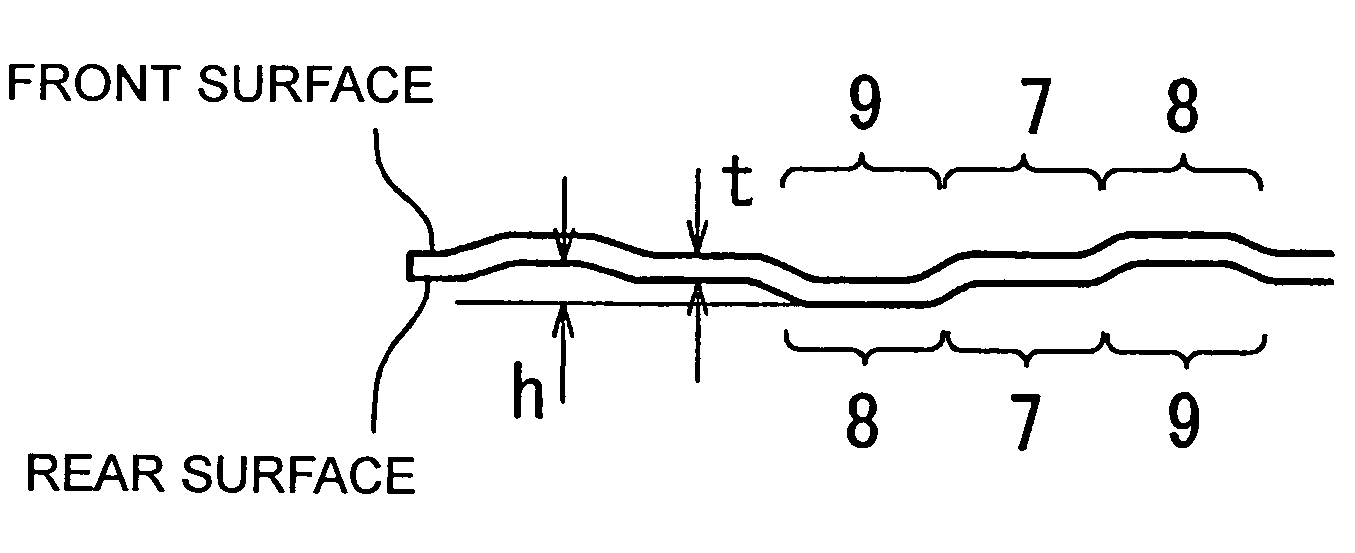

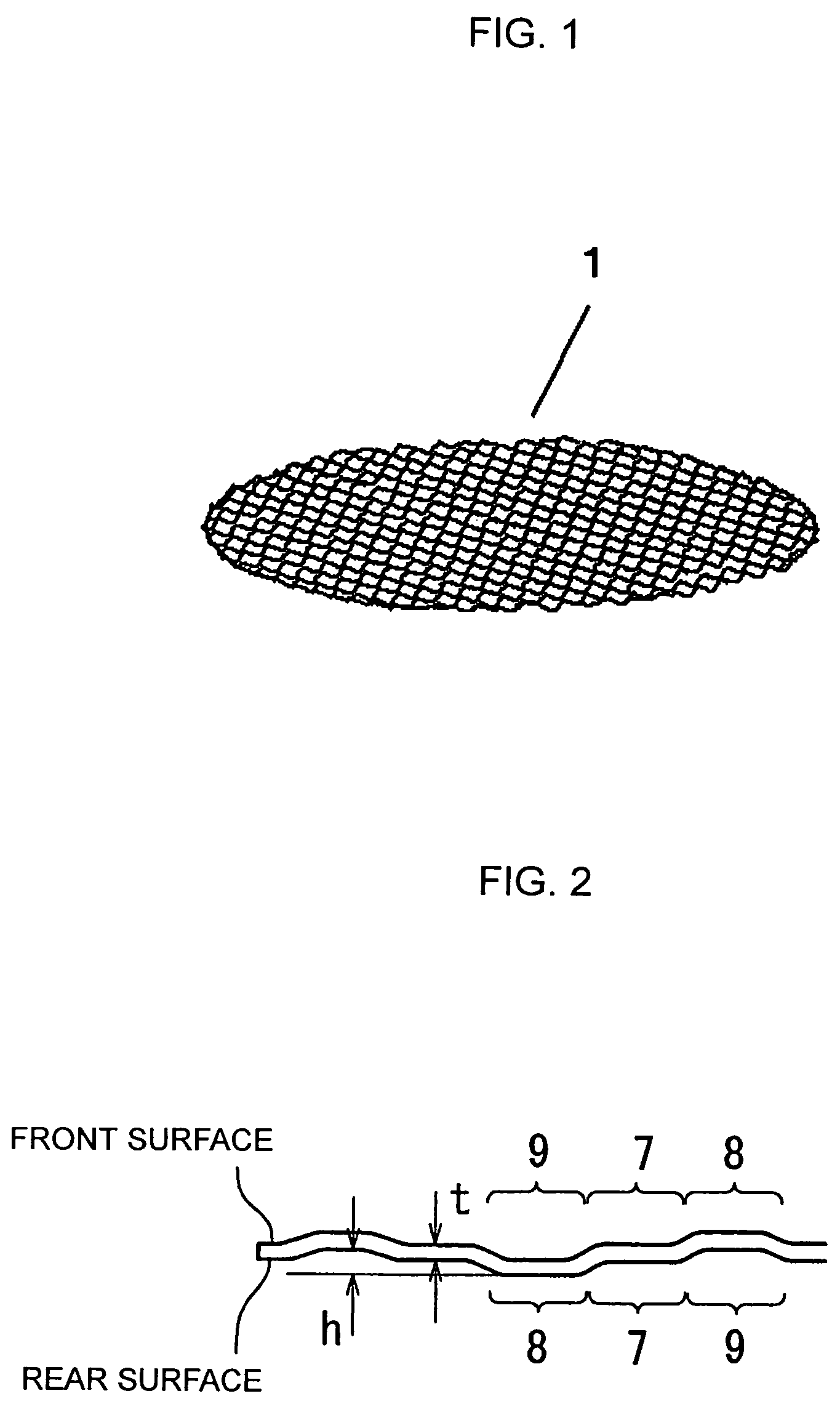

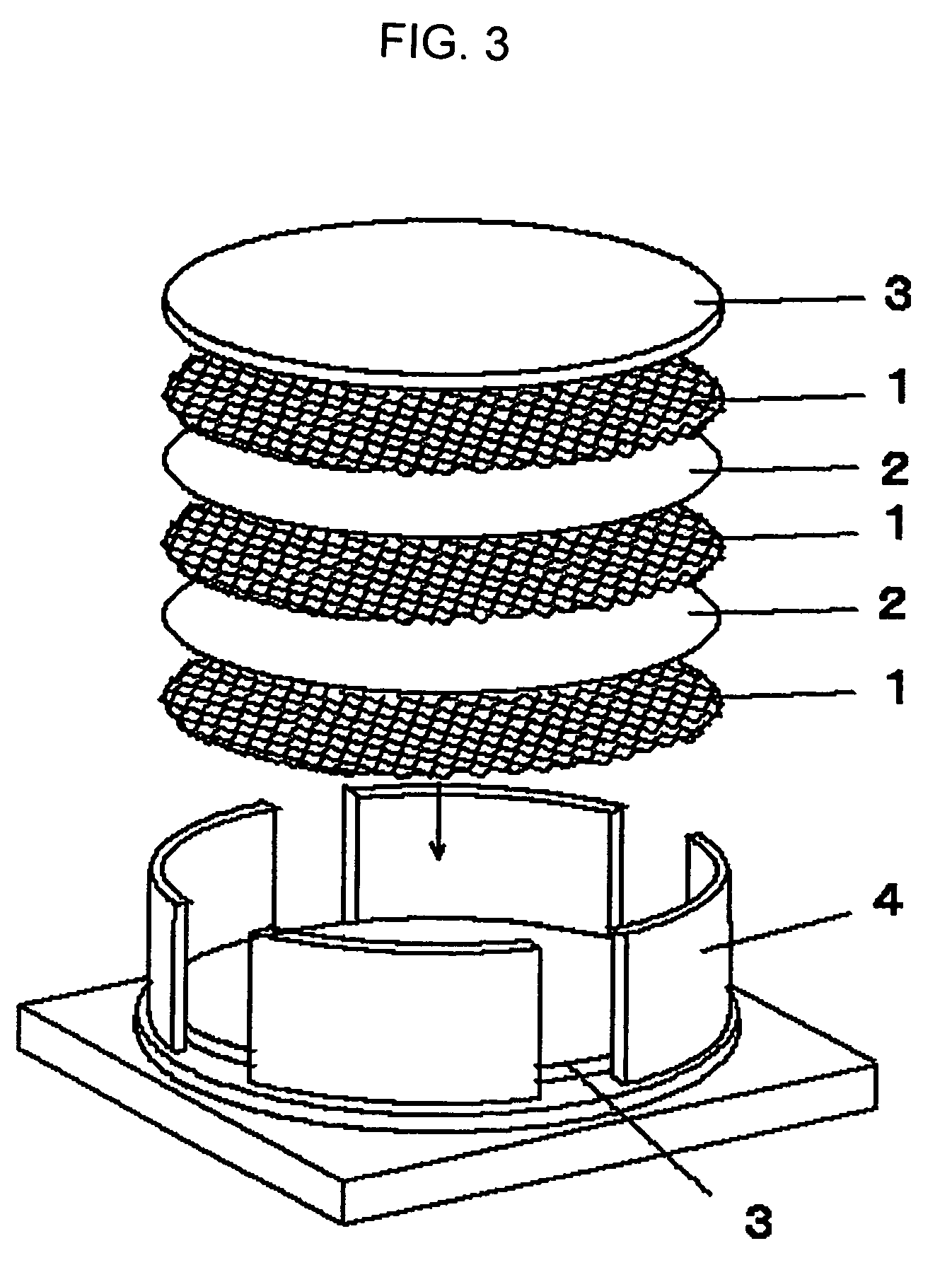

Wafer protective sheet

ActiveUS7611766B2Easy to handleAvoid scratchesLayered productsSemiconductor/solid-state device manufacturingEngineeringSynthetic resin

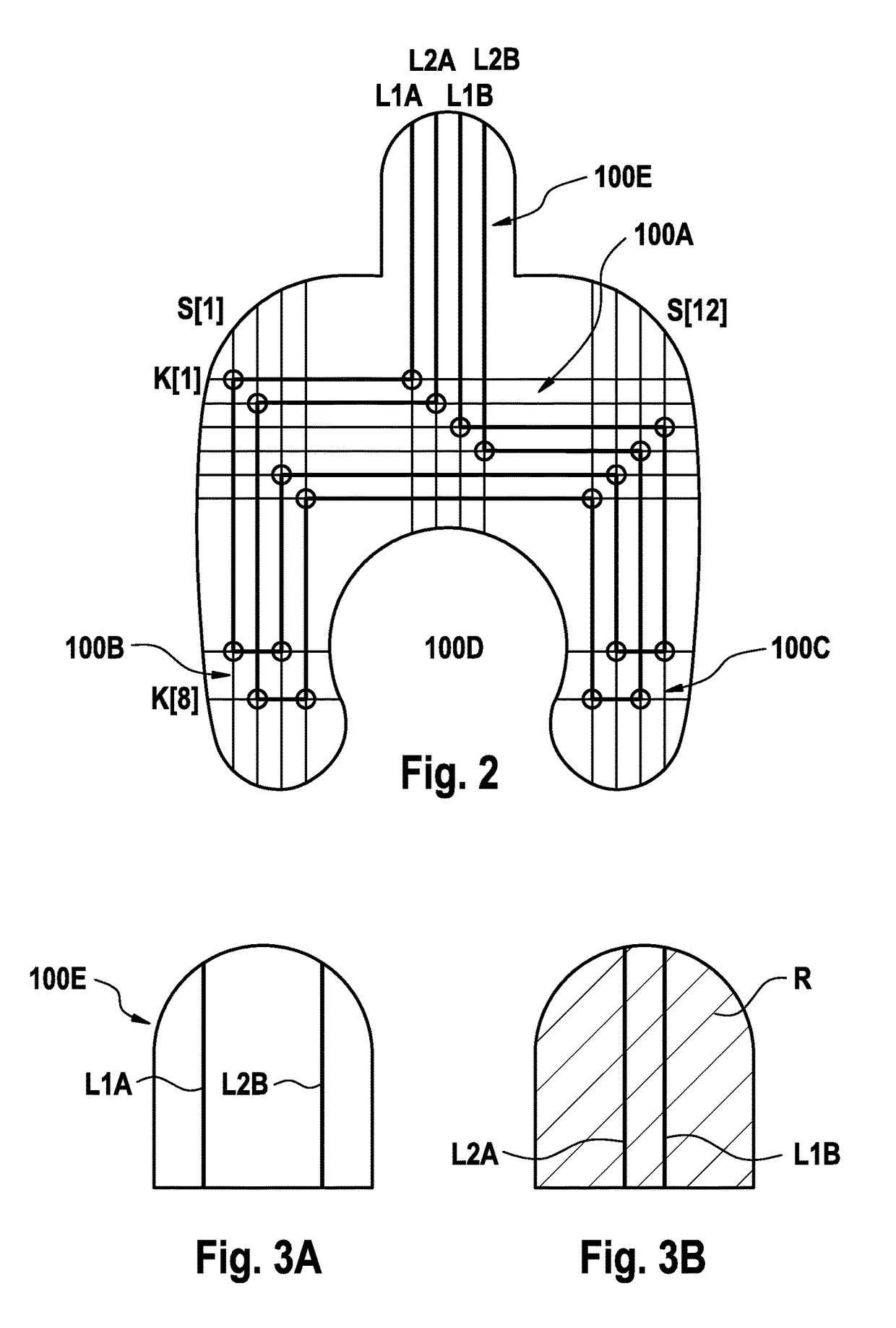

A wafer protective sheet 1 is made of a synthetic resin sheet with a thickness of 80 to 130 μm having a large number of projected parts and recessed parts on its front and rear surfaces. The large number of projected parts and the large number of recessed parts are respectively disposed so that each part is positioned at intersections of lattice stripes, and the projected part and the recessed part are disposed alternately each other. The sheet has such a water-like cross section that the recessed parts in the rear surface match the projected parts on the front surface and the projected parts on the rear surface match the recessed parts in the front surface. The wafer protective sheet 1 has a bending resistance of 30 to 80 mm. The wafer protective sheet 1 of the present invention is sufficiently thin. When the wafer protective sheets are interposed between stacked wafers to protect them, the sheets do not adhere to the wafers. Thus, wafers housed in a container can be protected against vibration during transportation.

Owner:ACHILLES CORP

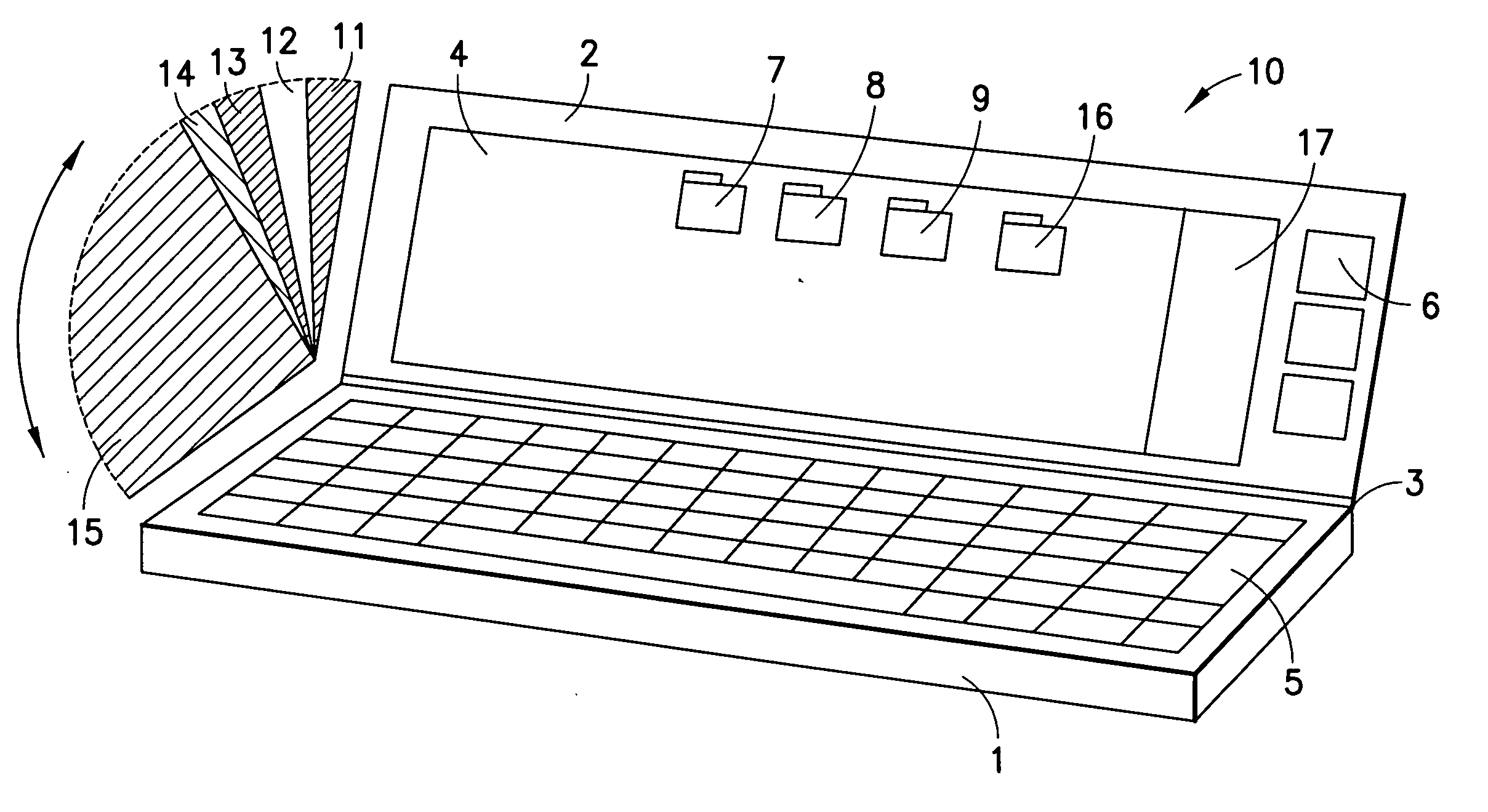

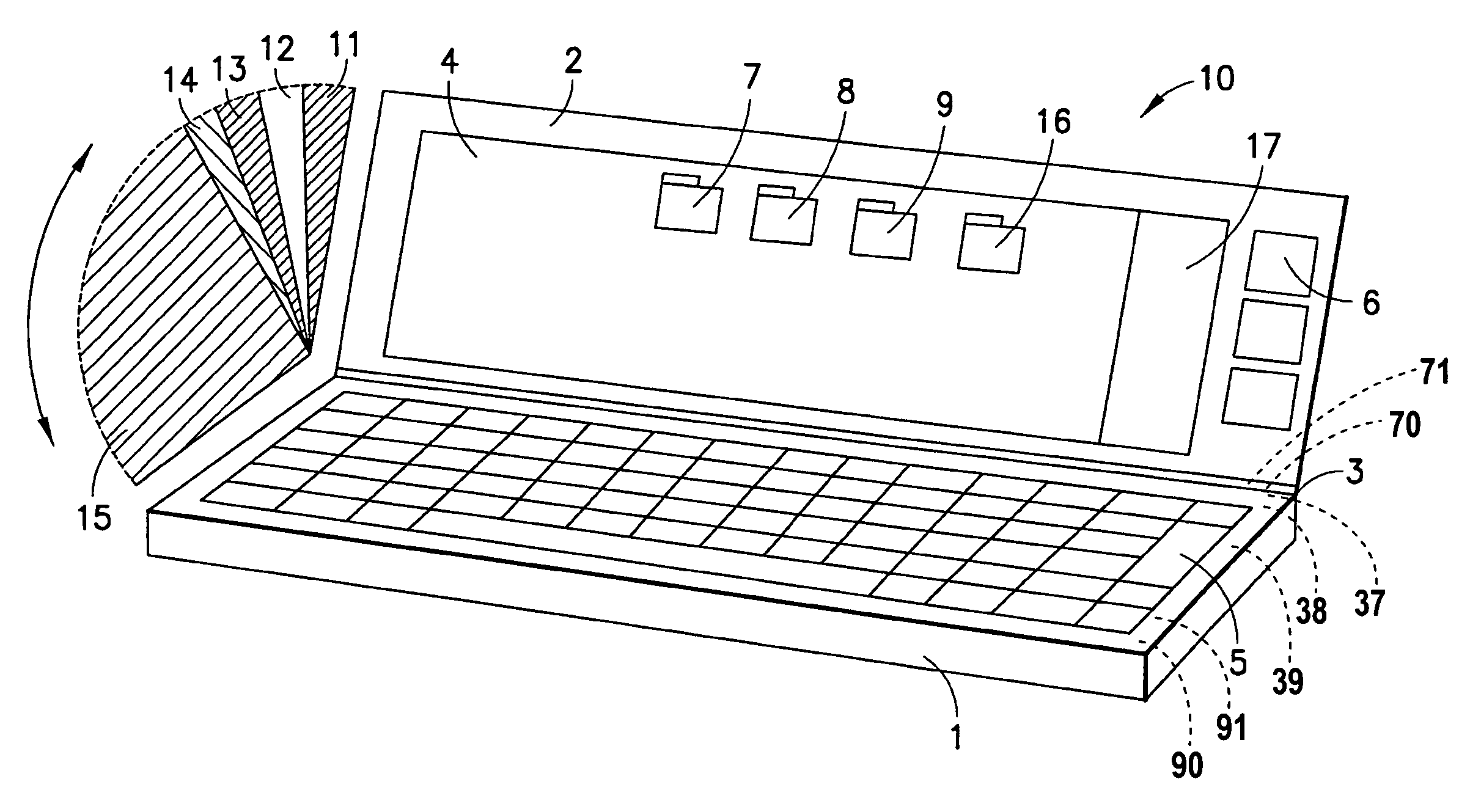

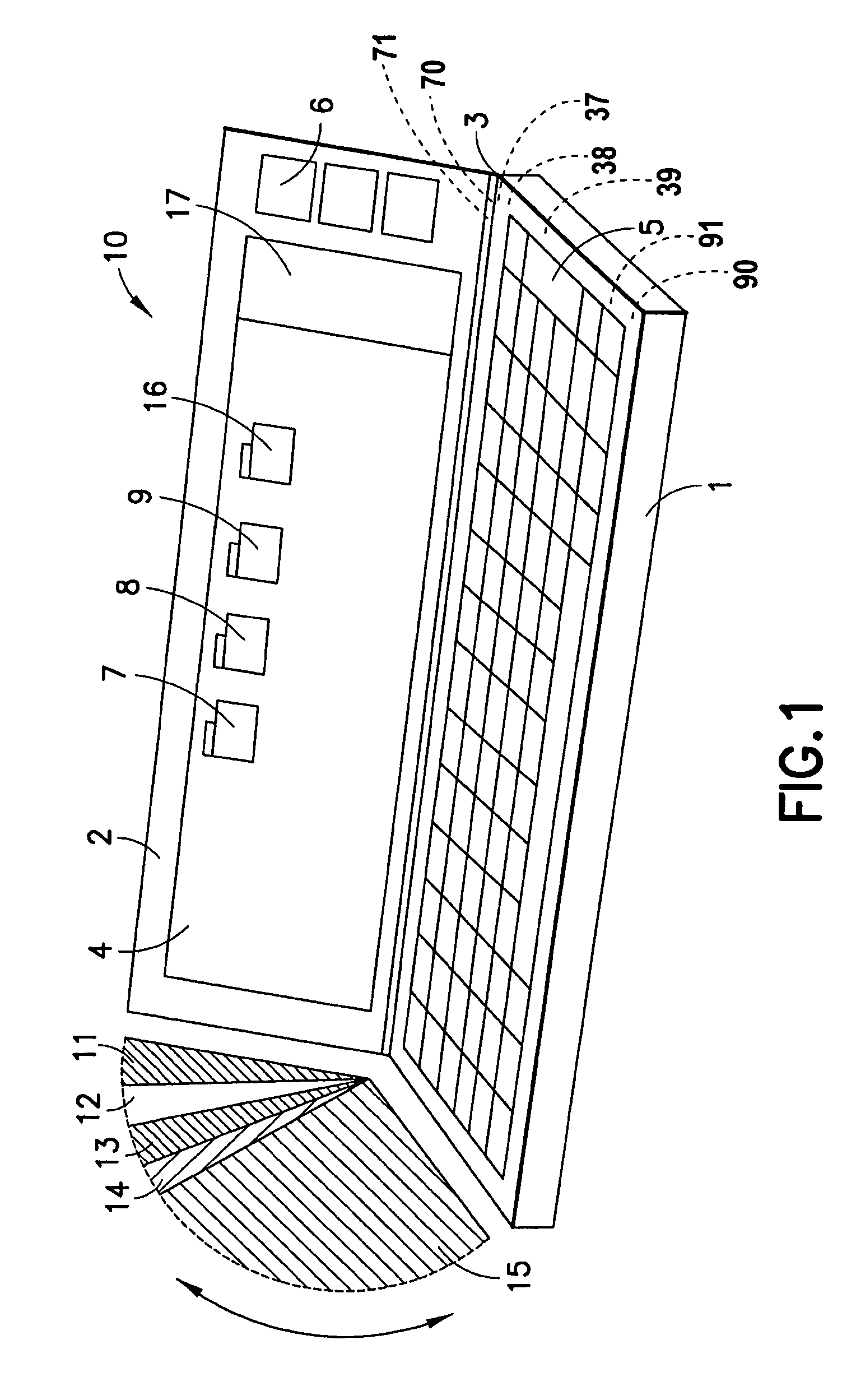

Portable electronic apparatus

ActiveUS20060182272A1Intuitive and more adroitEasy constructionInterconnection arrangementsDetails for portable computersEmbedded systemMobile telephony

A portable electronic apparatus, a mobile phone and a method of selecting a function in a portable electronic apparatus are disclosed. The portable electronic apparatus comprises a body and a lid pivotally mounted to the body with a hinge. Changes in the position of the lid around the hinge are detected and one of at least two possible functions available for a user is selected according to the detected change in the position of the lid.

Owner:NOKIA TECHNOLOGLES OY

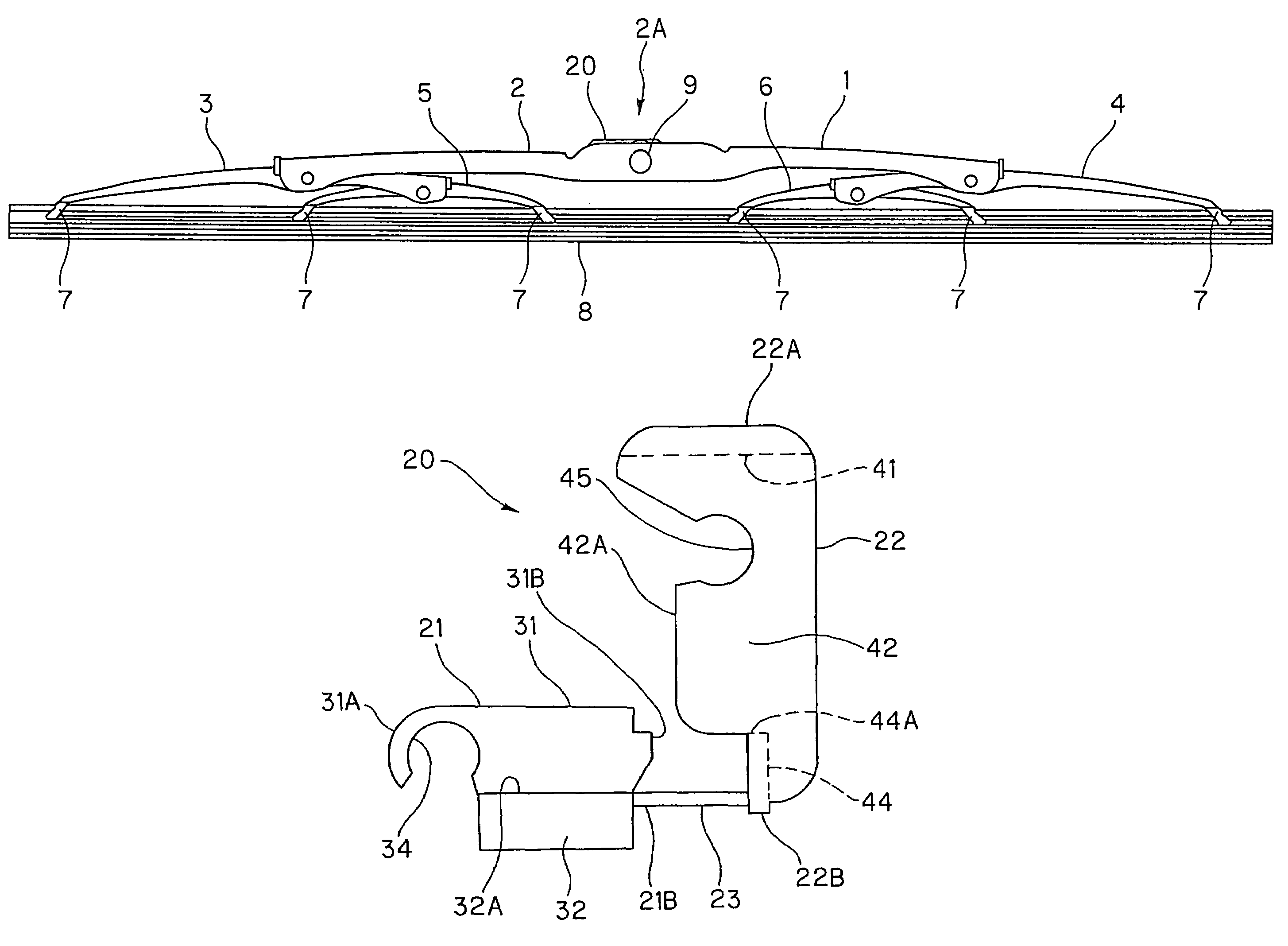

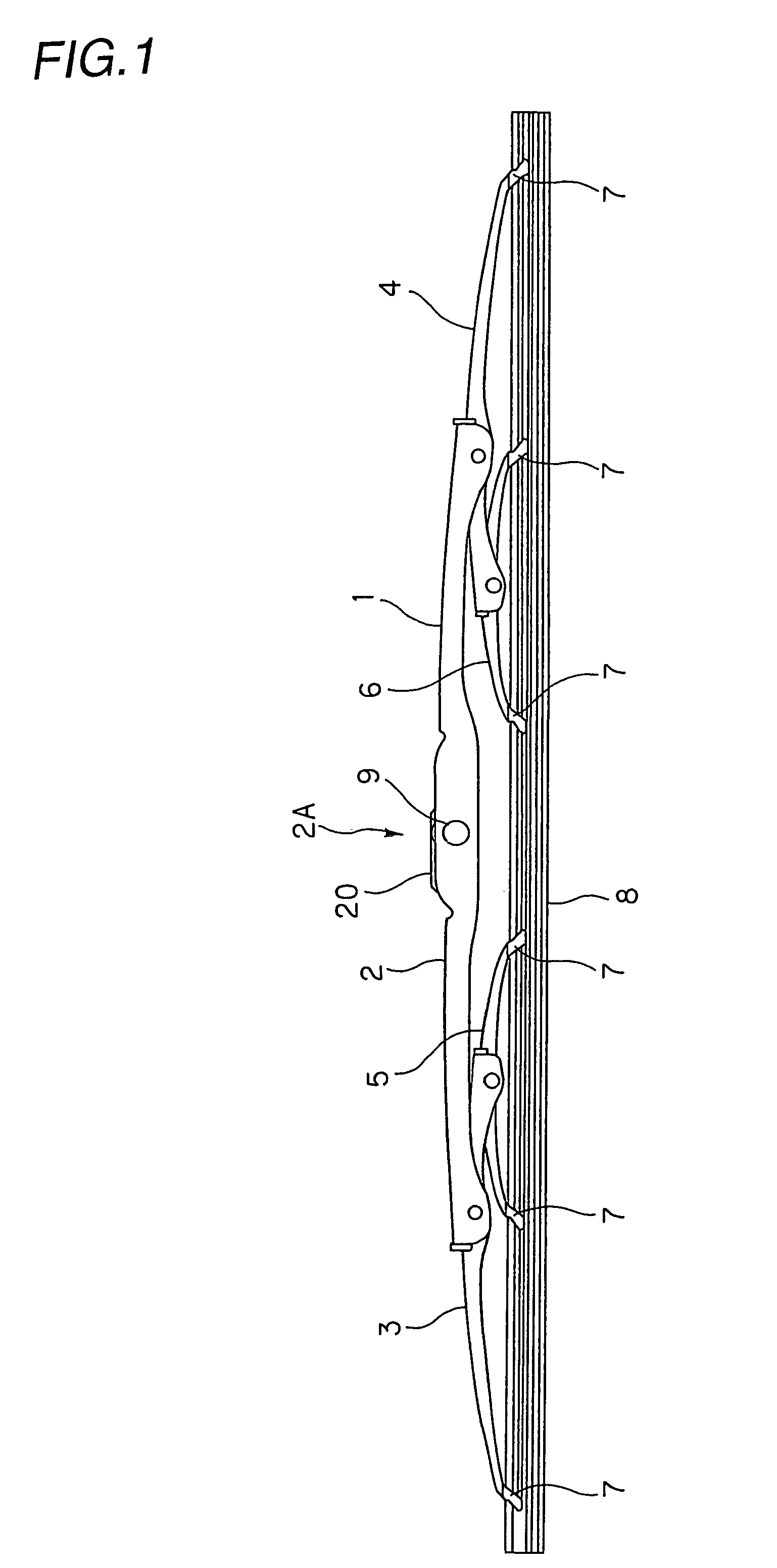

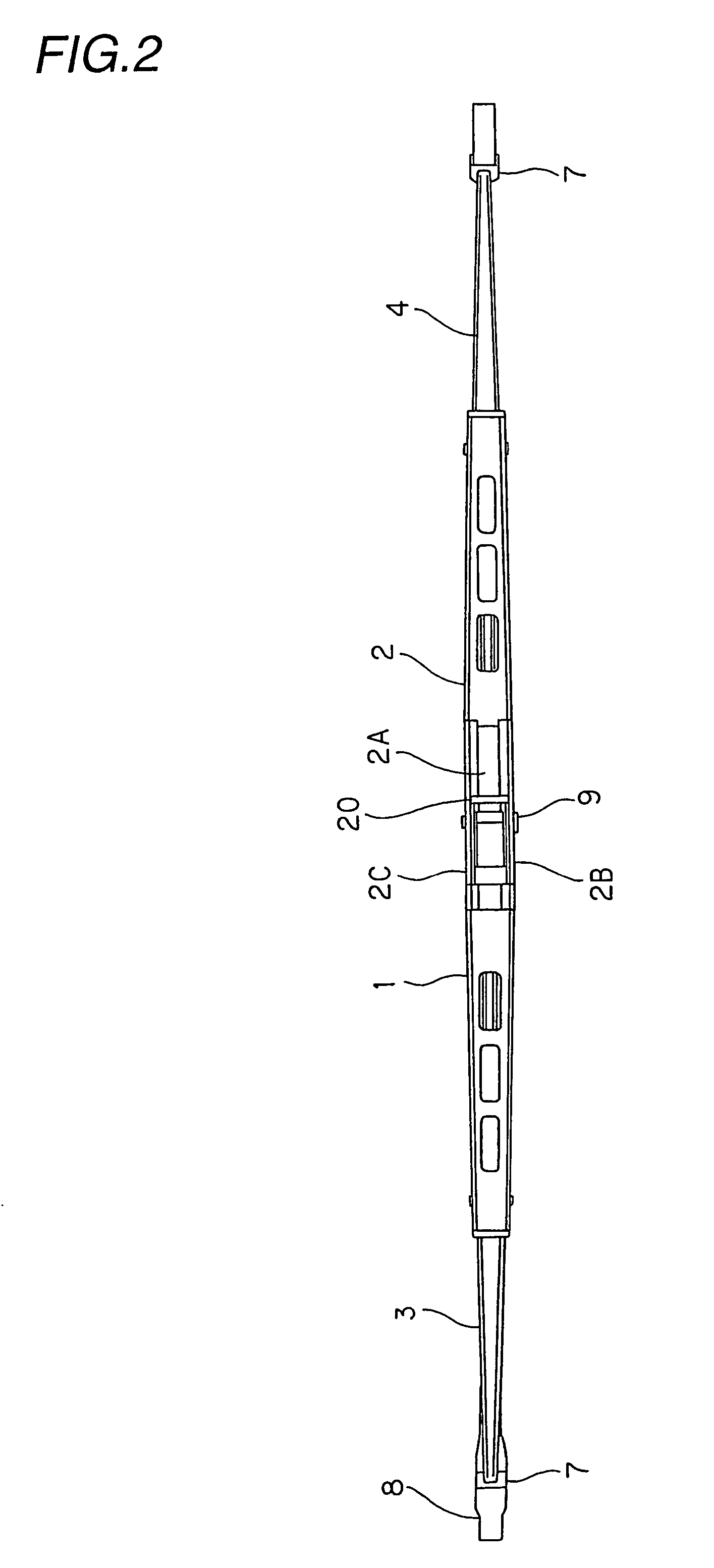

Joint member for wiper blade and wiper blade

InactiveUS7587782B2Easily and firmly joining a wiper armLow costCouplings for rigid shaftsWindow cleanersJoint componentEngineering

Owner:DENSO WIPER SYST INC

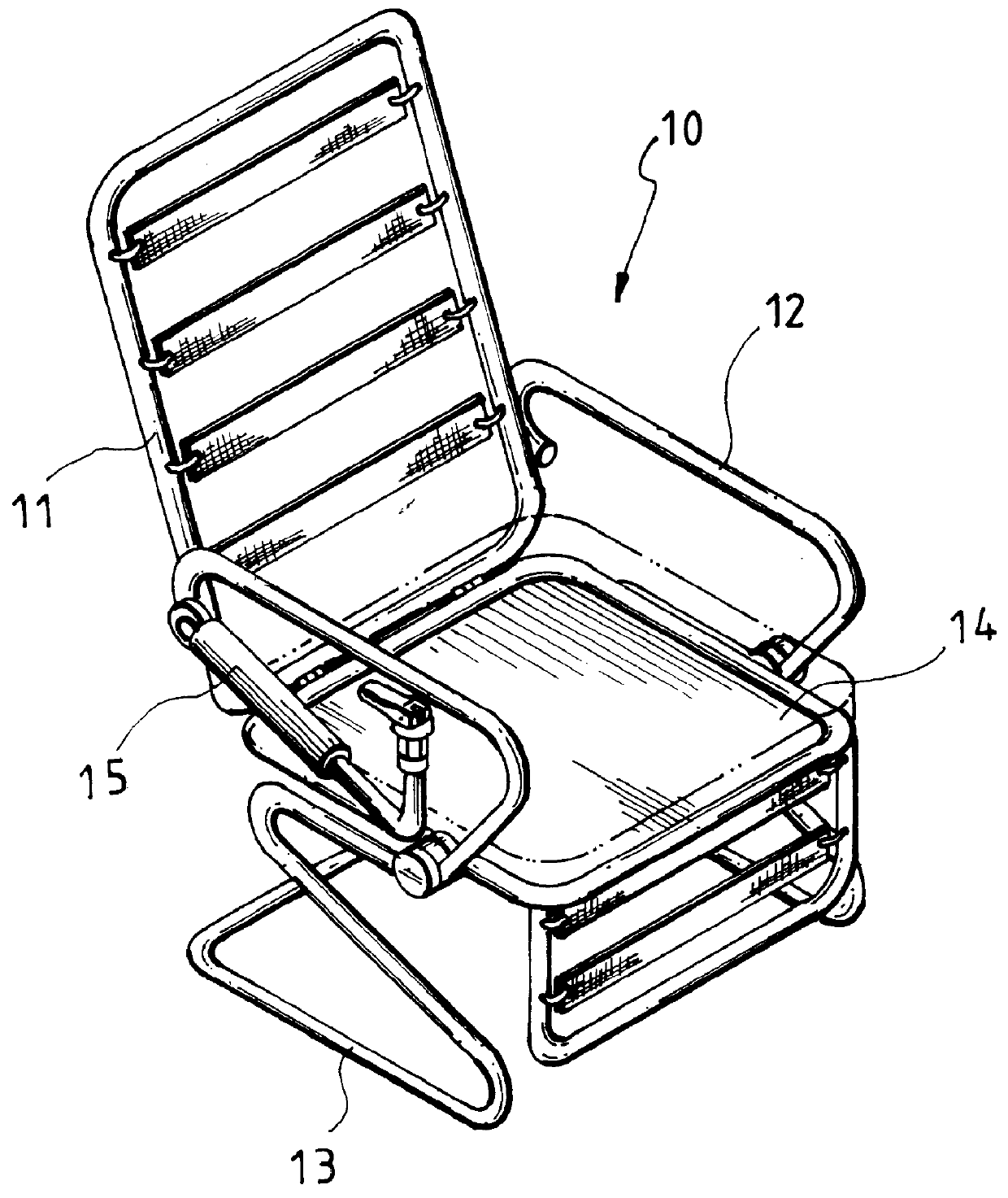

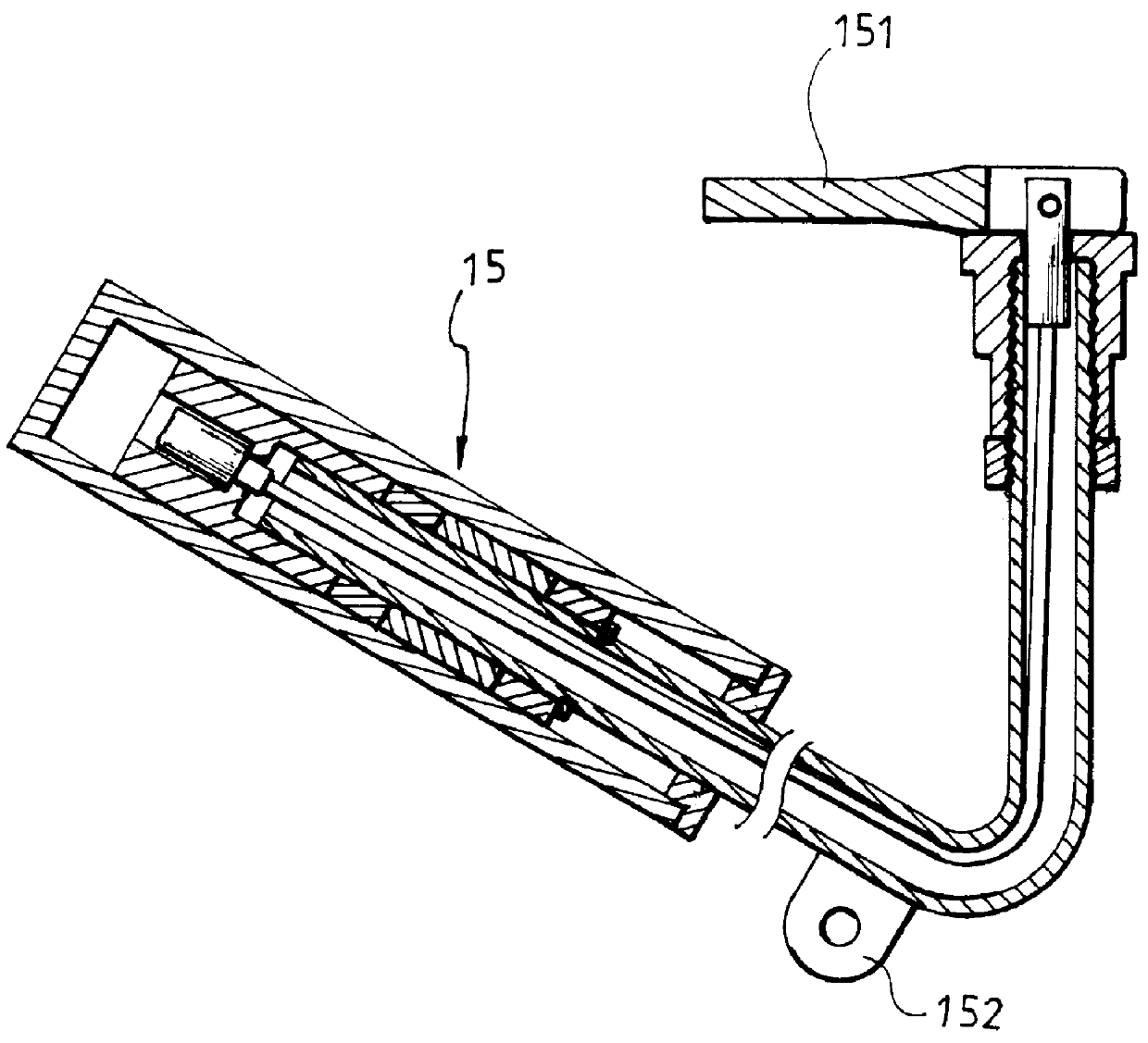

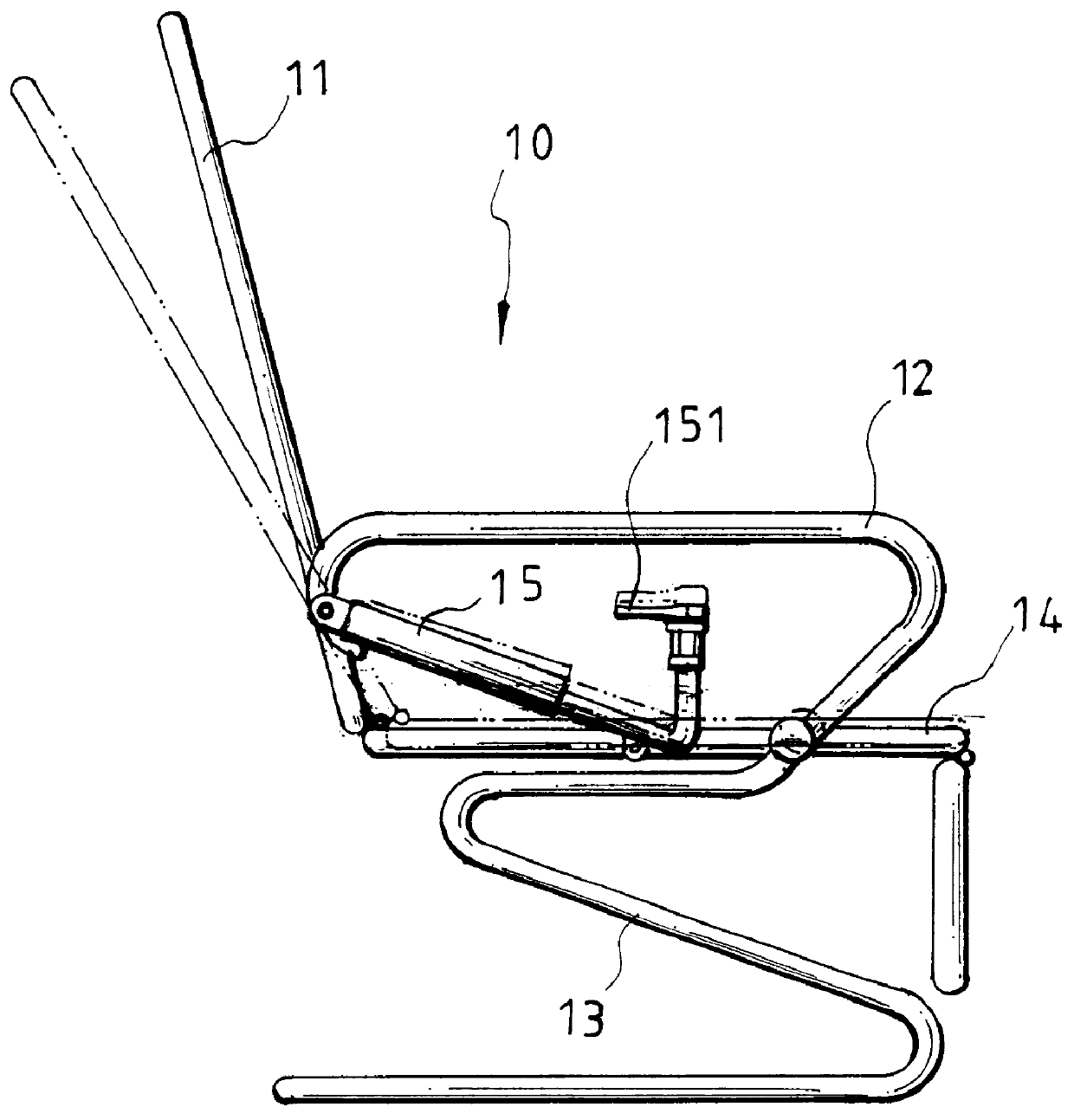

Armchair

InactiveUS6116686AAppropriate resistanceLower resistanceStoolsAdjustable chairsEngineeringPneumatic cylinder

An armchair is disclosed. The armchair has a seatback, a pair of armrests securely mounted on both sides of the seatback, a spring-like base securely and respectively engaged with the pair of armrests and a seat a side of which engages with a bottom side of the seatback and provided between the armrests. A pneumatic cylinder is provided between the seat and a joint of the seatback and one of the armrests, such that the inclination difficulty of the seatback with respect to the seat is adjusted via the adjustment of the pneumatic cylinder.

Owner:LUO WUN THONG

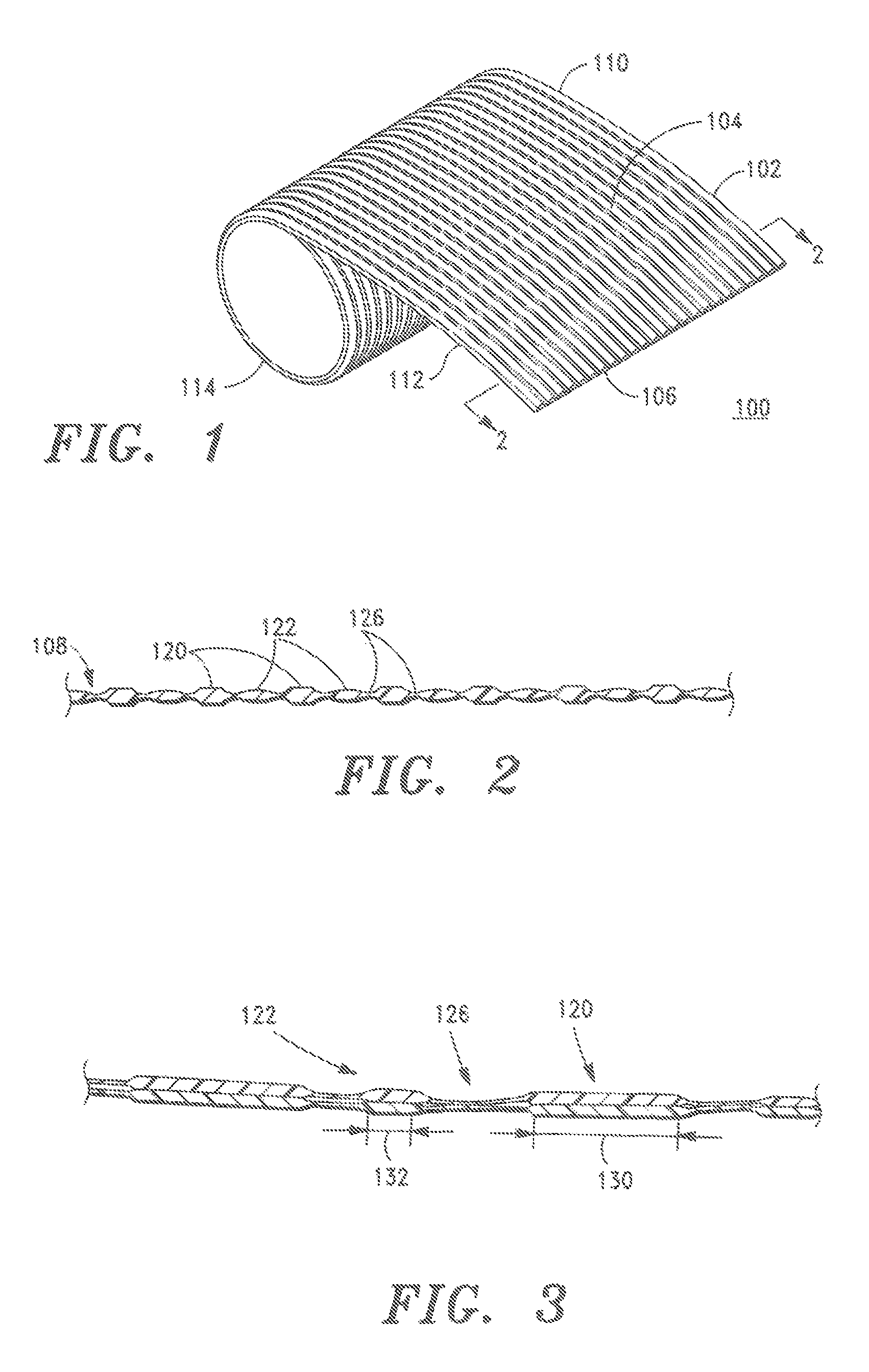

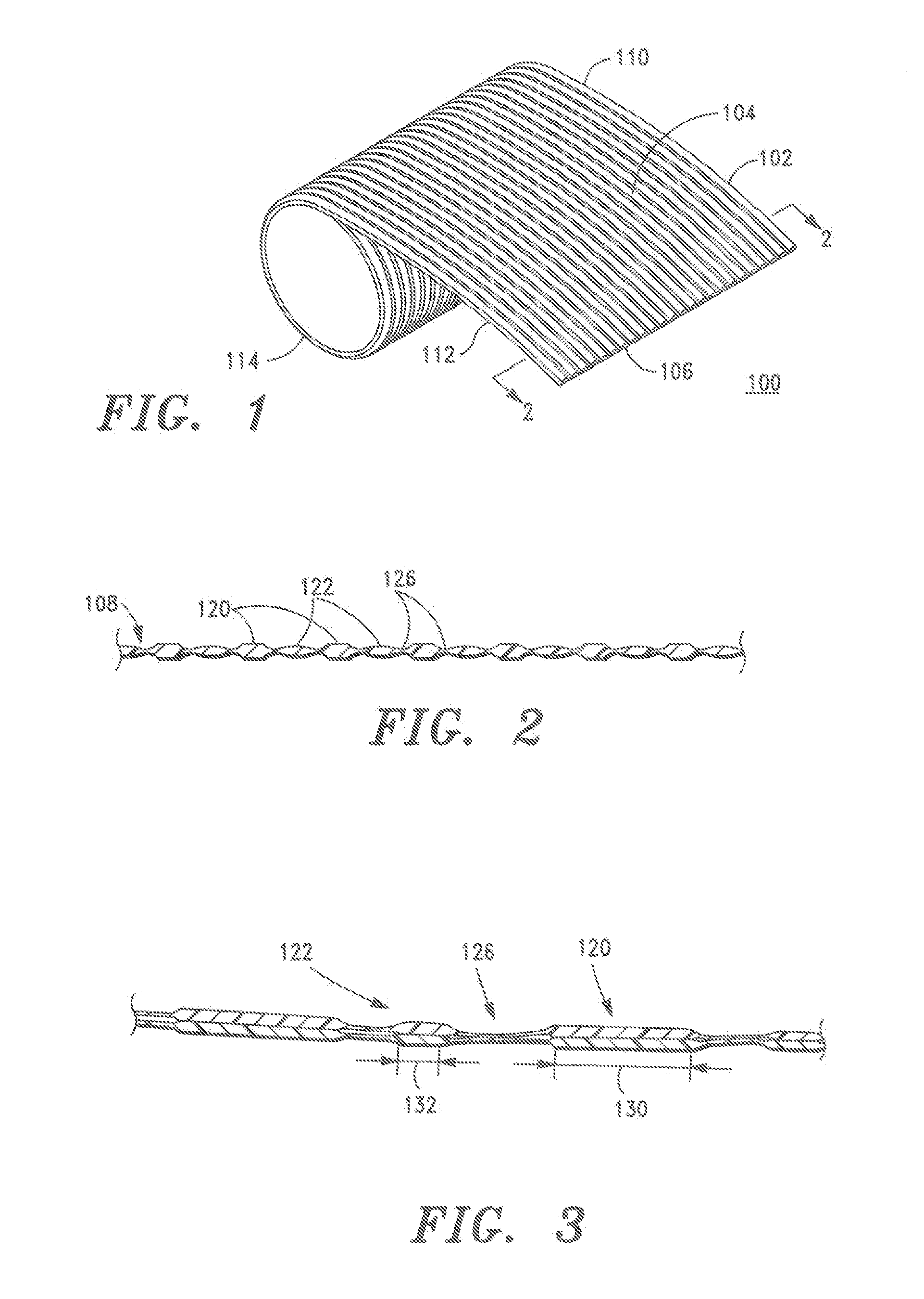

Cling wrap

ActiveUS9132956B2Increase the areaEasy to processFilament handlingFlat article dispensingEngineeringIngested food

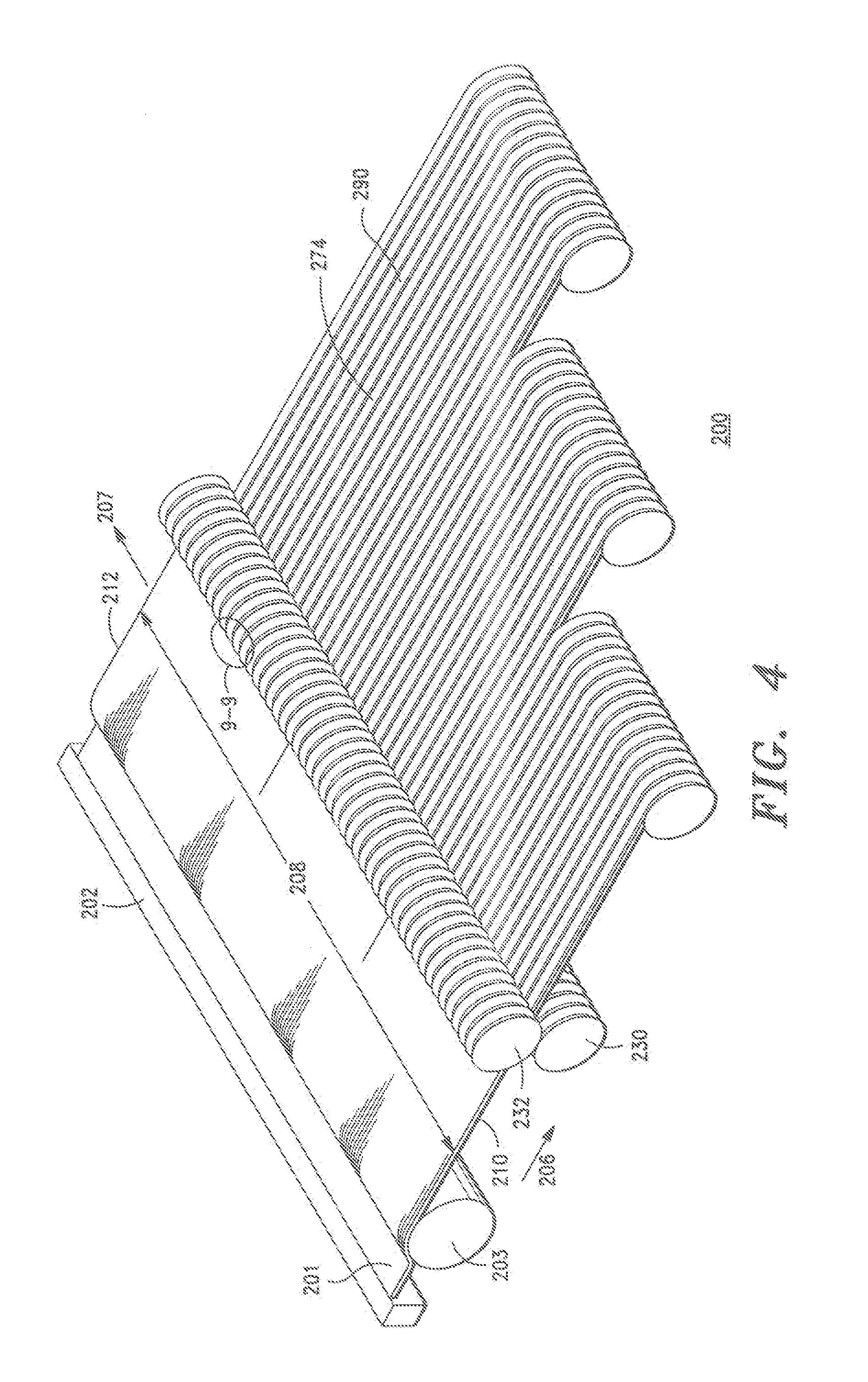

A thermoplastic food wrap film including a plurality of parallel ribs formed therein. To produce the film, a thermoplastic web may be directed between opposing first and second rollers having ridges. The formation of the ribs may increase the width of the web. The film may be formed into a roll and inserted into a box having a cutting strip.

Owner:THE GLAD PROD CO

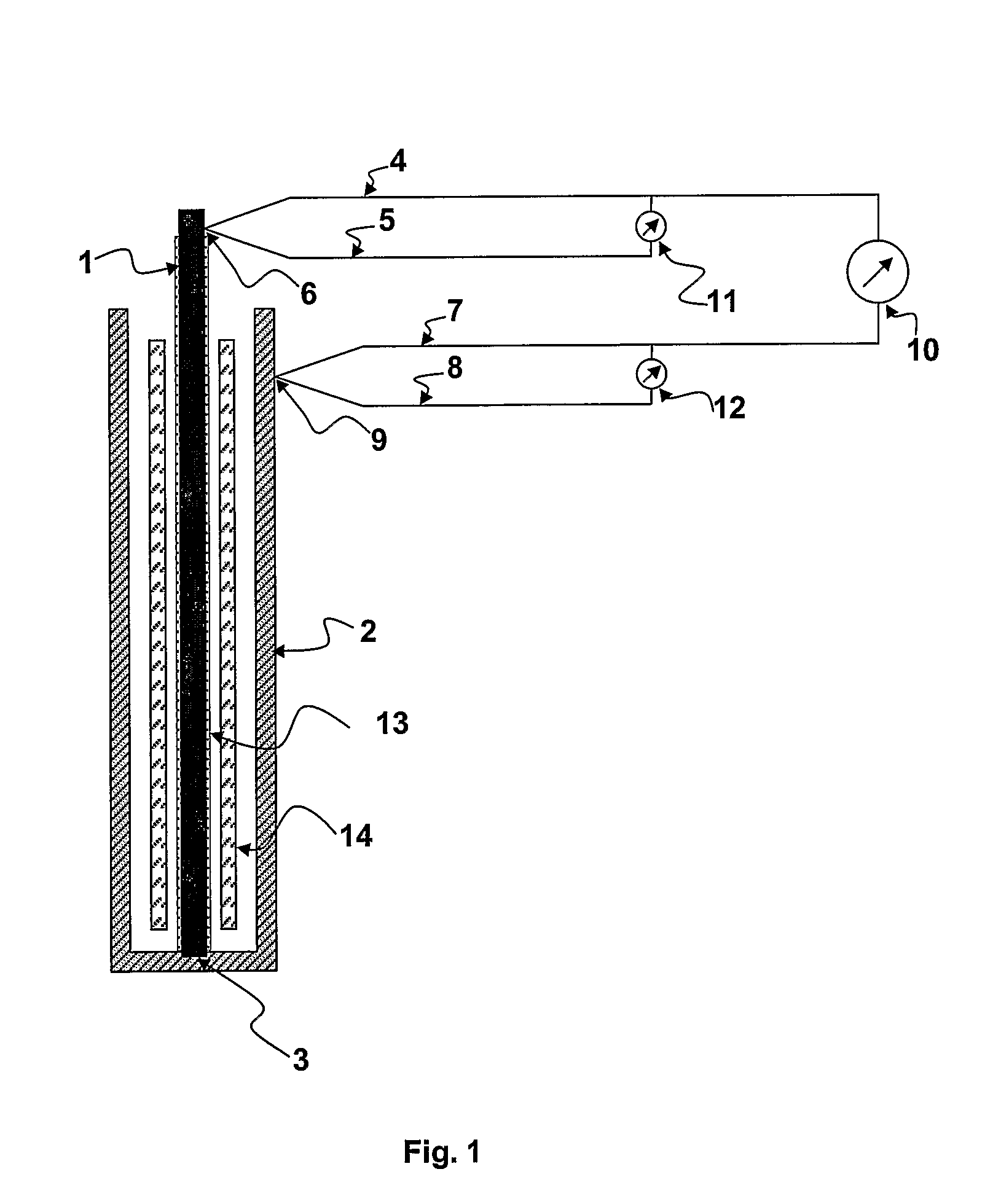

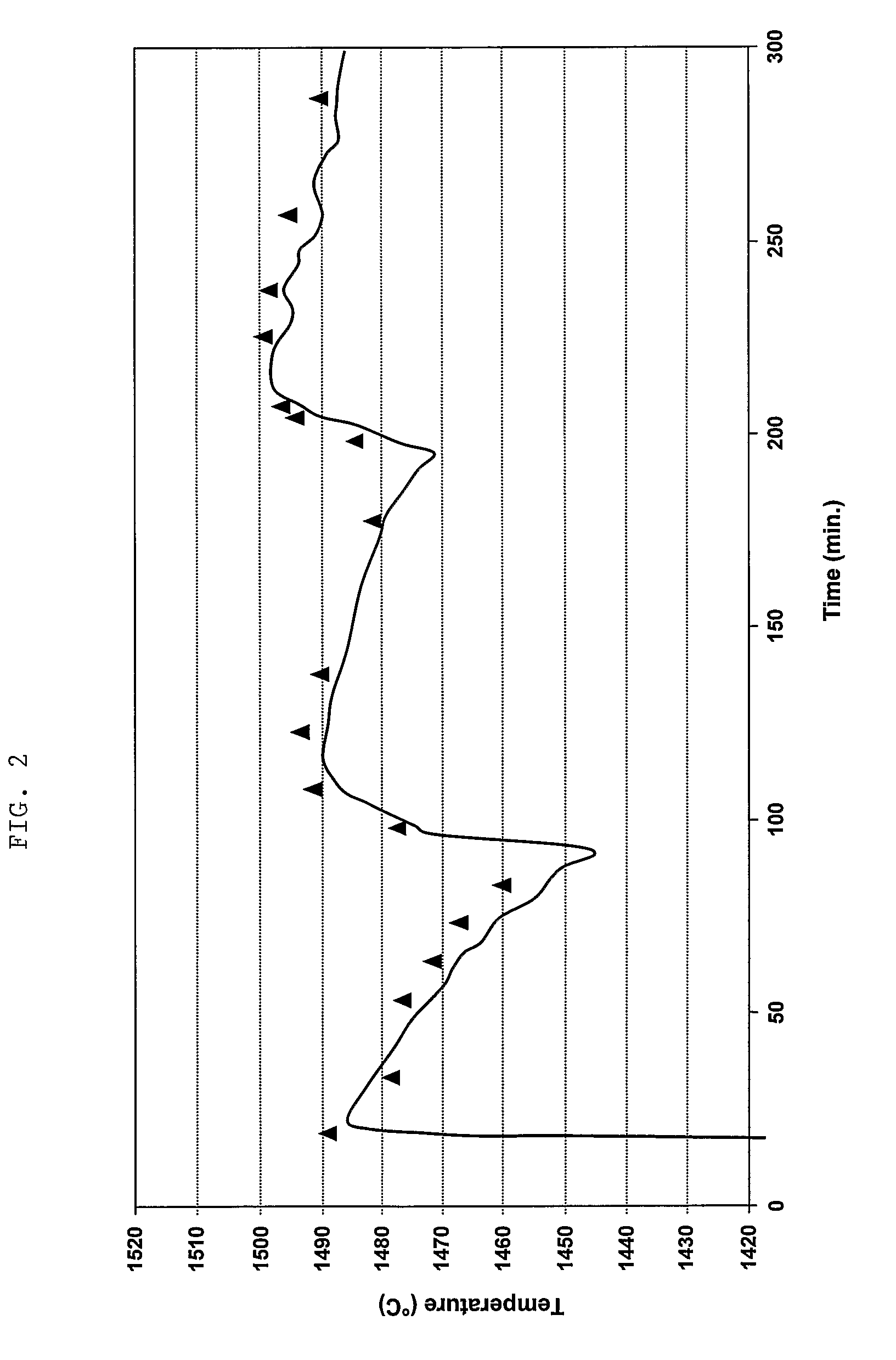

Thermocouple Assembly And Method Of Use

InactiveUS20080175303A1Appropriate resistancePrevent excessive rod movementThermometers using electric/magnetic elementsUsing electrical meansContinuous measurementContact element

A thermocouple assembly for the continuous measurement of the temperature of a molten phase contains first and second ceramic elements contacting each other at a first junction and forming thereby a first thermocouple, a second thermocouple formed of two different conducting elements contacting each other at a second junction located on the first ceramic element and a third thermocouple formed of two different contacting elements contacting each other at a third junction located on the second ceramic element. Both positive legs or both negative legs of the second and third thermocouples are connected to a first measuring device. Both legs of the second and third thermocouple are connected respectively to a second and third measuring device as well as to a process for the measurement of the temperature of a molten phase.

Owner:VESUVIUS CRUCIBLE CO

Portable electronic apparatus

ActiveUS7873159B2Intuitive and more adroitEasy constructionInterconnection arrangementsDetails for portable computersEmbedded systemMobile phone

A portable electronic apparatus, a mobile phone and a method of selecting a function in a portable electronic apparatus are disclosed. The portable electronic apparatus comprises a body and a lid pivotally mounted to the body with a hinge. Changes in the position of the lid around the hinge are detected and one of at least two possible functions available for a user is selected according to the detected change in the position of the lid.

Owner:NOKIA TECHNOLOGLES OY

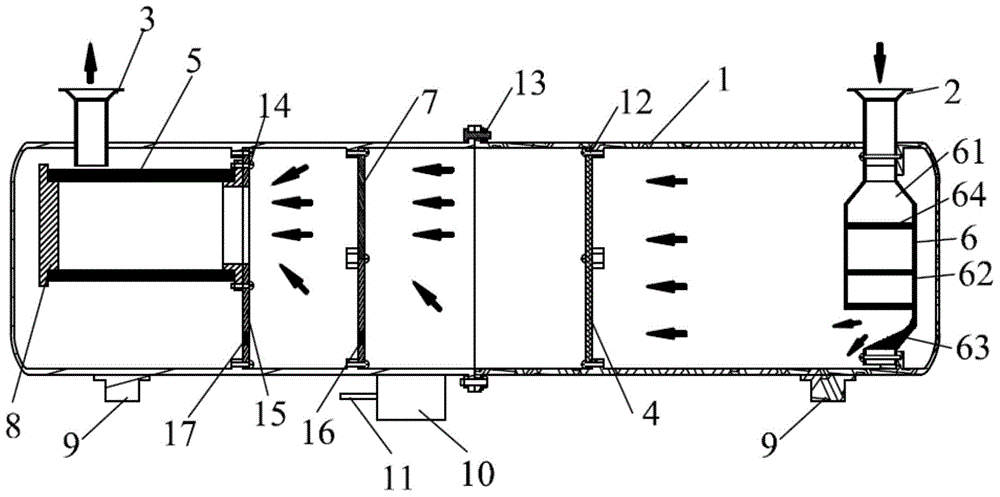

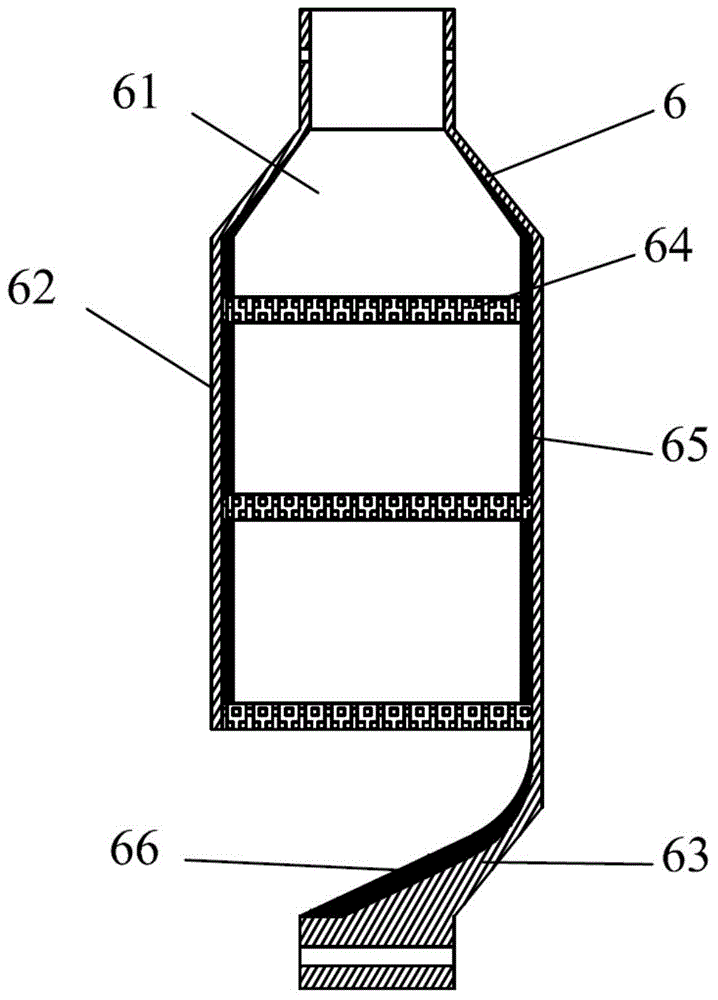

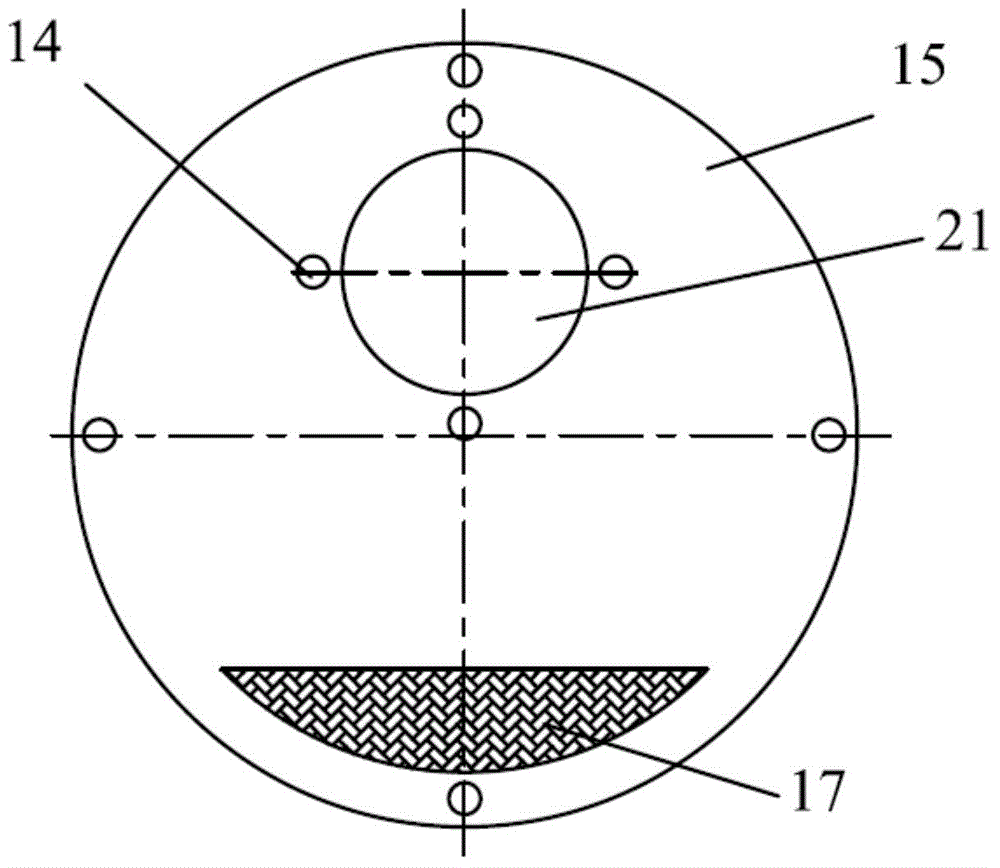

Oil separator for refrigerating system

ActiveCN104964494AAvoid noiseProtected against liquid splashingRefrigeration componentsBody segmentFilter element

The invention relates to an oil separator for a refrigerating system. The oil separator comprises a barrel, an inlet pipe and a discharge pipe. The inlet pipe and the discharge pipe are arranged at the two ends of the barrel and communicated with the barrel. A first main filter is arranged in the position, close to the pipe inlet end, in the barrel, and a cylindrical structure filter element is arranged at an outlet of the discharge pipe. The oil separator further comprises a denoiser in the barrel. The denoiser comprises a horn-shaped inlet segment with a small inlet, a columnar denoiser body segment and an arc-shaped open segment, and the horn-shaped inlet segment, the columnar denoiser body segment and the arc-shaped open segment are connected in sequence. The inlet of the horn-shaped inlet segment is connected with the inlet pipe, and at least one layer of denoiser filter screen is arranged in the denoiser body segment. Due to the fact that an end opening of the inlet pipe in the oil separator is connected with the denoiser, and the inlet segment of the denoiser is arranged to be in a horn shape with the small inlet, the flow-through section of a gas and oil mixture is fast enlarged, the flowing speed of the gas and oil mixture is reduced at this moment, and noise is lowered. Meanwhile, the gas and oil mixture directly impacts the first denoiser filter screen, and the noise is further lowered.

Owner:GD MIDEA HEATING & VENTILATING EQUIP CO LTD +1

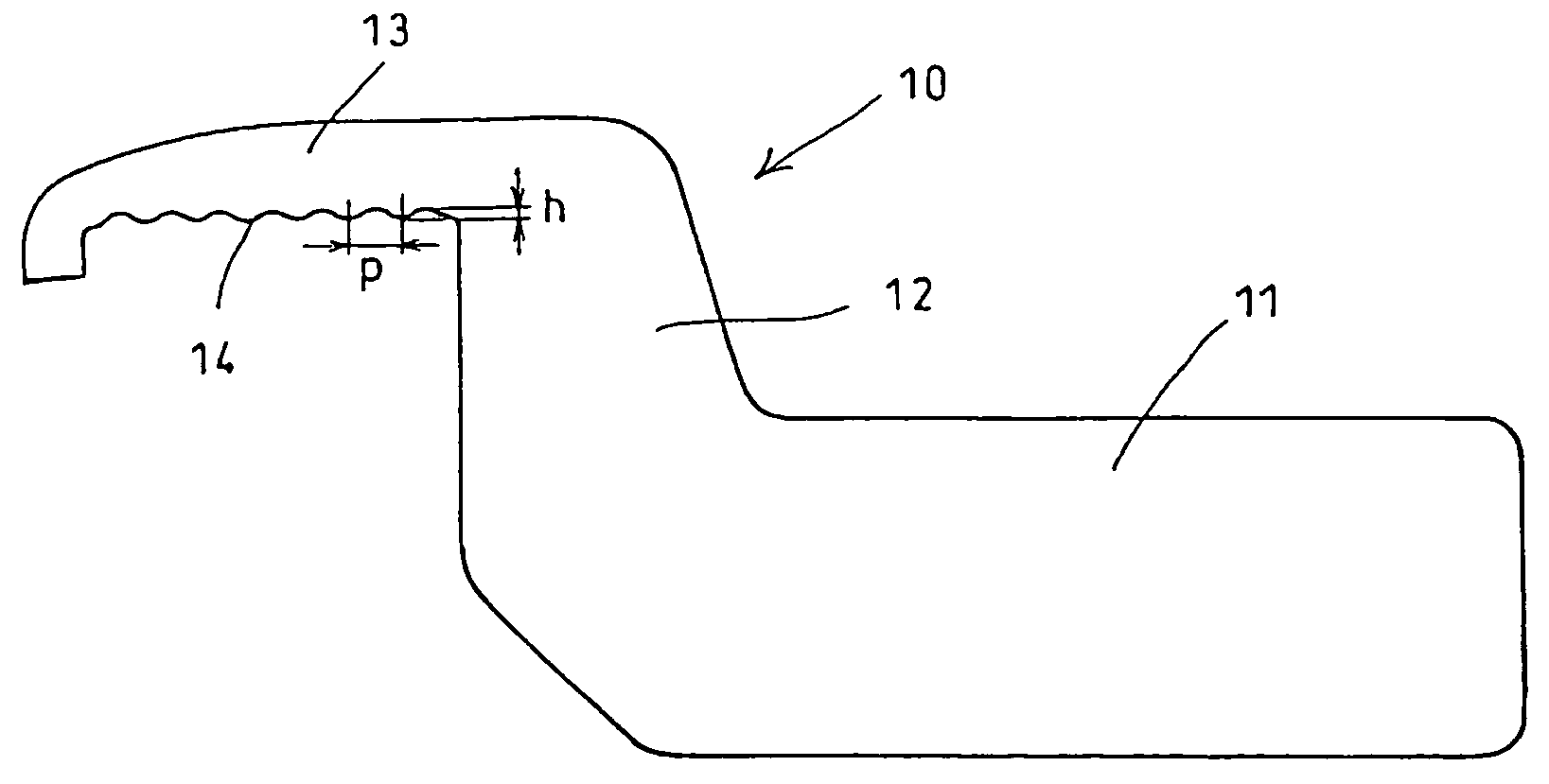

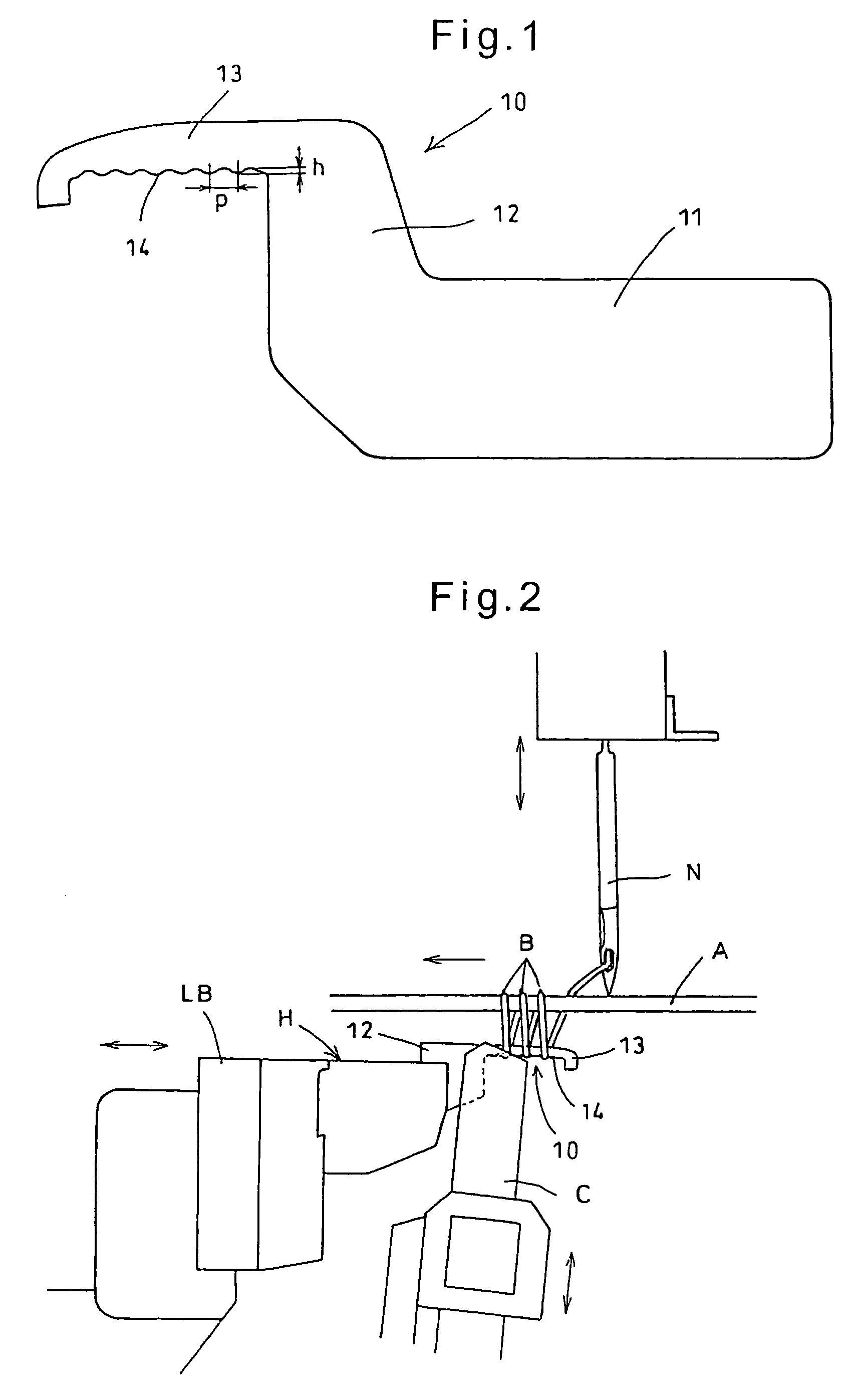

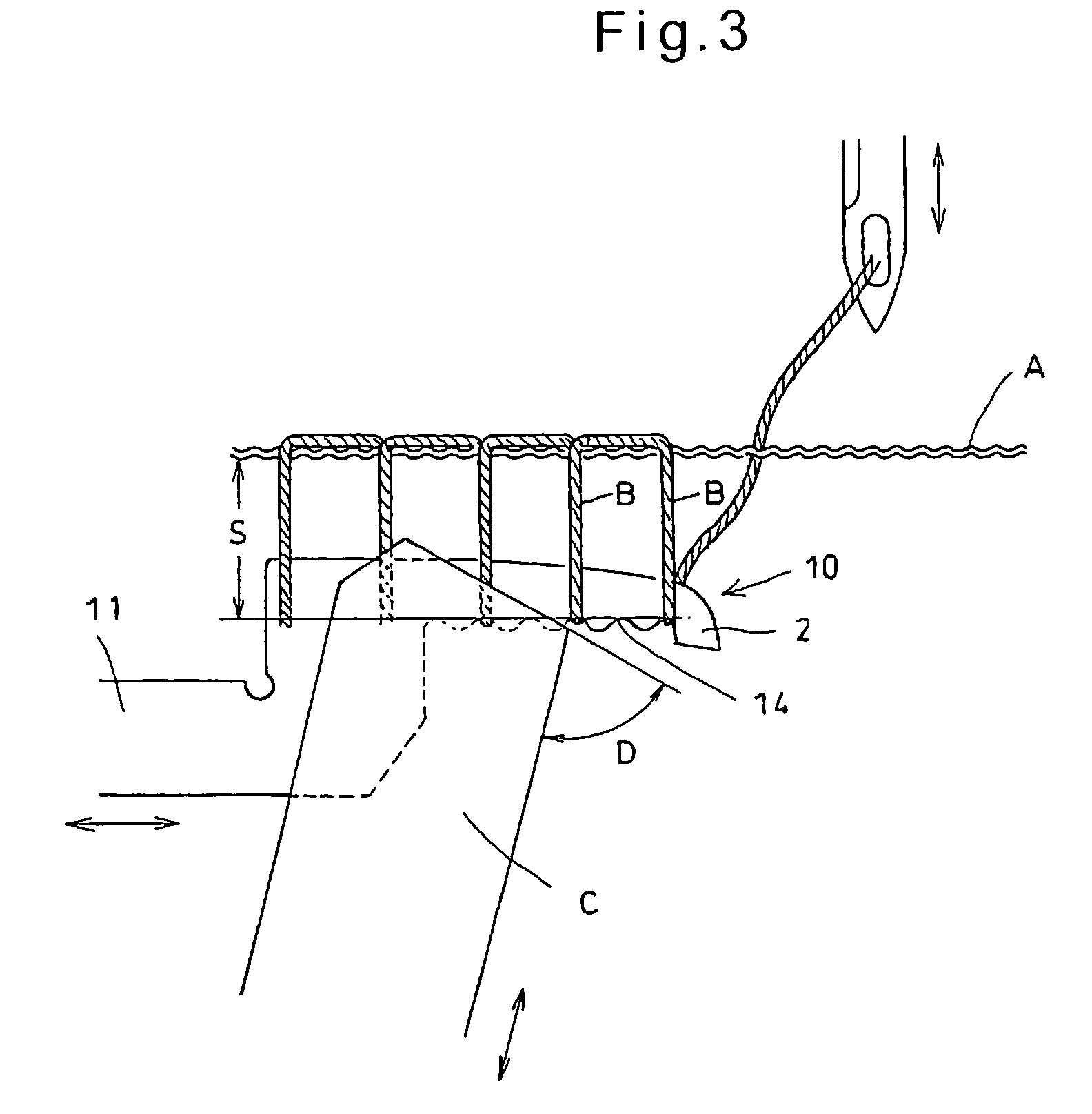

Looper for tufting machine

ActiveUS7165500B1Reliably and precisely cutCut evenlyTufting apparatusEngineeringMechanical engineering

A looper for use in a tufting machine includes a hook throat portion having a bottom edge. Corrugations are formed along the bottom edge. The corrugations provide suitable resistance to loop piles hooked by the hook throat portion, thereby preventing the loop piles from being held in an unexpected position of the hook throat portion. This makes it possible to form loop piles of uniform lengths on carpets. Also, the corrugations will prevent the loop piles from sliding away from a knife so that the loop piles can be reliably, precisely and cleanly cut at constant positions.

Owner:NARA +1

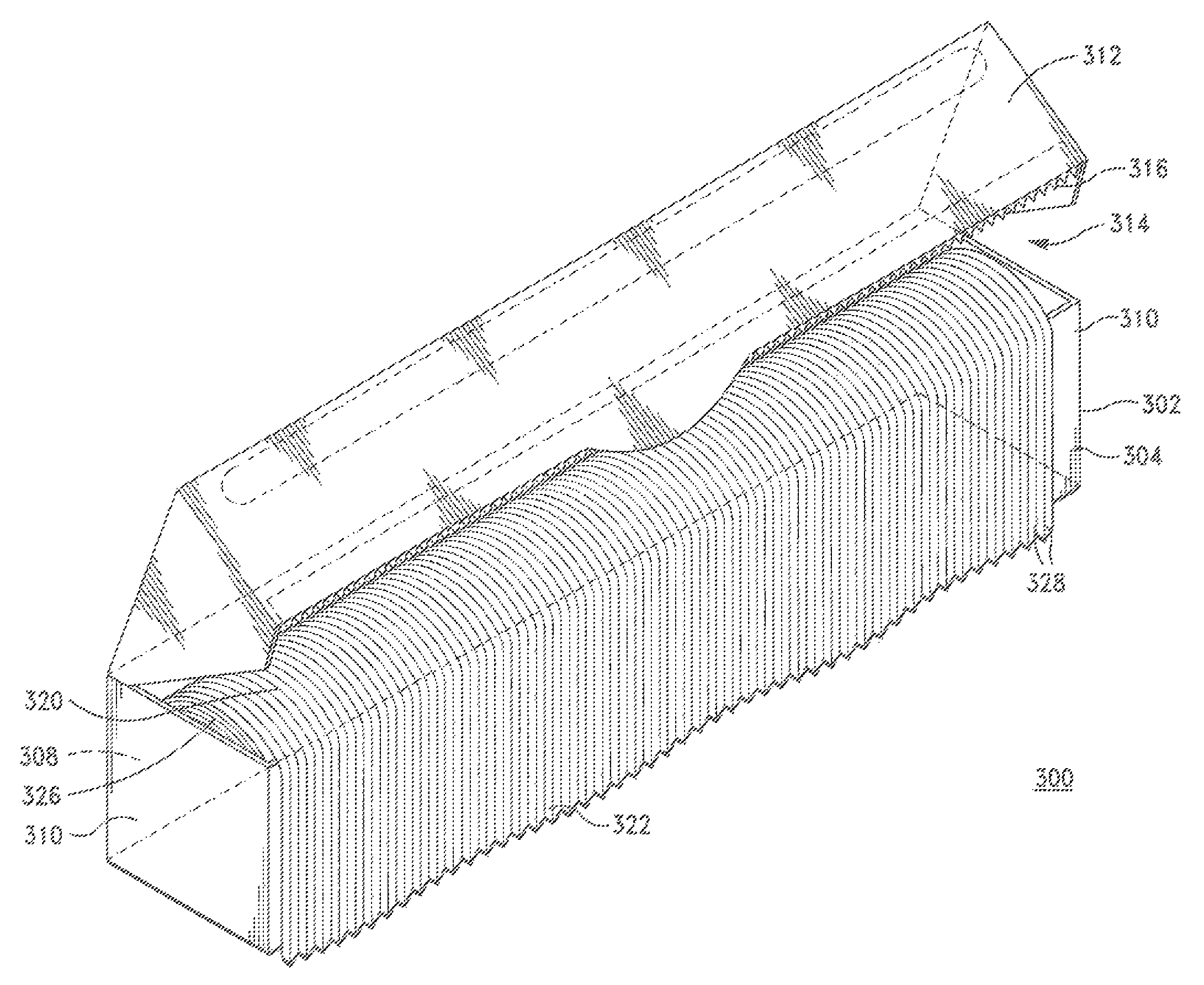

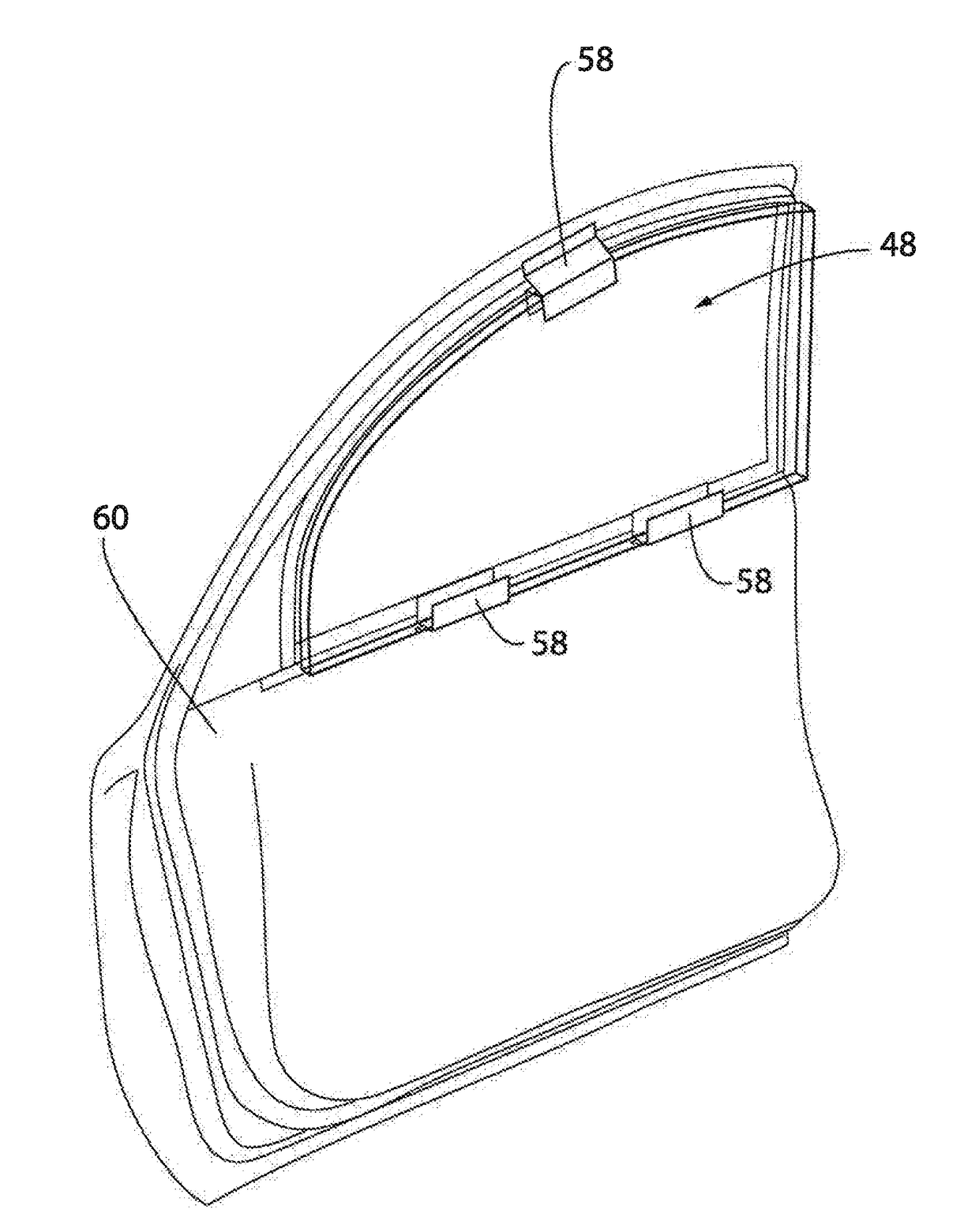

Projectile penetration resistance assemblies

ActiveUS20180149449A1Easily workablePromote formationArmoured vehiclesDoors/windowsEngineeringProjectile

Unidirectional transparent projectile penetration resistant panels and bidirectional opaque projectile penetration resistant assemblies and systems and methods of forming and mounting the same relative to underlying support structures.

Owner:TRUARMOR A DIV OF CLEAR ARMOR LLC

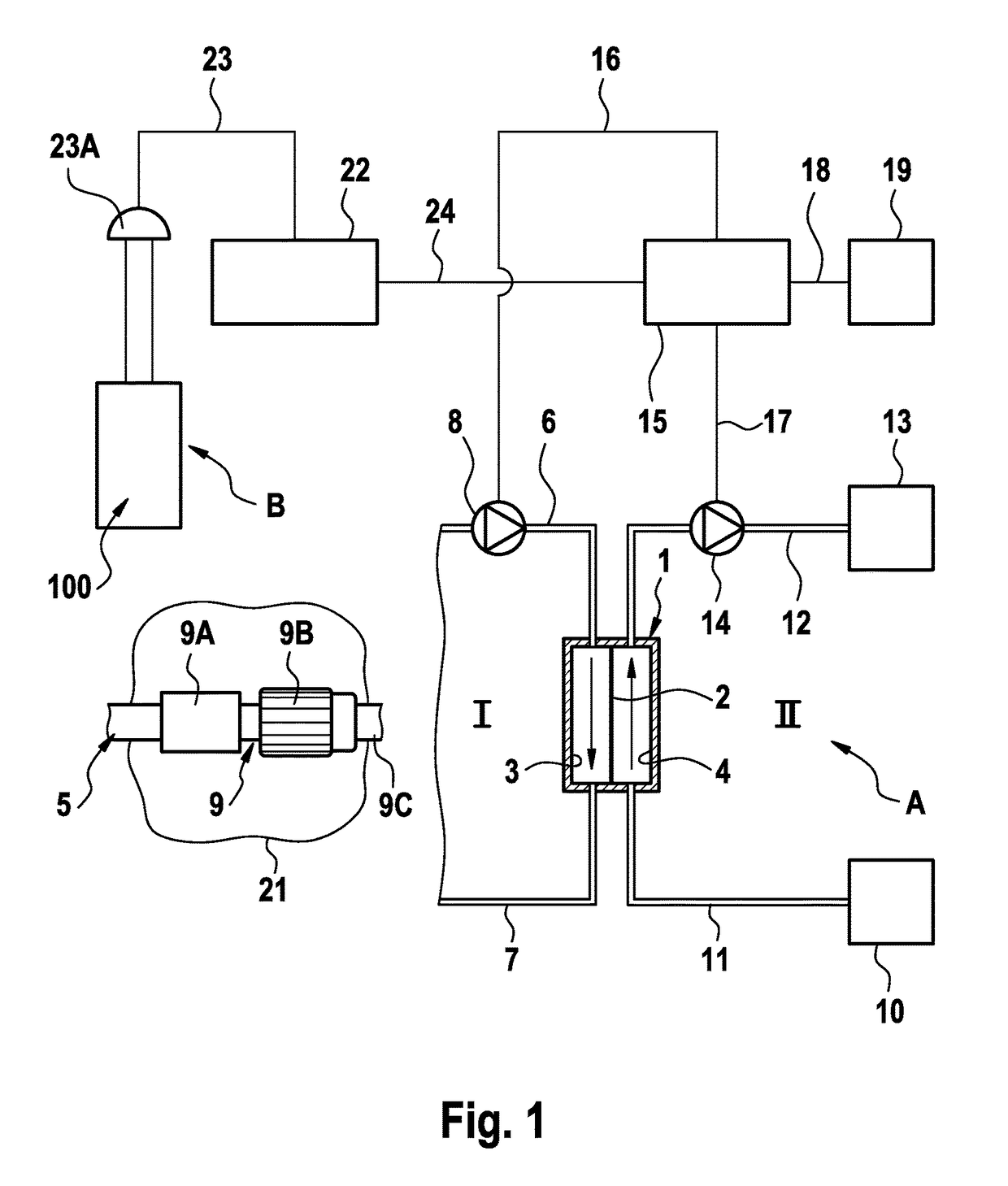

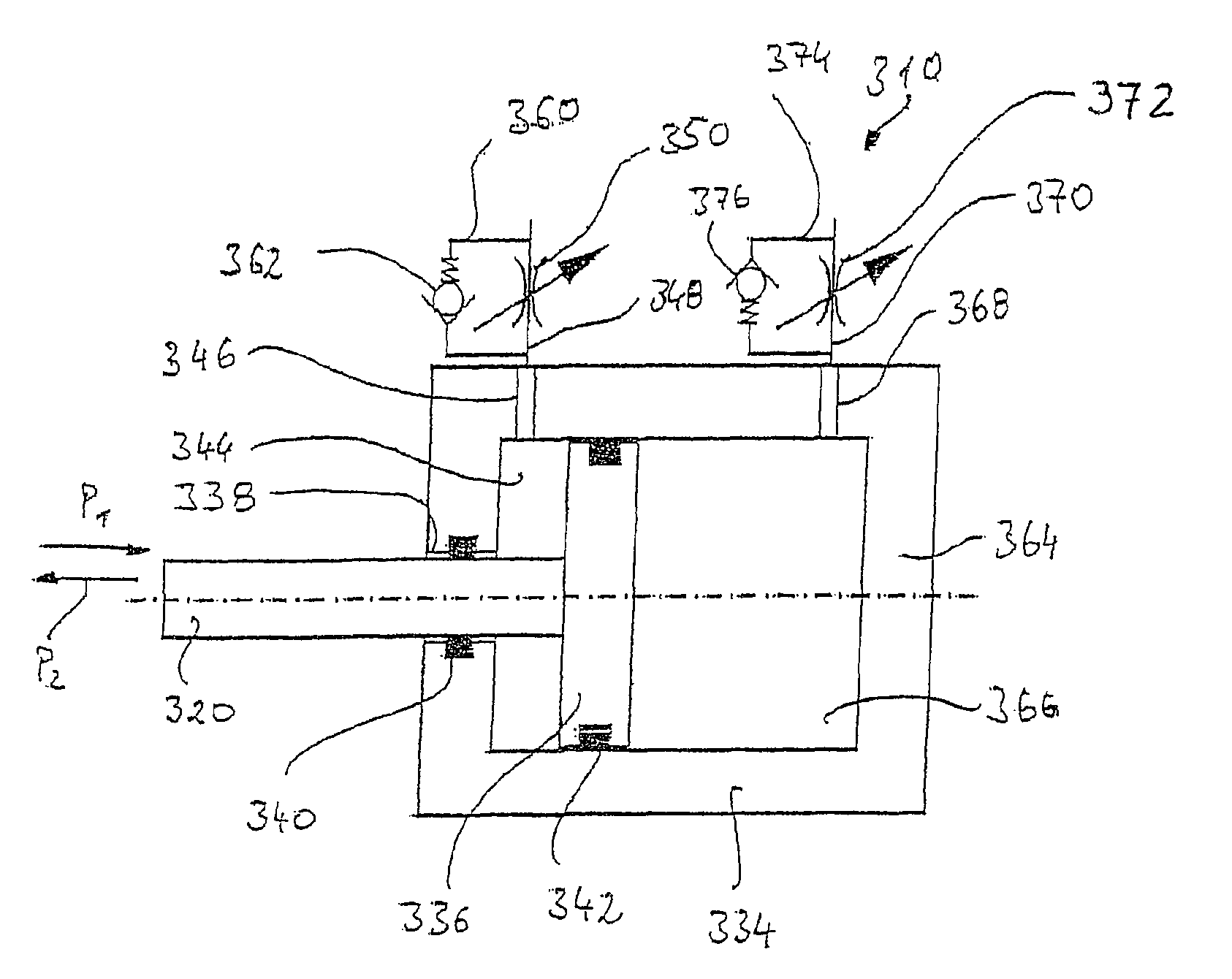

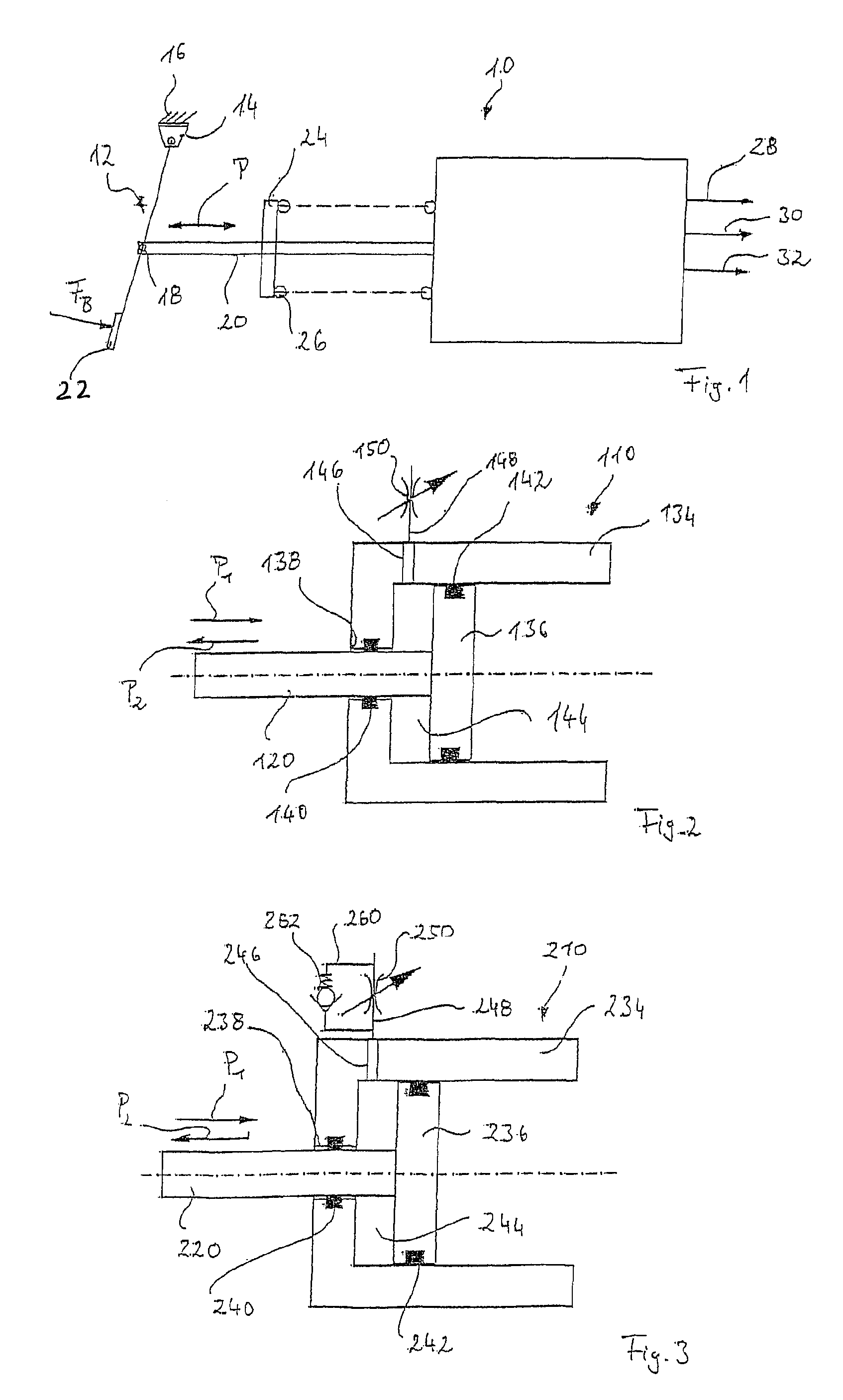

Pedal simulation device

ActiveUS7954908B2Quick responseControl flowControlling membersBraking action transmissionEngineeringReaction behavior

The invention relates to a pedal simulation device for simulating the reaction behavior of a pedal, in particular of a brake pedal of a vehicle brake system, comprising a cylinder, a piston disposed displaceably inside the cylinder and coupled to the pedal and delimiting a working chamber inside the cylinder, a resetting element which, upon an actuation of the pedal, exerts a resetting force on the pedal, and a modelling device, which is fluidically connected to the working chamber, for influencing the reaction behavior of the pedal. In the invention, for achieving the reaction behavior it is provided that, upon an actuation of the pedal, by means of the modelling device a vacuum, which is arising or has arisen in the working chamber, is built up.

Owner:LUCAS AUTOMOTIVE GMBH

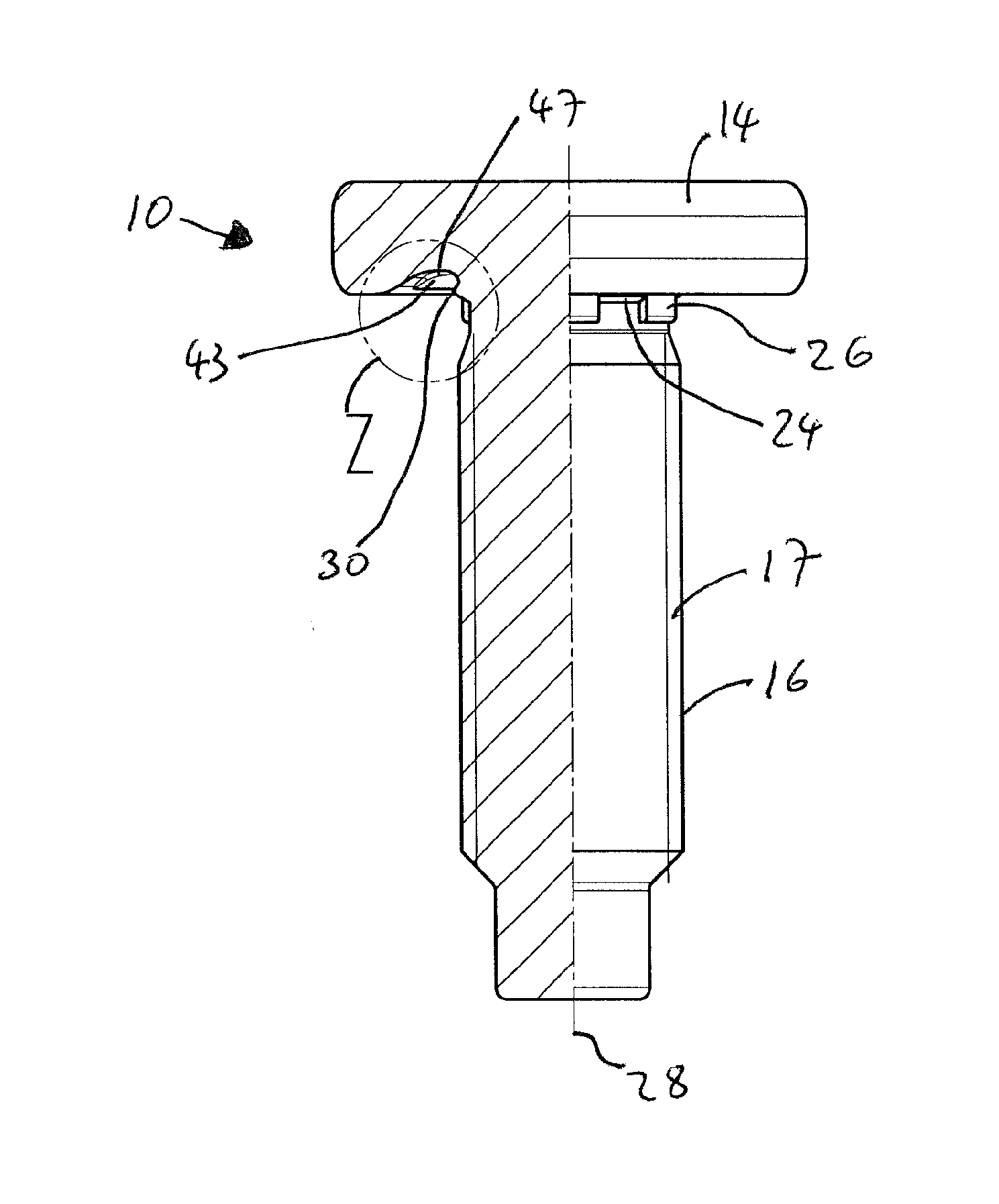

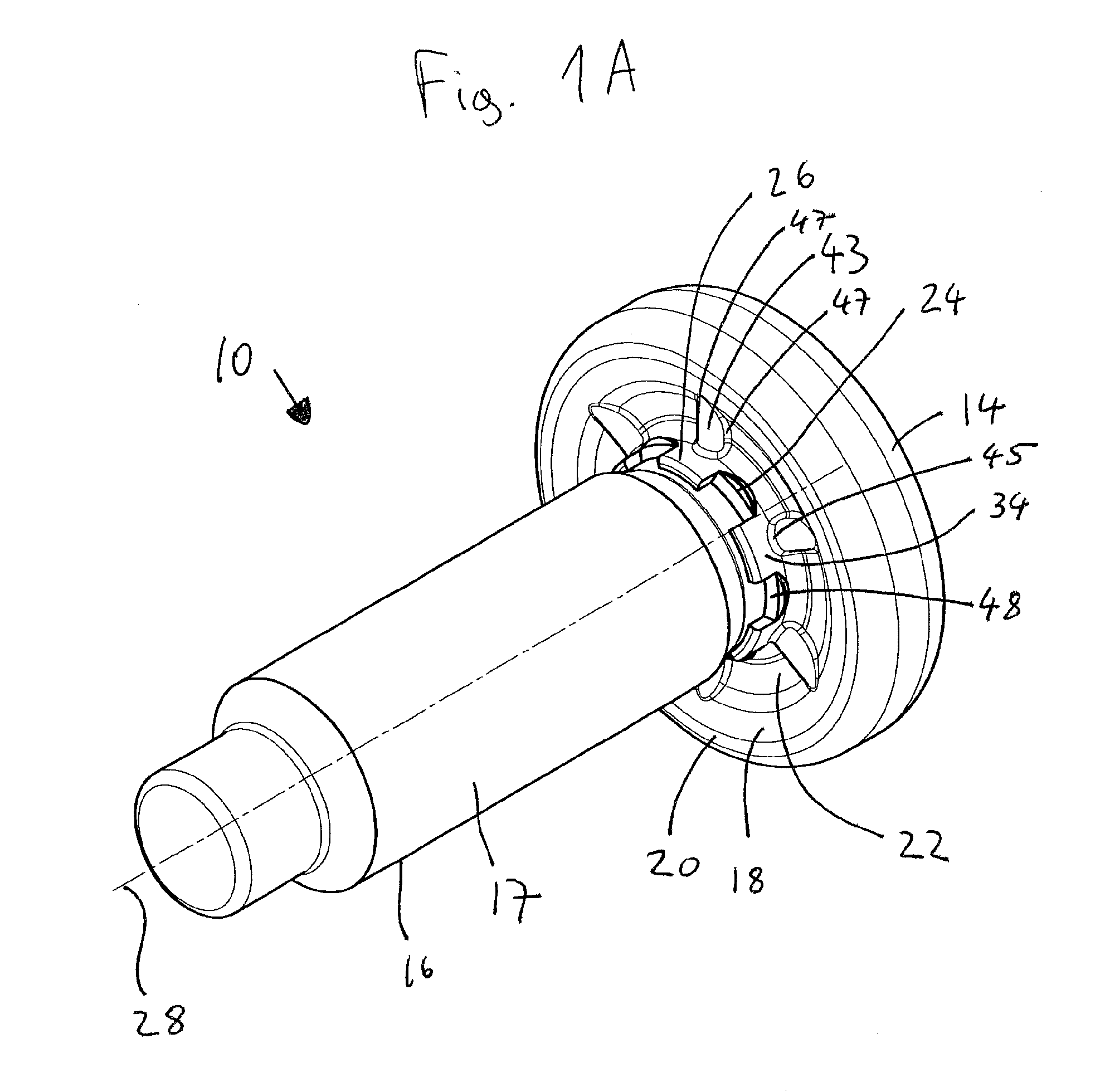

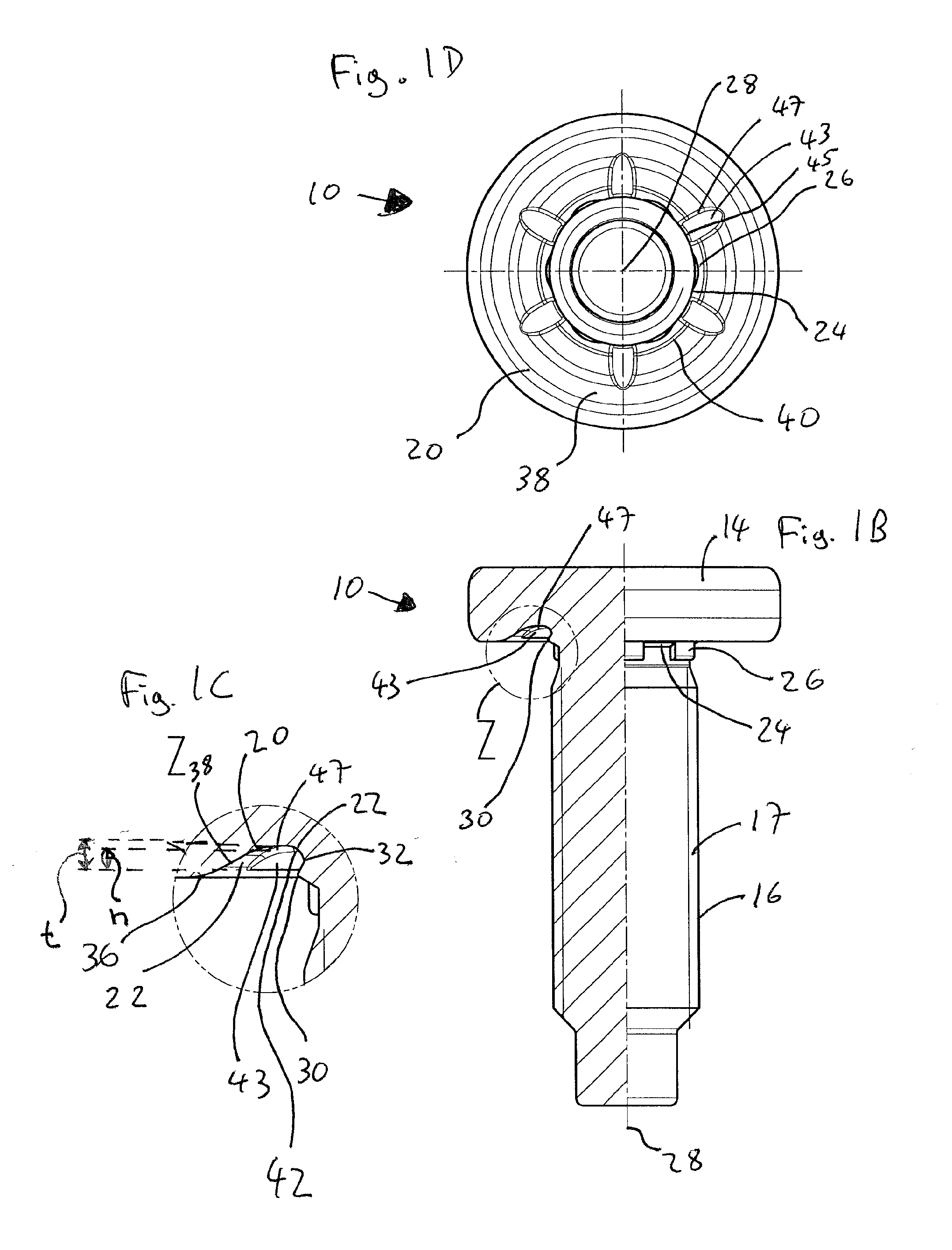

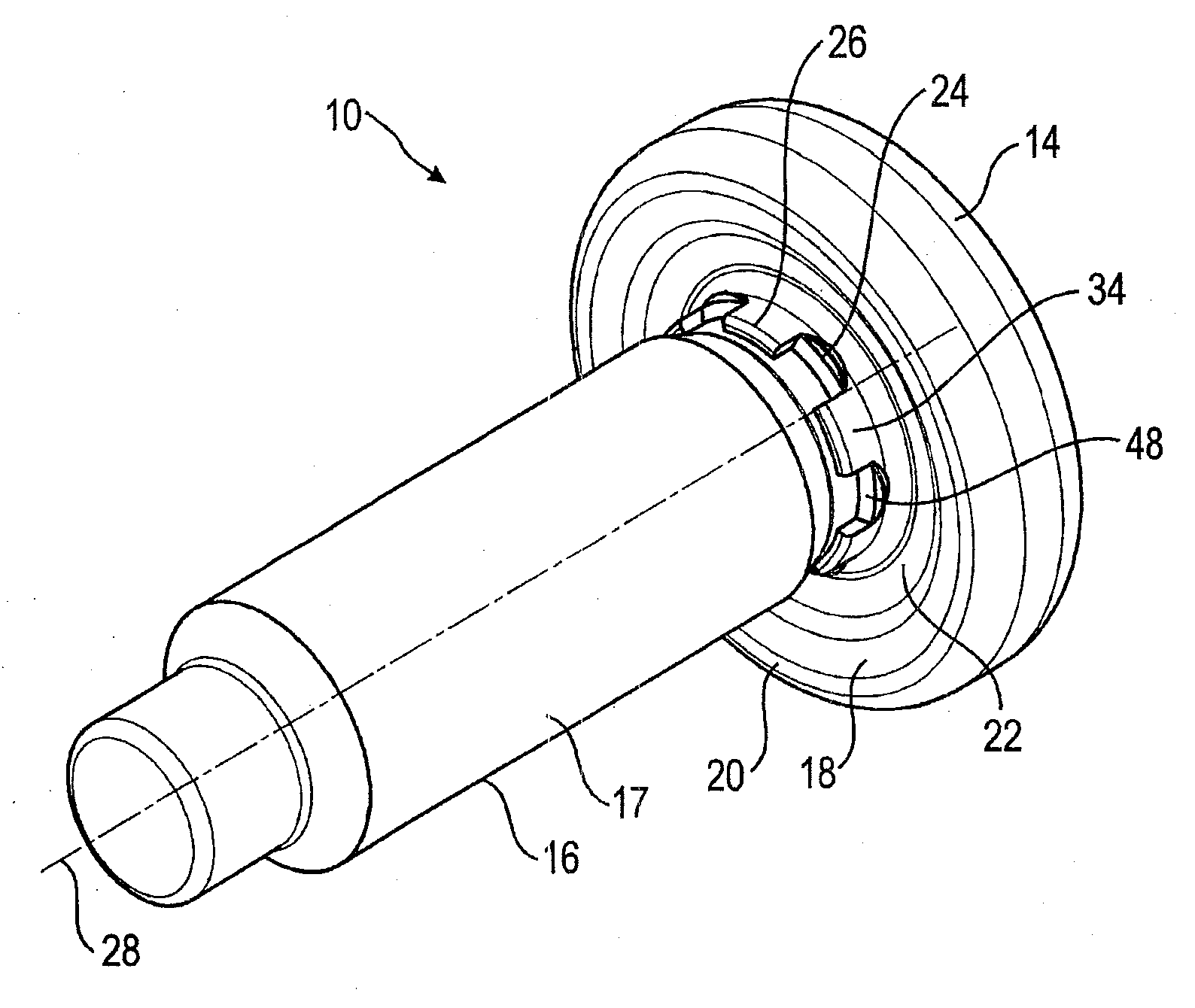

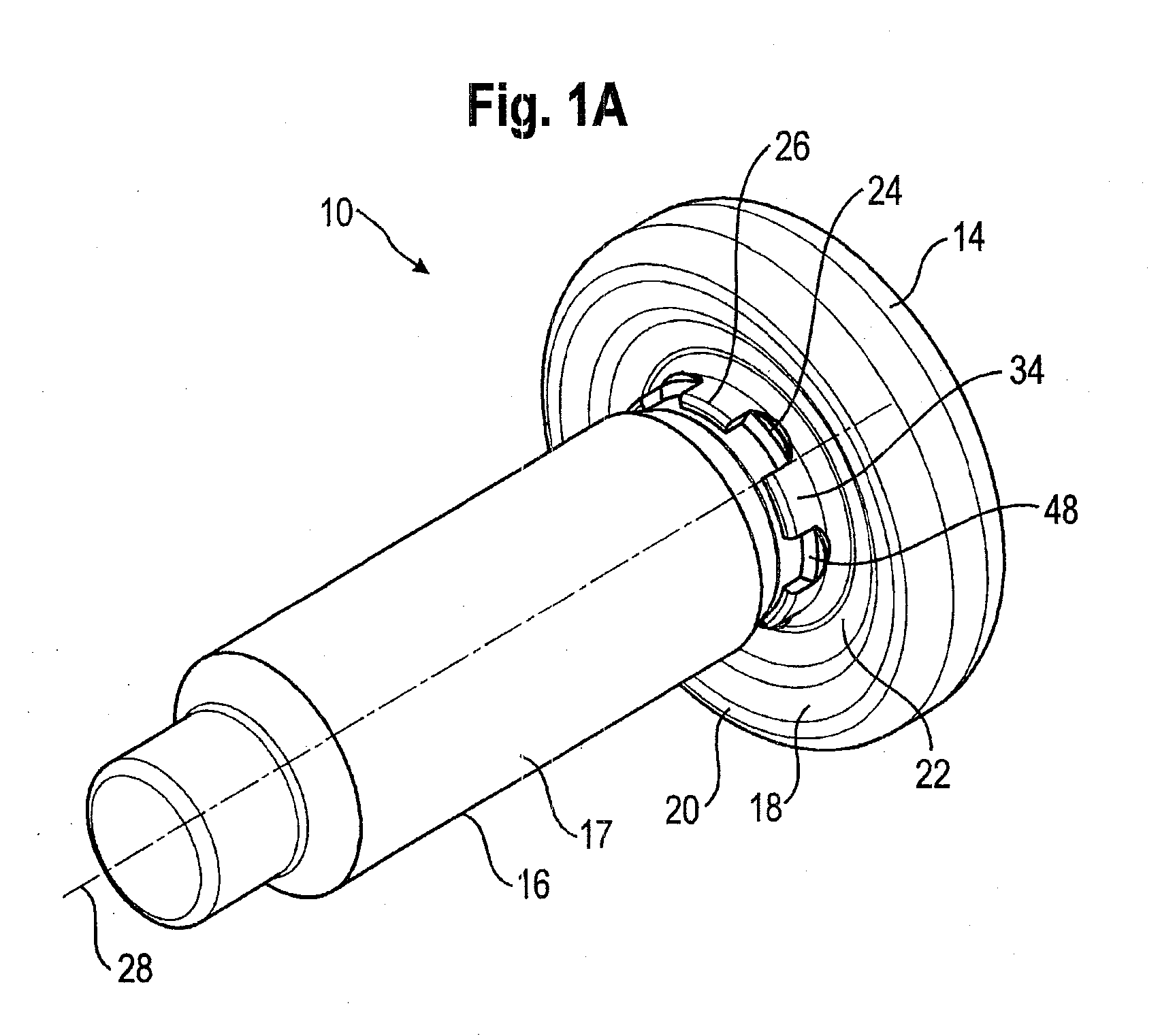

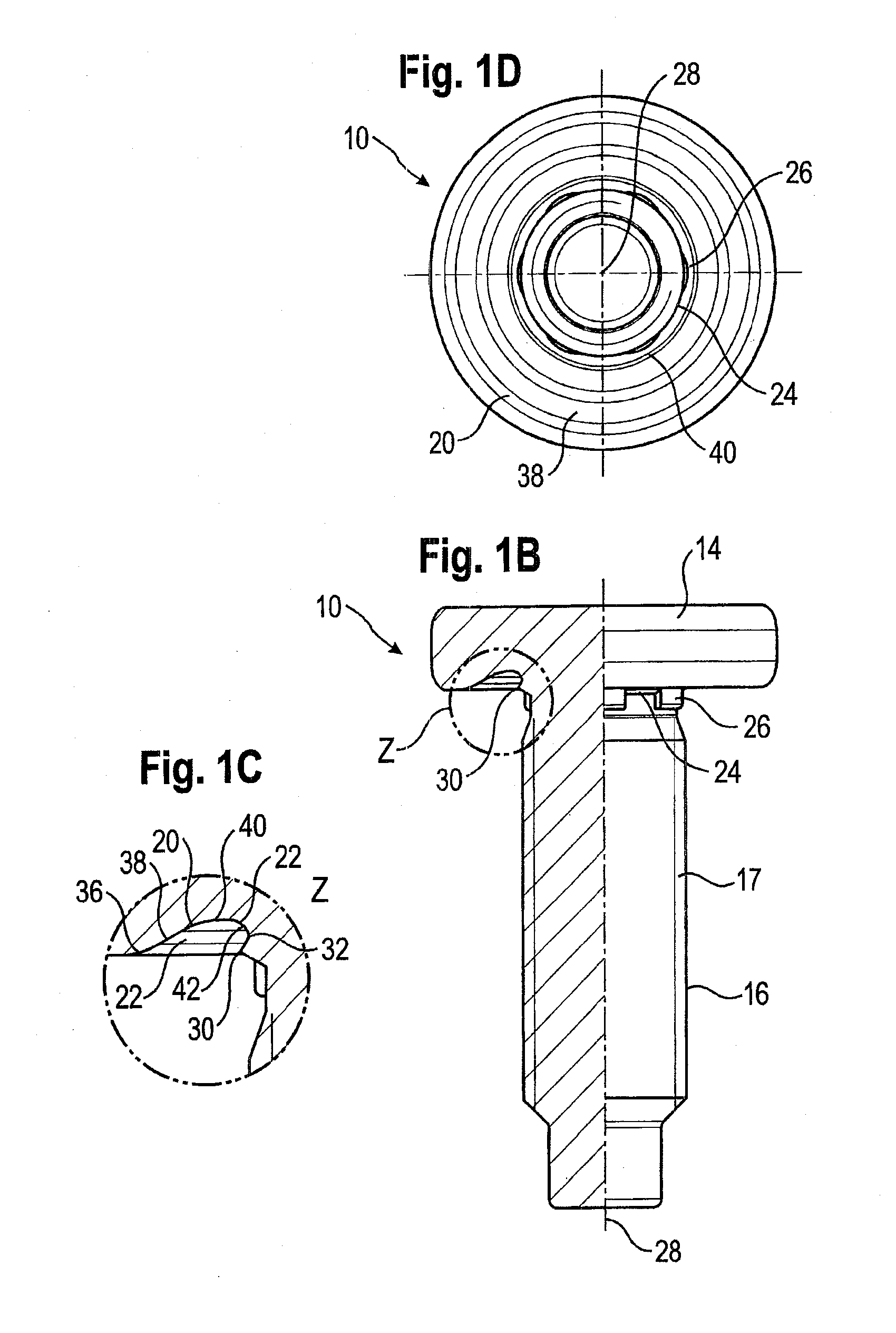

Functional element in the form of a press-in element

A functional element in the form of a press-in element for attachment to a sheet metal part is disclosed which has a head part and a shaft part, the head part has a ring-like sheet metal contact surface within which is a ring-like axial recess which surrounds the shaft part at the transition of the head part into the shaft part. The shaft part has a plurality of peripherally distributed radial recesses extending in the axial direction between which are axially extending and radially projecting noses having raised material portions which form undercuts with the head part in the region of the ring-like recess, the undercuts being present at the positions of the radial recesses at their axial ends adjacent to the head part. Radially extending ribs providing security against rotation, or other anti-rotation security features, are provided in the base region of the ring-like recess.

Owner:PROFIL VERBINDUNGSTECHN

Functional element in the form of a press-in element

The invention relates to a functional element in the form of a press-in element for attachment to a sheet metal part, wherein the functional element has a head part and a shaft part, the head part has a ring-shaped sheet metal contact surface at the side adjacent the shaft part and a ring-shaped axial recess inside this ring-shaped sheet metal contact surface and surrounding the shaft part at the transition from the head part into the shaft part. In accordance with the invention the shaft part has a plurality of circumferentially distributed radial recesses extending in the axial direction and between these noses which likewise extend axially and project radially, wherein raised material portions are present at the positions of the radial recesses at their axial ends adjacent the head part and form undercuts with the head part in the region of the ring-shaped recess.

Owner:PROFIL VERBINDUNGSTECHN

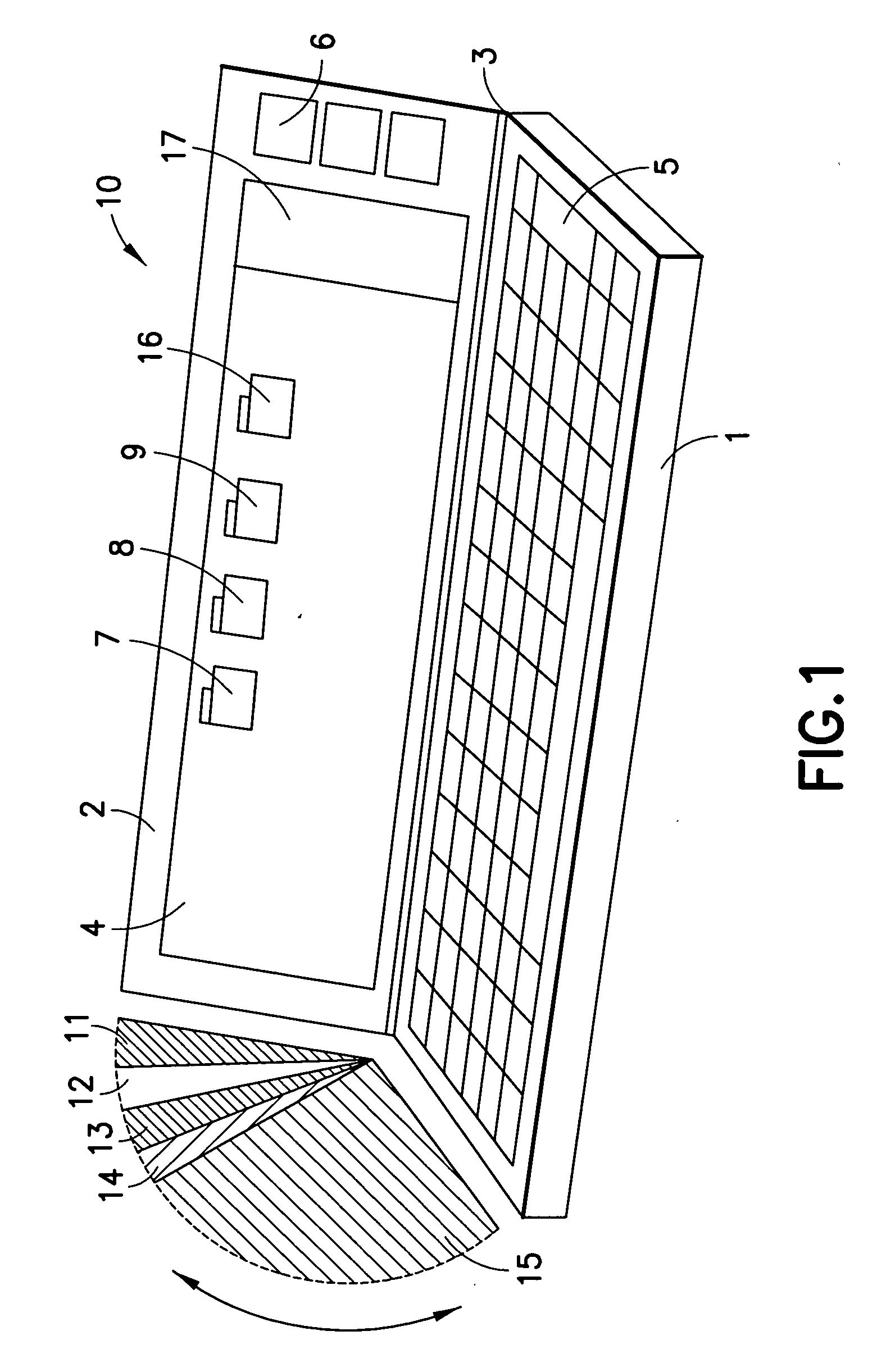

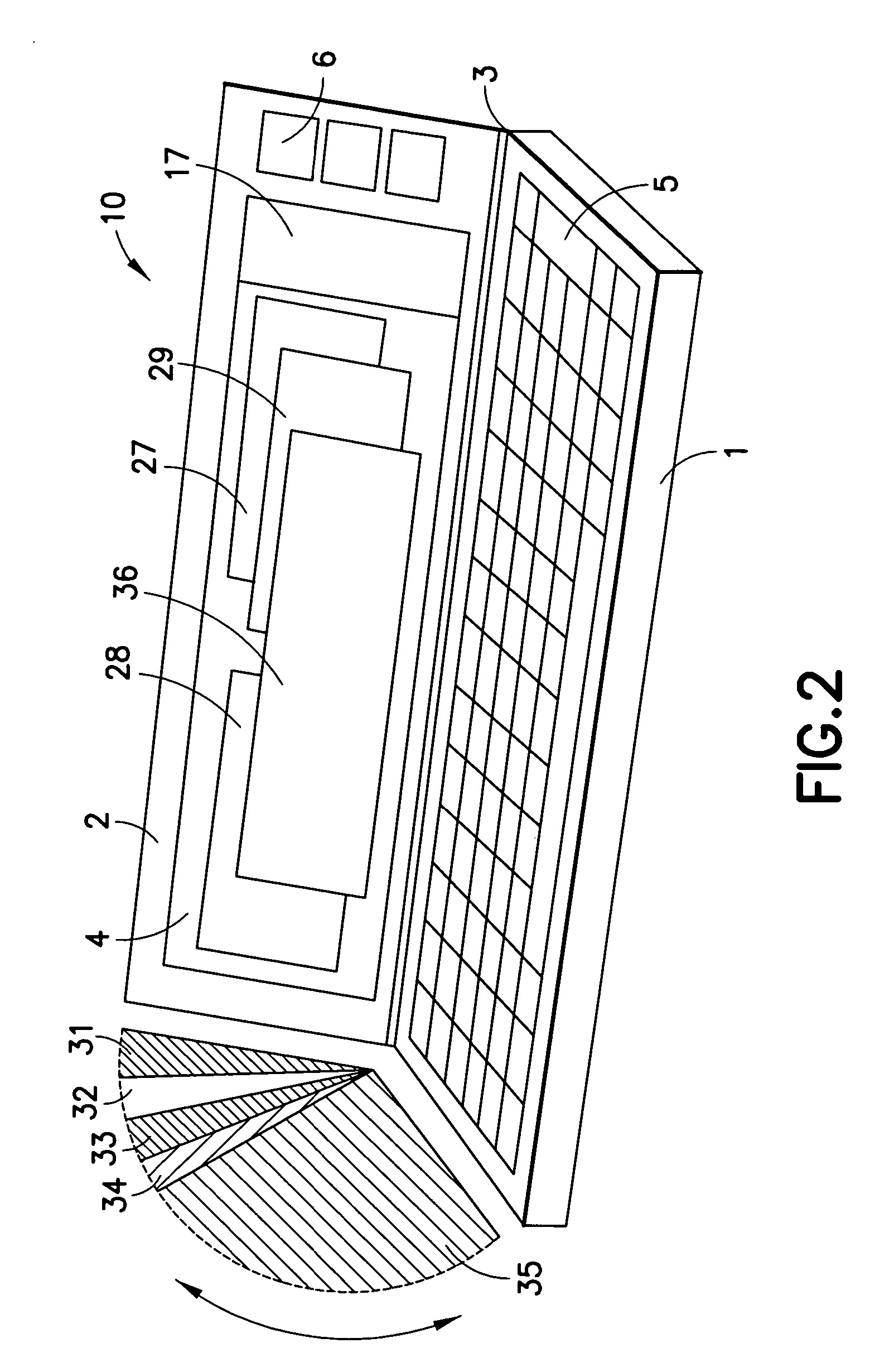

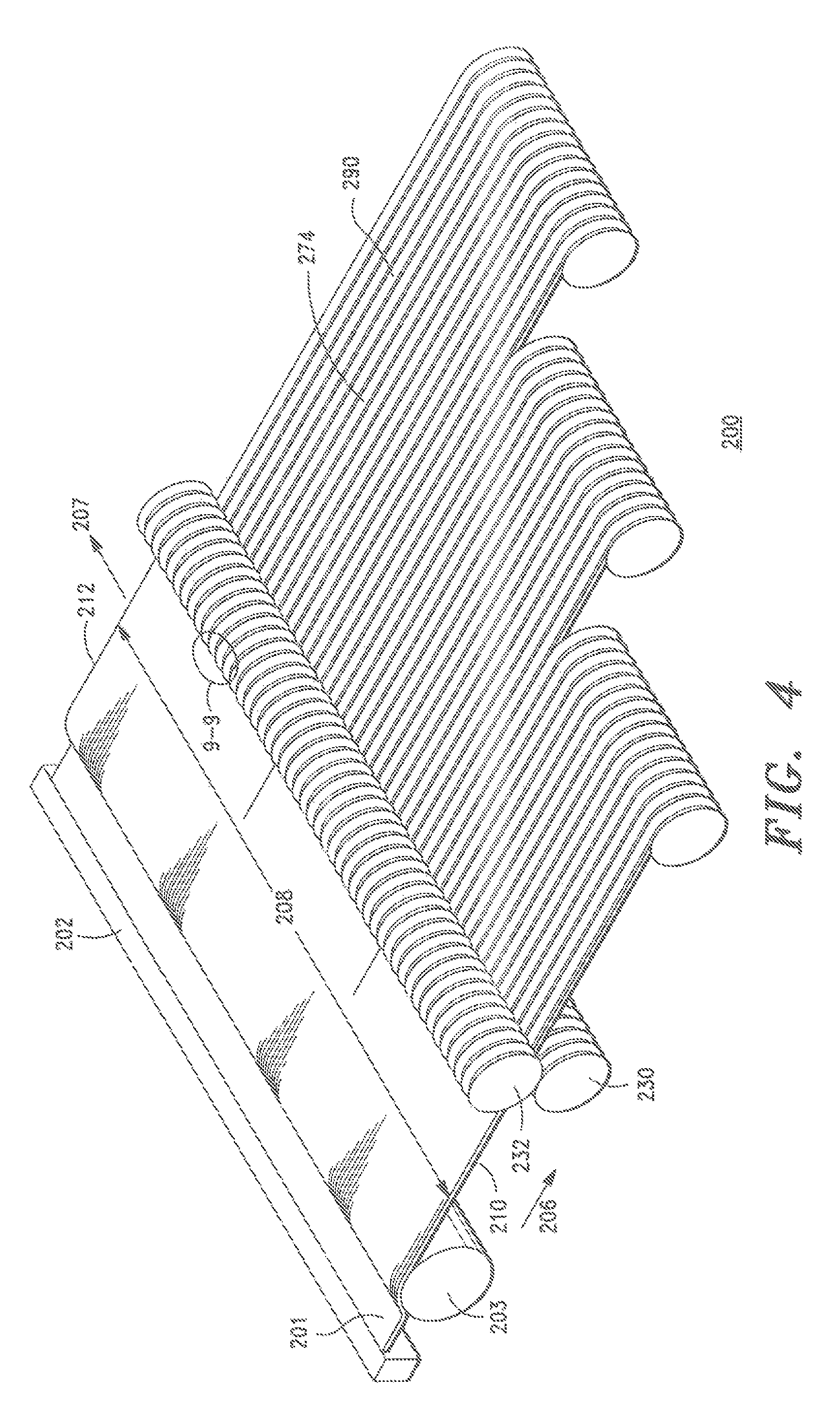

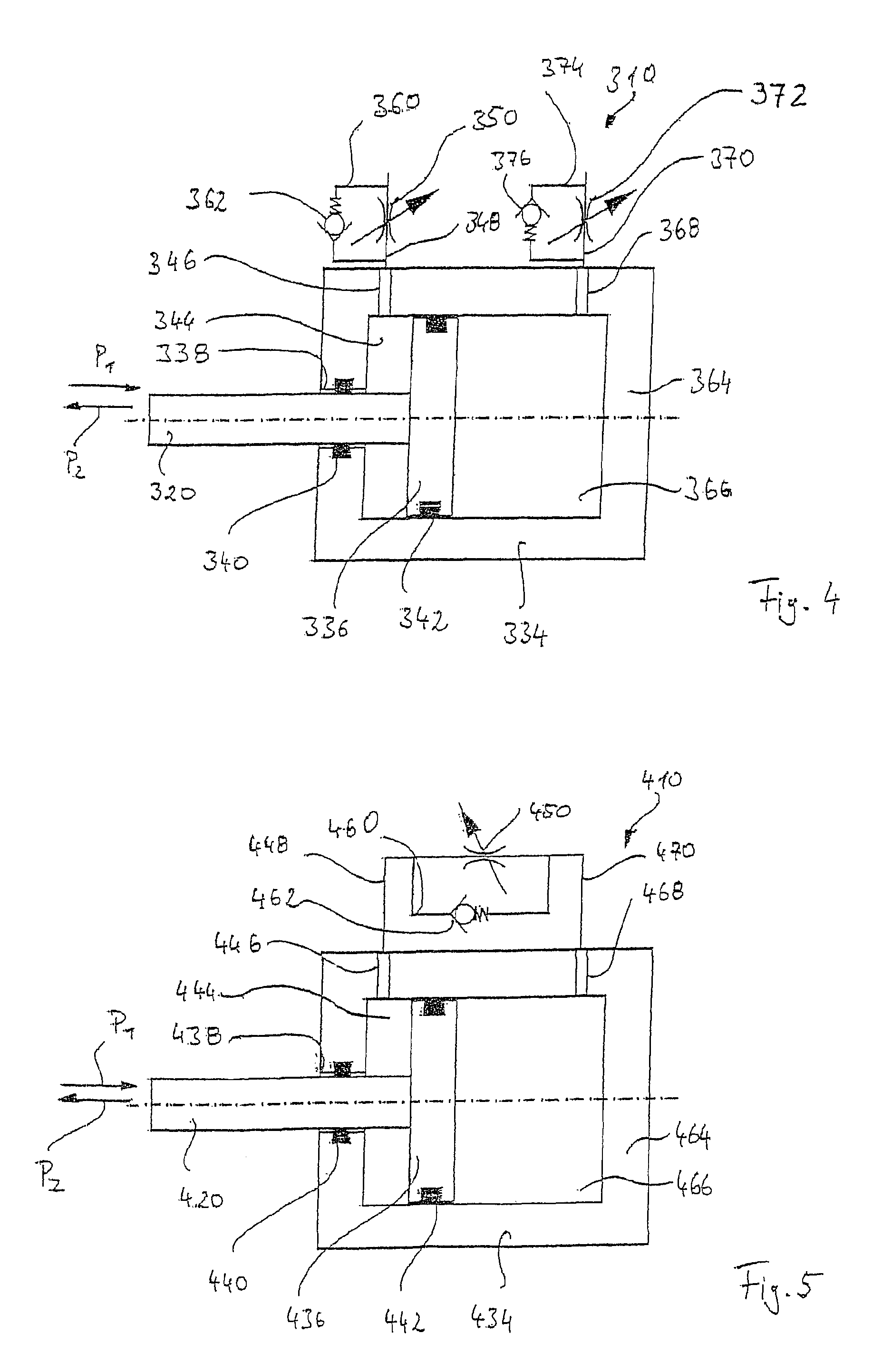

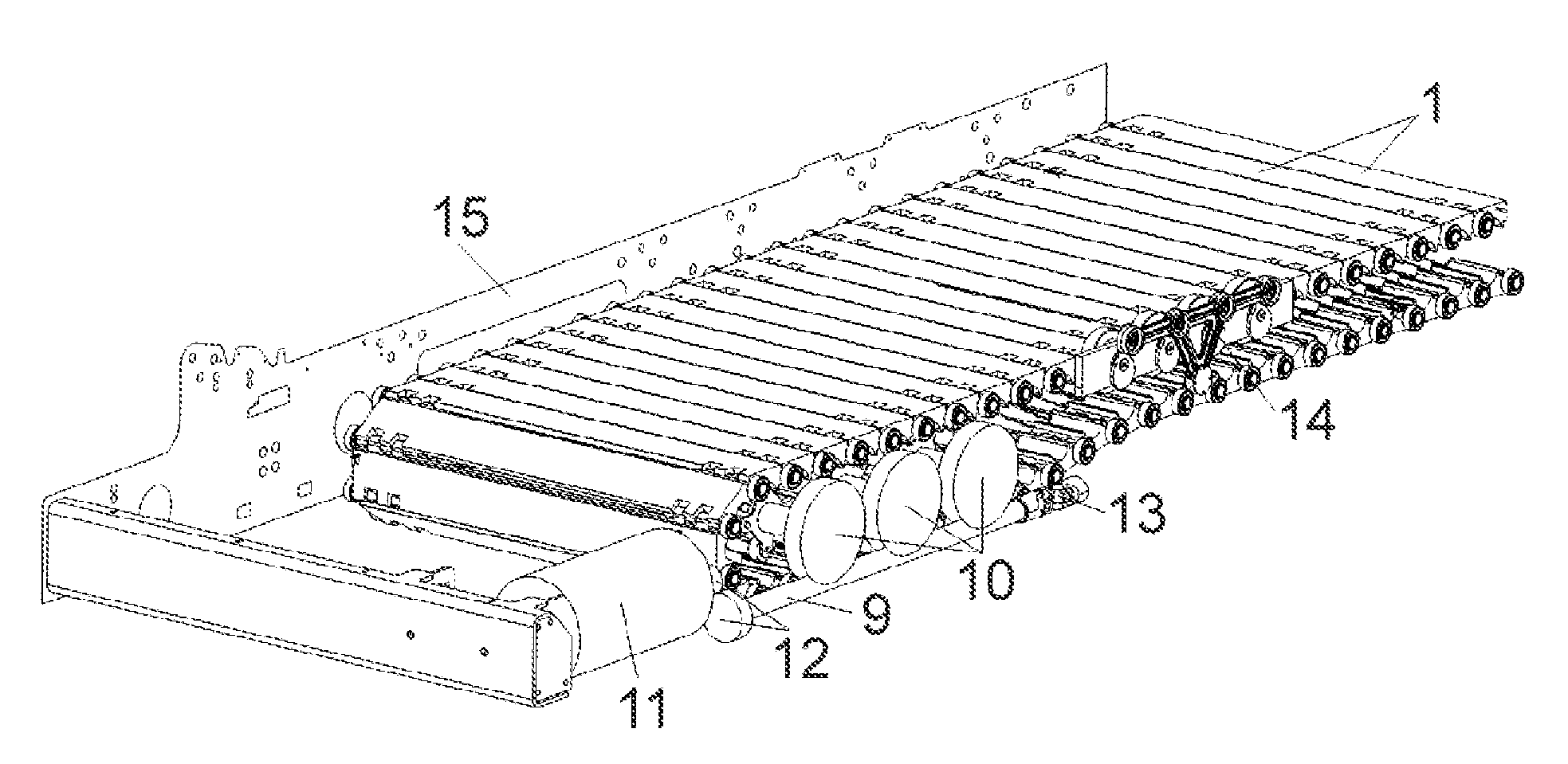

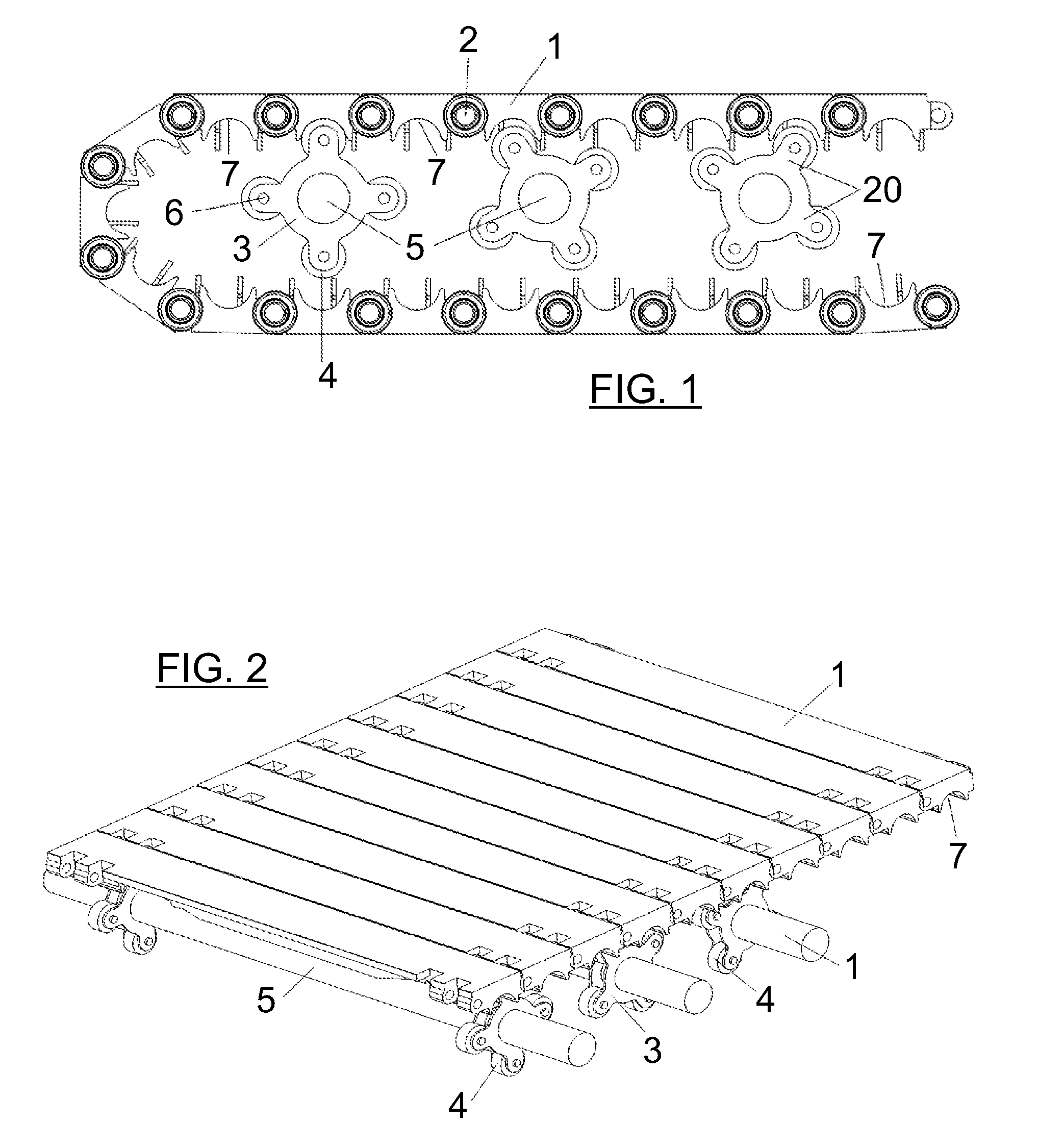

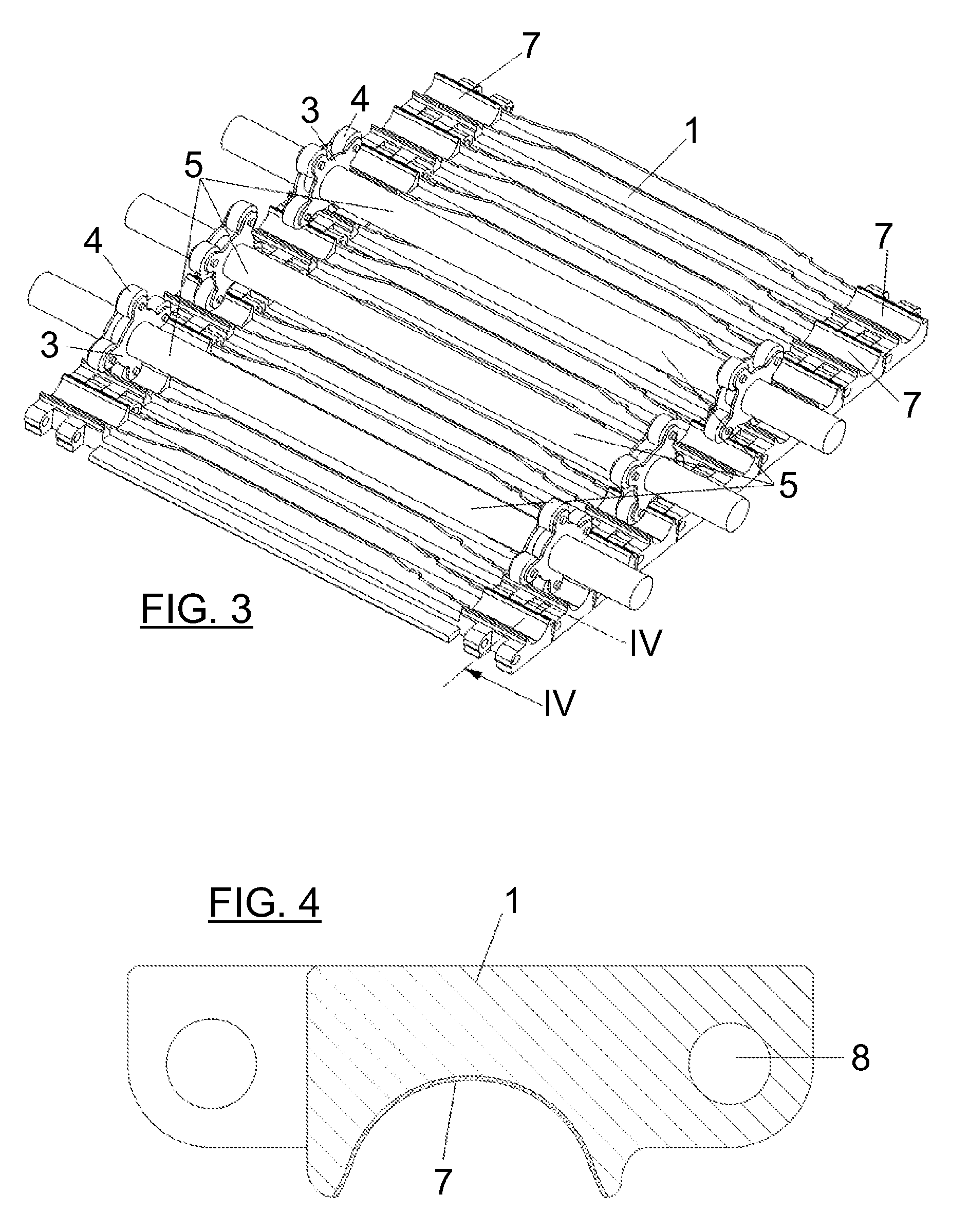

Drive system for escalators and moving walkways

Drive system for escalators and moving walkways, comprising a set of wheels (3) carrying free-rotating rollers (4), with parallel axes to that of the wheels, and one or more shafts (5) perpendicular to the movement direction of the belt of steps or pallets (1), in which said roller wheels are mounted. The shafts (5) and wheels (3) are arranged between the moving forward way and the return way of the belt of steps or pallets (1). The wheels (3) engage through the rollers (4) with the steps or pallets (1) through engaging formations (7) of said belt of steps or pallets (1). The shafts (5) connect to a driving assembly through a transmission mechanism.

Owner:THYSSENKRUPP ELEVATOR INNOVATION CENT SA +1

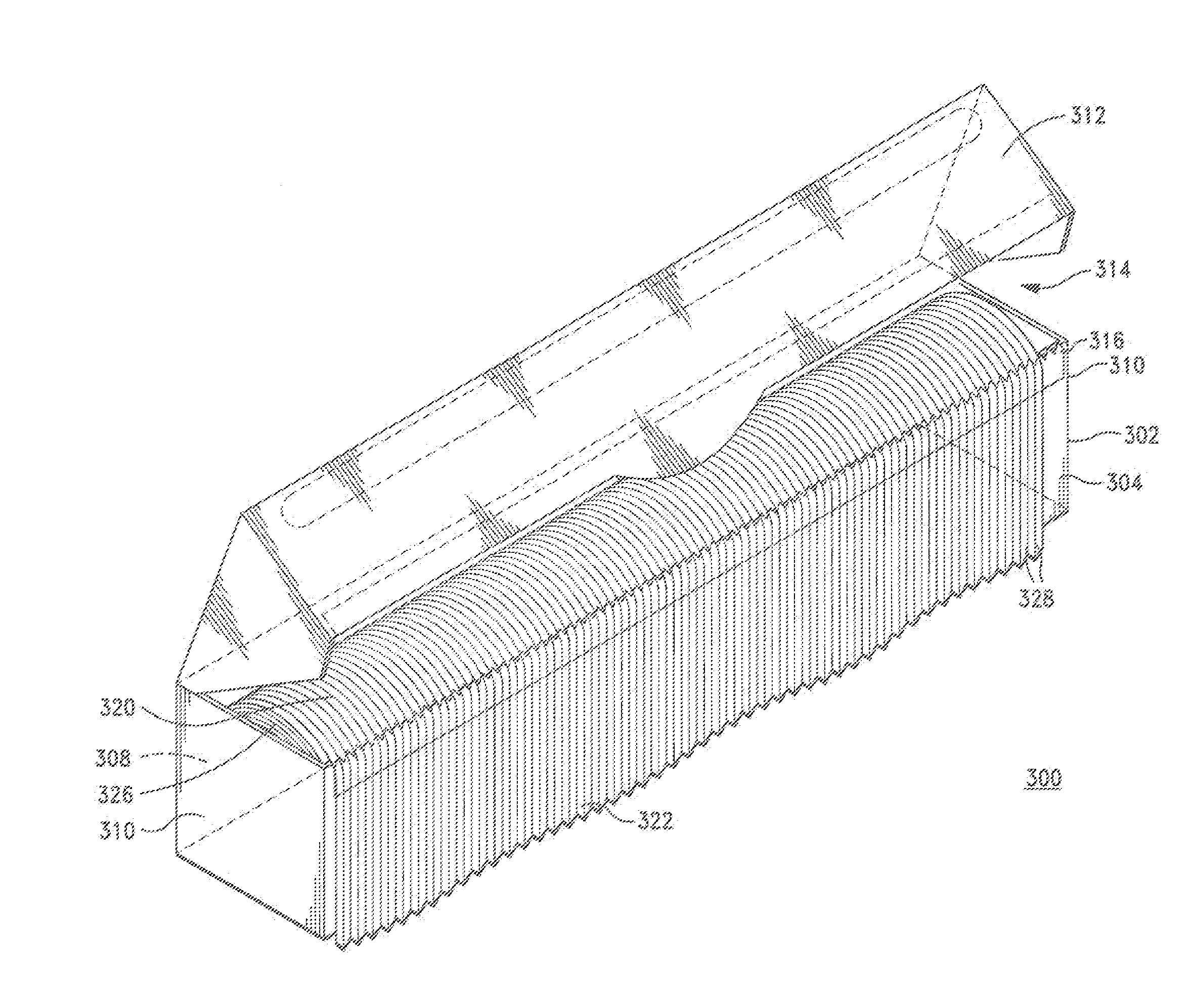

Cling wrap

ActiveUS20130140207A1Easy to processGreat loftContainers for annular articlesDispensing apparatusPlastic wrapEngineering

A thermoplastic food wrap film including a plurality of parallel ribs formed therein. To produce the film, a thermoplastic web may be directed between opposing first and second rollers having ridges. The formation of the ribs may increase the width of the web. The film may be formed into a roll and inserted into a box having a cutting strip.

Owner:THE GLAD PROD CO

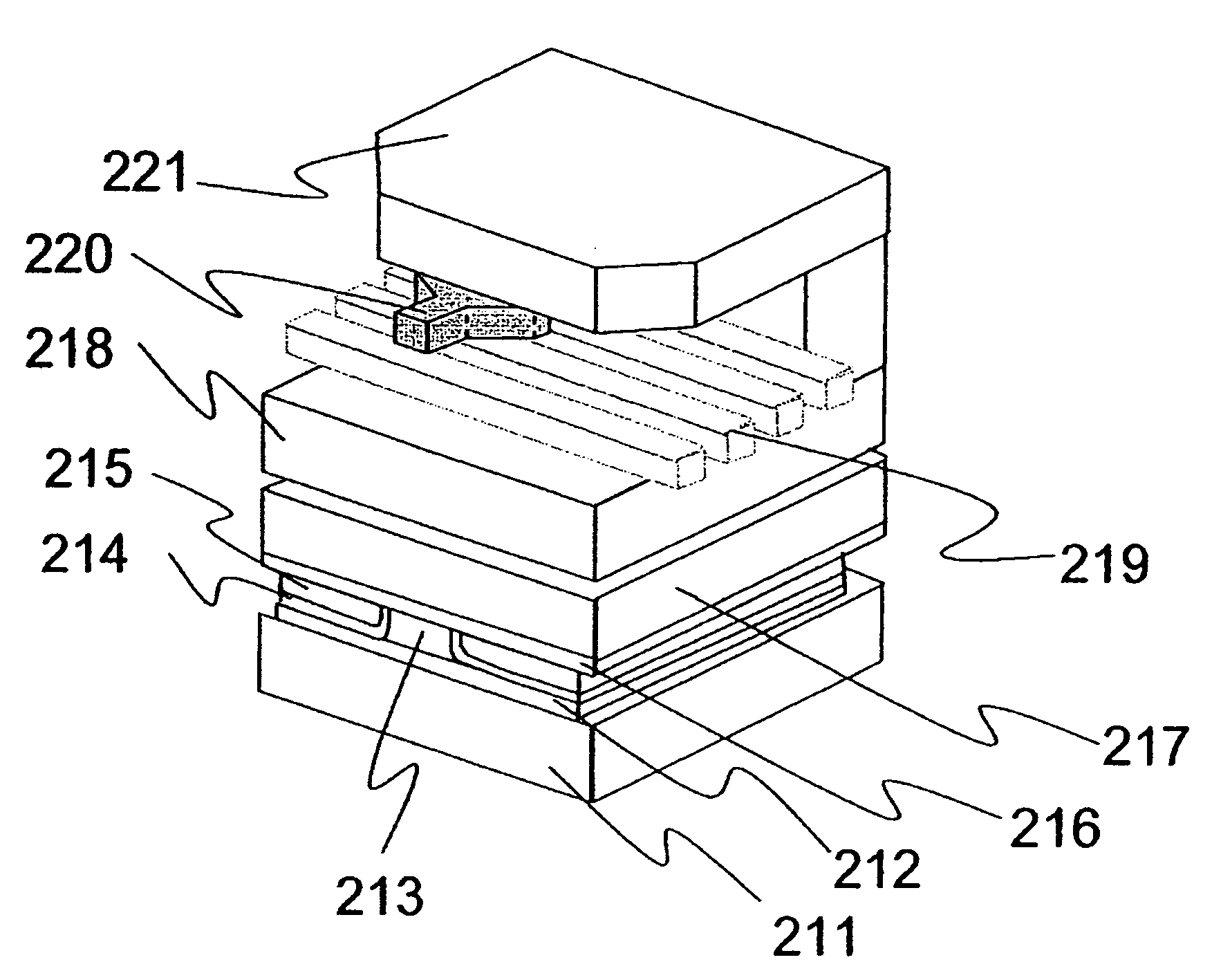

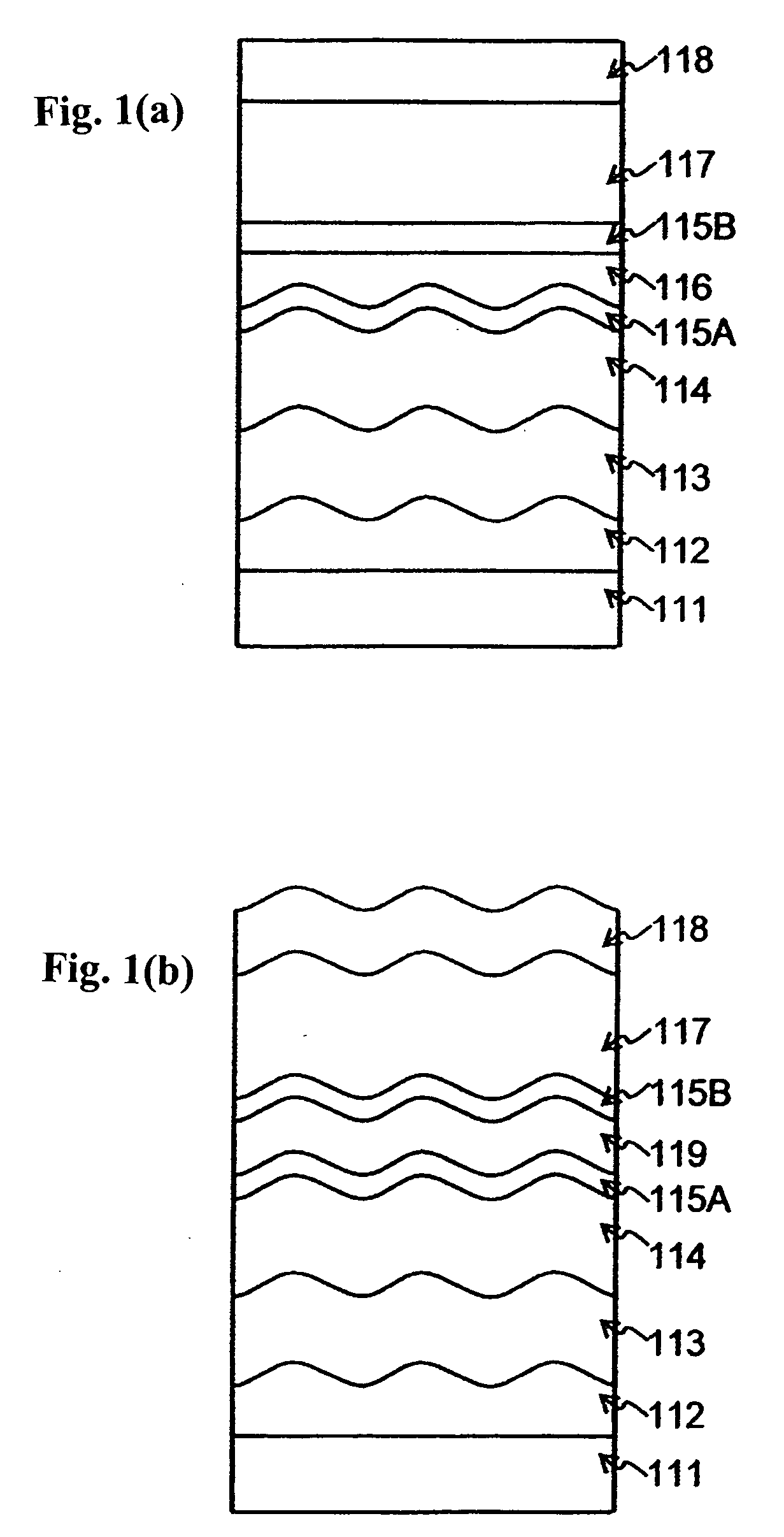

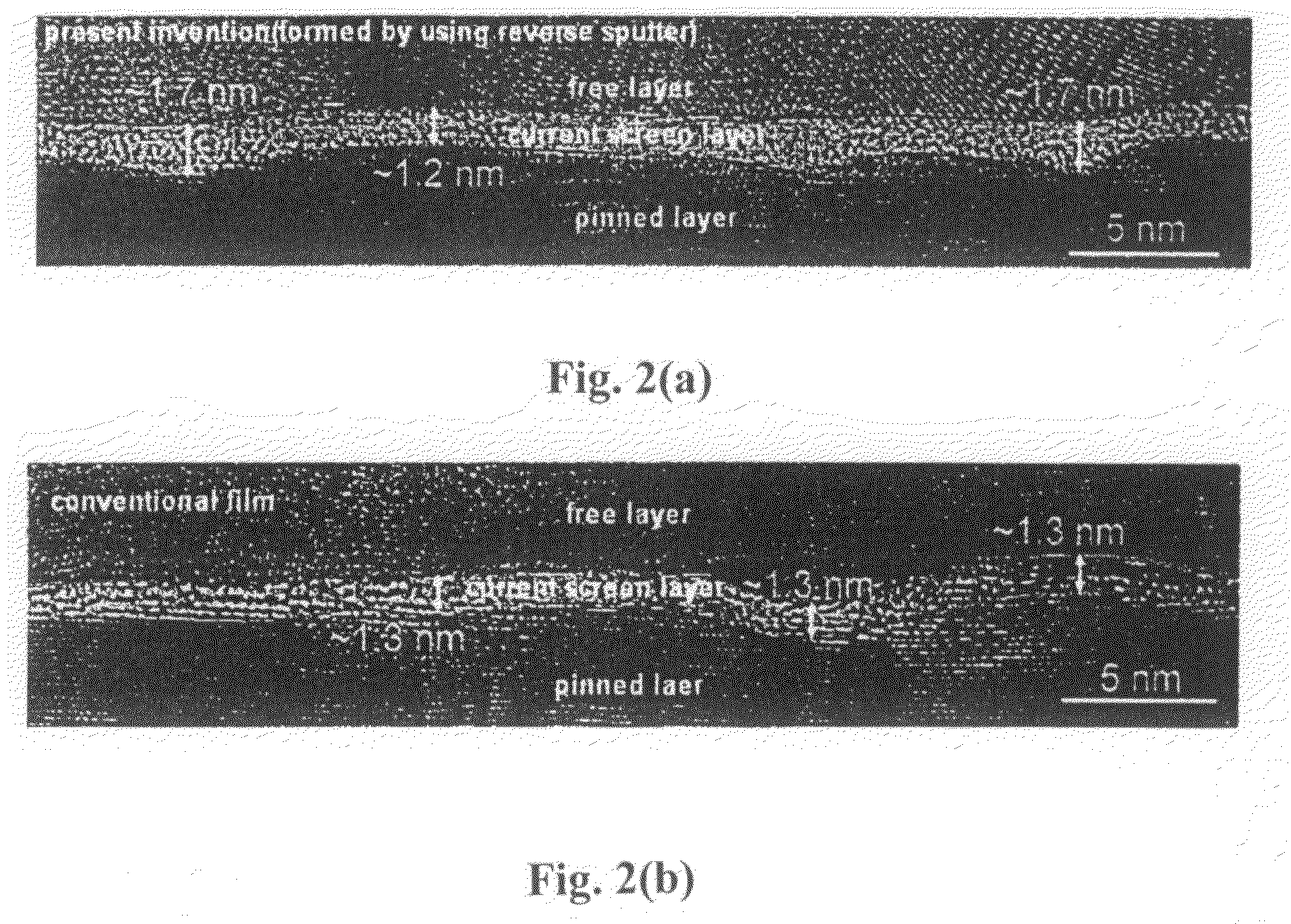

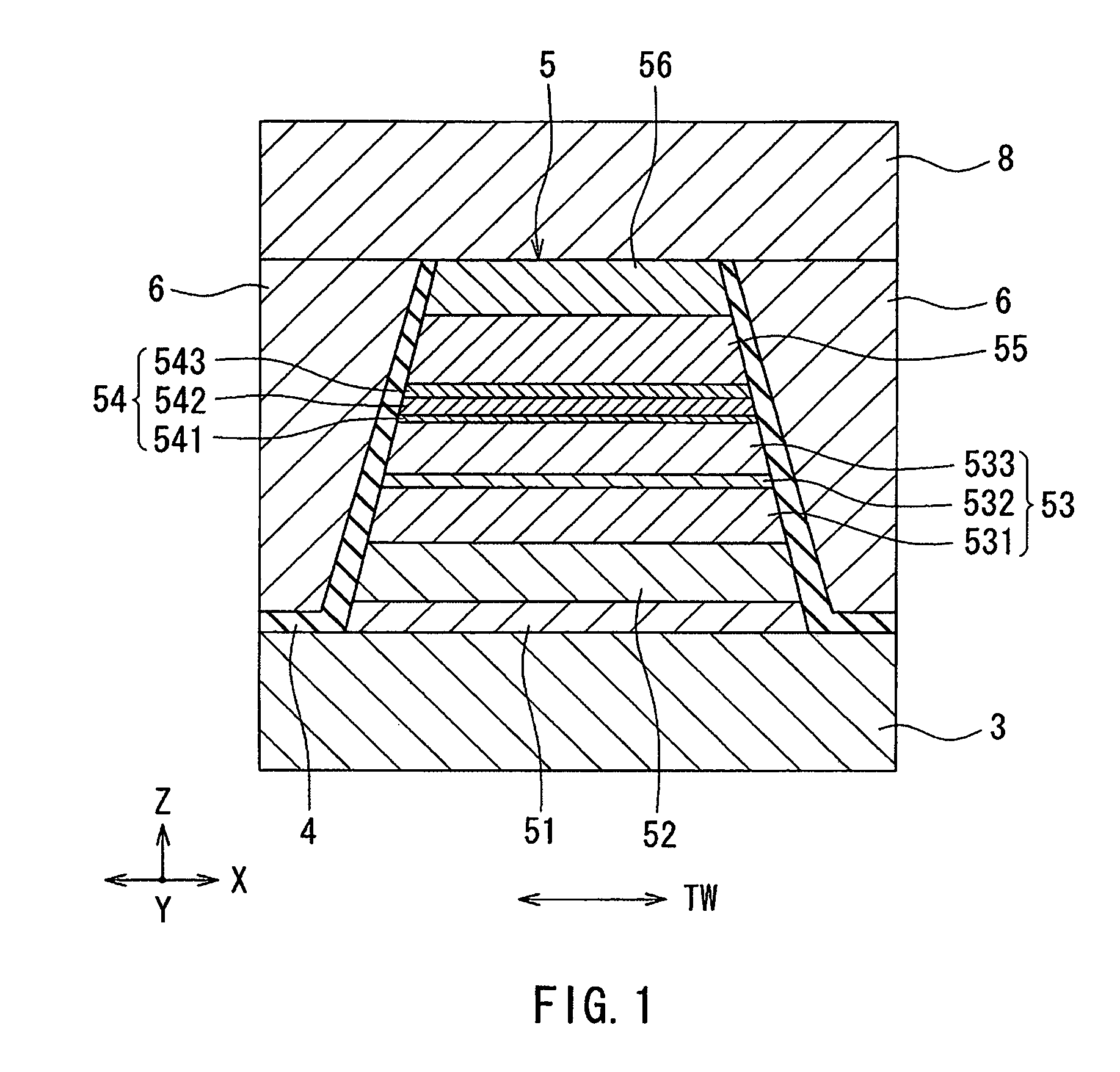

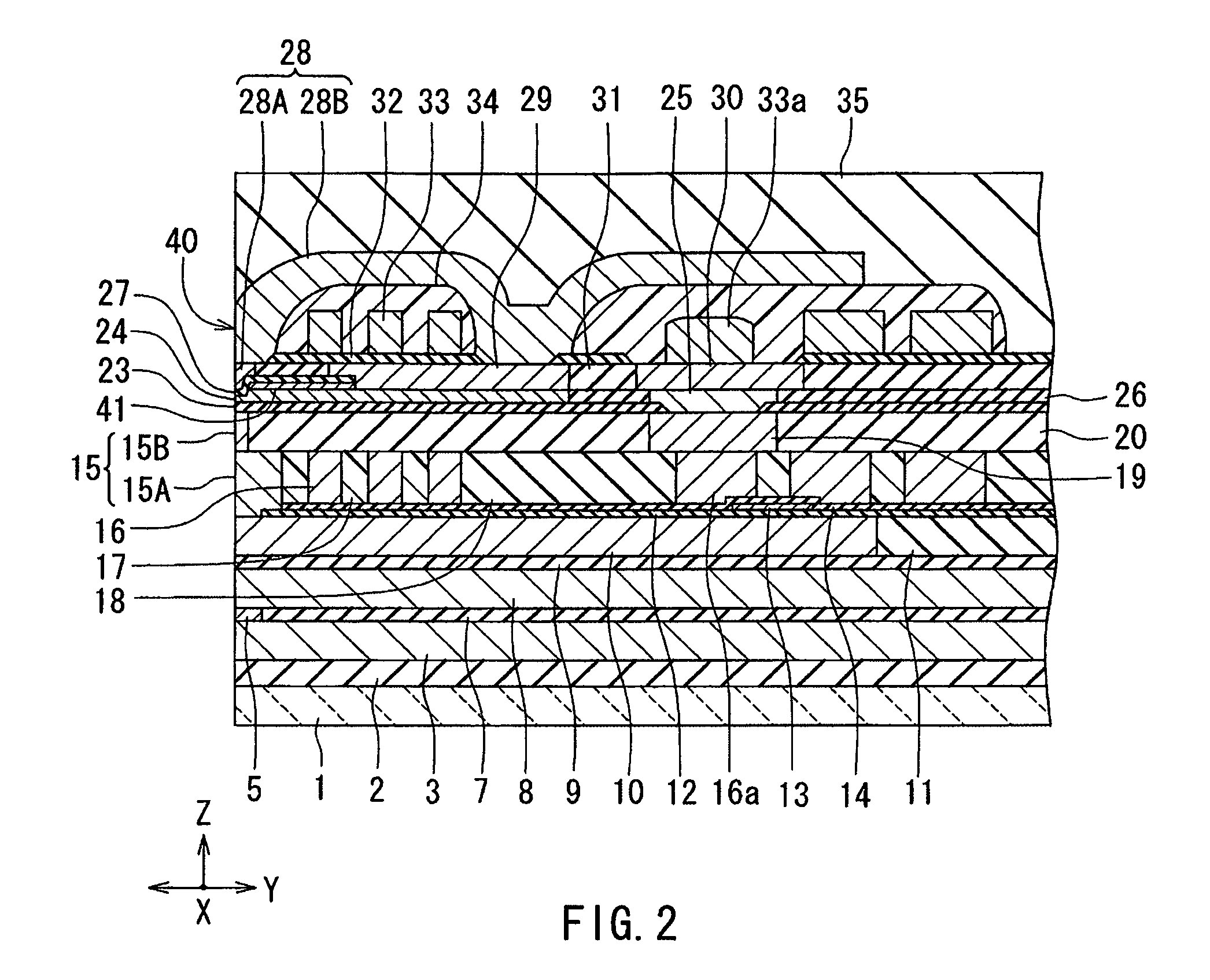

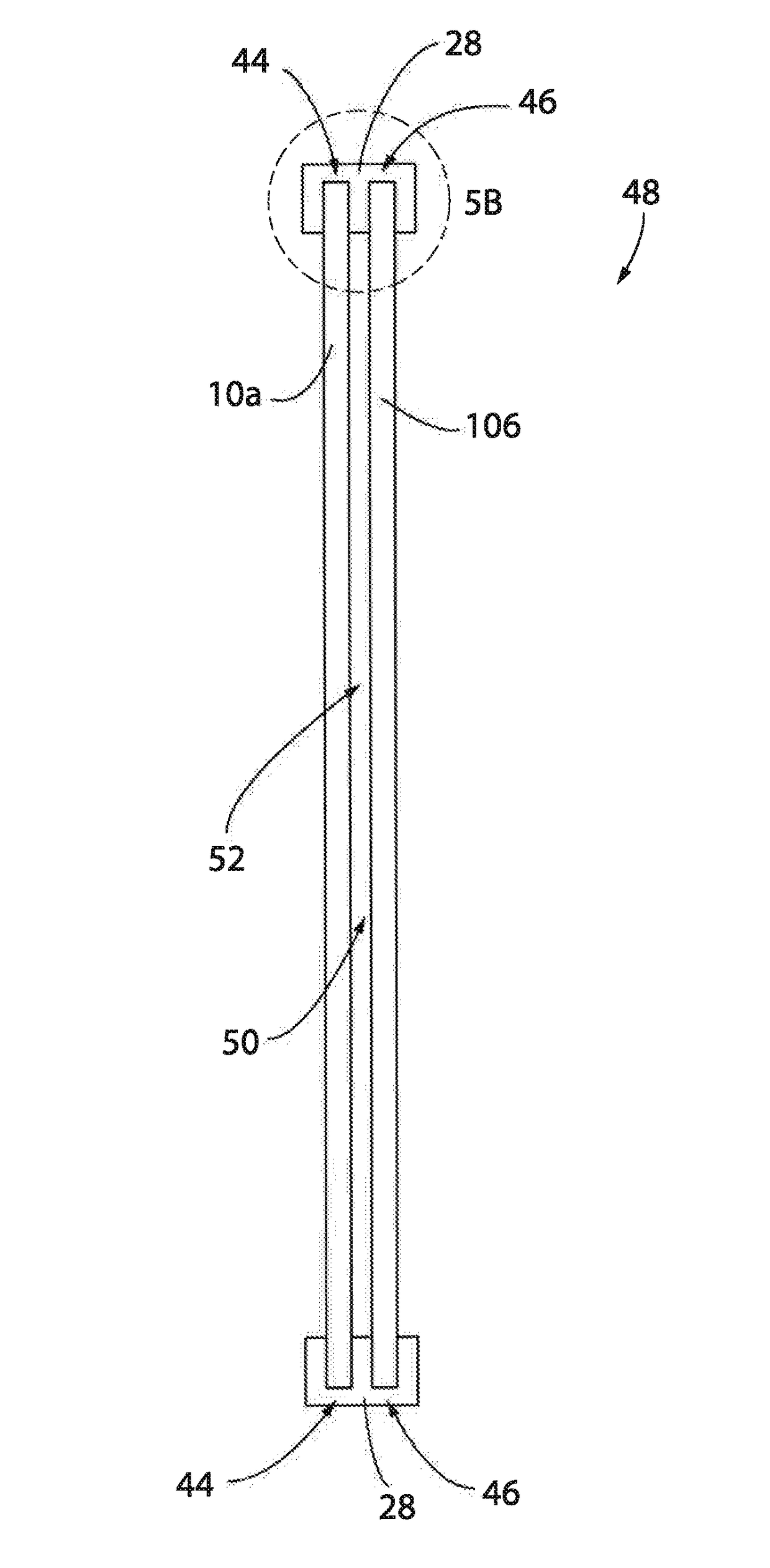

Magnetoresistive head, magnetic storage apparatus and method of manufacturing a magnetic head

InactiveUS20080144231A1Increase productionAppropriate resistanceNanomagnetismMagnetic measurementsElectrical resistance and conductanceCurrent limiting

Embodiments of the present invention provide a magnetic head incorporating a CPP-GMR device having a high output at a suitable resistance. According to one embodiment, in a Current Perpendicular to Plane-Giant Magneto Resistive (CPP-GMR) head comprising a pinned layer, a free layer, and a current screen layer for confining current therein, a planarization treatment is applied to the surface of the current screen layer, thereby allowing the current screen layer to have a fluctuation in film thickness thereof. As a result of the fluctuation being provided in the film thickness of the current screen layer, parts of the current screen layer, smaller in the film thickness, will be selectively turned into metal areas low in resistance, and as the metal areas low in resistance serve as current paths, effects of confining current can be adjusted by controlling the fluctuation in the film thickness.

Owner:WESTERN DIGITAL TECH INC

CPP-type magnetoresistive element including spacer layer

ActiveUS8379350B2Raise the ratioAppropriate resistanceNanomagnetismNanoinformaticsSemiconductorOxide semiconductor

An MR element includes a first ferromagnetic layer, a second ferromagnetic layer, and a spacer layer disposed between the first and second ferromagnetic layers. The spacer layer includes a nonmagnetic metal layer, a first oxide semiconductor layer, and a second oxide semiconductor layer that are stacked in this order. The nonmagnetic metal layer is made of Cu, and has a thickness in the range of 0.3 to 1.5 nm. The first oxide semiconductor layer is made of a Ga oxide semiconductor, and has a thickness in the range of 0.5 to 2.0 nm. The second oxide semiconductor layer is made of a Zn oxide semiconductor, and has a thickness in the range of 0.1 to 1.0 nm.

Owner:TDK CORPARATION

Projectile penetration resistance assemblies

ActiveUS20180156578A1Improve impact and penetration resistanceEasy to operateArmoured vehiclesDoors/windowsEngineeringProjectile

Unidirectional transparent projectile penetration resistant panels and bidirectional opaque projectile penetration resistant assemblies and systems and methods of forming and mounting the same relative to underlying support structures.

Owner:TRUARMOR A DIV OF CLEAR ARMOR LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com