Mass transfer enhancing high-efficiency desulfurization absorption tower

A desulfurization absorption tower, high-efficiency technology, applied in chemical instruments and methods, using liquid separation agents, combined devices, etc., can solve the problems of plate resistance, surface tension changes, low pollutant removal efficiency, and unsatisfactory desulfurization efficiency, etc. problems, to achieve the effect of improving the uniformity of liquid holding, reducing liquid leakage and smoke escape, and improving the uniformity of gas-liquid distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

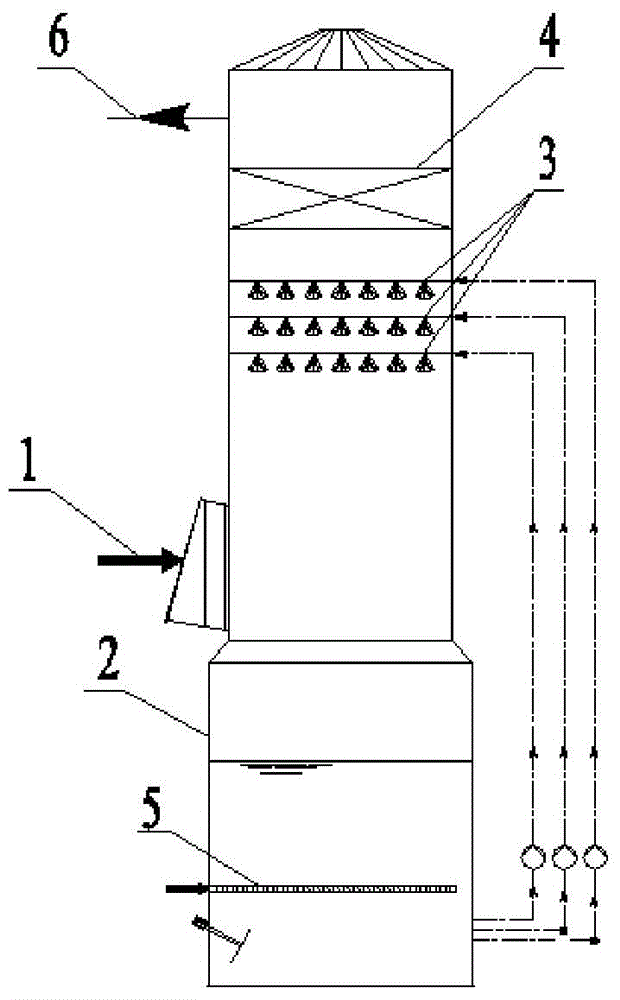

[0040] Such as figure 2 As shown, the enhanced mass transfer and high-efficiency desulfurization absorption tower of the present invention includes a tower body 2, the tower body adopts an empty tower type spray tower structure, a flue gas inlet 1 and a flue gas outlet 6 are arranged on the tower body, and a spray layer 3 is arranged in the tower body , the demister 4 and the aeration pipe 5 arranged at the bottom of the tower body, the spray layer 3 of the desulfurization absorption tower includes 3 spray layers, the flue gas inlet 1 is arranged below the spray layer 3, and the flue gas outlet 6 is located at the desulfurization The top of the absorption tower; the demister 4 is installed between the upper spray layer 3 and the flue gas outlet 6 of the desulfurization absorption tower; a gas-liquid redistribution strengthening ring 7 and a Layer sieve plate 8. The sieve plate is located under the bottom spray layer, and the gas-liquid redistribution reinforcing ring is loca...

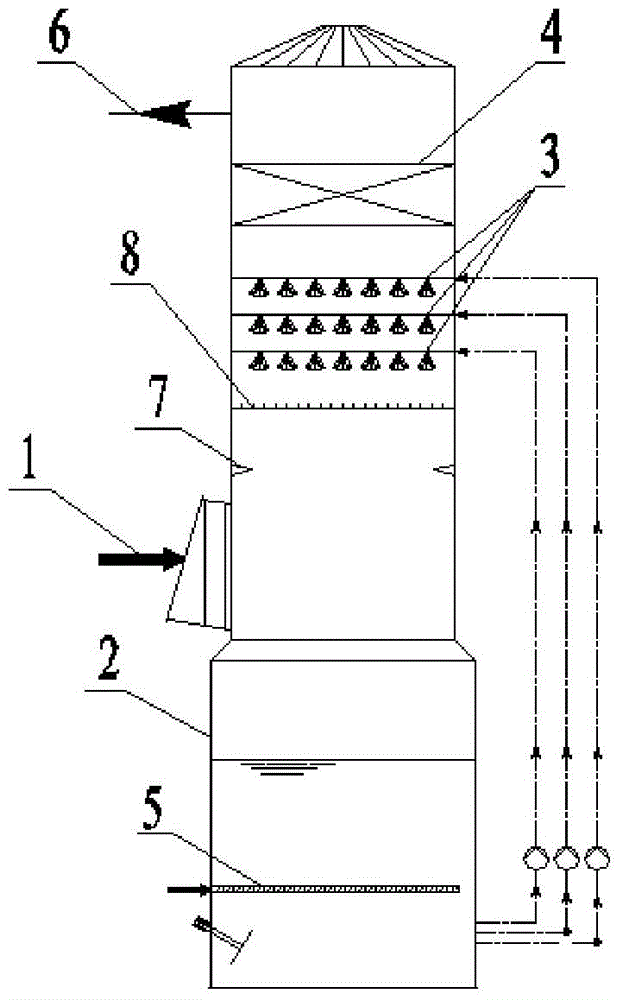

Embodiment 2

[0045] Such as image 3 The structure of the enhanced mass transfer and high-efficiency desulfurization absorption tower shown is the same as that of Example 1, except that two layers of sieve plates 8 are installed between the flue gas inlet 1 and the spray layer 3 . The upper end surface of the gas-liquid redistribution reinforcing ring forms an included angle of 15° with the horizontal direction ( Figure 11 α1 in the center), the lower end surface forms an angle of 20° with the horizontal direction ( Figure 11 in α2).

[0046] At this time, when the original flue gas SO 2 Concentration not exceeding 6000mg / Nm 3 , using a 3-layer spraying enhanced mass transfer and high-efficiency desulfurization absorption tower, which can realize SO 2 The emission concentration is lower than 35mg / Nm 3 .

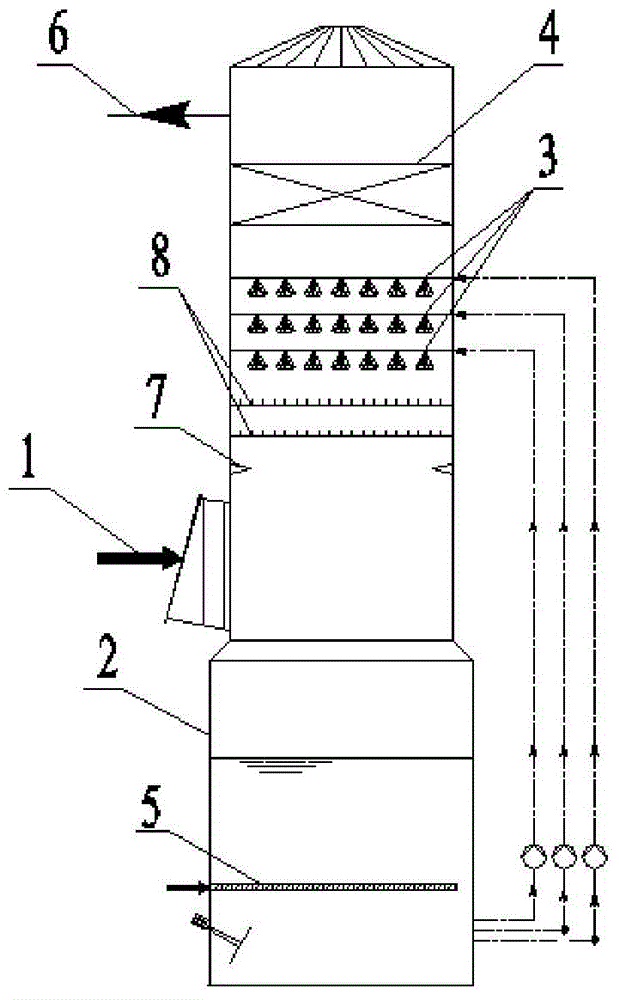

Embodiment 3

[0048] Such as Figure 4 The structure of the enhanced mass transfer and high-efficiency desulfurization absorption tower shown is the same as that of Example 1, except that a layer of sieve plate 8 is installed between the flue gas inlet 1 and the spray layer 3, and the bottom spray layer and the middle spray layer A layer of sieve plate is installed between the layers. The upper end surface of the gas-liquid redistribution reinforcing ring forms an included angle of 5° with the horizontal direction, and the lower end surface forms an included angle of 15° with the horizontal direction.

[0049] At this time, when the original flue gas SO 2 Concentration not exceeding 6000mg / Nm 3 , using a 3-layer spraying enhanced mass transfer and high-efficiency desulfurization absorption tower, which can realize SO 2 The emission concentration is lower than 35mg / Nm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Maximum thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com