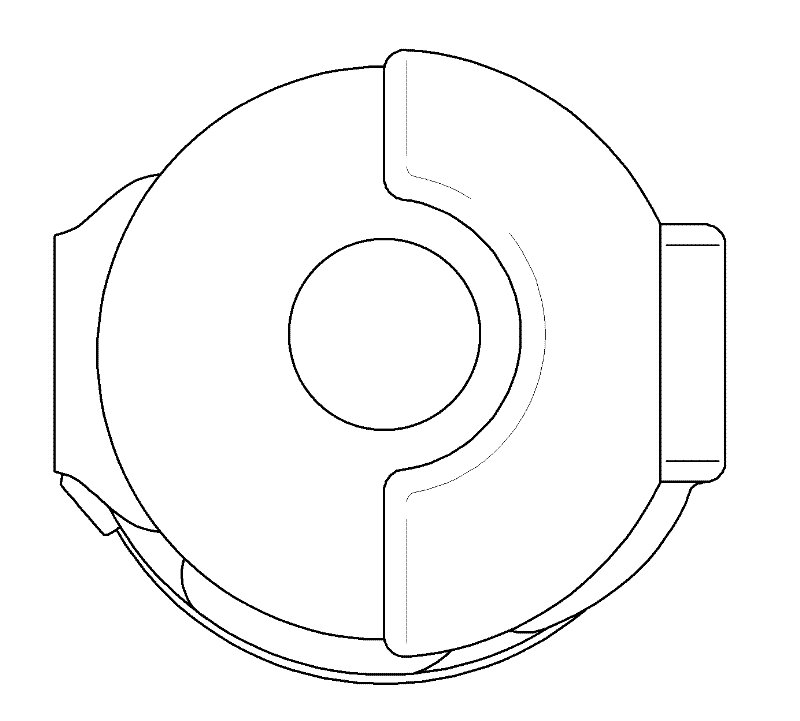

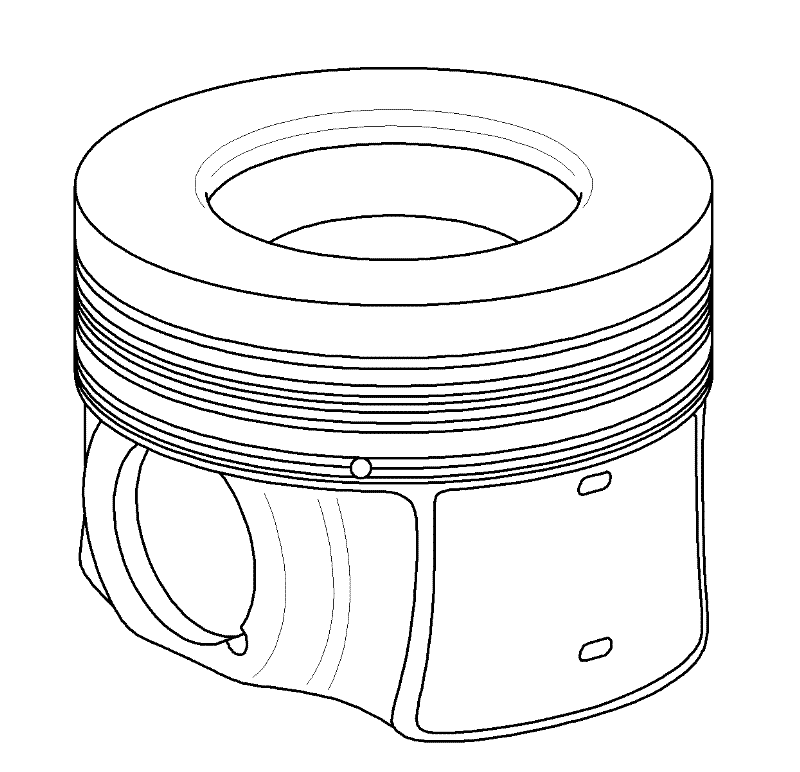

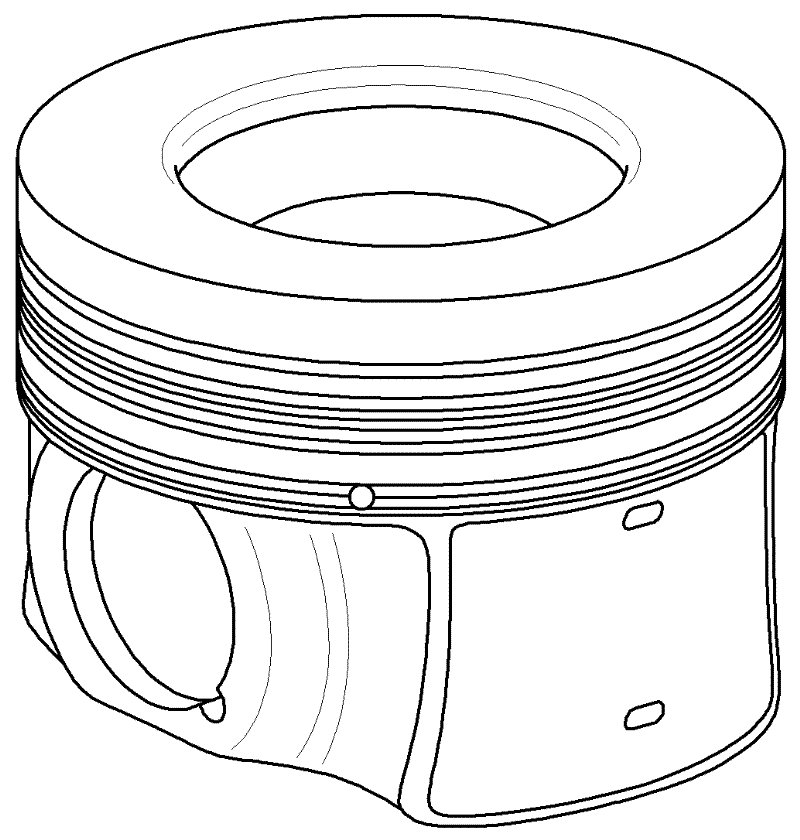

Sand casting a diesel piston with an as-cast, reentrant combustion bowl

A bowl, diesel engine technology, applied in pistons, casting equipment, molds, etc., can solve problems such as increasing the cost of pistons

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The ablation casting method can be used to produce a piston with a dome comprising an as-cast reentrant bowl and optionally internal cooling channels. Ablation casting uses inorganic (ie, water-soluble) cores, and water is sprayed onto the mold, which is slowly washed away (hence the term "ablation"), rapidly cooling the casting. Rapid cooling produces improved mechanical properties. Ablation casting allows the production of complex parts with fine solidified microstructures. The application of water allows controlling the solidification and cooling of the part independently of each other (for example, by applying water to specific areas of the casting before other areas or by applying different amounts of water to different areas). Ablation casting allows the formation of complex parts such as those that combine There are parts with thin and thick sections, and parts with complex inner cores. The overall cross-sectional properties are superior to those of parts fabr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com