Method for producing a plastic-metal hybrid component

一种混合构件、塑料金属的技术,应用在制造工具、金属层状产品、金属加工设备等方向,能够解决组织变化、保护层损坏或破坏等问题,达到复合特性优化、确定尺寸容易的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

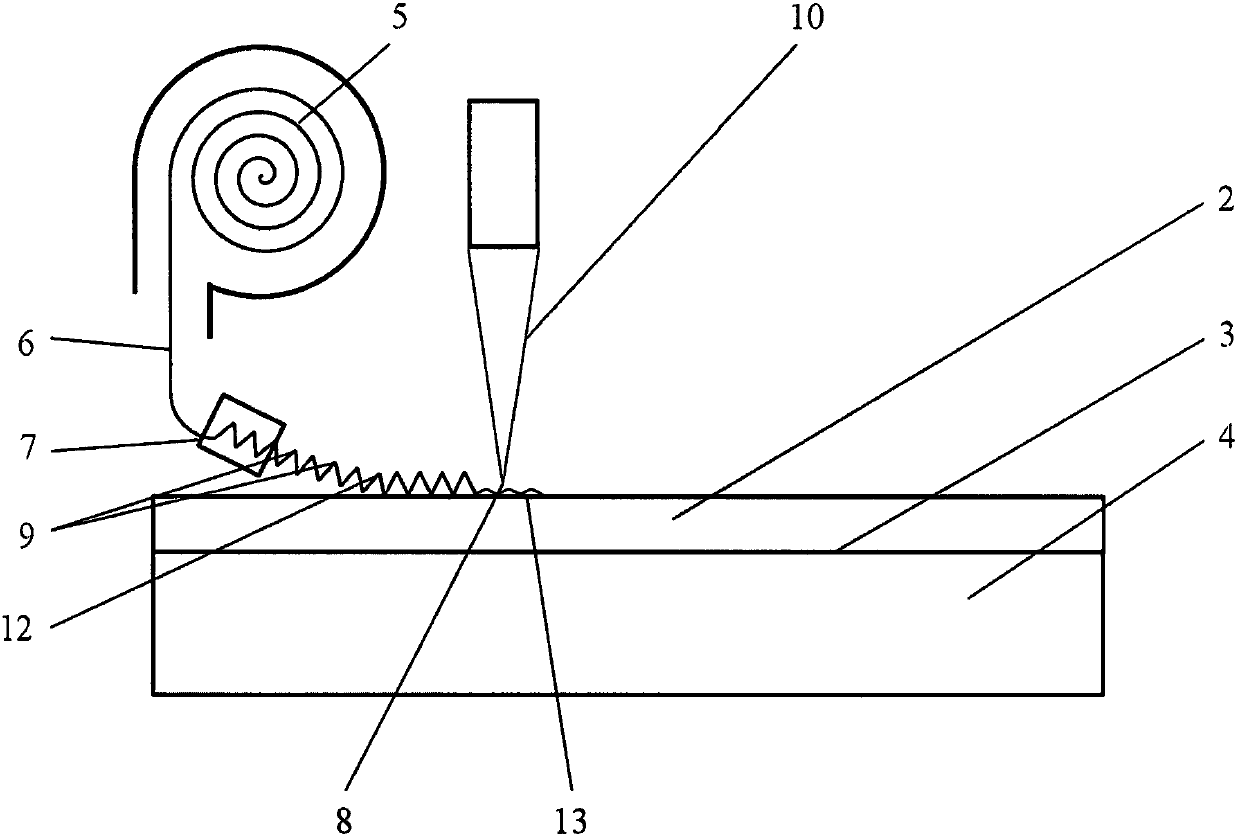

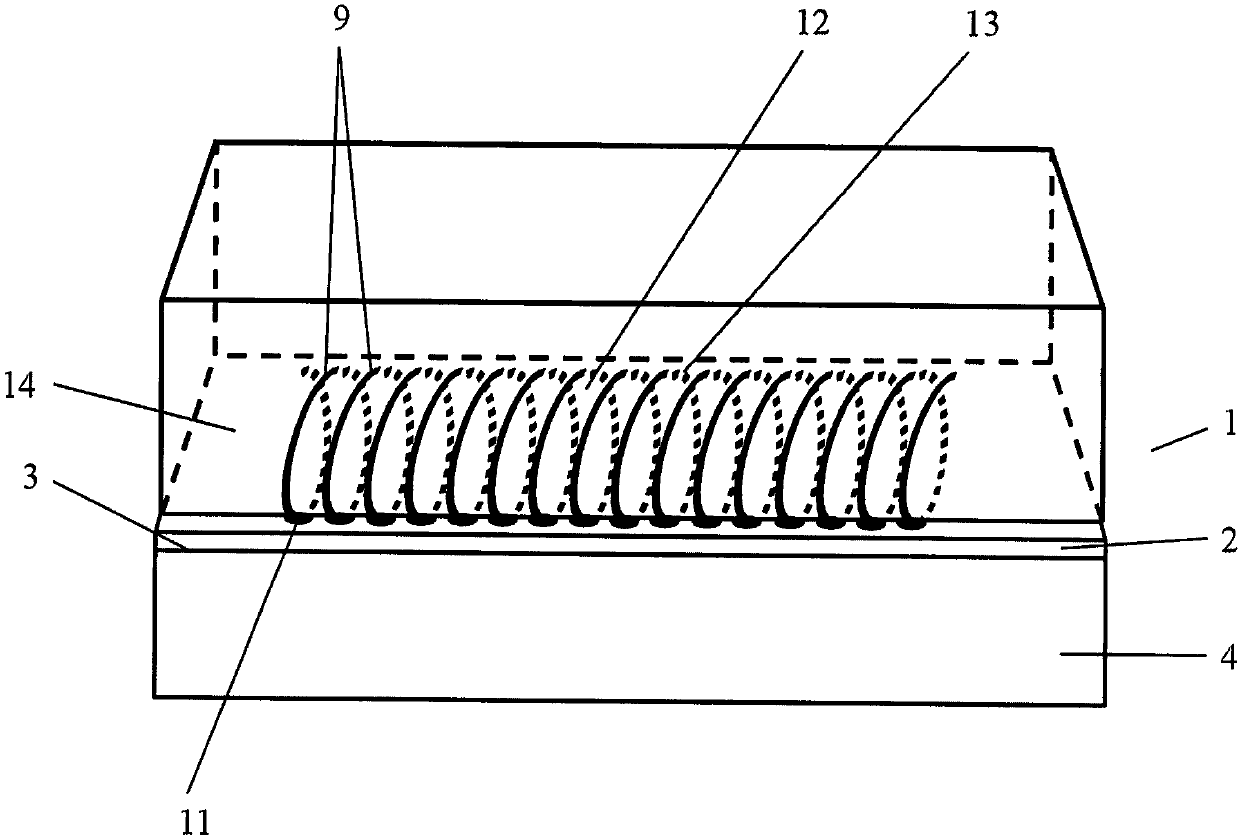

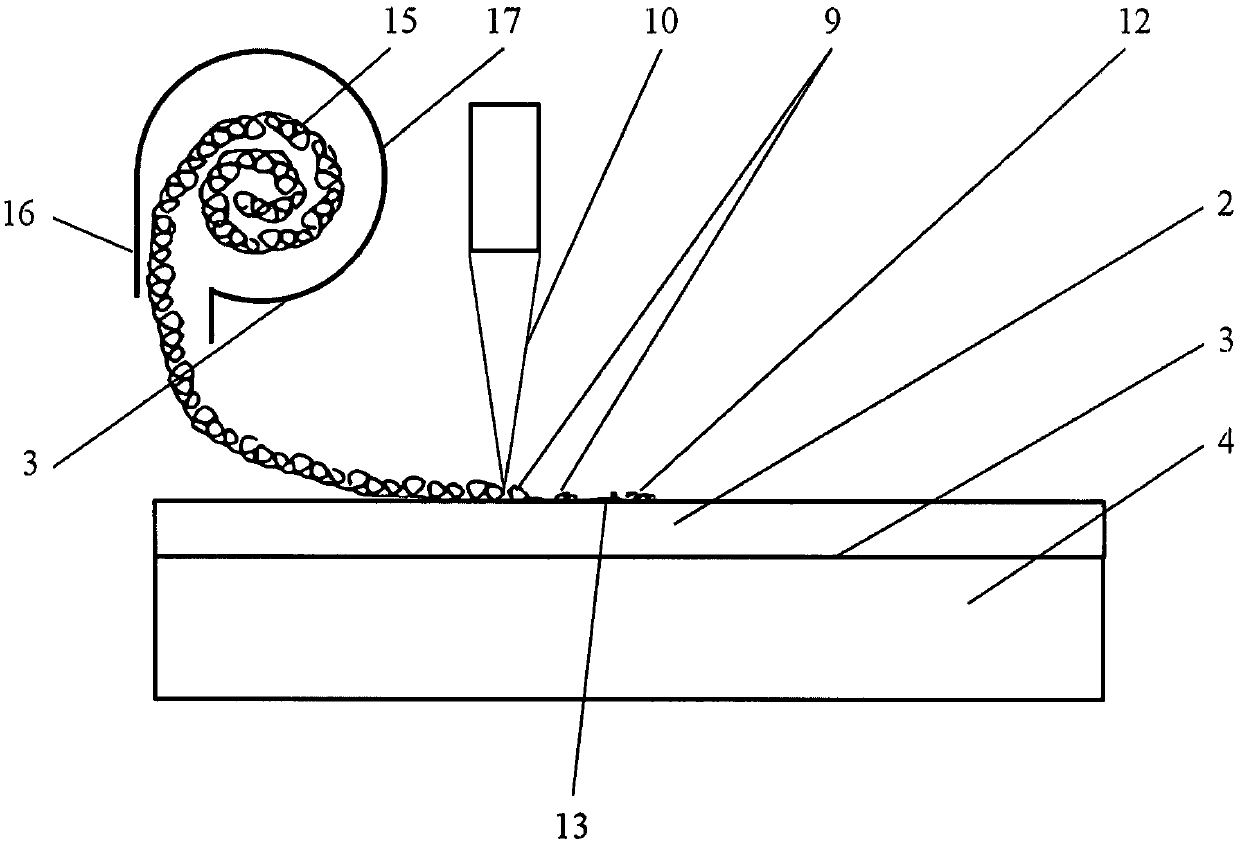

[0031] like figure 1 Illustrated, in an embodiment of the method for producing a plastic-metal hybrid component 1 (the plastic-metal component is figure 2 shown schematically in a free section view), using structural wire 6 unwound from a structural wire coil 5 as a corrosion protection layer made of zinc with a metal surface 3 of a base body 4 made of steel 2 Good bondable additional material. The structural wire 6 is continuously locally shaped from the unwound end 8 of the structural wire 6 into a geometrically determined and / or geometric Interconnected metal elements 9 of indeterminate form. The interconnected elements 9 of the shaped structural wire 6 are applied here successively from the unwound end 8 of the structural wire 6 onto the corrosion protection layer 2 and are welded at the welding point by means of a laser 10 or an alternative focused heat source. 11 places are welded on the anti-corrosion layer 2, such as figure 2 shown. In this case, a surface struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com