Applicator

A coating and equipment technology, which is applied in the field of coating liquid storage tubes and coating equipment, can solve the problems of no special restrictions on materials, etc., achieve sufficient three-dimensional effect, excellent writing performance, and prevent the effect of force reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0252] (ink composition)

[0253] The ink compositions used in the examples were produced in the following manner. The following "parts" are all "weight parts".

[0254] Mix and stir the following materials to make water-based ink composition: propylene glycol: 15.0 parts, NeocolYSK: 0.5 parts, KF-6011: 0.2 parts, Erujineo#325Silver: 0.8 parts, MowinylLDM7520: 10.0 parts, PrimalAC-3001: 60.0 parts, water : 6.2 units, ASE-6025P: 6.0 units, ProxelXL-2: 0.2 units, COURT_SIDEPH2: 0.2 units, P-30A color base (colorbase) #3: 0.9 units.

[0255] The pH of the obtained ink composition was 8.3.

[0256] According to JISK2283, using a viscometer ("TVE22HT"), the viscosity at 20 degreeC was 8.12 Pa*s under the condition of 1.34 cone (cone) 0.5 rpm.

[0257] (Example and Comparative Example)

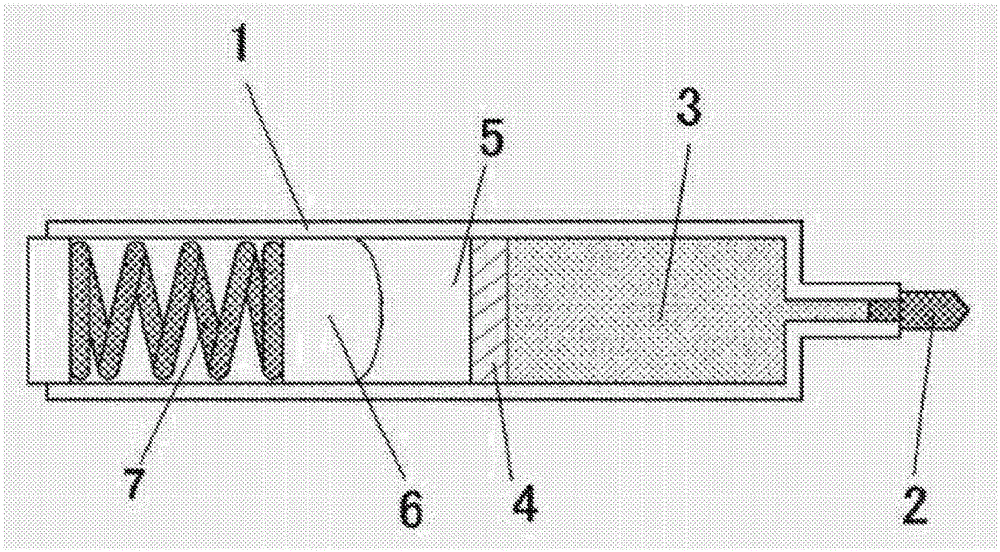

[0258] Writing utensils were manufactured by filling the above-mentioned ink composition in the ink accommodating portion of a coating liquid storage tube serving as an ink accommodating portion...

Embodiment 2

[0263] (ink composition)

[0264] The ink compositions used in the examples were produced as follows.

[0265] Resin emulsion A: 70 parts by weight, viscosity modifier: 3.0 parts by weight, wetting agent: 5.0 parts by weight, surfactant: 0.5 parts by weight, preservative: 0.5 parts by weight, and ion-exchanged water added to 100 parts by weight. The dissolution apparatus was stirred for 1 hour to obtain the desired ink composition.

[0266] Similarly, the ink compositions of Examples 2 to 27 and Comparative Examples 1 to 8 were produced so as to have the compositions described in Table 1 below, and these were filled in spring-loaded ballpoint pens.

[0267] Then, these results are shown below.

[0268] (evaluate)

[0269]

[0270] Measured under the conditions of a TVE-25L viscometer (manufactured by Toki Sangyo Co., Ltd.), 3° R14 cone, and 0.5 rpm.

[0271]

[0272] ◎…Sufficient uplift is felt when the handwriting is touched with a finger

[0273] ○...Feel a bump whe...

Embodiment 3

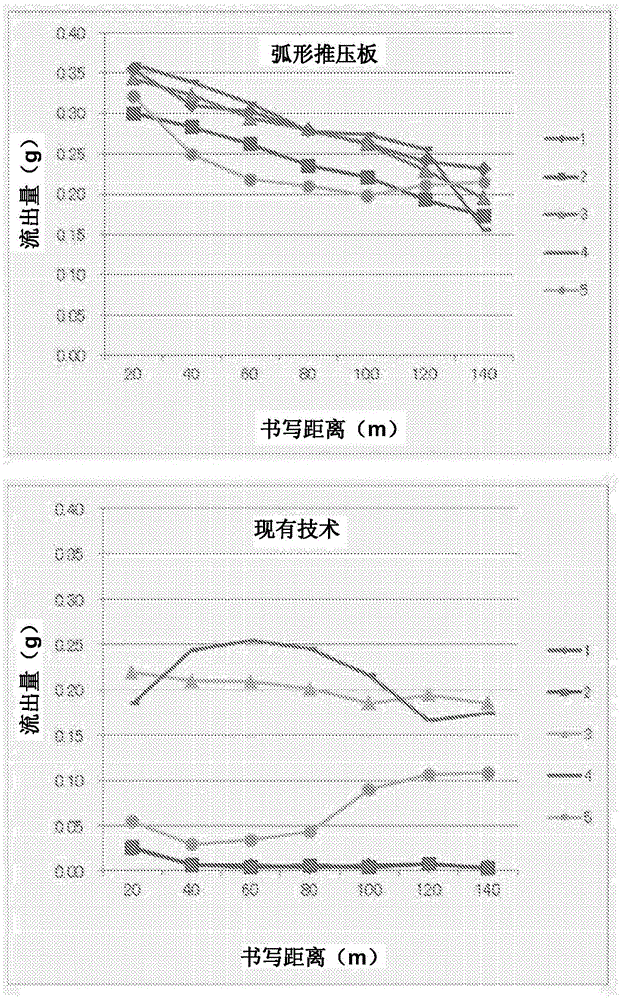

[0351] An applicator based on the ballpoint pen 8 of the above-mentioned embodiment is formed. In addition, in this applicator, the radial length of the interval L3 formed on one end portion side of the spring 13 in the radial direction was 0.15 mm. Furthermore, writing is continued while the applicator is used and the initial posture in which no ink is used is changed to a state in which no ink is stored in the ink tank forming portion.

[0352] Then, the change in the biasing force of the spring during this period was measured. As a result, it is possible to obtain Figure 14 The results shown.

[0353] The pressing force of 0.6N in the initial posture where ink is not used at all becomes 0.4N in the state where no ink is stored in the ink tank forming part, showing that the pressing force changes inversely proportional to the expansion of the spring. That is, it is shown that the pressurizing force does not decrease suddenly due to the resistance received from the inner ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com