Air silencer

A muffler and air technology, applied in the direction of sounding equipment, instruments, etc., can solve the problems of poor noise reduction and noise reduction, achieve good noise reduction and noise reduction, and increase the effect of residence time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

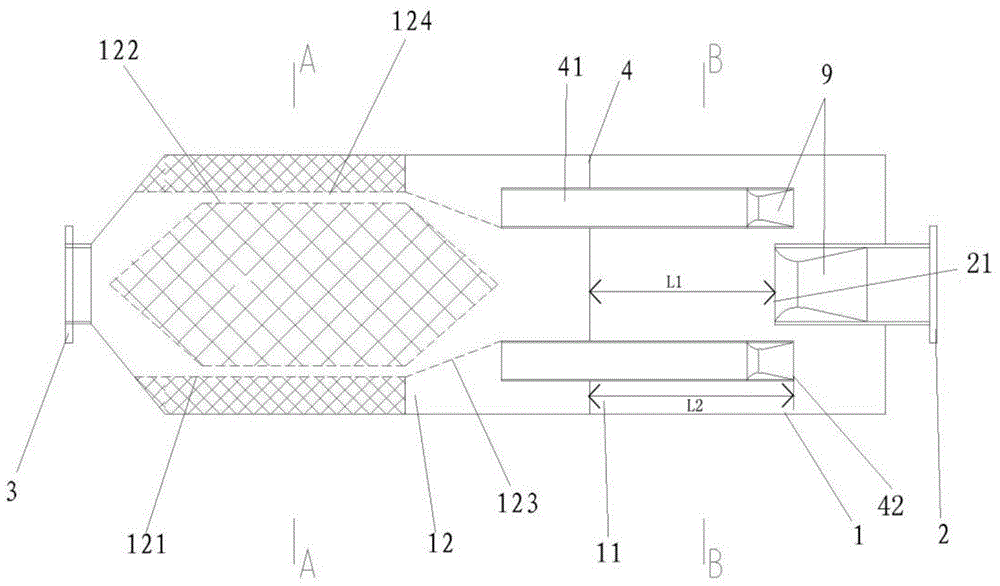

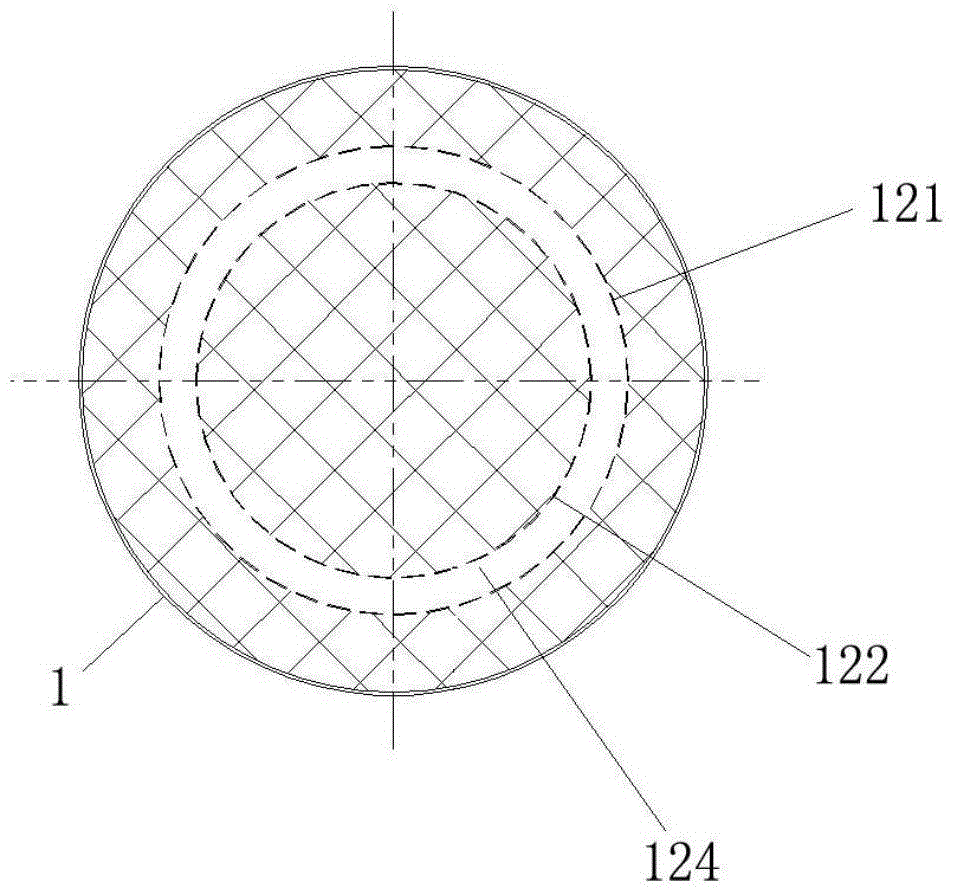

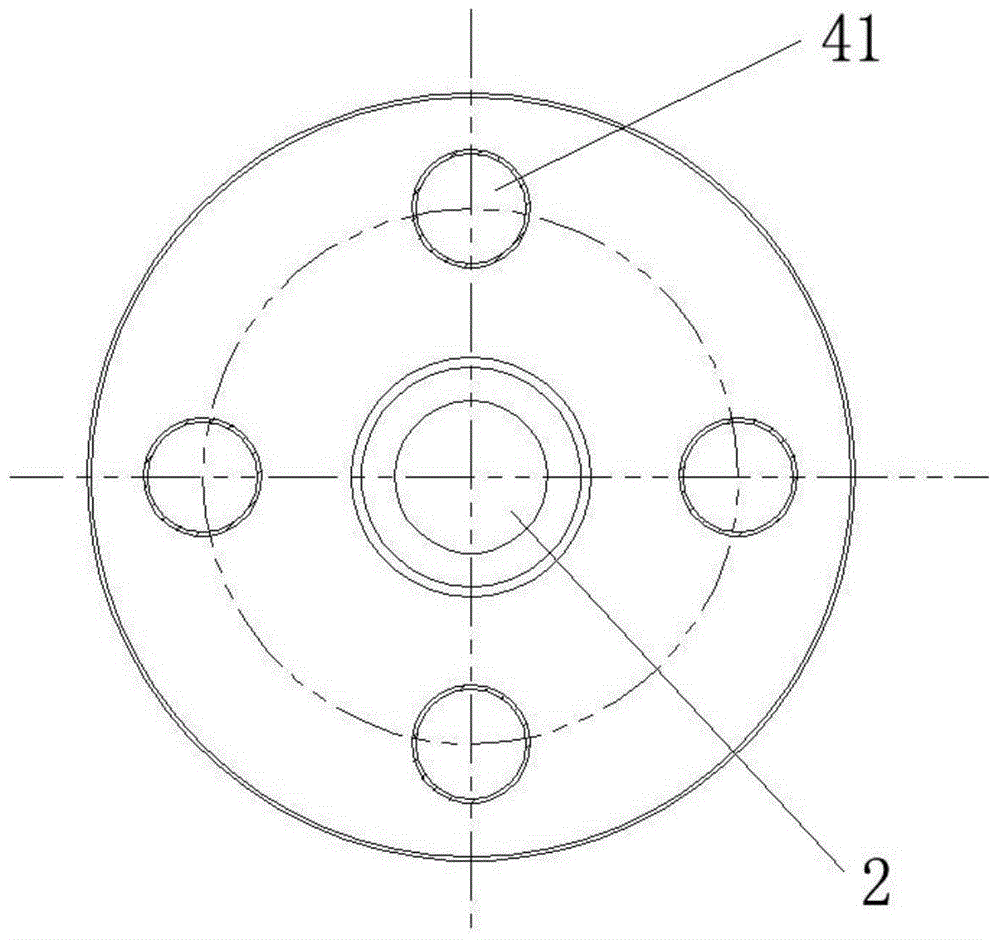

[0034] This embodiment provides an air muffler, such as Figure 1-4 As shown, it includes: an outer cylinder 1, the inside of the outer cylinder 1 is separated by a partition plate 4 to form a first chamber 11 and a second chamber 12, both ends of the outer cylinder 1 are respectively provided with The air inlet pipe 2 communicating with the first chamber 11 and the outlet pipe 12 communicating with the second chamber 12 are provided with a plurality of air pipes 41 communicating with the first chamber 11 and the second chamber 12 on the partition plate 4 , The distance L1 from the first end surface 21 of the air pipe 2 located in the first chamber 11 to the partition plate 4 is smaller than the distance L1 from the second end surface 42 of the air pipe 2 located in the first chamber 11 to the partition plate 4 L2, a sound absorbing structure for sound absorption is formed in the second cavity 12.

[0035] In this embodiment, the first chamber 11 is a resistive muffler used to e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com