Cold trap for purifying lead and lead-base alloy

A lead-based alloy and cold trap technology, which is applied in the field of liquid heavy metal and alloy purification equipment, can solve the problems of unsuitable liquid heavy metal and its alloy purification, and achieve the goal of expanding size, increasing impurity saturation volume, and increasing heat exchange efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

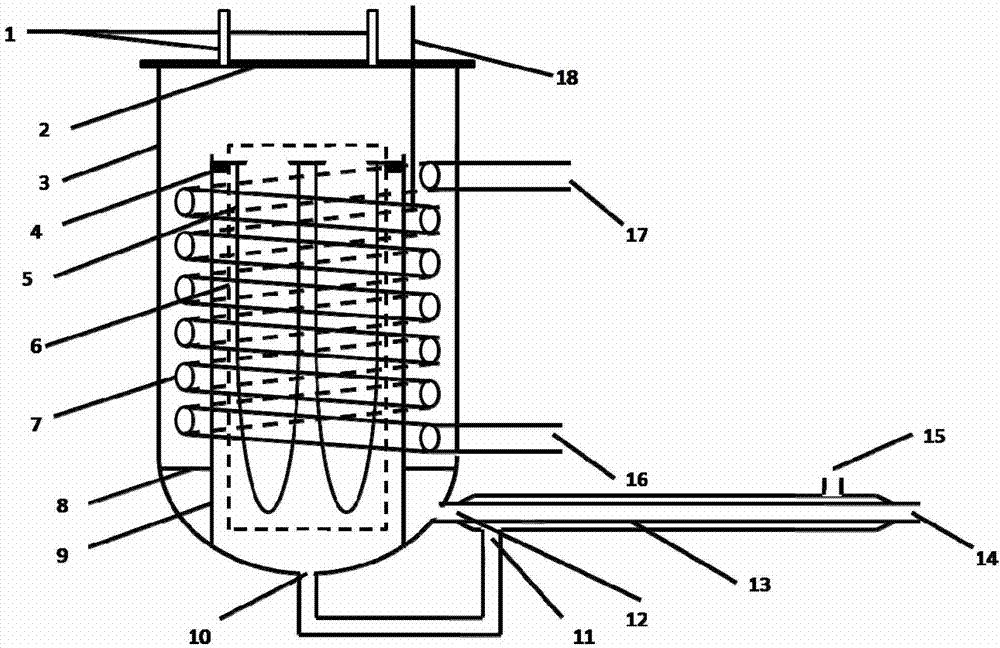

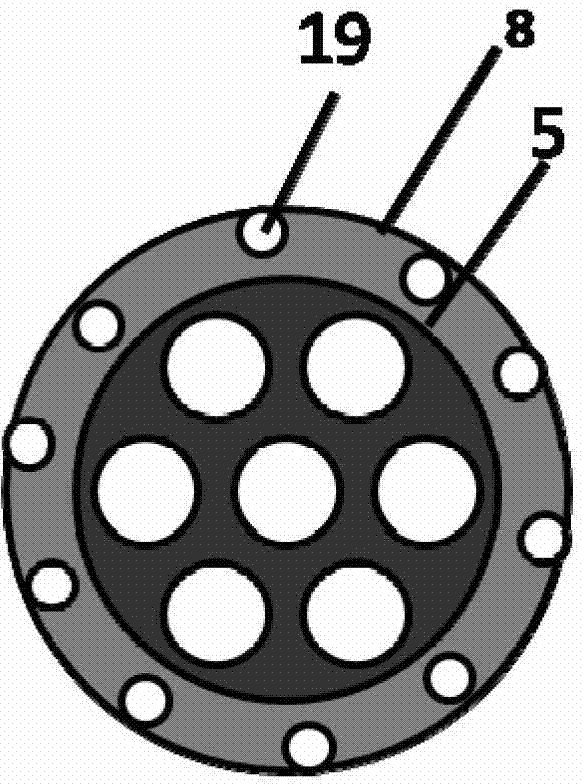

[0020] like Figure 1-2 As shown, a cold trap for purifying lead and lead-based alloys of the present invention includes a cylinder body 3 and a heat saver 13, a diversion partition 9 and a filter element 6 are arranged inside the cylinder body 3, and a sealing flange 2 is used on the top of the cylinder body 3 , the flange 2 is provided with an air passage 1, the lower part of the cylinder body 3 is provided with an inlet 12 and an outlet 10 of lead and lead-based alloy, the inlet 12 is externally connected to a heat saver 13, and the bottom of the cylinder 3 is provided with a diversion orifice 8, and the diversion orifice 8 is connected with the cylinder 3 and the diversion baffle 9, the filter element 6 is connected with the diversion baffle 9 through the fixing bolt 4, and the cooling coil 7 is between the diversion baffle 9 and the cylinder 3. The inlet 12 of the lead and lead-based alloy of the cylinder body 3 is connected with the outer economizer 13, the outer economi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com