Groove type end mill with double arcs

An end mill, double arc technology, used in milling cutters, manufacturing tools, milling machine equipment, etc., can solve the problems of unusable tools, obstacles to smooth chip discharge, and chips that cannot be curled and broken, so as to reduce chipping and machining. cost, the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

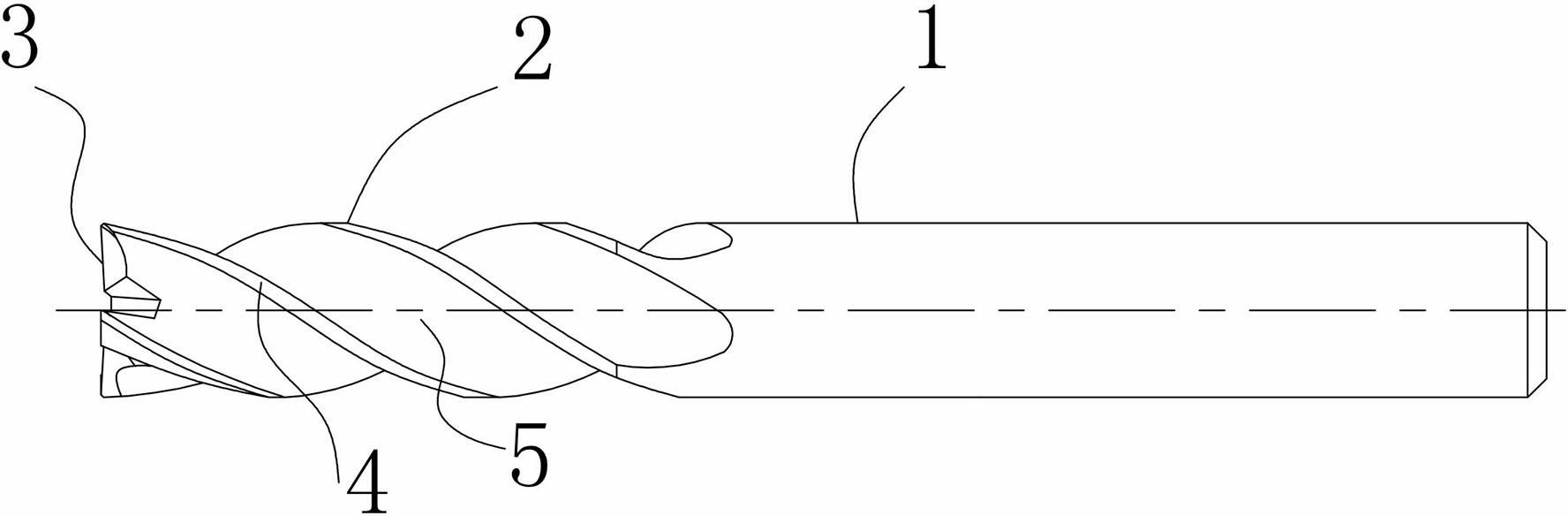

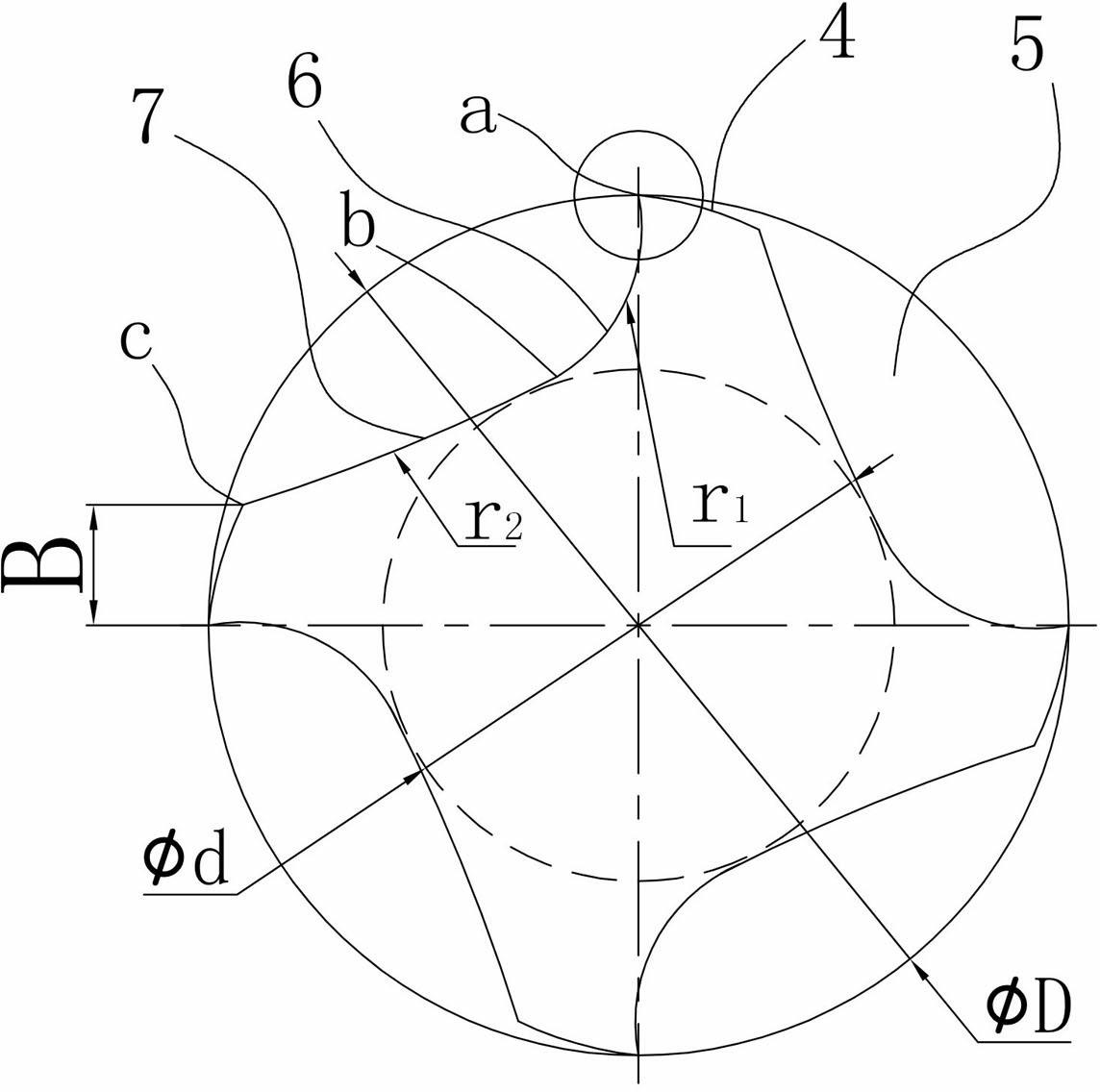

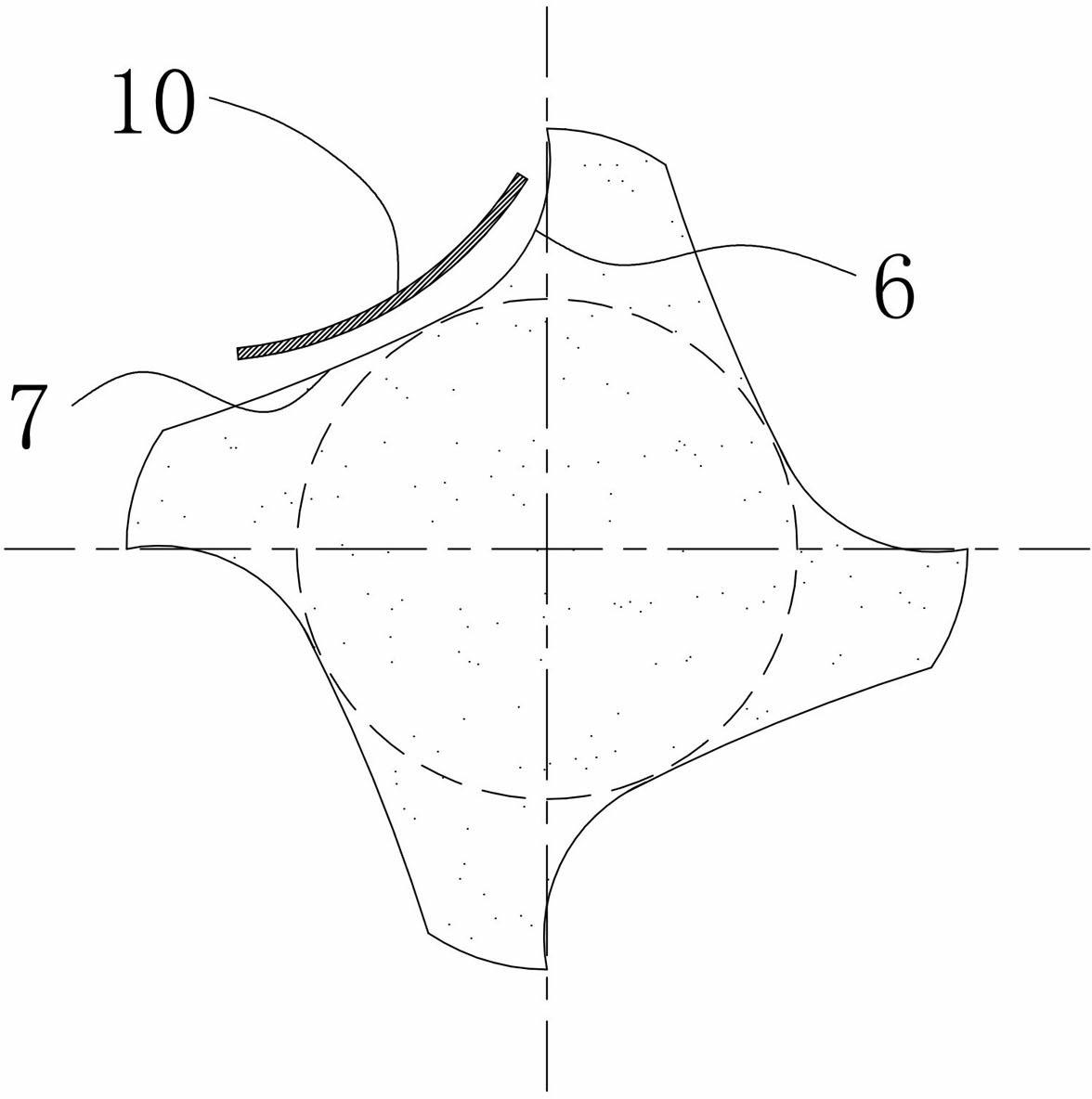

[0025] Figure 1 to Figure 2 It shows an embodiment of an end mill with double arc grooves according to the present invention. The end mill includes a shank 1 and a cutting part 2. The cutting part 2 includes end face cutting teeth 3, peripheral cutting teeth 4 and The chip flute 5 between the adjacent two peripheral cutting teeth 4, the chip flute 5 is composed of and only consists of the groove rake face arc 6 and the groove flank arc 7 in the radial section, and the groove rake face arc 6 passes through points a and b, the groove flank arc 7 passes through points b and c, and the groove flank arc 7 and the groove rake face arc 6 are inscribed at point b, taking the rotation center of the end mill as the origin , the coordinates of all points on the rake face arc 6 satisfy the equation (x-a 1 ) 2 +(y-b 1 ) 2 =r 1 2 , where r 1 is the radius of arc 6 on the rake face of the groove, a 1 and b 1 The value of is not equal to 0; the coordinates of all points on the groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com