Receiver tank for refrigeration cycle, heat exchanger with the receiver tank, and condensation device for refrigeration cycle

A refrigeration cycle and heat exchanger technology, applied in heat exchange equipment, evaporator/condenser, refrigerator, etc., can solve the problems of complex structure, increased cost, and high flow rate of refrigerant, and achieve simplified structure and reduced The effect of the number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

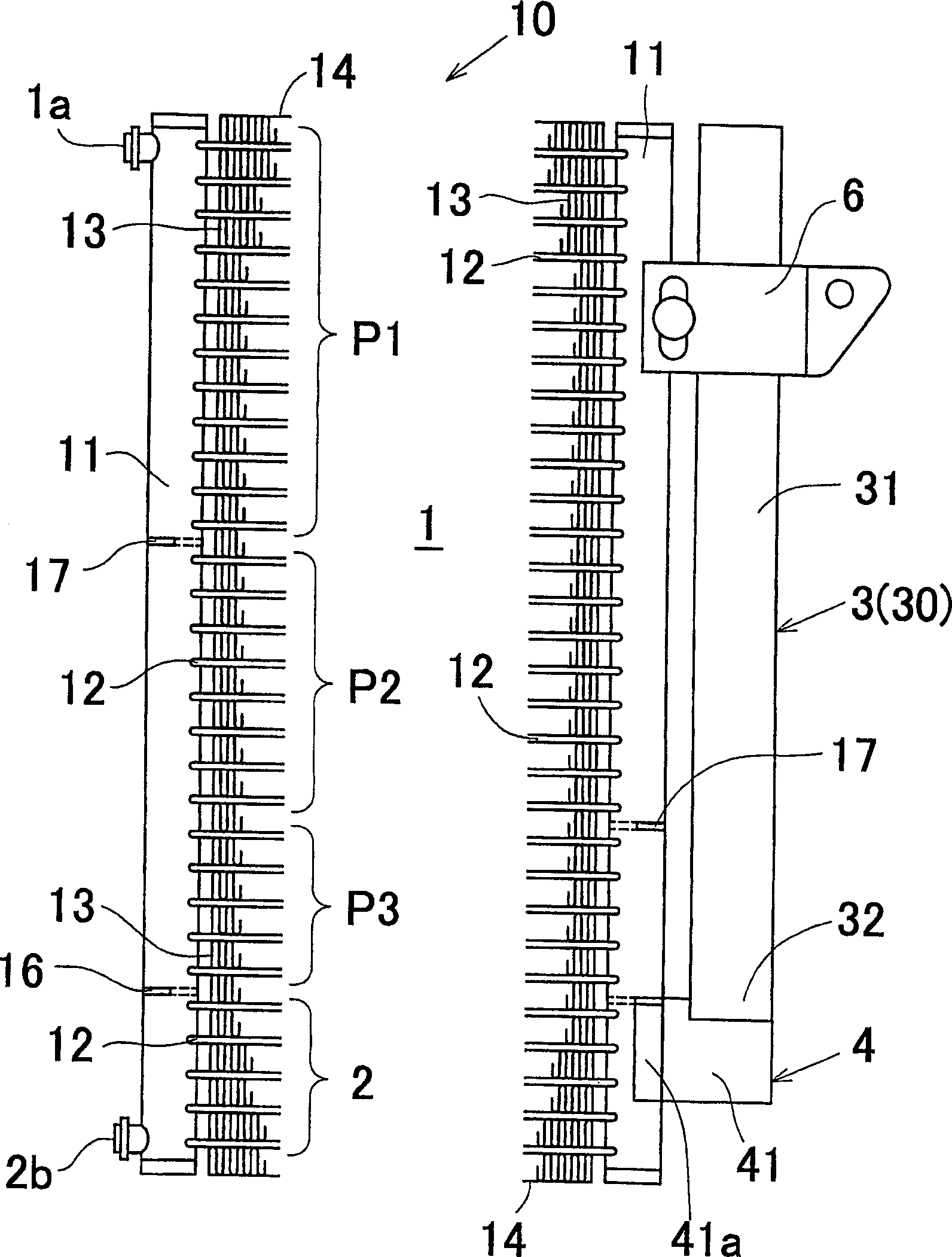

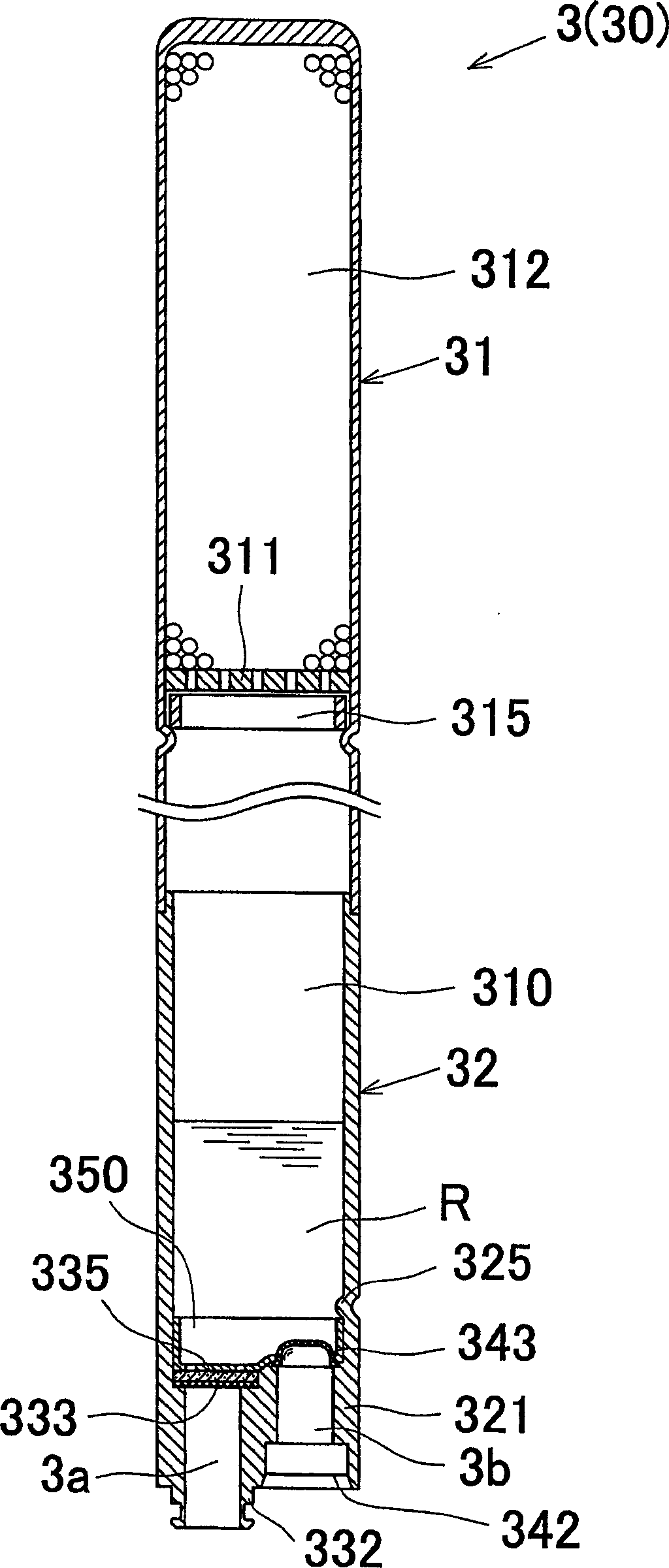

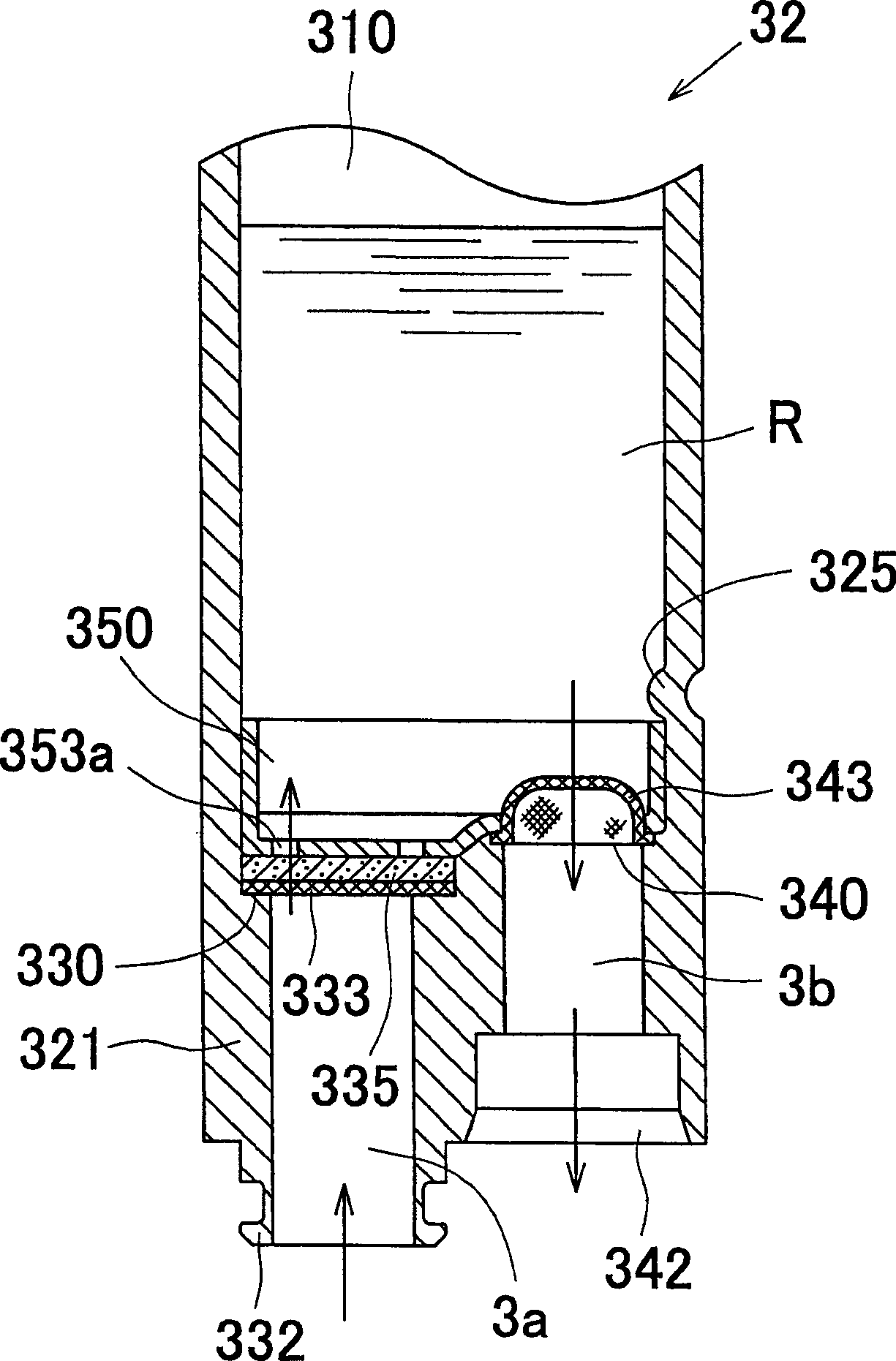

[0125] figure 1 It is a front view showing both side parts of the heat exchanger with storage tank which concerns on this embodiment of this invention. As shown in the figure, the heat exchanger is equipped with: a multi-channel type heat exchanger body (10), a storage tank (3), and a Block flange (4) for joining parts.

[0126] The heat exchanger body (10) is provided with a pair of header pipes (11) along the vertical direction opposite to each other with a certain interval. Between the pair of headers (11), a plurality of flat tubes (12) along the horizontal direction as heat exchange tubes are spaced vertically and vertically in a state where their respective ends are communicated with the two headers. arranged side by side at intervals. Furthermore, corrugated fins (13) are arranged between the flat tubes (12) and outside the outermost flat tube (12), and side plates are arranged outside the outermost corrugated fins (13). (14).

[0127] On the predetermined height ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com