Method and device for supporting weak adhesion bond soft rock roadway

A technology of roadway support and weak cementation, which is applied in the direction of drilling equipment and methods, earthwork drilling, installation of bolts, etc. It can solve the problems of large changes in the drilling angle of bolts, improve anchoring capacity, and achieve good hole expansion effects , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The weakly cemented soft rock roadway support method of the present invention comprises the following steps:

[0045] Step 1, determine the drilling position and the drilling depth according to the specific conditions of the surrounding rock mass around the roadway, adopt a drilling machine to drill, the diameter of the drilling is adapted to the diameter of the reaming drill bit, and the drilling diameter is 28mm, The depth is 2m;

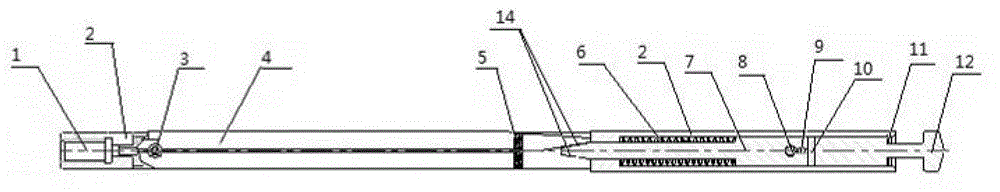

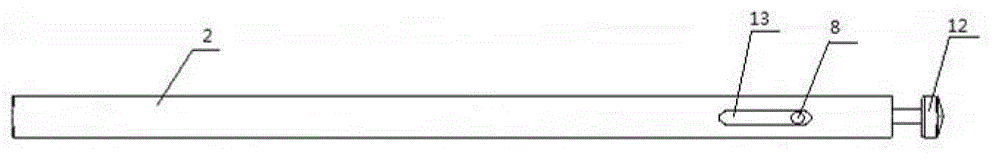

[0046] Step 2: Connect the reaming drill bit with the drill rod, the drill rod delivers the reaming drill bit to the bottom of the borehole, the drill rod is connected to the drilling machine, the cutter 4 of the reaming drill bit is automatically opened, and the drilling machine drives the The drill rod and the reaming bit rotate to ream the bottom of the borehole. The hole structure expanded by the reaming bit is an inverted wedge shape, and the length of the cutter is 300mm, which is the hypotenuse of the inverted wedge-shaped hole struc...

Embodiment 2

[0050] The weakly cemented soft rock roadway support method of the present invention comprises the following steps:

[0051] Step 1, determine the drilling position and the drilling depth according to the specific conditions of the surrounding rock mass around the roadway, adopt a drilling machine to drill, the diameter of the drilling is adapted to the diameter of the reaming drill bit, and the drilling diameter is 42mm, The depth is 3m;

[0052] Step 2. Connect the reaming bit to the drill rod, the drill rod delivers the reaming bit to the bottom of the hole, the drill rod is connected to the drilling rig, and the drilling rig gives the reaming bit a downward axial force to ream the hole The cutter 4 of the drill bit is automatically opened, and the drilling machine drives the drill rod and the reaming bit to rotate at the same time, and the bottom of the borehole is reamed. The hole structure expanded by the reaming bit is an inverted wedge shape, and the cutting The lengt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com