Block-wedge-type self-locking inner anchor head

An internal anchor head and wedge-type technology, applied in construction, sheet pile walls, foundation structure engineering, etc., can solve the problems of high labor intensity, low efficiency, and difficulty in guaranteeing anchoring quality, and achieve enhanced anti-oxidation, anchoring reliability and Improved durability and increased anchoring force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with accompanying drawing description and specific embodiment:

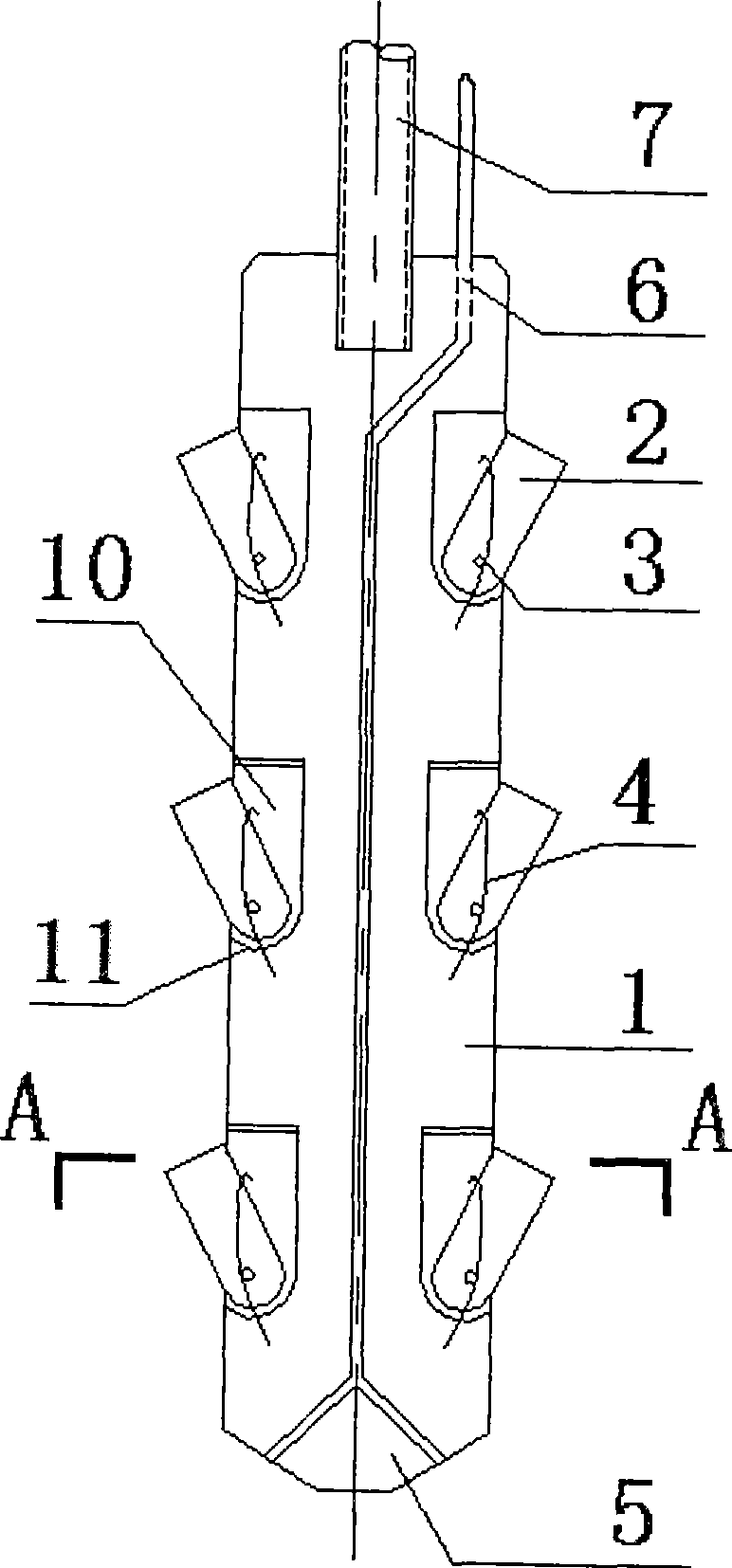

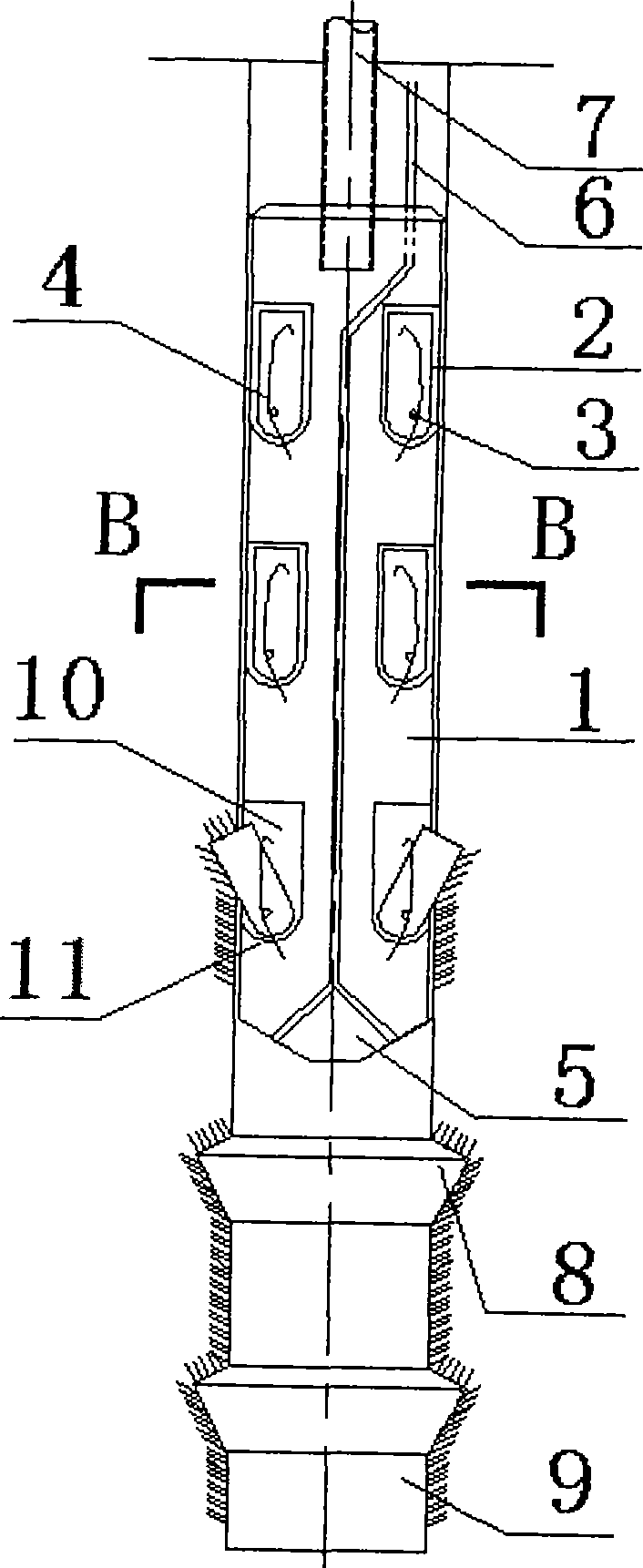

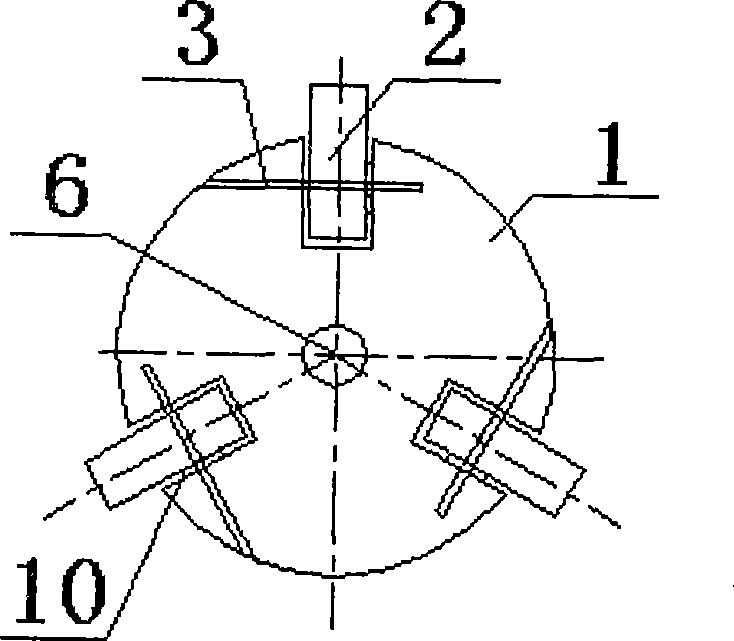

[0028] see figure 1 , figure 2 , Figure 5 , Figure 9 , Figure 10 , a wedge-type self-locking inner anchor head of the present invention has a body 1 that matches the anchor hole 9, and the body 1 is provided with a wedge groove corresponding to the inner cone segment 8 in the anchor hole 9 10. There is a pin 3 in the wedge groove 10 hinged with one end of the wedge 2, and the other end of the wedge 2 faces the opening of the anchor hole 9 and radially expands through the outward tension mechanism 4.

[0029] One or more layers of wedge grooves 10 can be vertically arranged on the body 1, and the number of layers of wedge grooves 10 is determined by the functional requirements of the anchor. The longitudinal distribution positions of the inner cone segments 8 are matched. A metal cylindrical bar can be used as the body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com