Self-adjusting building embedded part and embedded method thereof

A technology of embedded parts and self-adjustment, which is applied in the direction of construction and building structure, etc., can solve the problems of embedded parts movement, welding work not up to standard, flatness not up to the requirements, etc., to ensure the plane position and enhance the anchoring strength , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

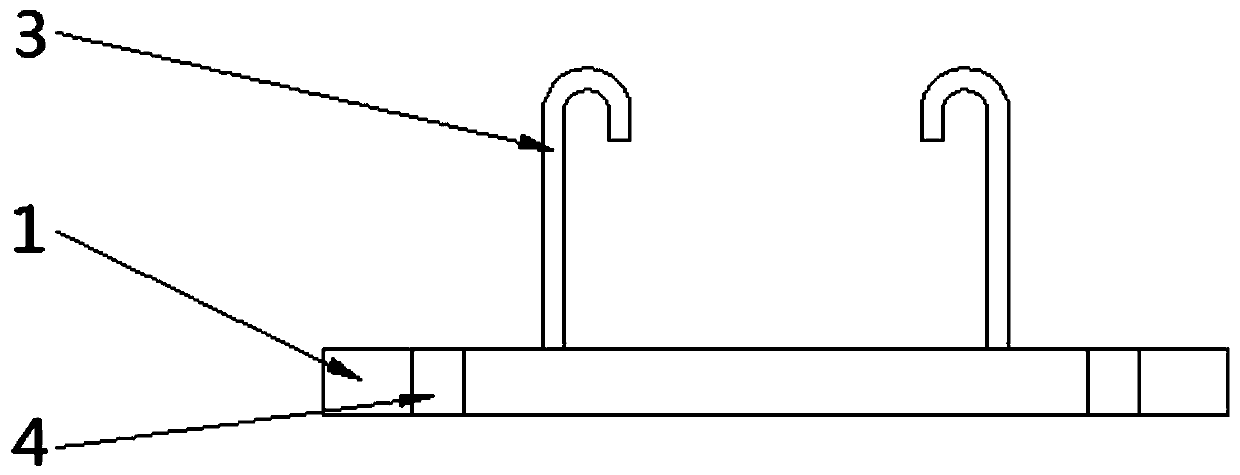

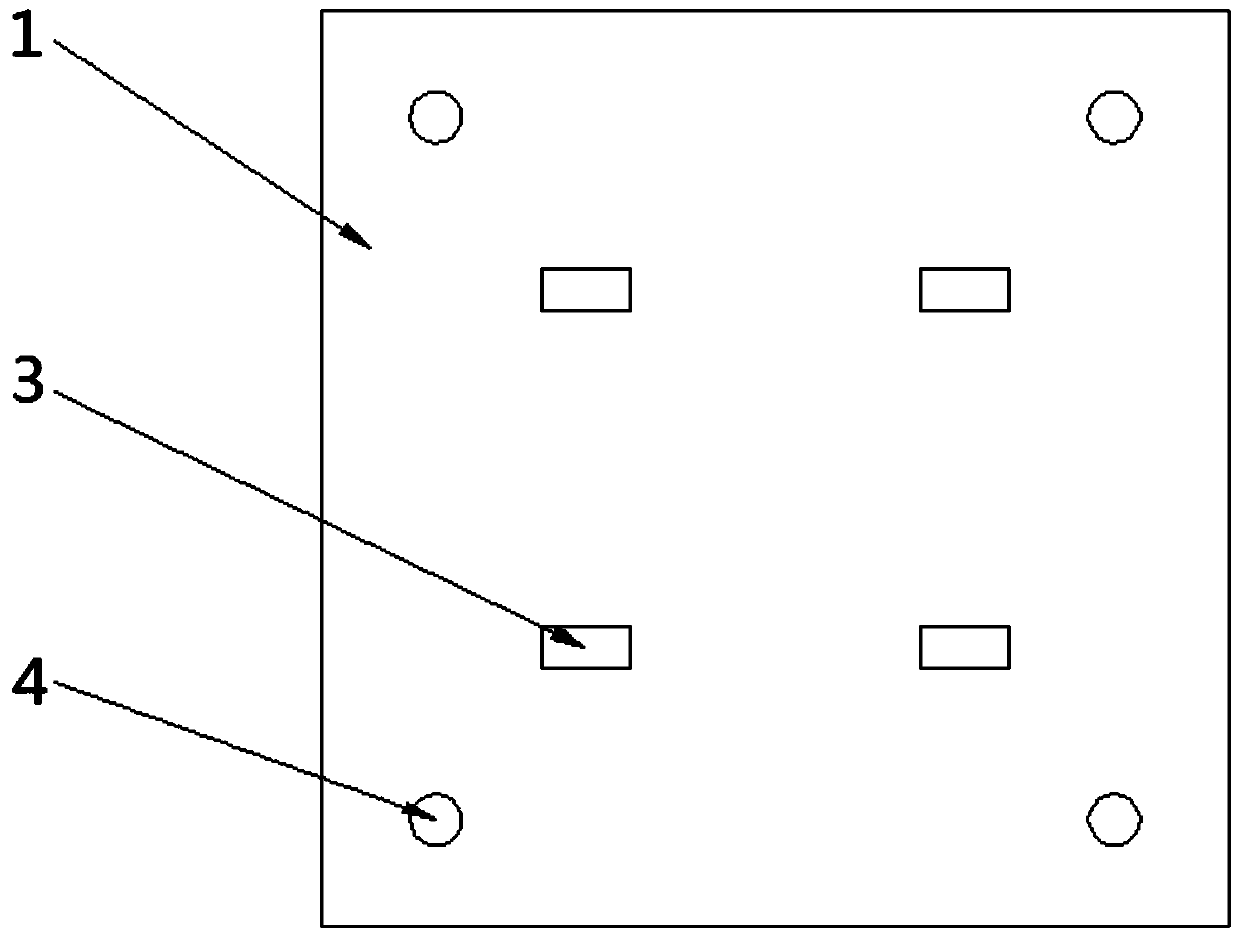

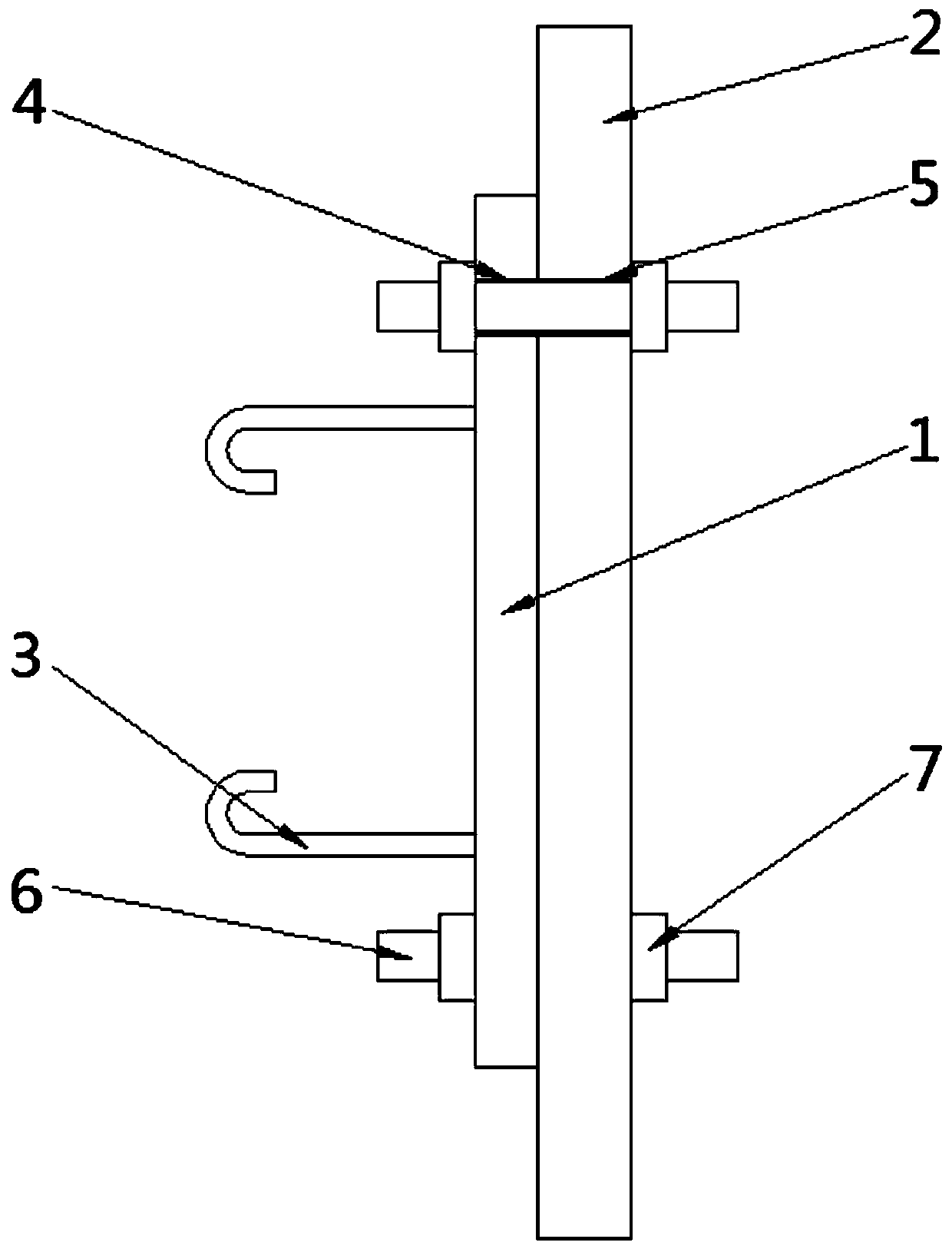

[0046] see Figure 1-3, a self-adjusting built-in part, including a pre-embedded part, the pre-embedded part includes a pre-embedded board 1 and a formwork 2, and the pre-embedded board 1 is provided with four anchor bars 3, and the shape of the anchor bar 3 is an inverted J shape , the bottom of the anchor bar 3 is welded to the pre-embedded plate 1, the four anchor bars 3 are arranged on the pre-embedded plate 1, the four corners of the pre-embedded plate 1 are provided with mounting holes 4, and the template 2 is provided with The positioning hole 5 corresponding to the mounting hole 4 is inserted with a positioning bolt 6 inside the mounting hole 4 and the positioning hole 5, and fastening nuts 7 are sleeved on the left and right sides of the positioning bolt 6.

[0047] The embedded parts are installed through the pre-embedded plate 1 and formwork 2, and four anchor bars 3 are set on the embedded plate 1, and the anchor bars 3 are in an inverted J shape, which ensures tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com