Embedded recoverable expansion anchor cable and construction method thereof

A built-in, expanded technology, applied in the direction of infrastructure engineering, buildings, sheet pile walls, etc., can solve the problems of affecting the development and construction of the surrounding environment, increasing the cost of steel strand processing, and the adverse effects of structure stability, so as to reduce underground pollution , Improve the anchoring strength and reduce the construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

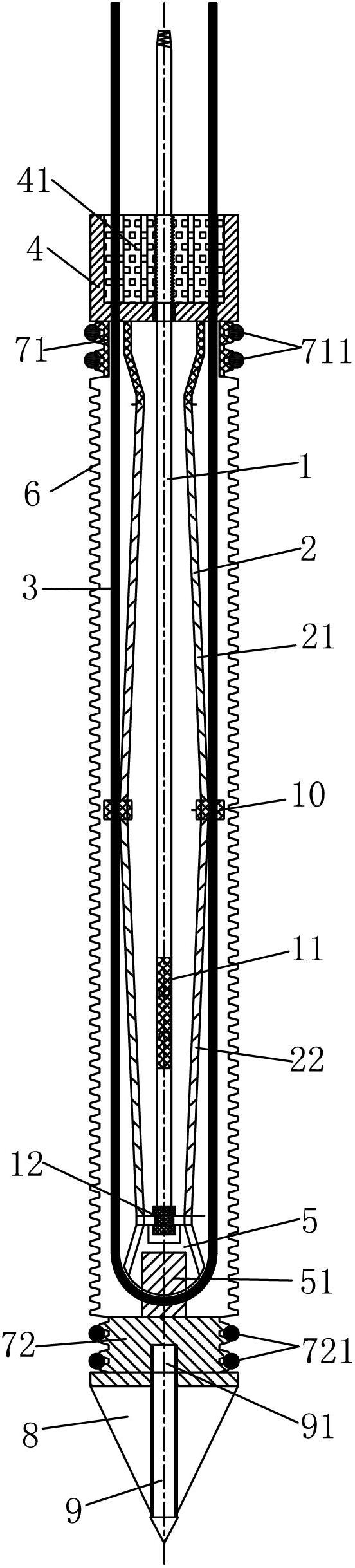

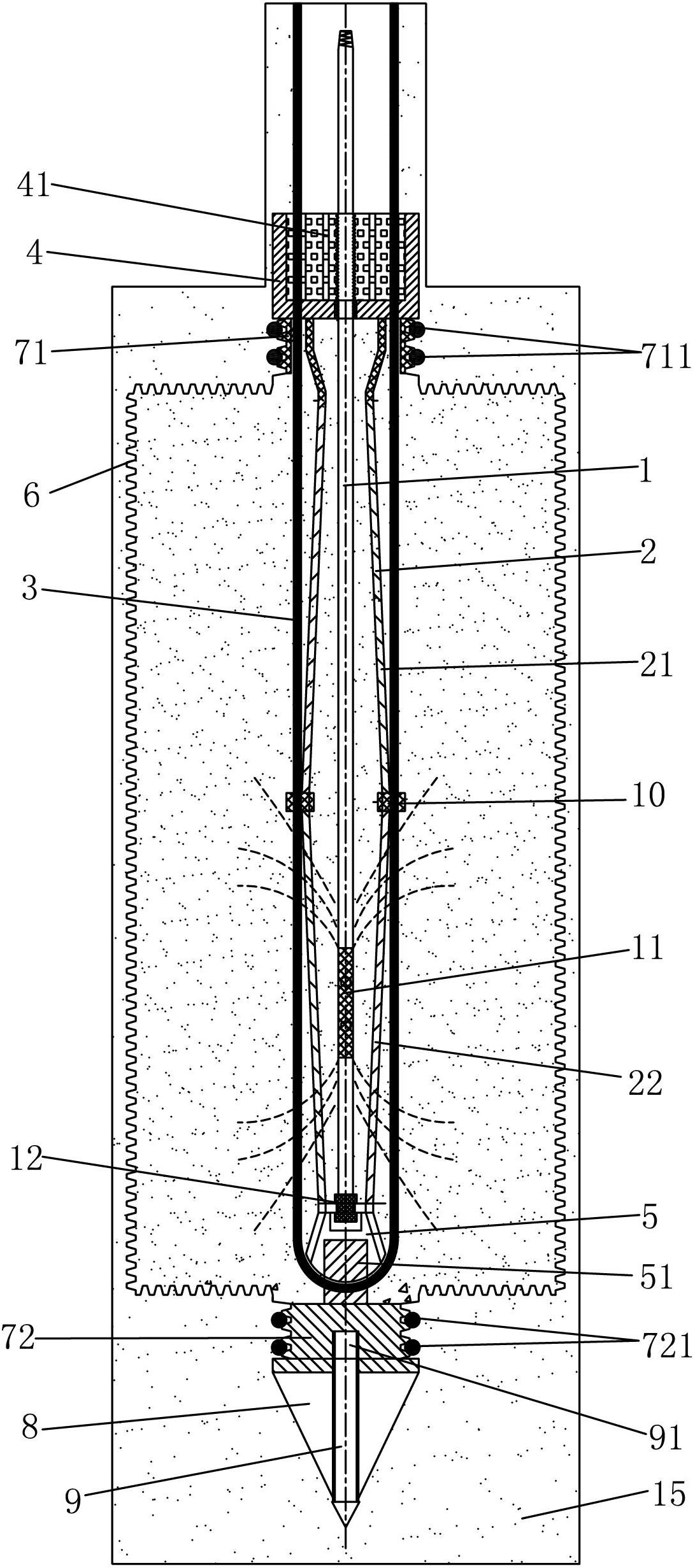

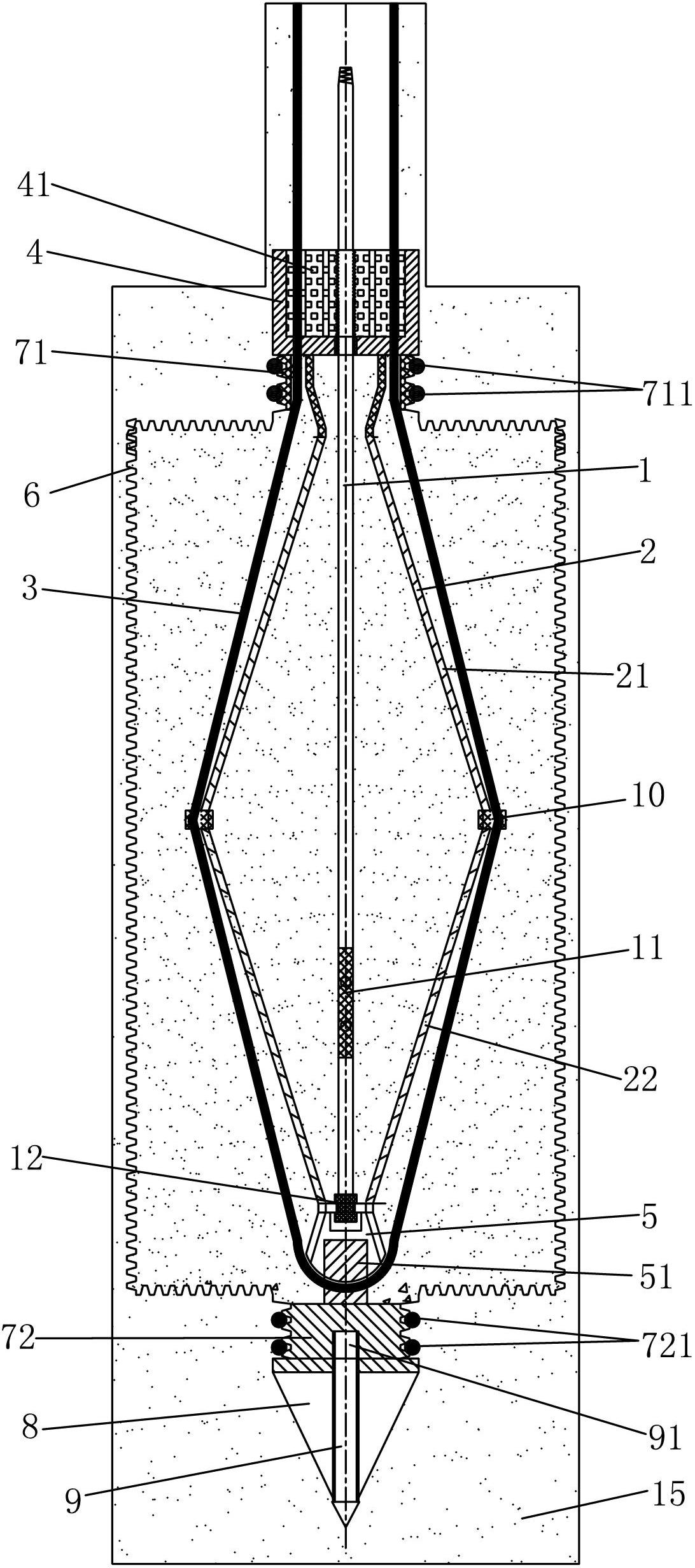

[0029] Such as figure 1 As shown, the built-in recyclable expansion anchor cable of the present invention includes a grouting pipe 1, an expansion arm 2, a steel strand 3, a steel strand free sliding warehouse 4, a fixed bearing device 5, a flexible telescopic sleeve 6, an upper , lower locking devices 71, 72, cushioning rubber body 8, drill tip 9, wherein, the middle part of the grouting pipe 1 is provided with a one-way grouting device 11, the upper part is provided with threads, and the steel strand free-slides on the end surface of the bottom of the warehouse 4 There is a central threaded hole, the upper part of the grouting pipe 1 is screwed into the central threaded hole of the steel strand free sliding warehouse 4, and the lower part is set on the fixed bearing device 5 through the rotating fixed clip 12, and the bottom surface of the fixed bearing device 5 is The arc-shaped surface, and the arc-shaped surface is provided with a plurality of parallel transverse arc-shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com