Assembly type prefabricated floor slab connecting piece for steel structure building and mounting method thereof

A steel structure, prefabricated technology, applied in the direction of construction, building structure, etc., can solve the problems of complex connection mode and poor anchoring performance, and achieve the effect of reducing construction procedures, improving anchoring strength and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

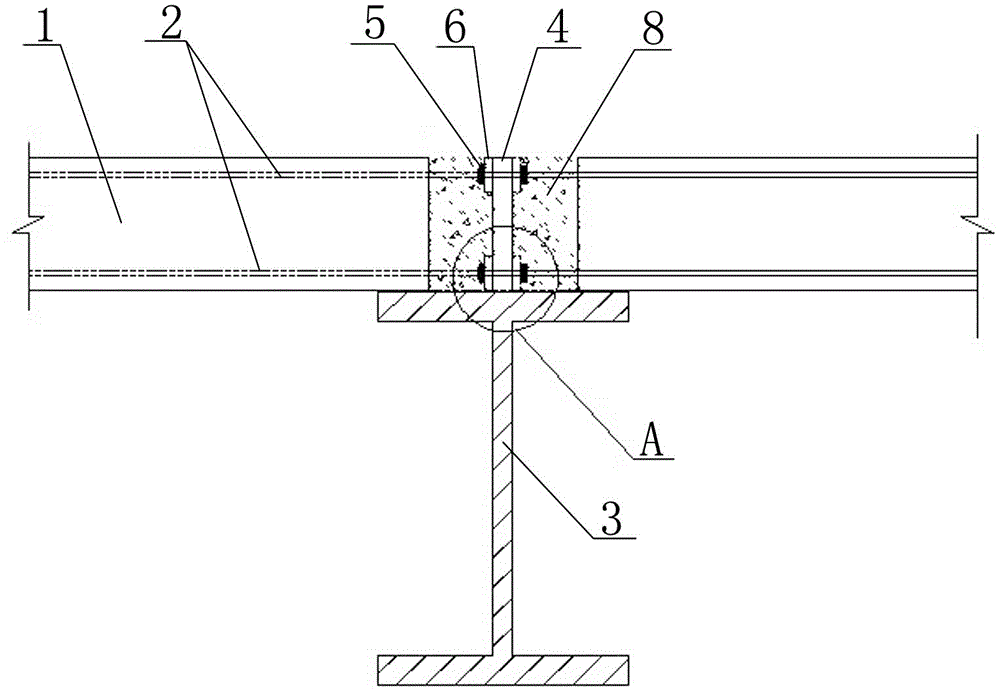

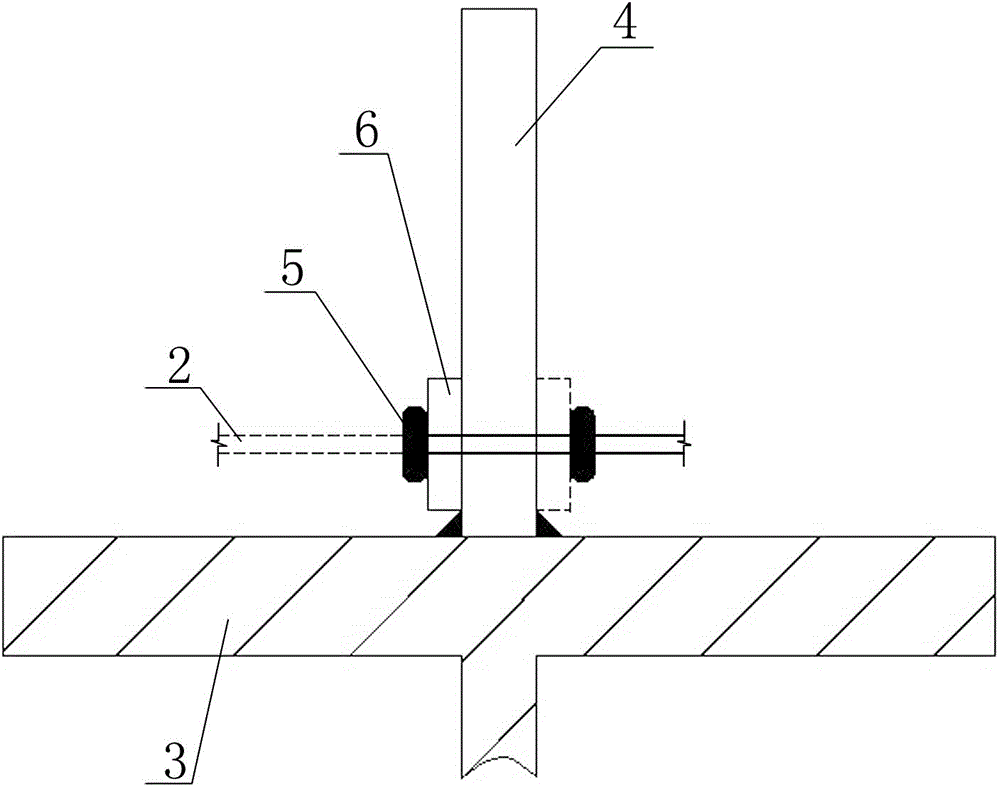

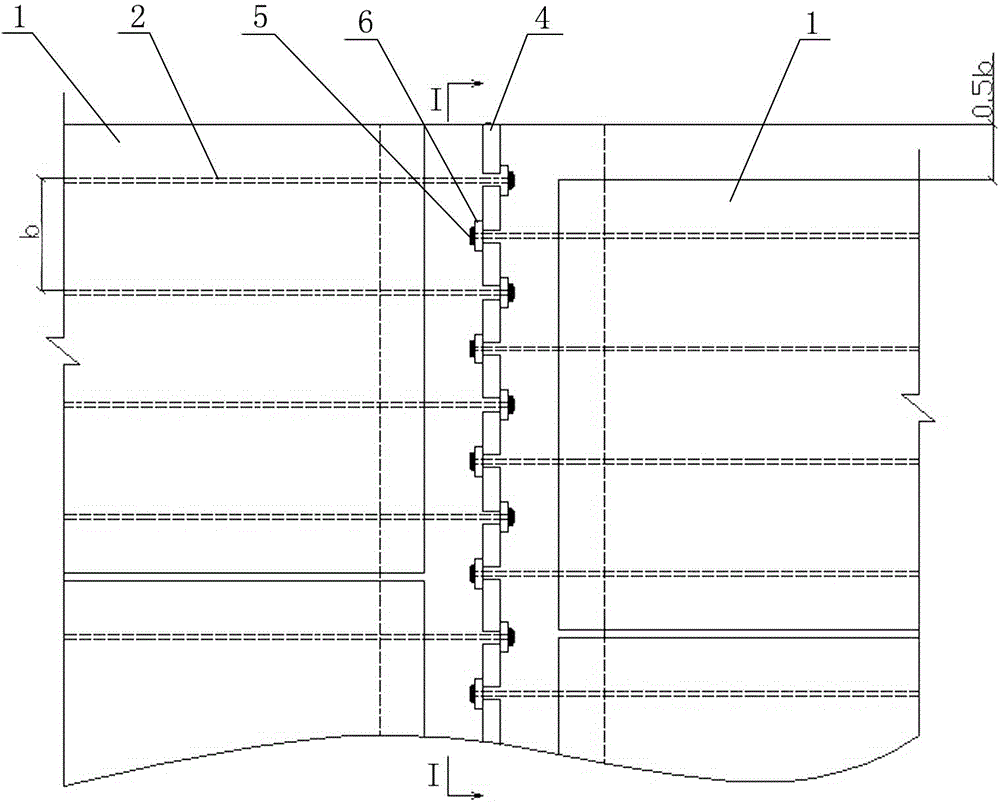

[0035] Examples see Figure 1-8 As shown in the assembly type prefabricated floor connector for steel structure buildings, the prefabricated floor 1 is placed on the I-beam 4, and the prefabricated floor 1 is distributed with upper and lower rows of longitudinal steel bars 2 at intervals, and the two ends of the longitudinal steel bars 2 pass through Exposed steel bars are formed on both ends of the prefabricated floor slab 1 . The prefabricated floor 1 may have a width of 0.6-1.0m and a thickness of 90-130mm.

[0036] The ends of the exposed steel bars at both ends of the prefabricated floor slab 1 are steel bar piers 5 equipped with a backing plate 6, or the exposed steel bars at one end of the prefabricated floor 1 are steel bar piers 5 equipped with a backing plate 6, and the other end The extruded sleeve 7 is installed at the end of the exposed steel bar.

[0037] The I-beam 3 is vertically welded with a strip-shaped steel plate 4 along the entire length of the top surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com