Preparation process of anti-settling prestressed concrete pipe pile

A technology of concrete pipe pile and preparation process, which is applied in the direction of manufacturing tools, sheet pile walls, foundation structure engineering, etc. It can solve the problems of derailment of foundation environment, heavy weight, uncontrollable settlement, etc., and achieve the effect of increasing anchorage strength and improving settlement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

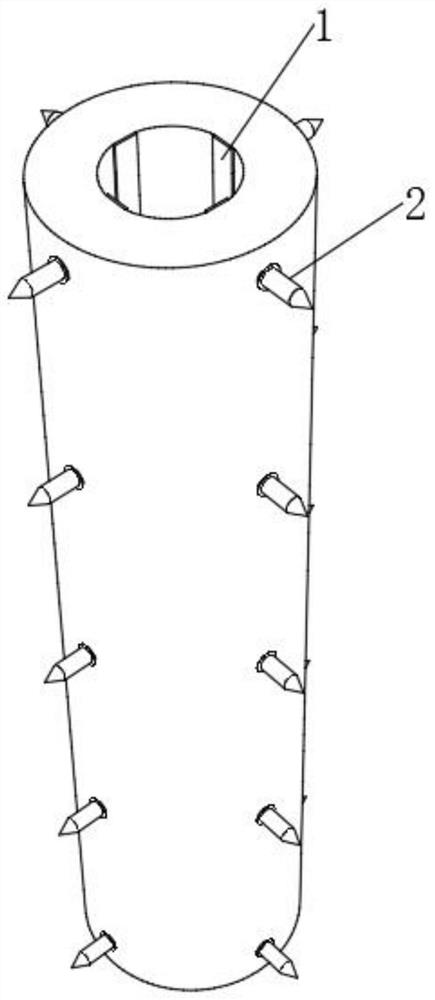

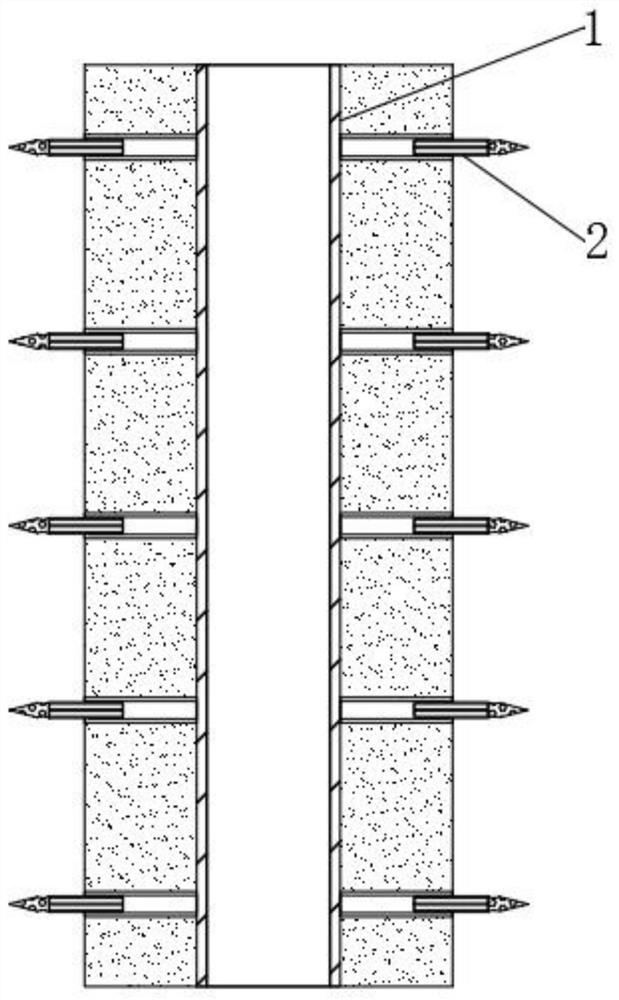

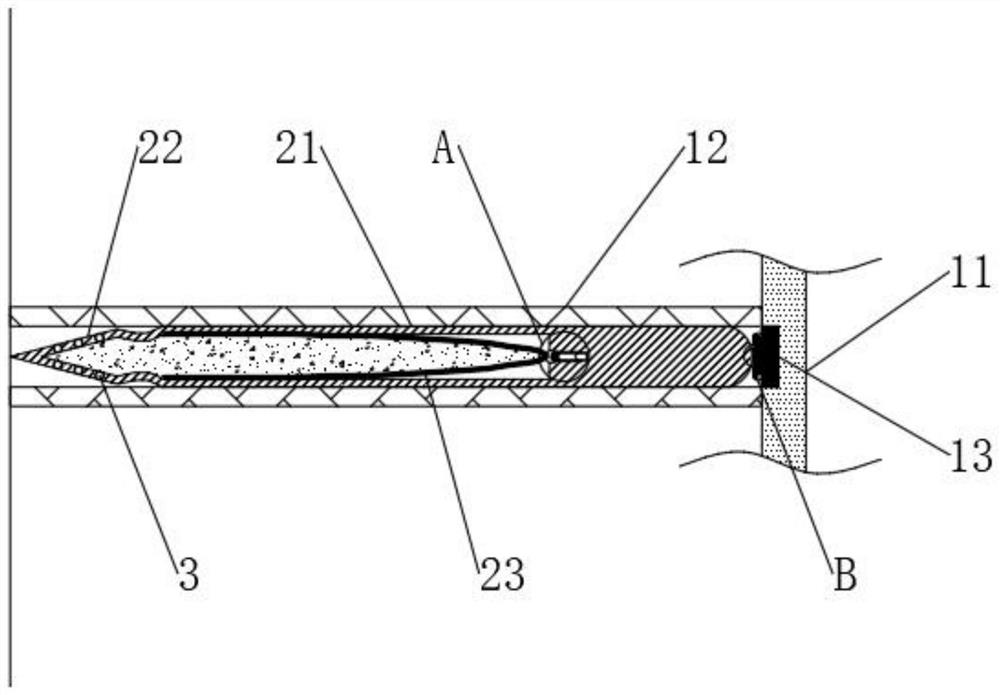

[0043] see Figure 1-2 , a preparation process of anti-settling prestressed concrete pipe piles, comprising the following steps:

[0044] S1. After tying the reinforcement cage, weld the magnetic pushing grid 1 along the designated position, and then put it into the pipe pile mold;

[0045] S2. Weighing appropriate raw materials for pre-mixing, and pouring into the pipe pile mold, stretching the fabric, and applying prestress;

[0046] S3. Concrete is centrifugally formed by a concrete pipe pile centrifuge, and the pipe pile mold is placed in a steam curing tank for atmospheric pressure steam curing;

[0047] S4. After the steam curing, take out the pipe pile mold and remove the mold, and install the magnetic migration anchor rod 2 on the magnetic pushing grid 1, and then naturally water and maintain for 3-10 days;

[0048] S5. After sinking the pile, the magnetic pushing grid 1 is heated to force the magnetic migration anchor rod 2 to shrink and trigger the anchoring action...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com