CFG pile composite foundation construction technology

A technology of composite foundation and construction technology, which is applied in the direction of foundation structure engineering, sheet pile walls, buildings, etc., can solve the problems of low construction efficiency and achieve the effects of accelerating construction efficiency, high supporting strength, and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present application is described in further detail below.

[0053] A kind of CFG pile composite foundation construction technique, comprises the steps:

[0054] Step 1: Excavate the site. Excavate the site to a point 1.2m above the design elevation of the pile top, level and compact it.

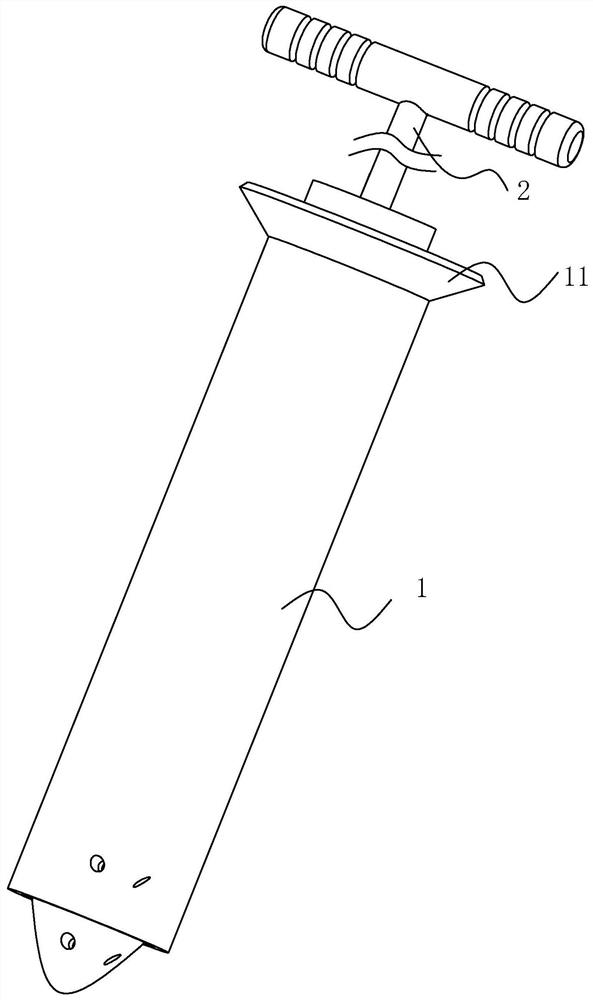

[0055] Step 2: Pile point positioning: Determine the position of the positioning pile, according to the pile position, spacing, and vertical beam designed in the foundation treatment diagram, guide and place the pile point of each pile from the two determined axis control points, and use the pile The point positioning tool drills and pours lime into the hole to mark the position of the pile point. After marking the pile point with white ash, a positioning rod for aligning the drill pipe is inserted into the white ash. The positioning rod in this embodiment can be selected from bamboo. chopsticks.

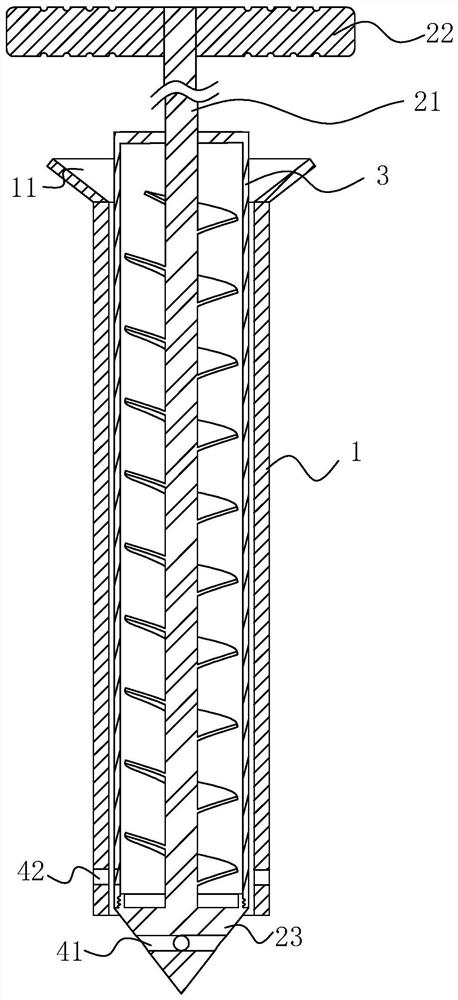

[0056] Step 3: Drilling operation is carried out with a drilling rig. Mark 20m, 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com