Surface treatment process of copper foil for high-Tg halogen-free plate

A surface treatment, halogen-free technology, applied in anodizing and other directions, can solve problems such as low Tg CTE, reduced bonding force of substrate resin to copper foil, etc., and achieve good oxidation resistance, high peel strength and corrosion resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

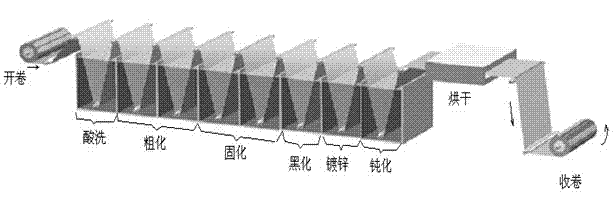

[0055] A surface treatment process of copper foil for high Tg, halogen-free boards, the specific treatment conditions are as follows:

[0056] (1), pickling: H 2 SO 4 150 g / L, temperature 35 ℃, treatment time 4s.

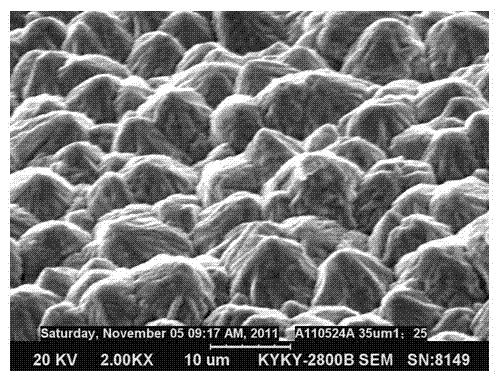

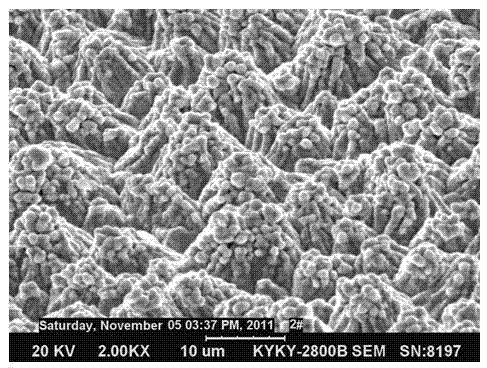

[0057] (2), coarsening: Cu 2+ 18g / L,H 2 SO 4 120g / L, additive T 55 mg / L, temperature 25°C, current density 25A / dm 2 , the processing time is 6.2s.

[0058] (3), curing: Cu 2+ 55g / L,H 2 SO 4 80g / L, temperature 43℃, current density 35A / dm 2 , the processing time is 8s.

[0059] (4), blackening: Ni 2+ 0.8g / L, Zn 2+ 0.25g / L, potassium pyrophosphate 40g / L, temperature 45°C, current density 2.5A / dm 2 , the processing time is 1.5s.

[0060] (5), galvanized: Zn 2+ 5 g / L, K 4 P 2 o 7 80g / L, pH 9.2, temperature 35℃, current density 1.2 A / dm 2 ; Processing time 3s.

[0061] (6), passivation: Cr 3+ 2.0g / L, Zn 2+ 1.4 g / L, Na 2 SO 4 25 g / L, additive P 0.6 g / L, pH 4.5, temperature 28°C, current density 3.0A / dm 2 , the process...

Embodiment 2

[0065] (1), pickling: H 2 SO 4 100 g / L, temperature 25°C, treatment time 4s.

[0066] (2), coarsening: Cu 2+ 10g / L,H 2 SO 4 80g / L, additive T 5 mg / L, temperature 20°C, current density 20A / dm 2 , the processing time is 2s.

[0067] (3), curing: Cu 2+ 40g / L, H 2 SO 460g / L, temperature 40℃, current density 20A / dm 2 , the processing time is 8s.

[0068] (4), blackening: Ni 2+ 0.1g / L, Zn 2+ 0.05g / L, potassium pyrophosphate 20g / L, temperature 20°C, current density 0.5A / dm 2 , the processing time is 0.5s.

[0069] (5), galvanized: Zn 2+ 1 g / L, K 4 P 2 o 7 50g / L, PH 8, temperature 25℃, current density 0.5 A / dm 2 ; Processing time 0.5s.

[0070] (6), passivation: Cr 3+ 1.0g / L, Zn 2+ 0.5 g / L, Na 2 SO 4 20 g / L, additive P 0.2 g / L, pH 4, temperature 25°C, current density 2.0A / dm 2 , the processing time is 4s.

[0071] (7) Silane treatment: epoxy silane coupling agent 0.2%, tetraethoxysilane (TEOS) 0.4%, pH 5.0, temperature 25°C, treatm...

Embodiment 3

[0074] (1), pickling: H 2 SO 4 200 g / L, temperature 40°C, treatment time 5s.

[0075] (2), coarsening: Cu 2+ 25g / L,H 2 SO 4 220g / L, additive T 150 mg / L, temperature 35°C, current density 50A / dm 2 , the processing time is 15s.

[0076] (3), curing: Cu 2+ 75g / L, H 2 SO 4 150g / L, temperature 65℃, current density 50A / dm 2 , the processing time is 25s.

[0077] (4), blackening: Ni 2+ 2.5g / L, Zn 2+ 1.5g / L, potassium pyrophosphate 100g / L, temperature 55°C, current density 10A / dm 2 , the processing time is 5s.

[0078] (5), galvanized: Zn 2+ 7 g / L, K 4 P 2 o 7 180g / L, PH 11, temperature 50℃, current density 1.5 A / dm 2 ; Processing time 5s.

[0079] (6), passivation: Cr 3+ 3.0g / L, Zn 2+ 2 g / L, Na 2 SO 4 30 g / L, additive P 1 g / L, pH 5, temperature 30°C, current density 4.5A / dm 2 , the processing time is 5s.

[0080] (7) Silane treatment: epoxy silane coupling agent 0.4%, tetraethoxysilane (TEOS) 0.6%, pH 6.0, temperature 30°C, trea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness of matte surface | aaaaa | aaaaa |

| Peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com