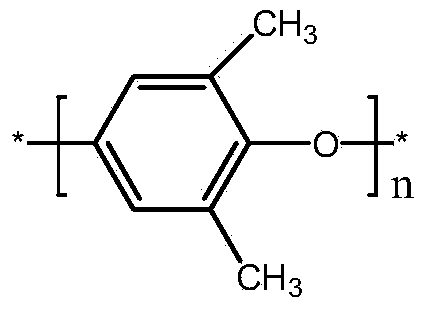

Thermosetting resin composition and use thereof

A resin composition, thermosetting technology, applied in the direction of synthetic resin layered products, layered products, metal layered products, etc., can solve the problems of poor production and processing stability, toughness, heat resistance, weak dielectric properties, and dielectric properties. and poor mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

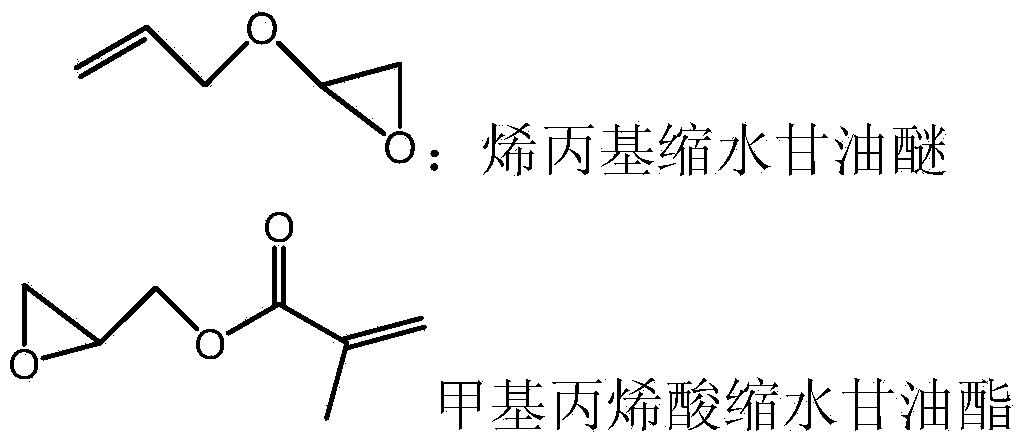

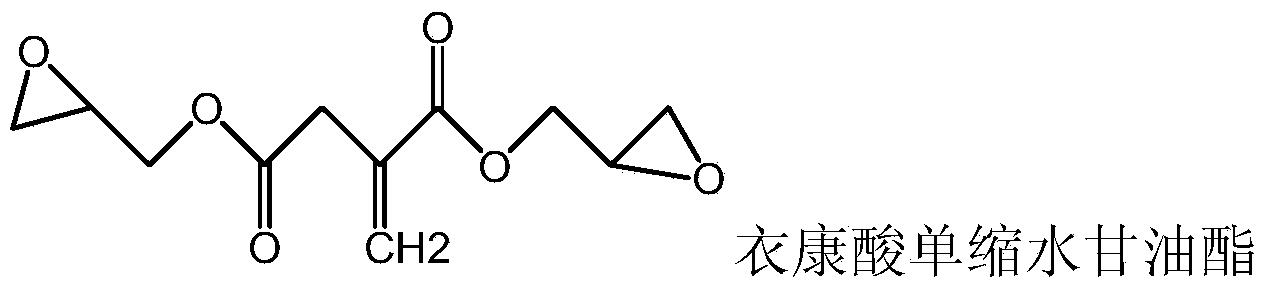

Method used

Image

Examples

Embodiment 1

[0095] 70 parts of methacrylic acid-terminated polyphenylene ether resin (SABIC, trade name: SA9000), 28 parts of tetrabromobisphenol A epoxy resin (Changchun Artificial Resin Factory, BEB400), 12 parts of anhydride curing agent styrene- Maleic anhydride copolymer (Sartomer, SMA EF40), 3 parts cumene peroxide DCP and 70 parts toluene were mixed and stirred until completely dissolved. 0.2 parts of 2-ethyl-4-methylimidazole was dissolved in 10 parts of butanone, and then added to the above solution. The above composition is fully stirred at room temperature to obtain a uniformly dispersed resin composition. The resin composition was impregnated into NE-type glass fiber cloth (Nittobo Co., Ltd., NEA2116), and dried at 155°C for 2-10 minutes to remove the solvent to obtain a prepreg with a resin content of about 55%.

[0096] A 1Oz copper foil is coated on both sides of eight overlapping prepregs, and hot-pressed at a temperature of 200°C and a pressure of 3.0MPa for 90min to obt...

Embodiment 2

[0098] 30 parts of methacrylic acid-terminated polyphenylene ether resin (SABIC, trade name: SA9000), 53 parts of acetone solution of brominated bisphenol A type epoxy resin (Dow Chemical, D.E.R.530A80, solid content 80wt%), 5 parts of tetrabromobisphenol A epoxy resin (Changchun Artificial Resin Factory, BEB350), 22 parts of biphenyl phenolic resin (Nippon Meiwa Chemical Co., Ltd., MEH-7851H), 0.05 parts of 2-ethyl-4 methylimidazole, 1.3 parts Mix cumene peroxide DCP and 60 parts toluene and dissolve completely. The above composition is fully stirred at room temperature to obtain a uniformly dispersed resin composition. The resin composition was impregnated into NE-type glass fiber cloth (Nittobo Co., Ltd., NEA2116), and dried at 155°C for 2-10 minutes to remove the solvent to obtain a prepreg with a resin content of about 55%.

[0099] A 1Oz copper foil is coated on both sides of eight overlapping prepregs, and hot-pressed at a temperature of 190°C and a pressure of 3.0MP...

Embodiment 3

[0101] 70 parts of methacrylic acid-terminated polyphenylene ether resin (SABIC, trade name: SA9000), 28 parts of tetrabromobisphenol A epoxy resin (Changchun Artificial Resin Factory, BEB400), 12 parts of anhydride curing agent styrene- Maleic anhydride copolymer (Sartomer, SMA EF40), 10 parts of 2,6-glycidylphenyl allyl ether (commercially available reagent), 3 parts of cumene peroxide DCP and 70 parts of toluene were mixed and completely dissolved . 0.2 parts of 2-ethyl-4-methylimidazole was dissolved in 10 parts of butanone, and then added to the above solution. The above composition is fully stirred at room temperature to obtain a uniformly dispersed resin composition. The resin composition was impregnated into NE-type glass fiber cloth (Nittobo Co., Ltd., NEA2116), and dried at 155°C for 2-10 minutes to remove the solvent to obtain a prepreg with a resin content of about 55%.

[0102] A 1Oz copper foil is coated on both sides of eight overlapping prepregs, and hot-pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com