Polytetrafluoroethylene composite membrane and preparation method thereof

A technology of polytetrafluoroethylene and polytetrafluoroethylene layer, which is applied in the field of composite film and its preparation, can solve the problems of limiting the application range of composite film, low peeling strength of composite film, short service life, etc., and achieves high viscosity and increased use The effect of life and increase in peel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

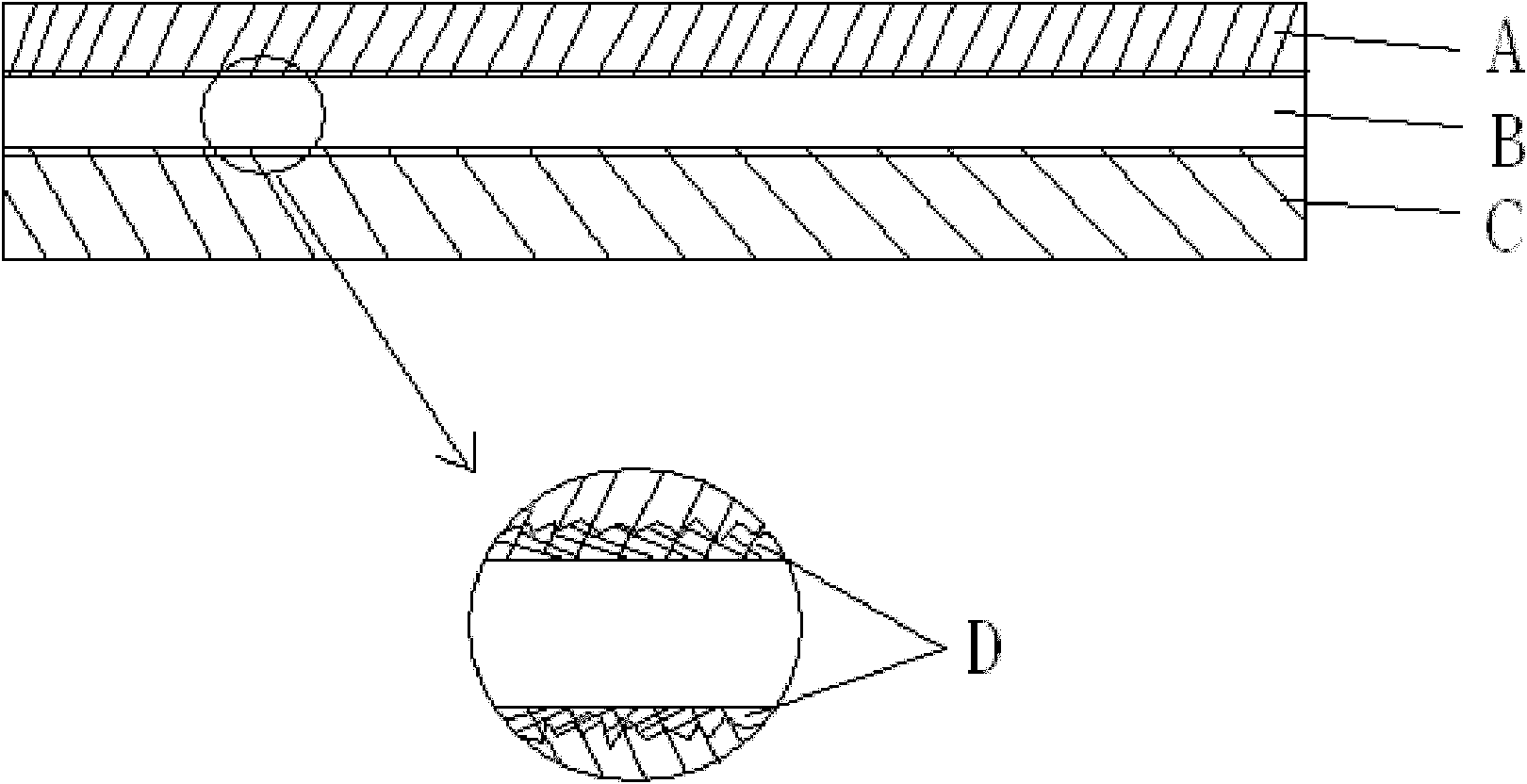

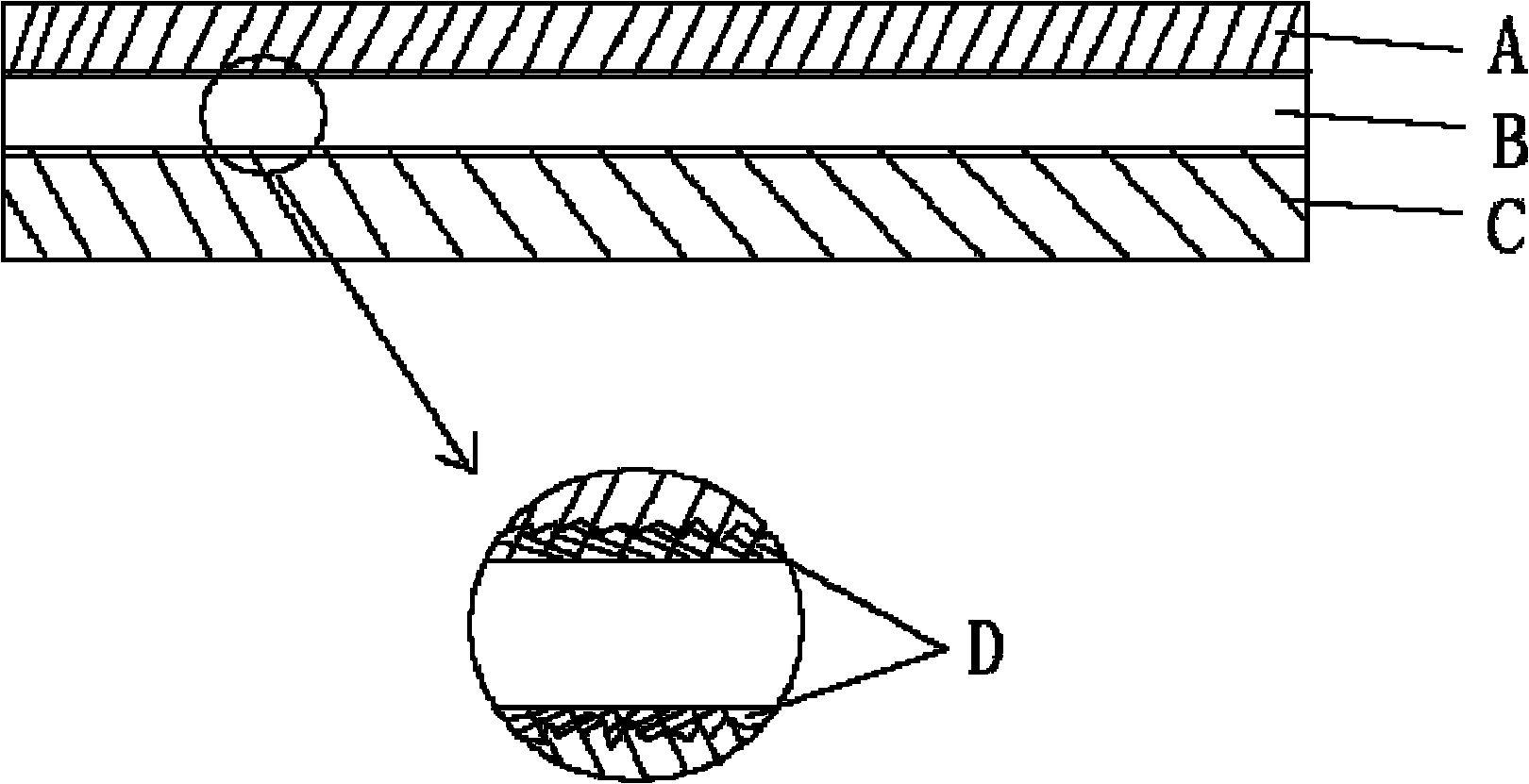

[0045] The present invention also provides a preparation method of a polytetrafluoroethylene composite membrane, comprising: a) dissolving a porous polymer and an additive in a solvent to prepare a polymer solution; the weight ratio of the porous polymer, solvent, and additive is 15 ~20:10~15:50~70;

[0046] b) providing a support layer and a polytetrafluoroethylene layer;

[0047] c) coating the polymer solution on the surface of the support layer, and compounding the polytetrafluoroethylene layer on the surface to obtain a nascent film

[0048] d) immersing the nascent film prepared in c) in a gel bath, and solidifying the polymer solution to form an adhesive layer to obtain a polytetrafluoroethylene composite film.

[0049] According to the present invention, the porous polymer and the additive are dissolved in a solvent to obtain a polymer solution. Due to the high viscosity of the polymer solution, defoaming treatment is preferably performed on it, and the treatment time...

Embodiment 1

[0059] Dissolve 20g of polysulfone and 10g of polyvinylpyrrolidone in 50g of dimethylacetamide to form a polymer solution. After the polymer solution was allowed to stand for defoaming for 24 hours, the polymer solution was cast onto a polyethylene terephthalate non-woven support layer, and the film was scraped with a scraper with a gap of 10-20 μm between the scrapers. Spread the porous vinyl fluoride film on the surface of the scraped adhesive layer solution, flatten it with a round roller, immediately immerse it in water at 40°C for curing, and after 2 minutes, wash it in water at 70°C for 3 minutes, take it out and dry it to obtain polytetrafluoroethylene porous composite membrane. The polytetrafluoroethylene composite membrane was subjected to gas flux detection and peel strength detection.

[0060] Gas flux detection:

[0061] When the air relative humidity is 50%, the gas flux detection of the polytetrafluoroethylene composite membrane prepared by using a gas permeati...

Embodiment 2

[0067] Dissolve 15g of polyethersulfone, 5g of polyethylene glycol and 10g of polyvinylpyrrolidone in 50g of dimethylformamide to form a polymer solution. After the polymer solution was allowed to stand for defoaming for 24 hours, the polymer solution was cast onto a polyethylene terephthalate non-woven support layer, and the film was scraped with a scraper with a gap of 10-20 μm between the scrapers. Spread the porous vinyl fluoride film on the surface of the scraped adhesive layer solution, flatten it with a round roller, immediately immerse it in water at 40°C for curing, and after 2 minutes, wash it in water at 60°C for 3 minutes, take it out and dry it to obtain polytetrafluoroethylene porous composite membrane. The polytetrafluoroethylene composite membrane was subjected to gas flux detection and peel strength detection.

[0068] According to the method of Example 1, the polytetrafluoroethylene composite membrane prepared in Example 2 is tested for gas flux, peel streng...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Peel force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com