Process for sealing port of metal pipe

A metal tube and port technology, which is applied to the sealing field of metal tube ports, can solve the problems of low qualification rate and low processing efficiency, and achieve the effects of high qualification rate, high processing efficiency and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

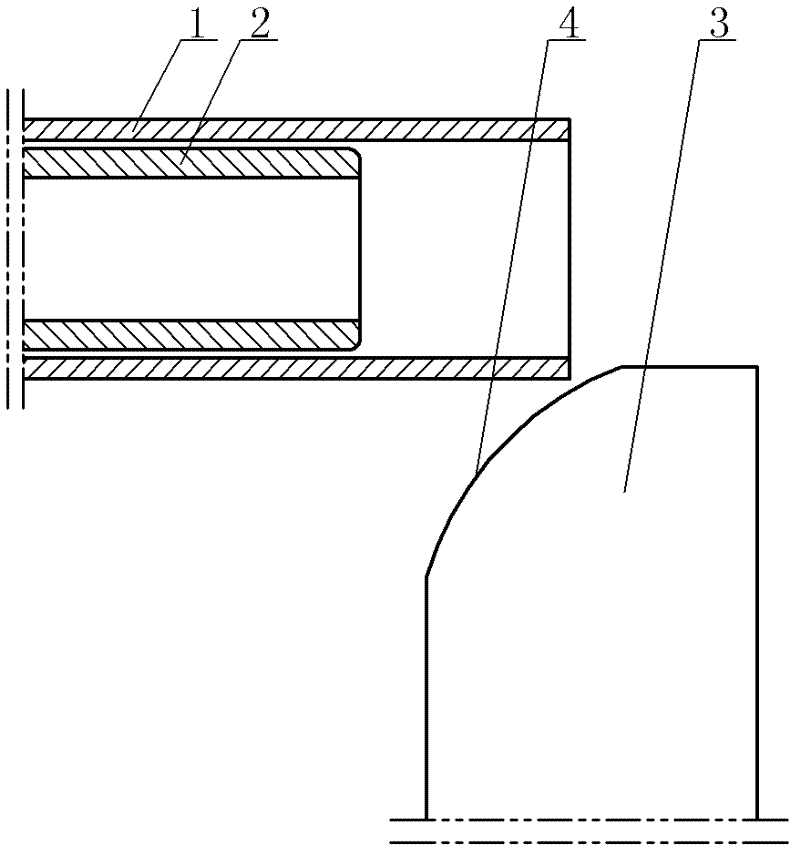

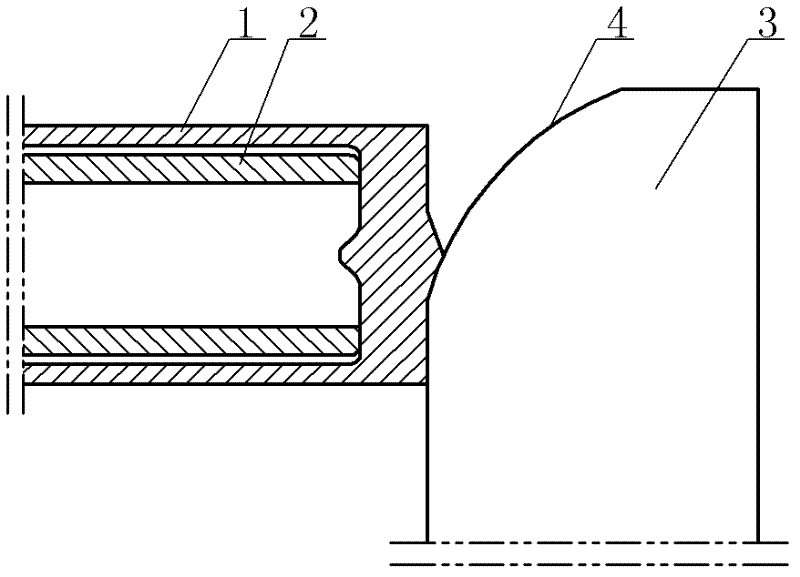

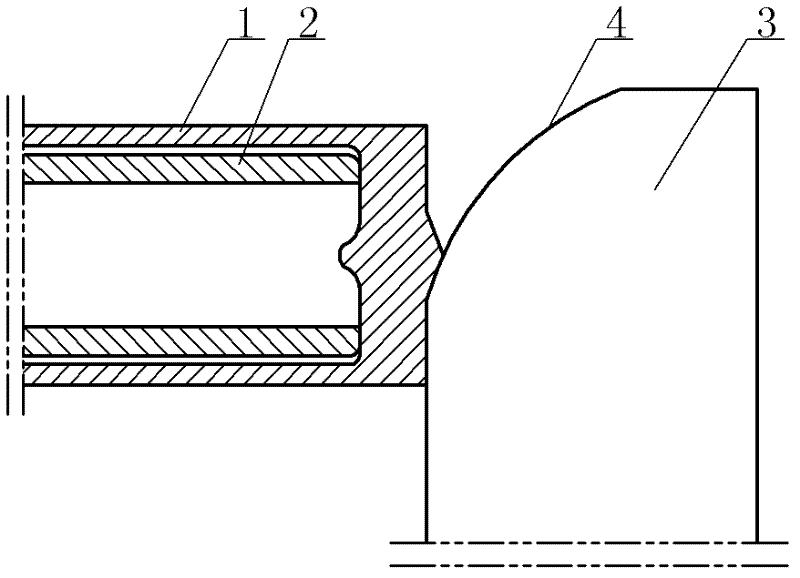

[0016] The present invention will be further described below in conjunction with accompanying drawing:

[0017] Depend on figure 1 to combine figure 2 As shown, the sealing process steps of the metal pipe port are as follows:

[0018] a. The metal pipe 1 is clamped in the elastic collet that can rotate on the machine tool, and a positioning part 2 is inserted into the elastic collet. The metal pipe 1 is set outside the positioning part 2. There is a certain distance between the end faces of the metal pipe 1;

[0019] b. Adopting the edgeless cutter 3 with the extruding surface 4 at the end, the extruding surface 4 can make the port of the metal pipe 1 gradually deform towards its center, and utilize the edgeless cutter 3 to extrude the metal pipe 1 rotating at high speed The heat generated by the friction between the port of the metal tube 1 and the edgeless tool 3 softens the port of the metal tube 1, and the port of the metal tube 1 slowly gathers towards the center, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com