Large displacement corrugated pipe

A corrugated pipe and large displacement technology, applied in the direction of hoses, pipes, pipes/pipe joints/pipe fittings, etc., can solve the problems of easy leakage, complicated manufacturing process, and many materials, so that it is not easy to leak, the manufacturing process is simple, and the process simple effect

Inactive Publication Date: 2008-01-30

沈阳东韩波纹管有限公司

View PDF0 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] Compared with the formed bellows, the advantage of welded bellows is that the amount of compression (that is, the displacement) is large, up to 70%.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

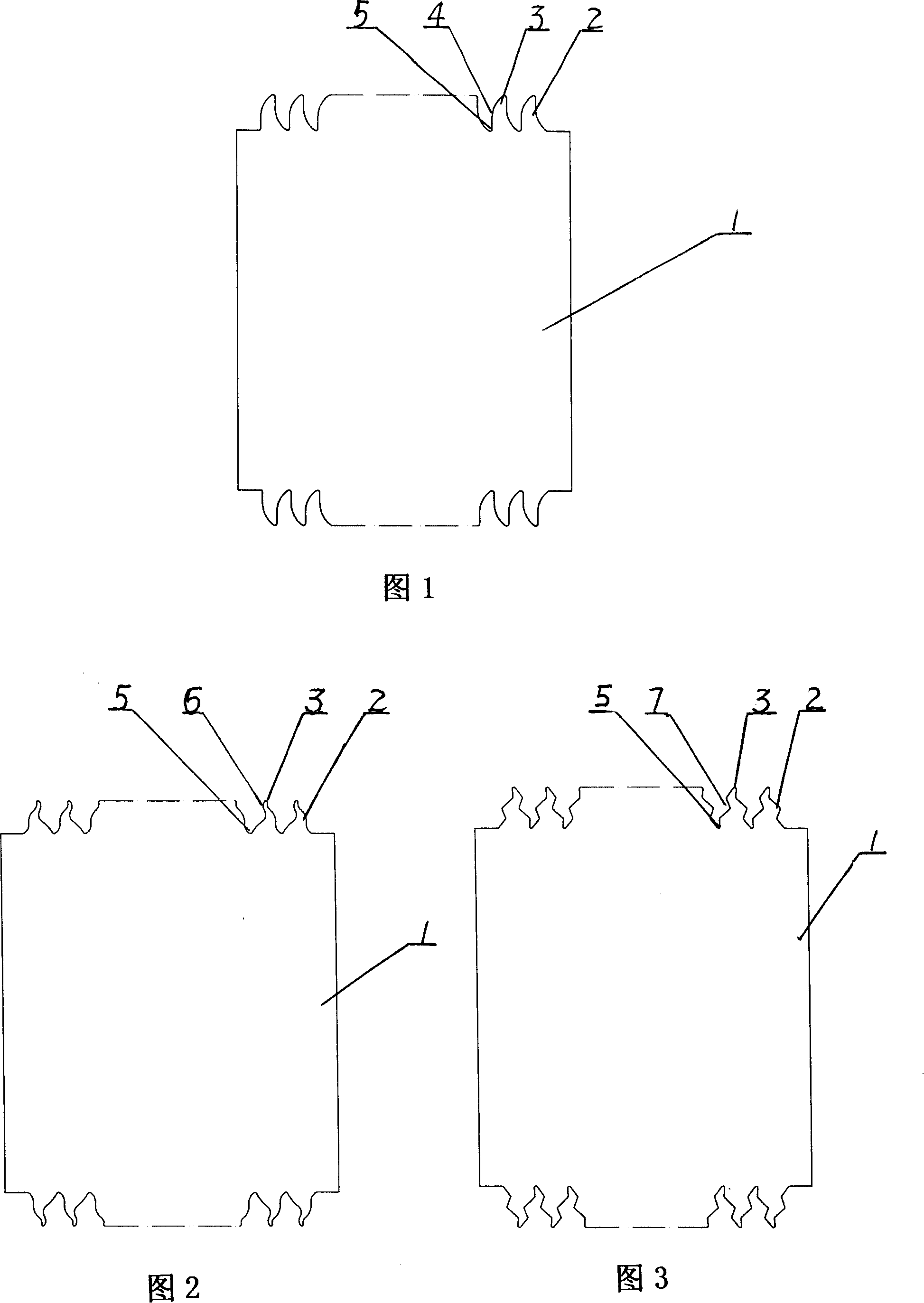

[0017] The present invention includes a corrugated pipe 1. The corrugated pipe 1 is provided with an annular surface 2 with the same shape and along the same direction. The top and bottom ends of the annular surface 2 are connected by rounded corners 3 and 5.

[0018] The torus 2 may be arcuate 4 or sinusoidal 6 or triangular 7 .

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

A large displacement corrugated pipe relates to a modified corrugated pipe structure. The invention provides a large displacement corrugated pipe with the advantages of a shaping corrugated pipe and a welding corrugated pipe. The invention comprises a corrugated pipe, the structure key points of which is that: the outside of the corrugated pipe is provided with a circular surface with the same shape and arranged in the same direction, and the top end and the bottom end of the circular are all connected by a round angle.

Description

Technical field: [0001] The present invention relates to the improvement of bellows structure. Background technique: [0002] At present, bellows are roughly divided into two types: one is formed bellows, and the other is welded bellows. Production of formed bellows: (1) The outside of the bellows is a corrugated mold, and then liquid pressure is formed inside the bellows; (2) Three rollers are set on the inside and outside of the bellows, and the three rollers are rolled and formed at the same time ; (3) A mechanical expansion mold is arranged in the bellows, and the expansion mold expands and presses outward wave by wave to form. The shape of the outer ring has three types: U-shape, V-shape, and Ω-shape. Another production of welded bellows: First, use a composite die to punch a plurality of arc-shaped, triangular, sinusoidal, etc. ring pieces on the metal plate, and then weld multiple ring pieces inside and outside in the same direction into an integrated bellows. [0...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F16L11/15

Inventor 崔民秀

Owner 沈阳东韩波纹管有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com