Embossed photovoltaic welding band and processing method thereof

A photovoltaic ribbon and embossing technology, applied in the field of solar energy, can solve the problems of special-shaped metal wires falling off, difficult to arrange parallel and twisted special-shaped metal wires, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

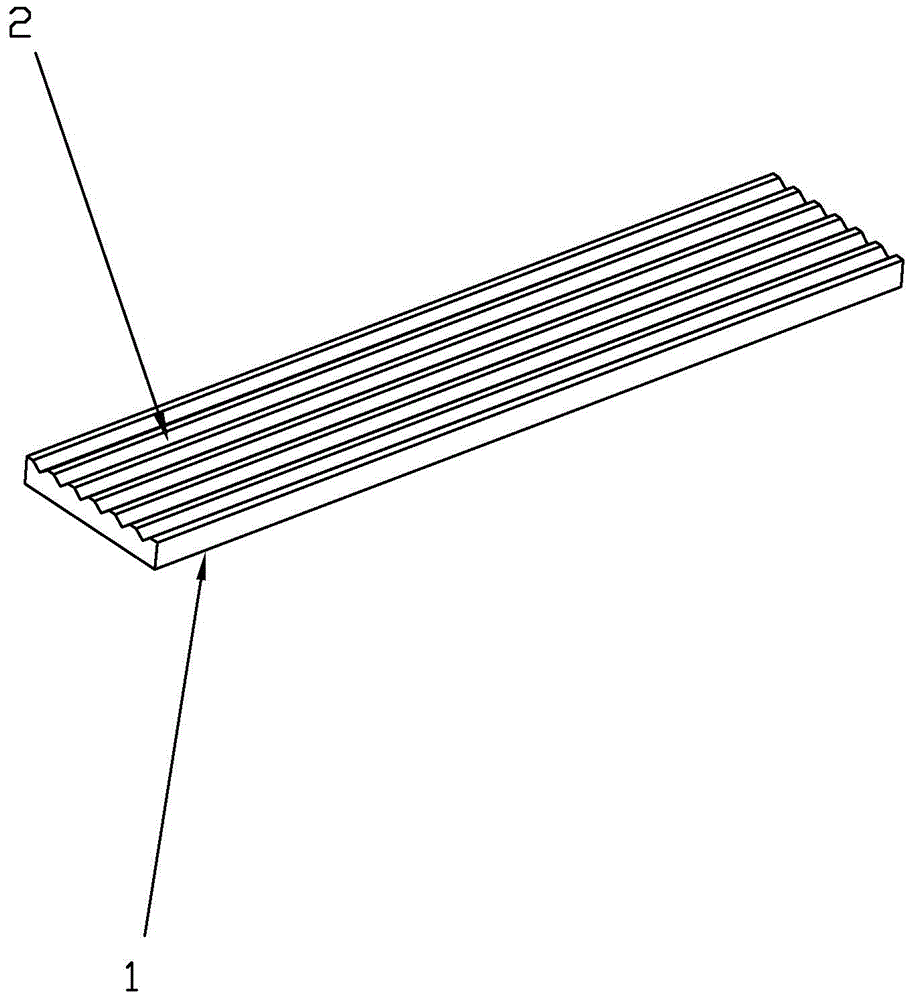

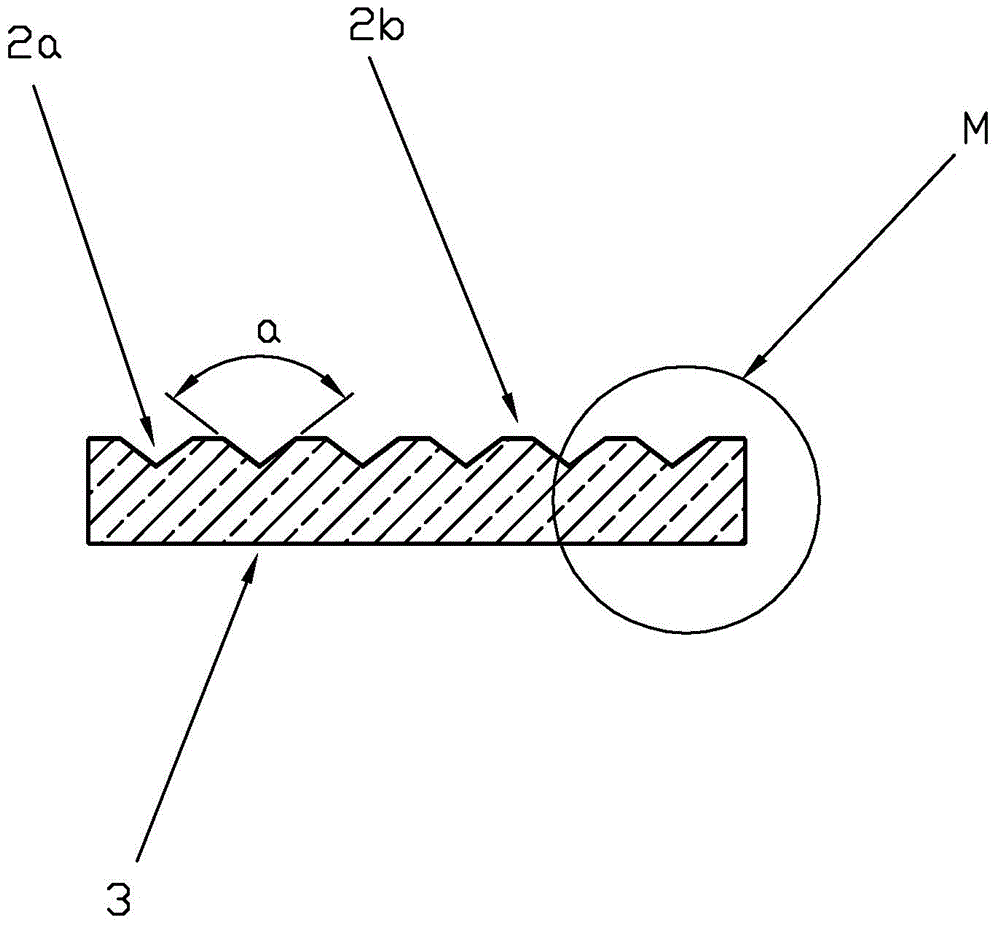

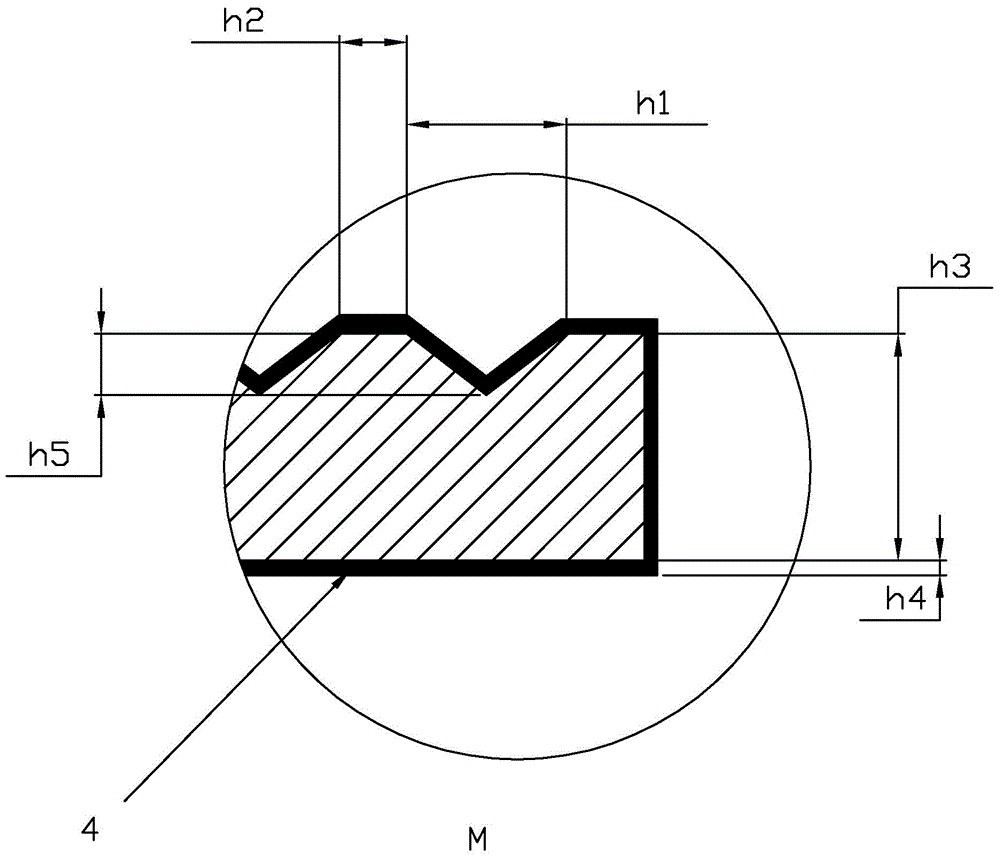

[0022] An embossed photovoltaic ribbon, comprising a conductive base tape 1, the conductive base tape 1 has a lower bonding surface 3 and an upper reflecting surface 2, the lower bonding surface 3 is a flat surface, and the upper reflecting surface 2 is distributed with reflecting grooves 2a, and the adjacent reflecting A coupling strip 2b is formed between the grooves 2a, the reflective groove 2a extends parallel to the length direction of the conductive base strip 1, the width h2 of the coupling strip is 0.2 to 0.4 times the width h1 of the top of the reflective groove, and the thickness h3 of the conductive base strip is 0.5mm- 1.0mm, and the depth h5 of the reflection groove is 0.1mm-0.2mm. If the width h2 of the coupling band is too large, it will affect the light reflected from the top of the reflective groove 2a, reducing the light utilization rate. If the width h2 of the coupling band is too small, there will be false welding and desoldering with the back electrode of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com