Bottom ring for submerged arc furnace and manufacturing method thereof

A manufacturing method and bottom ring technology, which can be used in manufacturing tools, furnaces, electric furnace heating, etc., can solve the problems of labor-consuming, time-consuming, poor manufacturability, and increase production costs, so as to reduce production costs, ensure quality, and extend service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

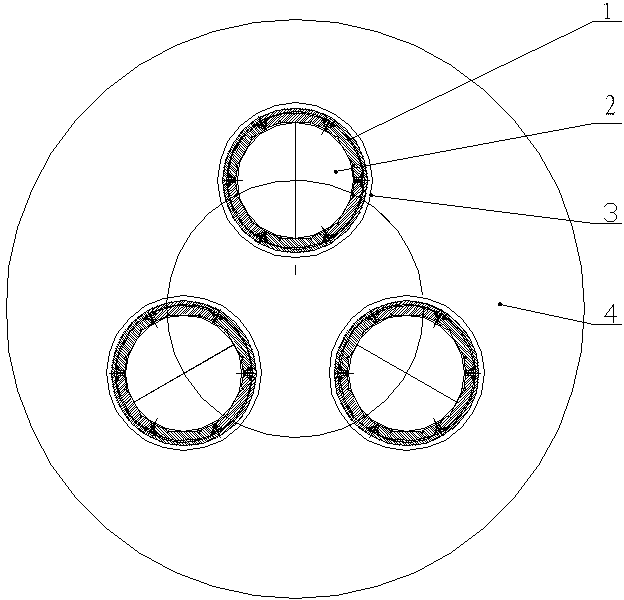

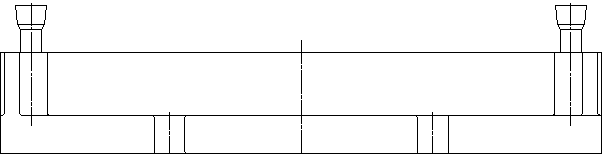

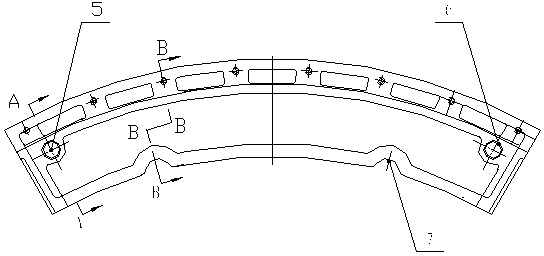

[0033] The bottom ring for the submerged arc furnace of the present invention is made of a closed metal shell with a cavity structure by integral casting, and specifically includes the bottom ring body 1. The cavity 11 is a water cooling chamber. Two ends of the main body 1 are provided with a water inlet 5 and a water outlet 6 , the cooling water enters through the water inlet 5 and flows out through the cavity 11 through the water outlet 6 . The upper end of the water inlet and outlet is extended section 12, and the extended section is made of the same material as the bottom ring body 1, and the joint part is threaded. Both ends of the bottom ring are provided with lugs 8 for installation and suspension, flanges 9 for sealing and fastening bolt holes 10 are provided on the top surface, and gaps 7 for the passage of electrode conductive fins are provided on the inner surface.

[0034] The bottom ring body 11 is connected by multiple pieces to form a circular ring around the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com