Cellular board and manufacturing method thereof

A technology of honeycomb panels and honeycombs, which is applied in the field of honeycomb panels and its preparation, which can solve the problems of complicated process of round tube honeycomb, complicated and laborious glue coating process, too much glue consumption, etc., and achieve good consistency, stable and reliable quality , the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

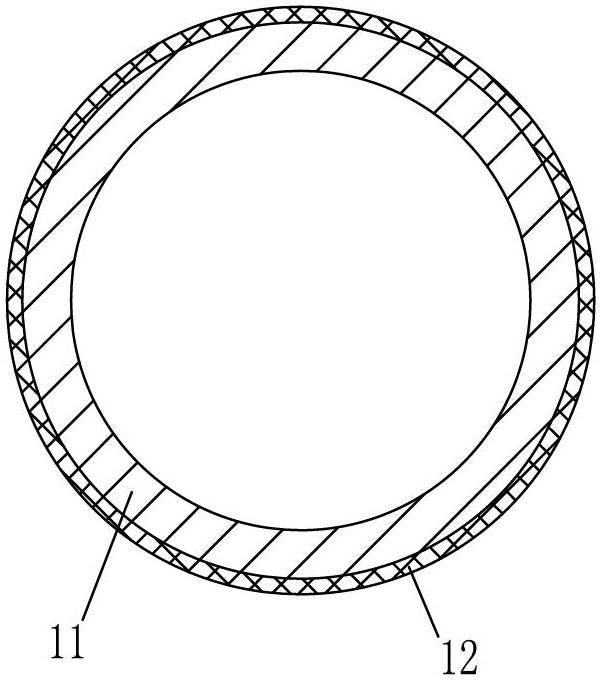

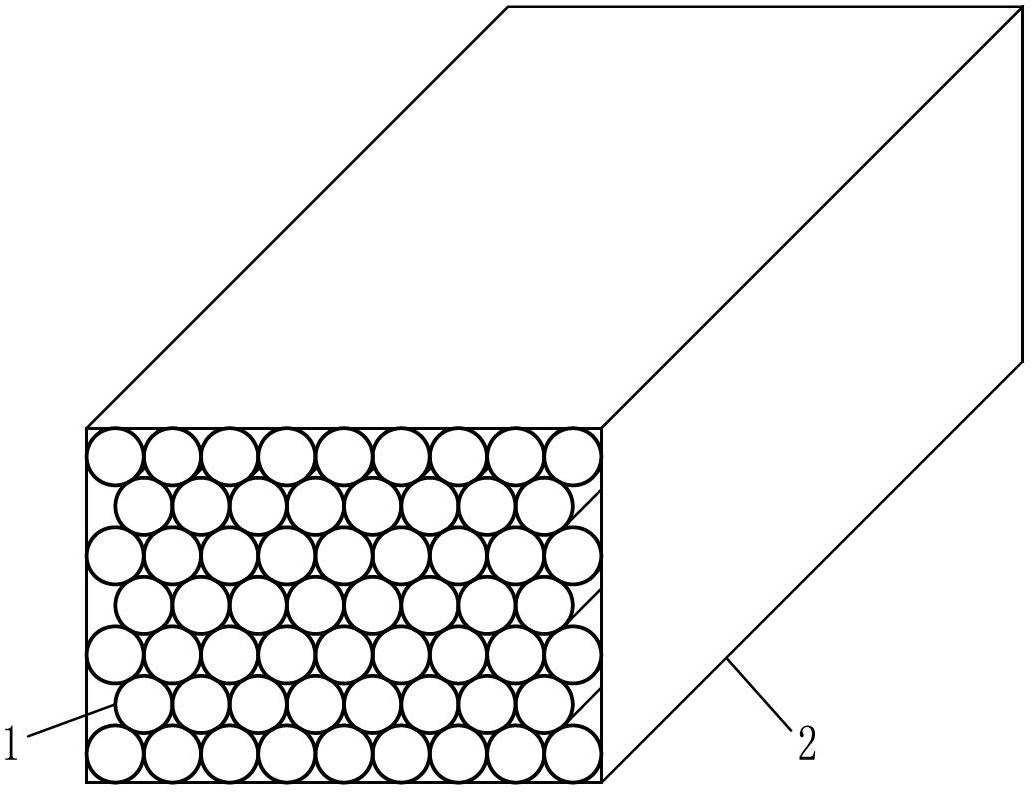

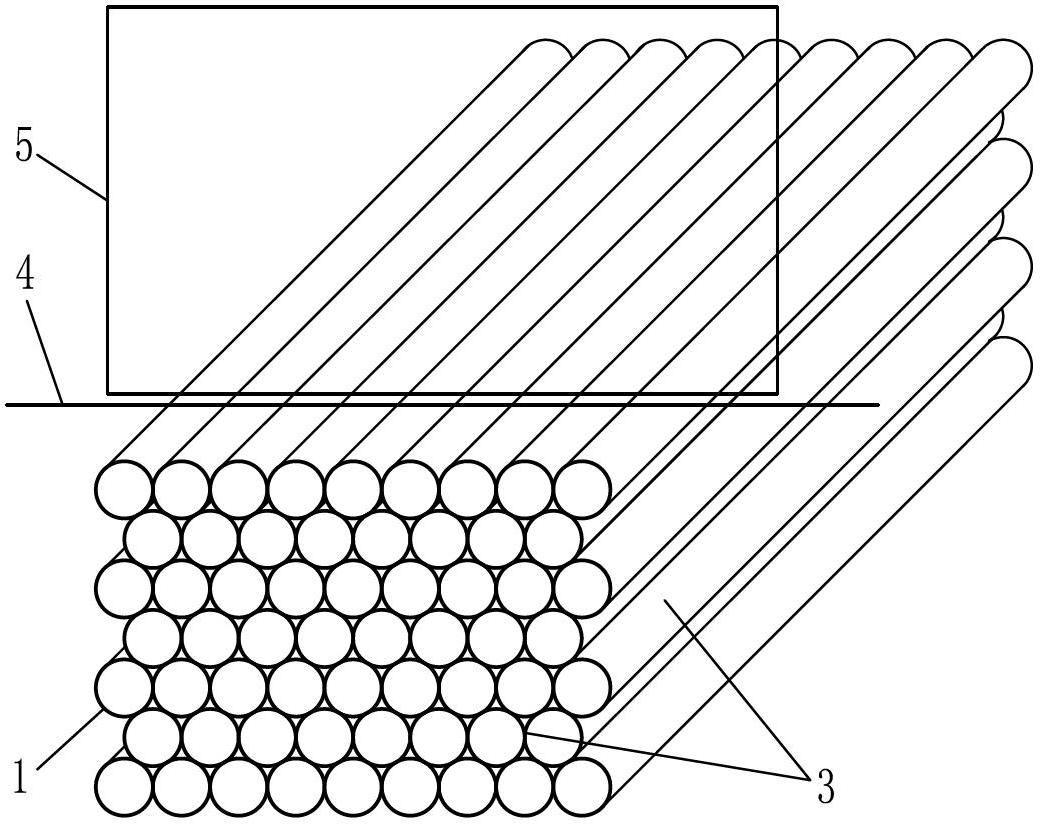

[0033] like Figure 4 , Image 6 A kind of honeycomb panel shown, comprises the honeycomb core material layer that is formed by a plurality of double-layer composite tubes 1 and the face material layer 9 that is compounded on the upper and lower surfaces of the core material, and the outer layer of the adjacent double-layer composite tube 1 12 are bonded together, and the end faces of the inner layers 11 of adjacent double-layer composite pipes 1 are fused to form glue bumps 71 . The thickness of the glioma 71 is 2 to 10 mm.

[0034] The preparation method of above-mentioned honeycomb plate, comprises the steps:

[0035] 1) Fabricate double-layer composite pipe 1, such as figure 1As shown, the inner layer of the double-layer composite pipe 1 is a high melting point material layer 11, and the outer layer of the double-layer composite pipe 1 is a low melting point material layer 12, and the melting point of the low melting point material layer 12 is lower than the melting poi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com