Vacuum plating UV cured primer

A technology of vacuum electroplating and ultraviolet light, which is applied in coatings, epoxy resin coatings, polyester coatings, etc., can solve the problems of poor chemical resistance, insufficient wear resistance, and low production efficiency, and achieve high gloss and volatile Sexually low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below with specific examples, but the present invention is not limited by the following examples.

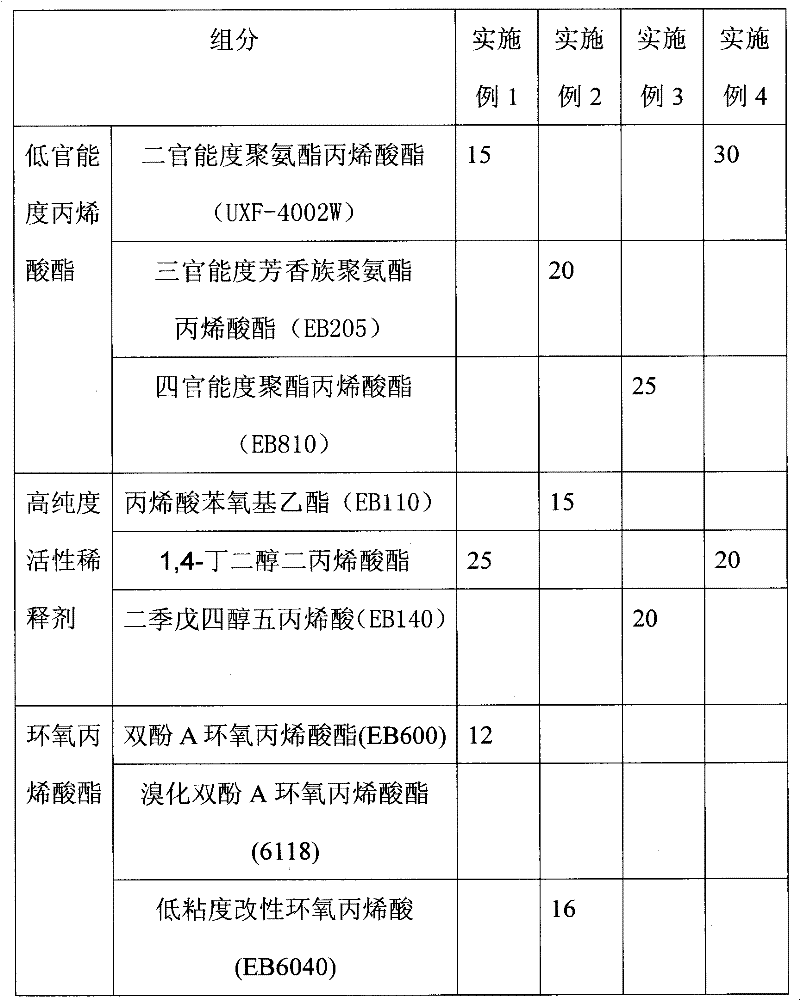

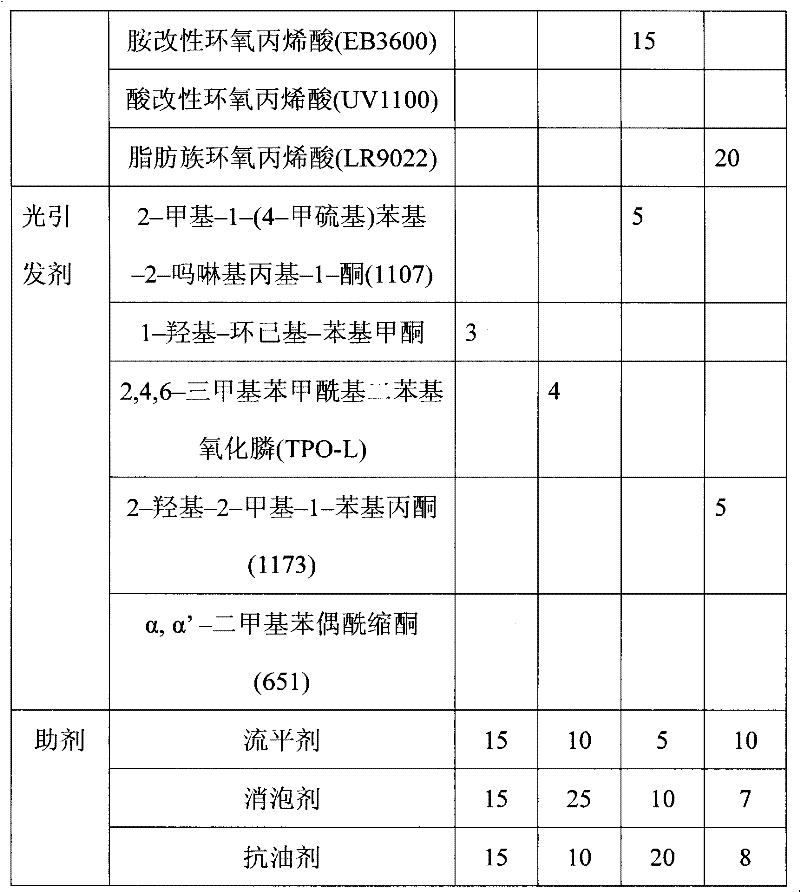

[0031] Embodiment 1~4 are as shown in table 1:

[0032]

[0033]

[0034] UXF-4002W is the brand name of difunctional polyurethane acrylate produced by Nippon Kayaku Co., Ltd.;

[0035] EB205 is the brand name of the trifunctional aromatic urethane acrylate produced by Ubixi Company;

[0036] EB810 is the brand name of the four-functionality polyester acrylate of Ubixi Company;

[0037] EB110 is the brand name of phenoxyethyl acrylate of Ubisil;

[0038] EB140 is the brand name of the dipentaerythritol pentaacrylic acid of Ubixi Company;

[0039] EB600 is the brand name of bisphenol A epoxy acrylate of Ubiscil;

[0040] 6118 is the trade name of brominated bisphenol A epoxy acrylate of Jiangsu Sanmu Chemical Co., Ltd.;

[0041] EB6040 is the brand name of low viscosity modified epoxy acrylate produced by Ubixi Com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com