Adhesive composition and adhesion layer

A composition and adhesive technology, applied in the field of pressure-sensitive adhesive composition and pressure-sensitive adhesive layer, can solve problems such as uneven coating, textured appearance, and formation of rubber blocks, and achieve good durability and good Coatability and effects of appropriate stretchability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

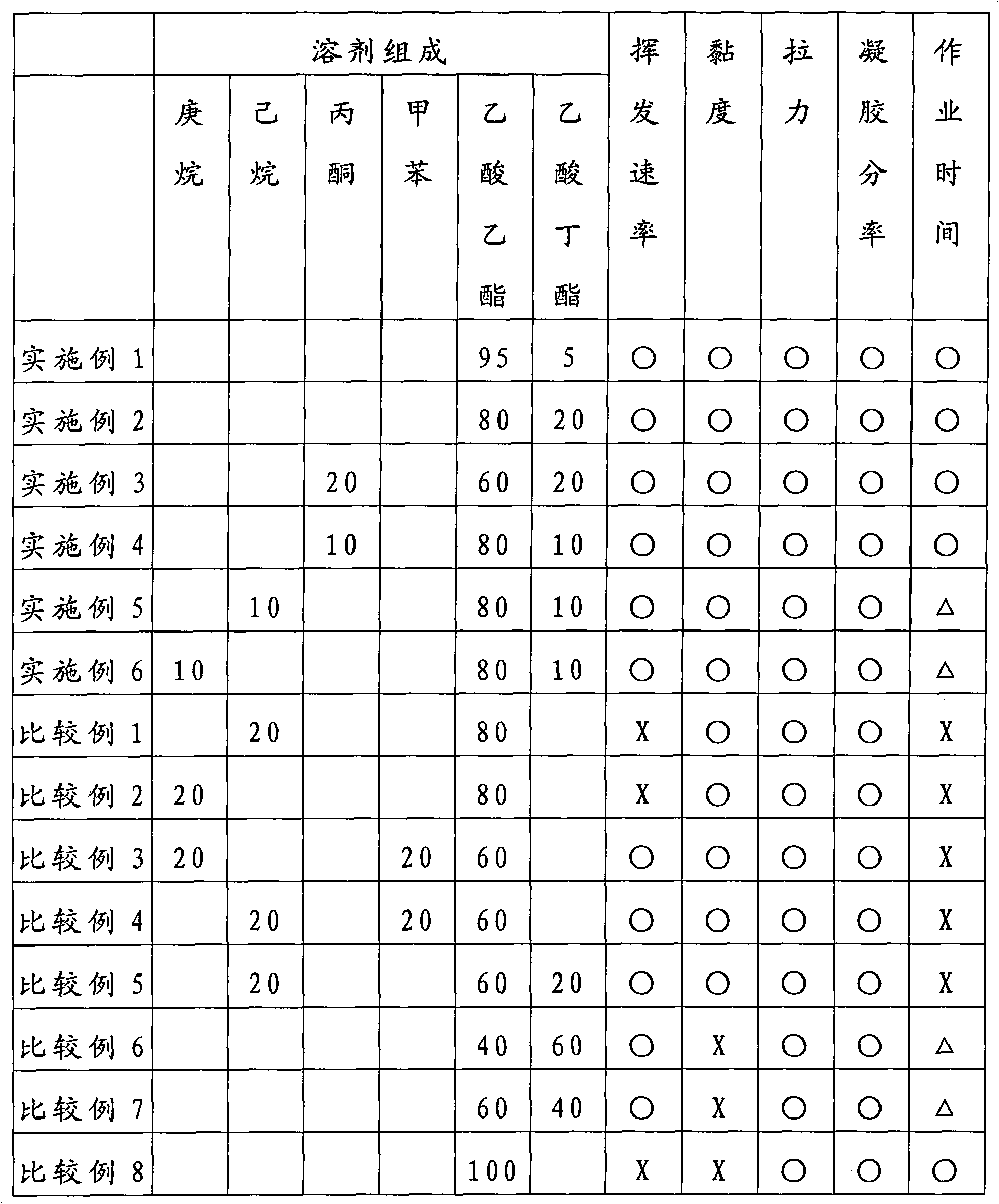

Embodiment 1

[0046] In the acrylate copolymer solution (1) of 130 parts by weight, add solvent: the ethyl acetate of 110 parts by weight and the butyl acetate of 10 parts by weight, and obtain the solid content accounted for ((0.35*130) / (130+120) ) = 18% (w / w) solution (2). At this moment, the weight of solvent ethyl acetate (110+130*(1-35%)): the weight of butyl acetate (10) is 95:5. With respect to the solid content of the acrylate copolymer in the solution (2) as 100 parts by weight, add 0.72 parts by weight of the isocyanate crosslinking agent (AD75, TDI series, the manufacturer is Superchimici S.P.A.), 0.72 parts by weight in the solution (2). The metal chelate cross-linking agent (CA190T, aluminum metal chelate, manufacturer is I-TAI Chemicals Inc.) of weight part and the silane coupling agent (GLYMO, epoxy silane series, manufacturer is I-TAI Chemicals Inc.) of 0.036 weight part Evonik (Degussa)), the adhesive composition was obtained after thorough mixing.

[0047] Coating the ad...

Embodiment 2

[0049] Similar to Example 1, wherein the solvents are changed to 80 parts by weight of ethyl acetate and 41 parts by weight of butyl acetate, so the weight of ethyl acetate: butyl acetate in this example is 80:20.

Embodiment 3

[0051] Similar to Example 1, the solvents were changed to 39 parts by weight of ethyl acetate, 41 parts by weight of butyl acetate and 41 parts by weight of acetone. The weight of this example acetone: the weight of ethyl acetate: the weight of butyl acetate is 20:60:20.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com