Process for fibrillating lignocellulosic material, fibres and their use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

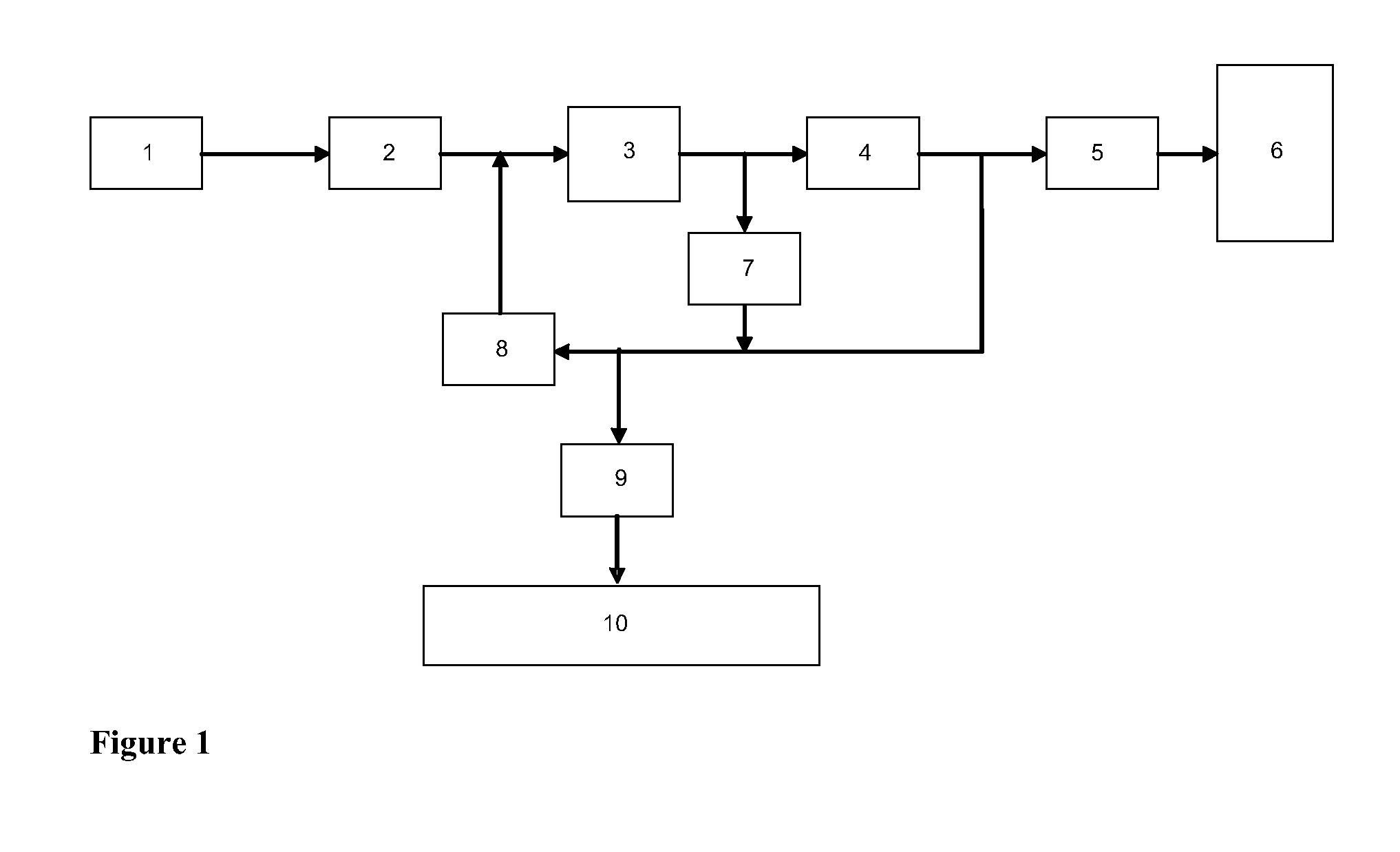

Method used

Image

Examples

example 1

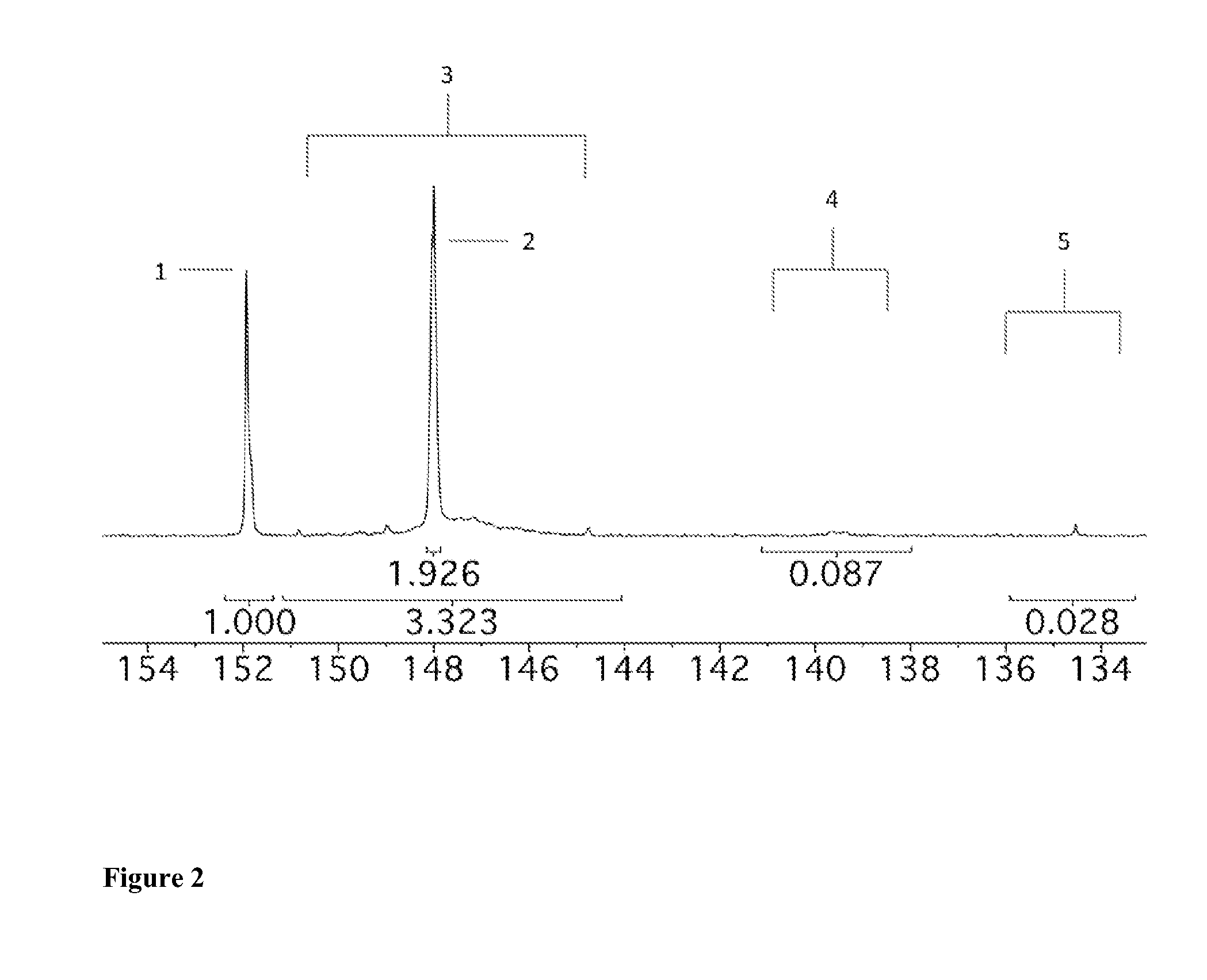

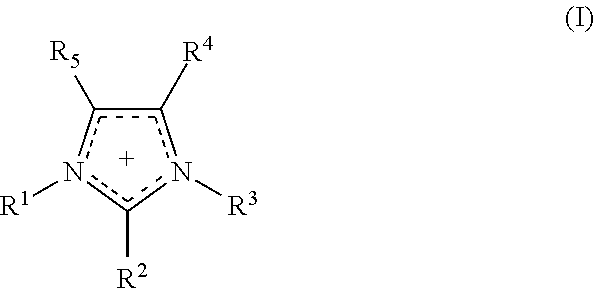

Preparation of 1-methyl-3-methylimidazolium dimethylphosphate ([mmim]Me2PO4)

[0070]A mixture of 1-methylimidazole (50 ml, 0.519 mol) was added over a space of 4 hrs to trimethylphosphate (60.7 ml, 0.519 mol) at 100° C., with stirring. The solution was heated at 100° C. for a further 18 hrs. The reaction of the mixture was determined to be complete by analyzing a sample by 1H NMR from CDCl3. The mixture was rotary evaporated under high vacuum for 18 hrs to give a pale yellow oily product (110 ml). The purity of the product was determined to be >99% by 1H NMR analysis.

example 2

Preparation of 1-ethyl-3-methylimidazolium dimethylphosphate ([emim]Me2PO4)

[0071]A mixture of 1-ethylimidazole (50 ml, 0.519 mol) was added over a space of 4 hrs to trimethylphosphate (60.7 ml, 0.519 mol) at 120° C. with stirring. The solution was heated at 120° C. for a further 18 hrs. The reaction of the mixture was determined to be complete by analyzing a sample by 1H NMR from CDCl3. The mixture was rotary evaporated under high vacuum for 18 hrs to give a pale yellow oily product (110 ml). The purity of the product was determined to be >99% by 1H NMR analysis.

example 3

Preparation of 1-ethyl-3-methylimidazolium methylhydrogenphosphonate ([emim]MeHPO3)

[0072]A mixture of 1-ethylimidazole (50 ml, 0.519 mol) was added over a space of 4 hrs to diethylphosphite (47.6 ml, 0.519 mol) at 140° C. with stirring. The solution was heated at 140° C. for a further 18 hrs. The reaction of the mixture was determined to be complete by analyzing a sample by 1H NMR from CDCl3. The mixture was rotary evaporated under high vacuum for 18 hrs to give a pale yellow oily product (97 ml). The purity of the product was determined to be >99% by 1H NMR analysis.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Responsivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com