Composite nano plastic hose and its making process

A technology of nano-plastics and hoses, which is applied in the direction of hoses, pipes, pipes/pipe joints/fittings, etc., to achieve the effects of good compatibility, low volatility, and good extraction resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

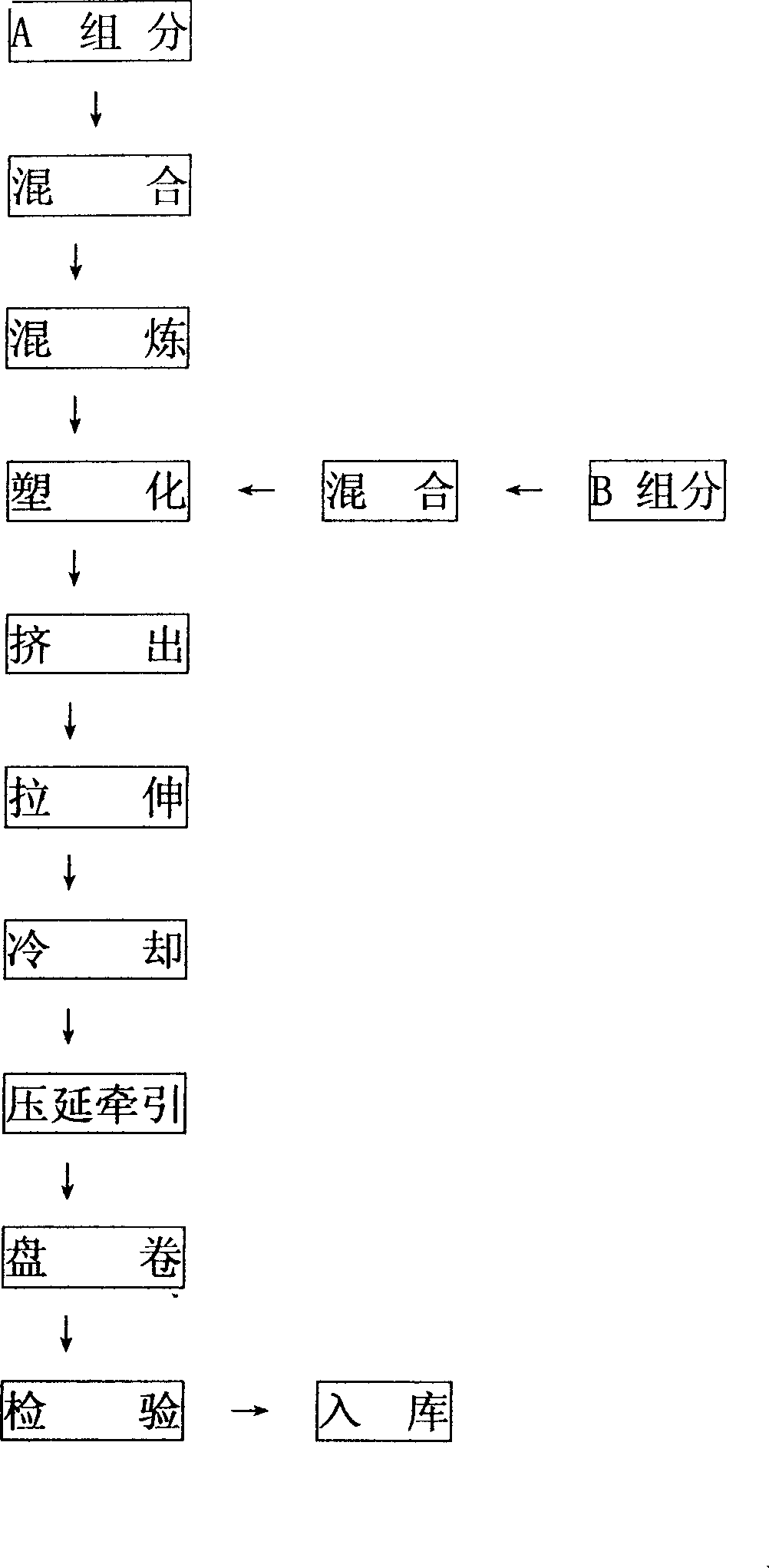

Method used

Image

Examples

Embodiment 1

[0027] Weigh the material according to the weight percentage of the formula:

[0028] Very low density polyethylene (VLDPE) 38;

[0029] Ultra-low density polyethylene (ULBPE) 44;

[0030] Ethylene-vinyl acetate copolymer (EVA) 4;

[0031] and the mixed

[0032] Nanoscale CaCO 3 4;

[0033] Nanoscale SiO 2 6;

[0034] Nanoscale TiO 2 3;

[0035] Put it into the plastic refining machine for mixing, and the mixing temperature is controlled at 180-200°C, and then mix the mixed materials with

[0036] Antioxidant 1010 0.1;

[0037] Antioxidant DSTP 0.35;

[0038] Light stabilizer UV-326 0.1;

[0039] Titanate coupling agent TTS 0.15;

[0041] Put it into the extruder, heat it in the temperature range of 90-160°C for 3-5 minutes to make it plasticized, then extrude, stretch, cool, calender, draw and shape with the die of the tube, and then coil and pack , become the product.

Embodiment 2

[0043] Weigh the material according to the weight percentage of the formula:

[0044] Very low density polyethylene (VLDPE) 35;

[0045] Ultra-low density polyethylene (ULBPE) 48;

[0046] Ethylene-vinyl acetate copolymer EVA 3;

[0047] and the mixed

[0048] Nanoscale CaCO 3 5;

[0049] Nanoscale SiO 2 5;

[0050] Nanoscale TiO 2 3;

[0051] Put it into the plastic refining machine for mixing, and the mixing temperature is controlled at 180-200°C, and then mix the mixed materials with

[0052] Antioxidant 1010 0.11;

[0053] Antioxidant DSTP 0.37;

[0054] Light stabilizer UV-326 0.1;

[0055] Titanate coupling agent TTS 0.13;

[0057] Put it into the extruder, heat it in the temperature range of 90-160°C for 3-5 minutes to make it plasticized, then extrude, stretch, cool, calender, draw and shape with the die of the tube, and then coil and pack , become the product....

Embodiment 3

[0059] Weigh the material according to the weight percentage of the formula:

[0060] Very low density polyethylene (VLDPE) 36;

[0061]Ultra-low density polyethylene (ULBPE) 47;

[0062] Ethylene-vinyl acetate copolymer EVA 3;

[0063] and the mixed

[0064] Nanoscale CaCO 3 4;

[0065] Nanoscale SiO 2 5;

[0066] Nanoscale TiO 2 4;

[0067] Put it into the plastic refining machine for mixing, and the mixing temperature is controlled at 180-200°C, and then mix the mixed materials with

[0068] Antioxidant 1010 0.09;

[0069] Antioxidant DSTP 0.34;

[0070] Light stabilizer UV-326 0.11;

[0071] Titanate coupling agent TTS 0.19;

[0072] Zinc stearate 0.27

[0073] Put it into the extruder, heat it in the temperature range of 90-160°C for 3-5 minutes to make it plasticized, then extrude, stretch, cool, calender, draw and shape with the die of the tube, and then coil and pack , become the product....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com