Vacuum-plating ultraviolet curing intermediate paint

A technology of vacuum electroplating and ultraviolet light, applied in the direction of coating, etc., can solve the problems of poor chemical resistance, low production efficiency, insufficient wear resistance, etc., and achieve the effect of low volatility, beautiful appearance and enhanced adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

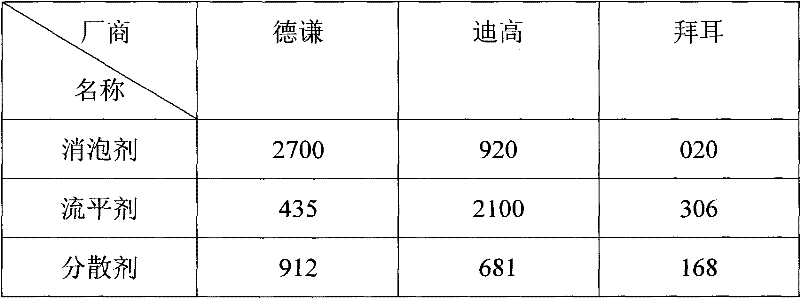

[0058] By weight percentage, first 15% of ethyl acetate, 10% of butyl acetate, and 8% of isobutanol are mixed to prepare a mixed solvent for subsequent use; , is aliphatic urethane acrylate), thermoplastic acrylic resin 15% is added in the container, then adds photocuring initiator 3% [photocuring initiator selects Swiss Ciba 819, is bis(2,4,6-trimethylbenzene Formyl) phenyl phosphine oxide] and 0.3% of defoamer (defoamer chooses Tego 920), leveling agent 0.5% (leveling agent chooses Tego 2100), dispersant 0.2% (dispersant chooses Tego 681 ), after the formed mixture is uniformly dispersed at a low speed, add the above-mentioned mixed solvent, then fully stir for 10 to 15 minutes, and finally add 3% of nano-pigments (nano-pigments are selected from the various color pigments of Chaoquan Chemical), after the dispersion is uniform Filter with 400 mesh gauze to get the finished product.

Embodiment 2

[0060]According to the percentage by weight, first mix 20% ethyl acetate, 10% butyl acetate and 10% isobutanol to prepare a mixed solvent for later use; then take 10% hydroxyl acrylic resin and 25% polyurethane acrylate EB264, is aromatic polyurethane acrylate), 15% of thermoplastic acrylic resin is added to the container, and then 3% of photocuring initiator is added [photocuring initiator is selected from Beijing Yingli 907, which is 2-methyl-1-(4-methyl Mercaptophenyl)-2-morpholine-1-acetone] and defoamer 1% (defoamer selects Bayer 020), leveling agent 0.5% (leveling agent selects Bayer 306), dispersant 0.5% (dispersant Choose Bayer 168), after the formed mixture is uniformly dispersed at a low speed, add the mixed solvent prepared above, then fully stir for 10 to 15 minutes, and finally add 5% nano-pigments (nano-pigments are selected from Yiming Sebao’s various color pigments) After dispersing evenly, filter with 400 mesh gauze to get the finished product.

Embodiment 3

[0062] According to percentage by weight, first mix 15% ethyl acetate, 10% butyl acetate, and 8% isobutanol to prepare a mixed solvent for later use; Leaf UV2100, is aromatic polyether urethane acrylate), thermoplastic acrylic resin 15% is added in the container, then adds photocuring initiator 3% (photocuring initiator selects Beijing Yingli 1173, is 2-hydroxyl-2-methyl -1-phenylacetone) and 1% of defoamer (Deqian 2700 is used for defoaming agent), 1% of leveling agent (Deqian 435 is used for leveling agent), 1% of dispersant (Deqian 912 is used for dispersant) , after the formed mixture is uniformly dispersed at a low speed, add the mixed solvent prepared above, then fully stir for 10 to 15 minutes, and finally add 4% nano-pigments (nano-pigments are selected from Changxing Chemical's various color pigments), and disperse evenly with 400 The finished product is obtained by filtering with mesh gauze.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com