Cam mechanism contour design and driven part motion characteristic mapping platform

A technology of cam mechanism and motion characteristics, applied in printing, instruments, teaching models, etc., can solve the problems of few knowledge points, single structure, heavy weight, etc., to cultivate practical ability and innovation ability, small size, cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

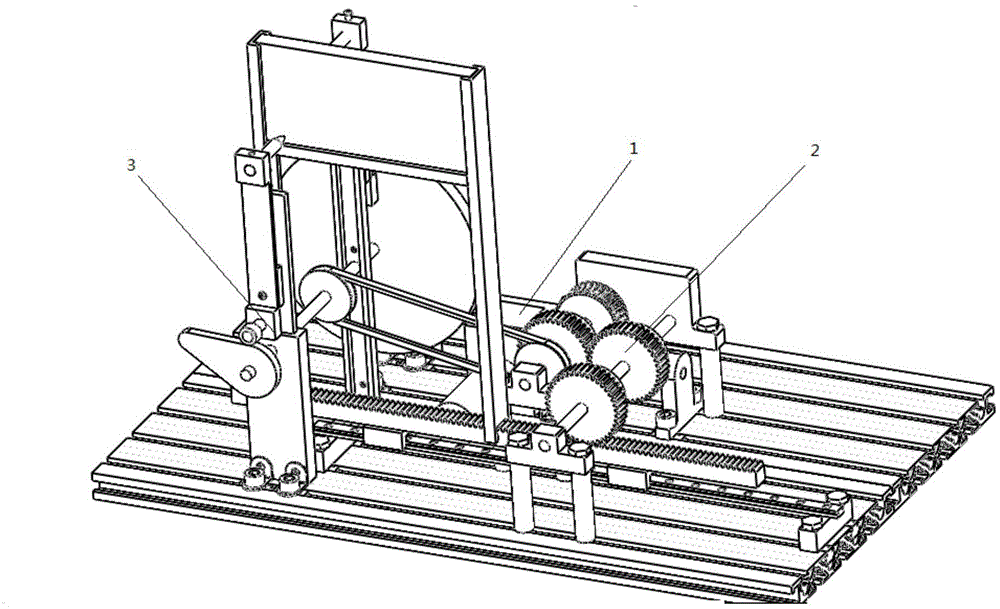

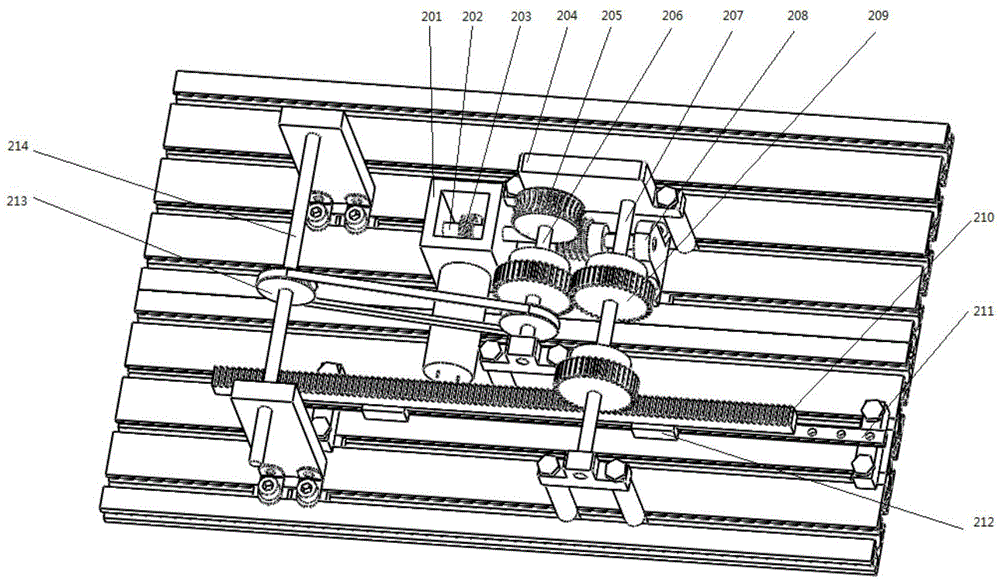

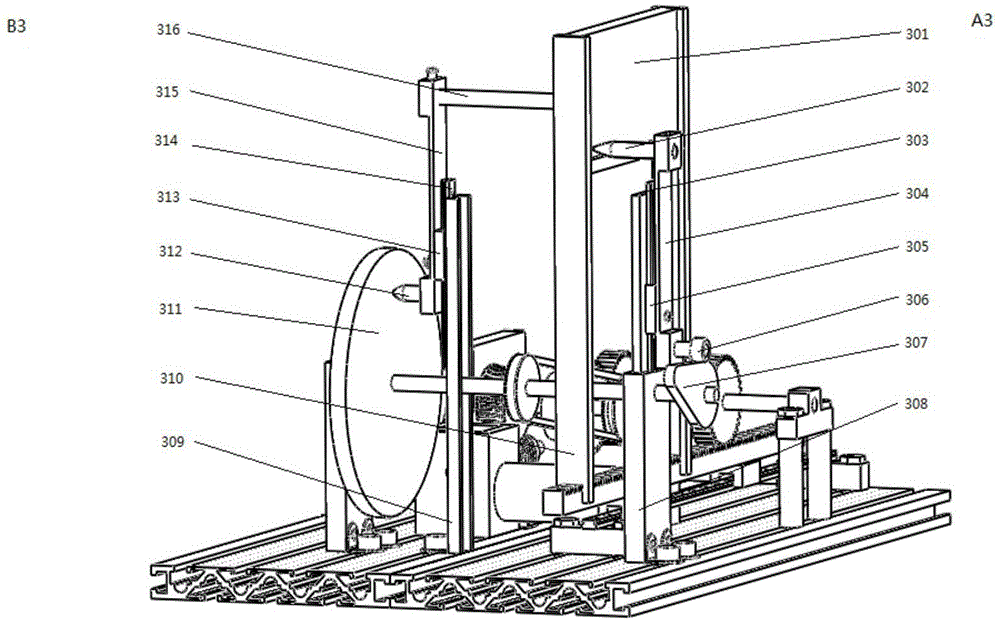

[0024] See attached figure 1 , the present invention is composed of an electromechanical integrated power input system 1, a power split system 2, an output cam drawing system 3, and the like. The cam drawing system at the output end can be divided into a known cam drawing follower characteristic curve module A3 and a known follower curve drawing cam module B3. One working cycle of the present invention only needs the cam to rotate one circle, and the two steps of drawing the characteristic curve of the follower and drawing the cam can be completed.

[0025] See attached figure 1 , in the electromechanical integrated power input system, we use a low-speed motor 101, and realize the positive and negative rotation of the motor through an electromagnetic switch, so as to ensure that the moving parts can be reset accurately.

[0026] See attached figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com