Heat zincplating planisher roll shape curve design method

A technology of curve design and flattening machine, applied in the direction of rolls, metal processing equipment, metal rolling, etc., can solve problems such as insufficient shape quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

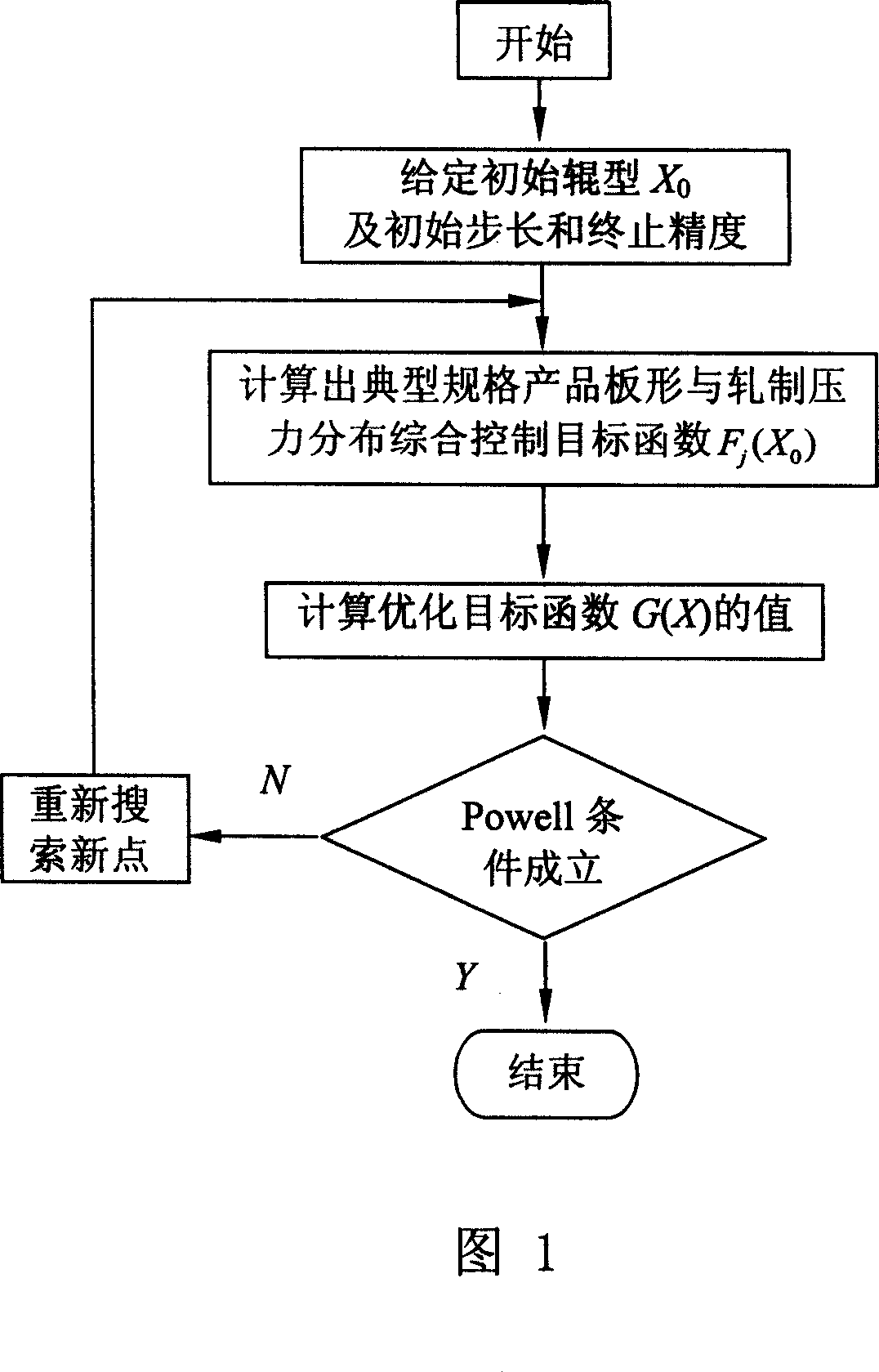

Method used

Image

Examples

Embodiment Construction

[0096] The design process and calculation results of adopting the method of the present invention to optimize a certain skin pass roll profile curve are given below:

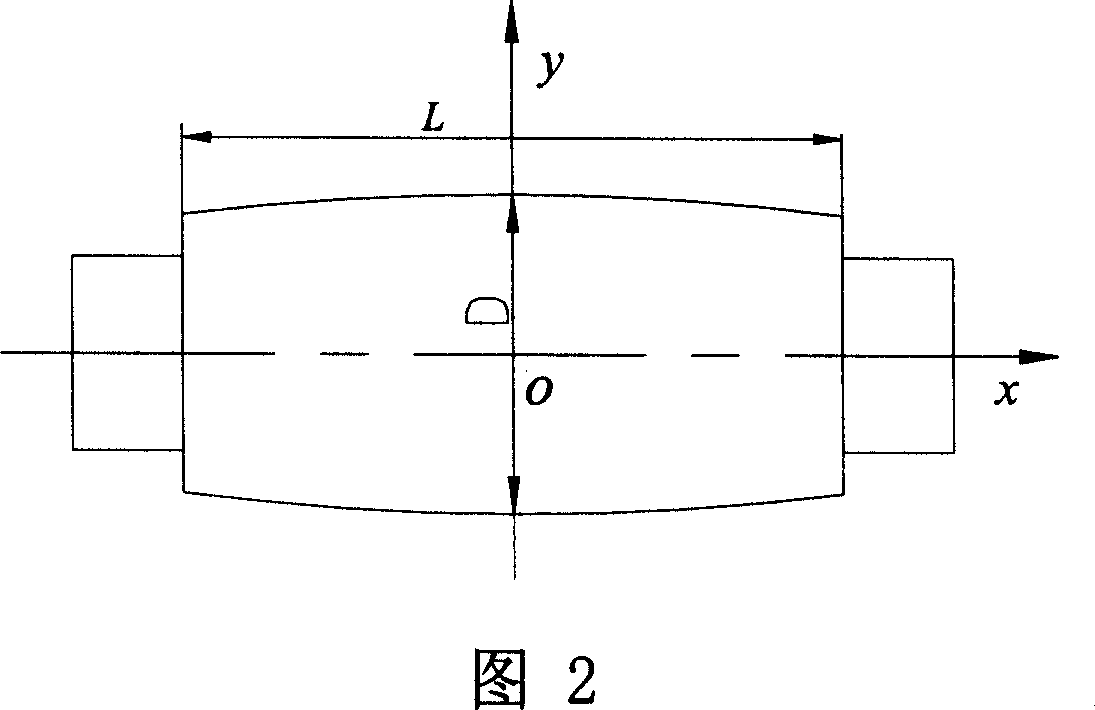

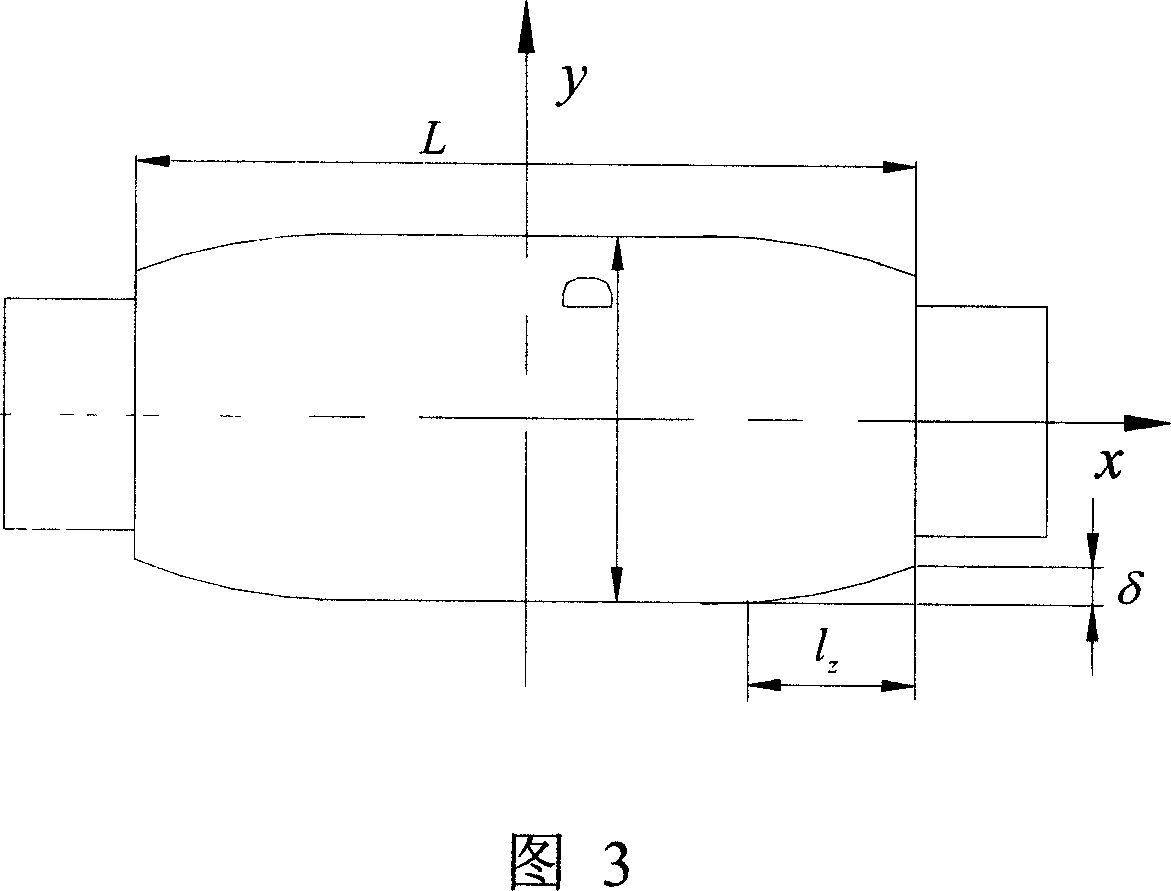

[0097] (1) Raw data related to equipment and product outline required for calculation:

[0098] Equipment parameters of temper mill: work roll body length L w =1500mm, working roll diameter D w =φ480 / 520mm, back-up roll body length L b =1450mm, back-up roll diameter D b =φ1150 / 1250mm, the center distance between the driving side of the back-up roller and the pressing screw on the working side l 1 =2.67m, positive and negative bending rolls of working rolls, center distance between drive side and working side bending roll hydraulic cylinder l 2 =2.47m. Maximum roll bending force ±60t, maximum rolling pressure 700t, maximum rolling speed 180m / min, wet leveling.

[0099] Product variety specification range: strip width 800~1250mm, thickness 0.20~1.3mm, yield strength σ s 280 ~ 620Mpa, flat elongation 0.5 ~ 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com