Plunger pump for preparing liquid chromatographic column

A technology for preparing liquid phases and chromatographic columns, which is applied in the direction of piston pumps, pumps, mechanical equipment, etc., and can solve the problems of discontinuous and large fluctuations in the suction flow

Inactive Publication Date: 2011-06-15

北京清博华科技有限公司

View PDF7 Cites 12 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Existing plunger pumps usually use a flow pulsation damper to reduce the fluctuation of the discharge flow, and the suction flow is discontinuous or fluctuates greatly

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

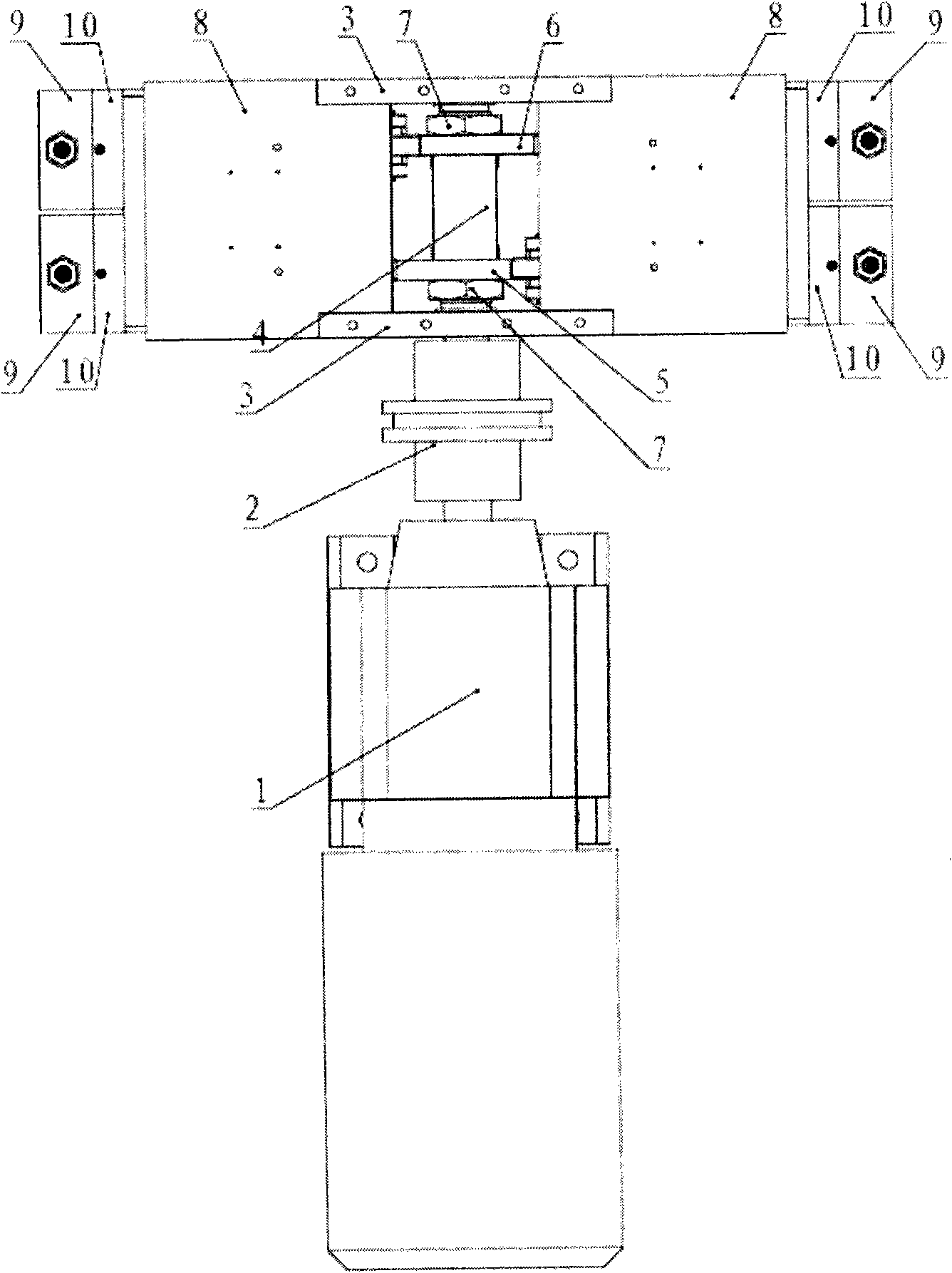

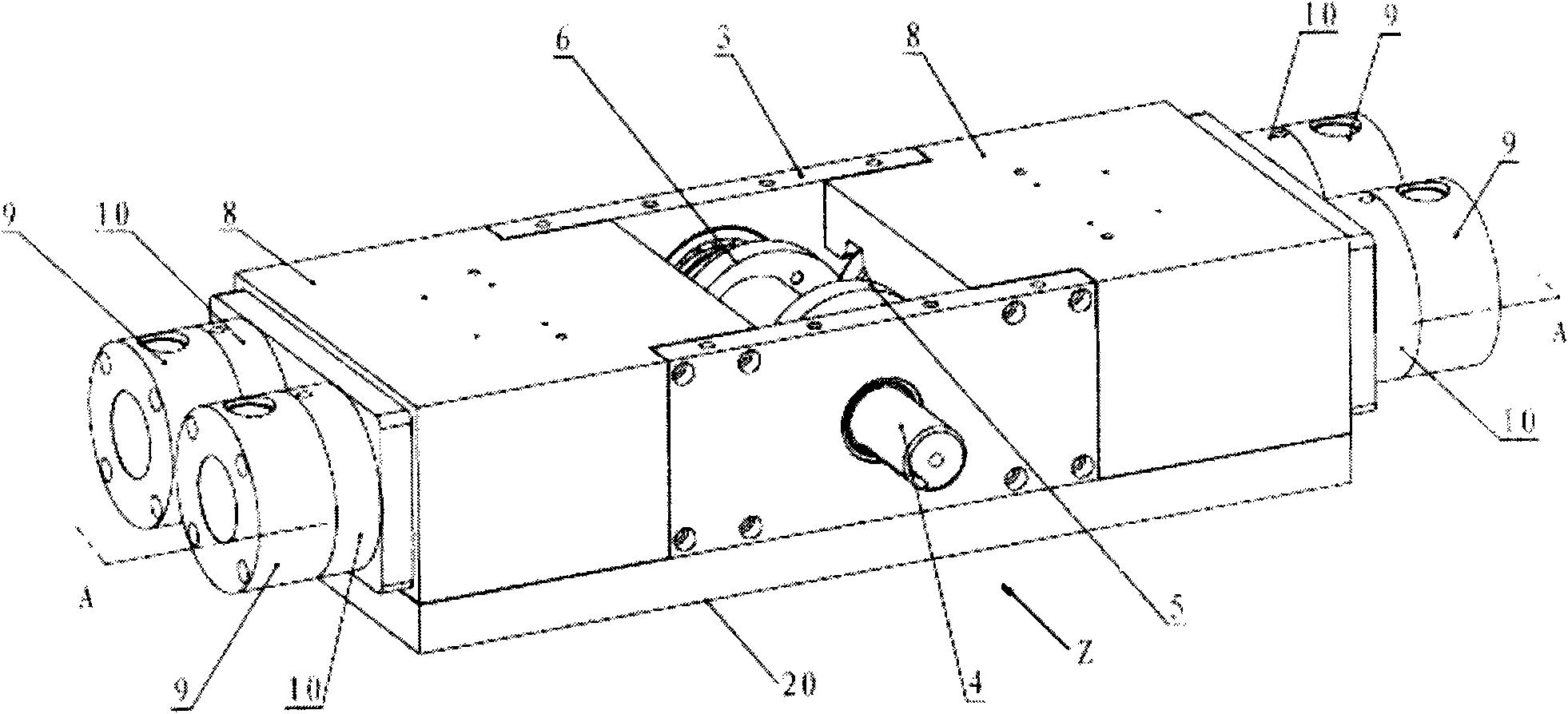

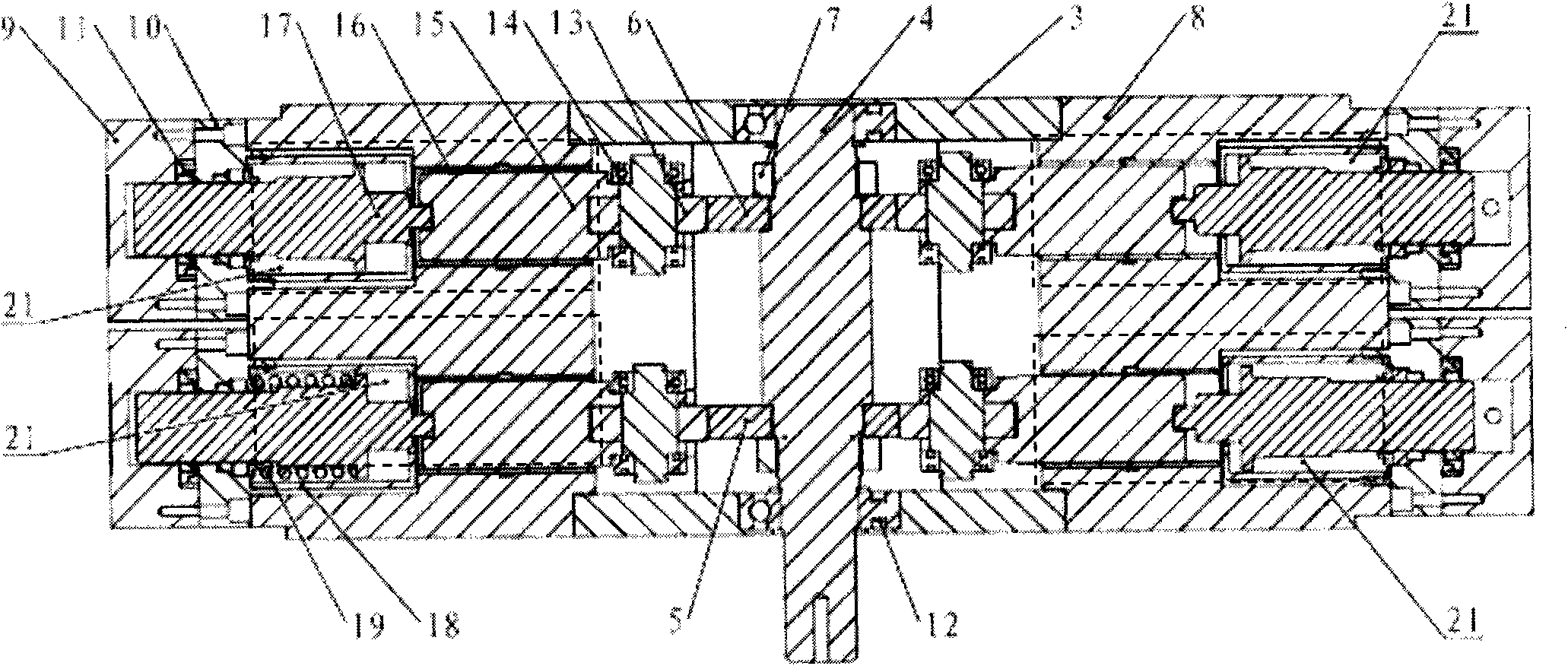

The invention provides a plunger pump for preparing a liquid chromatographic column. A master cam and a slave cam are arranged on a spindle; two pump casings are symmetrically arranged on the two sides of the spindle; four groups of pump heads and pump head seats with the same structure are arranged at the ends of the two pump casings; four groups of sliders with the same structure are arranged inside the two pump casings, and are matched with the master cam and the slave cam by cam bearings; and the spindle rotates to drive the master cam and the slave cam to drive the four groups of sliders to reciprocate. The working curves of the master cam and the slave cam are completely the same, the master cam and the slave cam have the same basic circle radius and the phase angle difference of 90 degrees. Due to the special working curve designs and the phase angles with the difference of 90 degrees of the master cam and the slave cam, the plungers of the four groups of sliders reciprocate in a mutually compensating mode, and the plunger pump can suck and discharge liquid stably and pulselessly.

Description

Preparative liquid chromatography plunger pump Technical field: The invention relates to a plunger pump for preparative liquid chromatography, which belongs to the application field of industrial preparative chromatography. Background technique: In order to speed up the separation time and improve the separation efficiency in industrial preparative chromatography, the flow rate of the preparative liquid chromatography pump is required to be large and stable. Currently commonly used liquid chromatography pumps include plunger pumps, diaphragm pumps, etc. Diaphragm pumps use the reciprocating movement of the diaphragm to change the volume to achieve liquid suction and discharge. During the reciprocating motion of the diaphragm pump, the diaphragm made of polymer material is easily broken and cannot withstand high pressure. In addition, due to the irregular deformation of the diaphragm during the reciprocating motion, the flow rate fluctuations during the diaphragm pumping ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F04B9/04

Inventor 肖勇田林

Owner 北京清博华科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com