Roll-shaped curve design method of high-strength steel temper mill

A technology of curve design and high-strength steel, applied in the field of rolling rolls, can solve problems such as back-up roll gnawing, meat loss, and large consumption of work rolls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

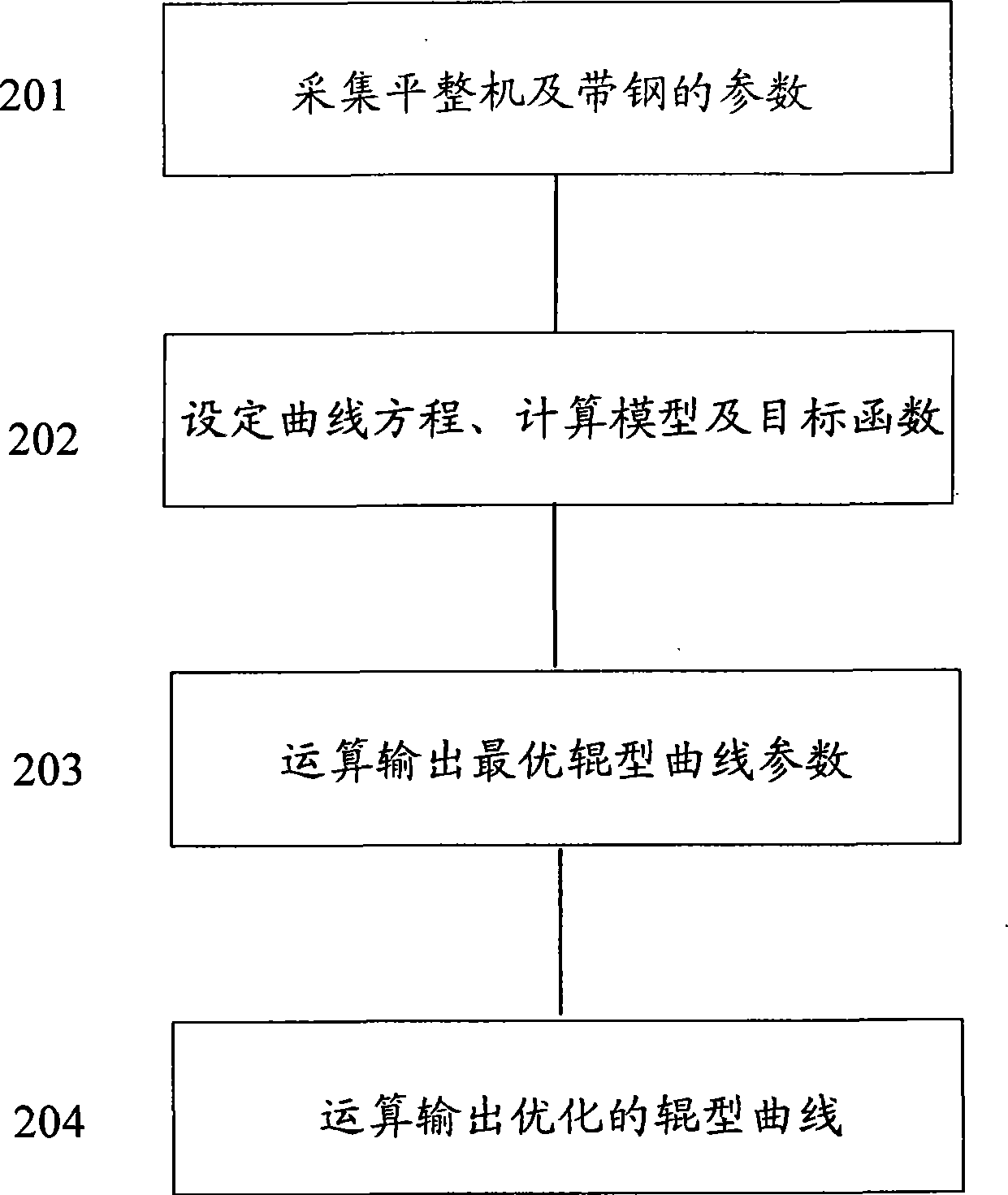

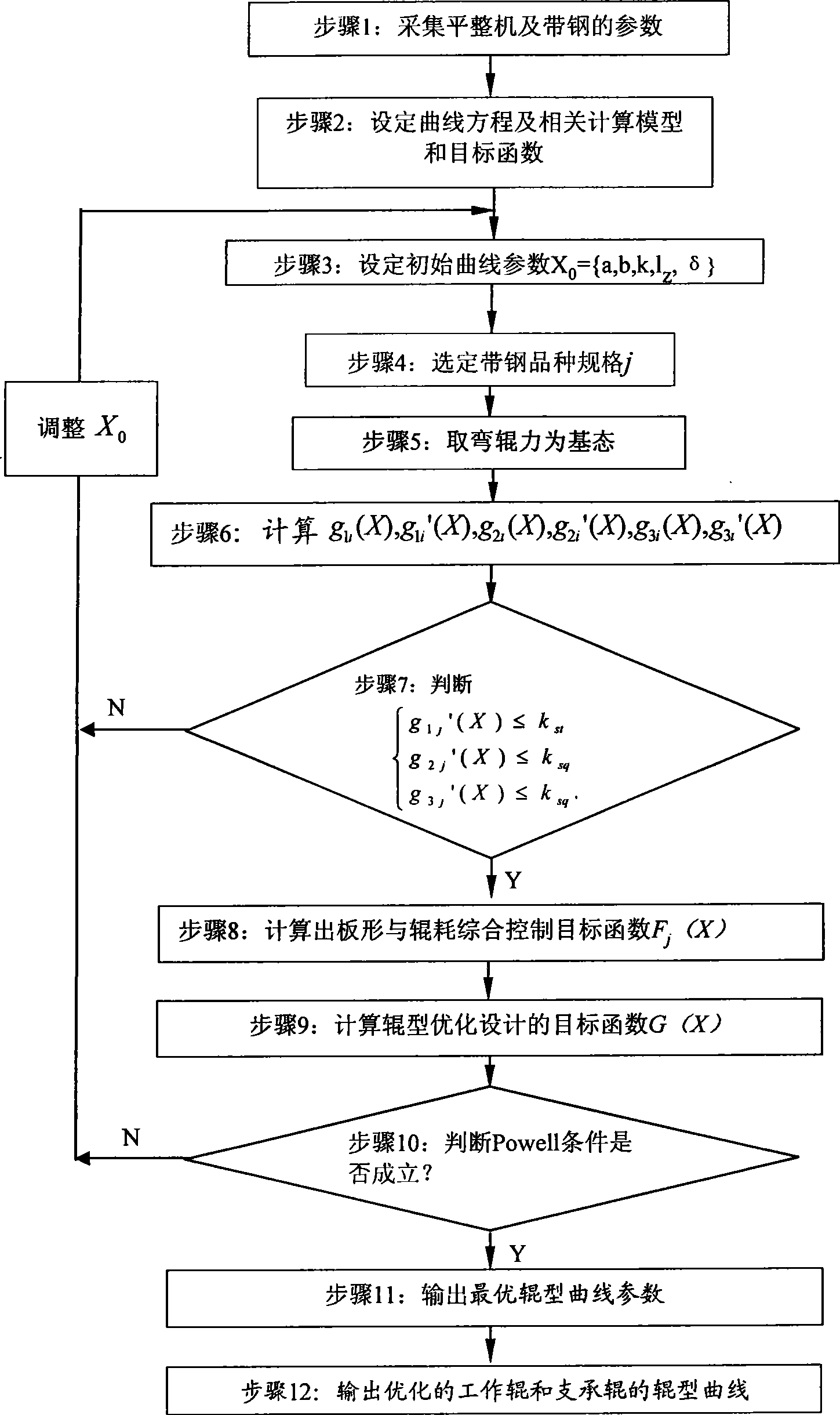

[0070] See figure 1 , the figure schematically shows the flow of the roll profile curve design method of high-strength steel pass mill, which specifically includes the following steps:

[0071] 201. Collect the parameters of temper mill and strip steel. Collect the equipment parameters of the tempering machine and the parameters of the specification range of the strip steel, select the representative specification of the strip steel and determine the weighting coefficient of the representative specification.

[0072] 202. Set the curve equation, calculation model and objective function. Establish the roll shape curve equations of the work roll and the back-up roll, the calculation model of the uniformity index and the peak index calculation model of the shape, the pressure between the rolls and the rolling pressure, and establish the comprehensive control objective function of the shape and roll consumption and the optimization of the roll shape The designed objective functi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com