Gingival margin curve design method for personalized implant tooth

A technology for curve design and dental implants, applied in the field of biomedical engineering, which can solve the problems of severe deformity and large segmentation deviation of interdental interference models, low degree of automation, and multiple manual experience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] Embodiments of the present invention will be further described below in conjunction with accompanying drawings:

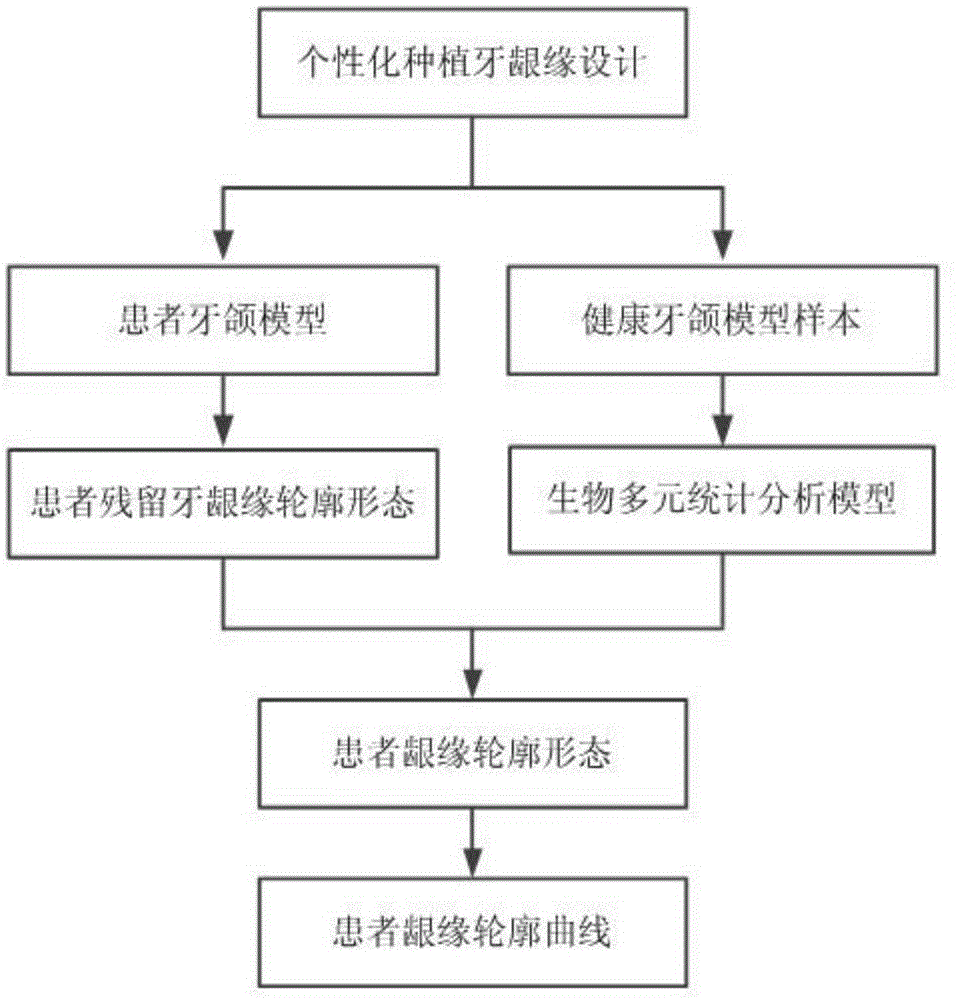

[0056] Such as figure 1 As shown, the intelligent gingival margin curve design process based on the biometric identification model mainly includes reconstructing the residual teeth of patients with missing teeth and the gingival margin contour of the three-dimensional dental model of the sample, constructing the gingival margin biomultivariate statistical analysis model of the sample, and the patient's missing tooth There are three steps, including the personalized gingival margin curve design of teeth, and the specific implementation steps are as follows:

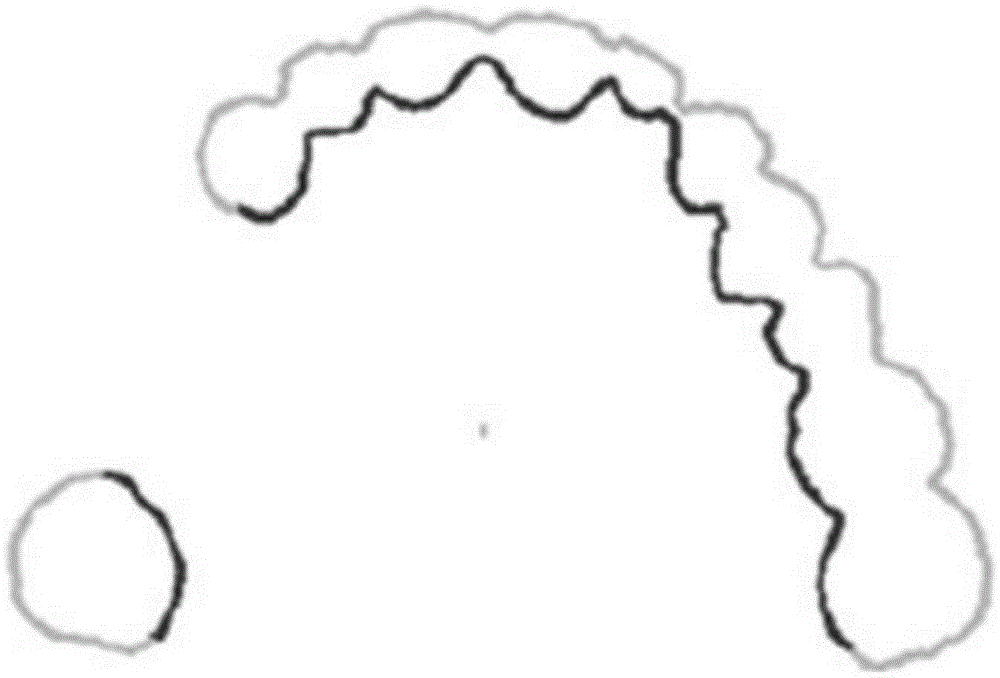

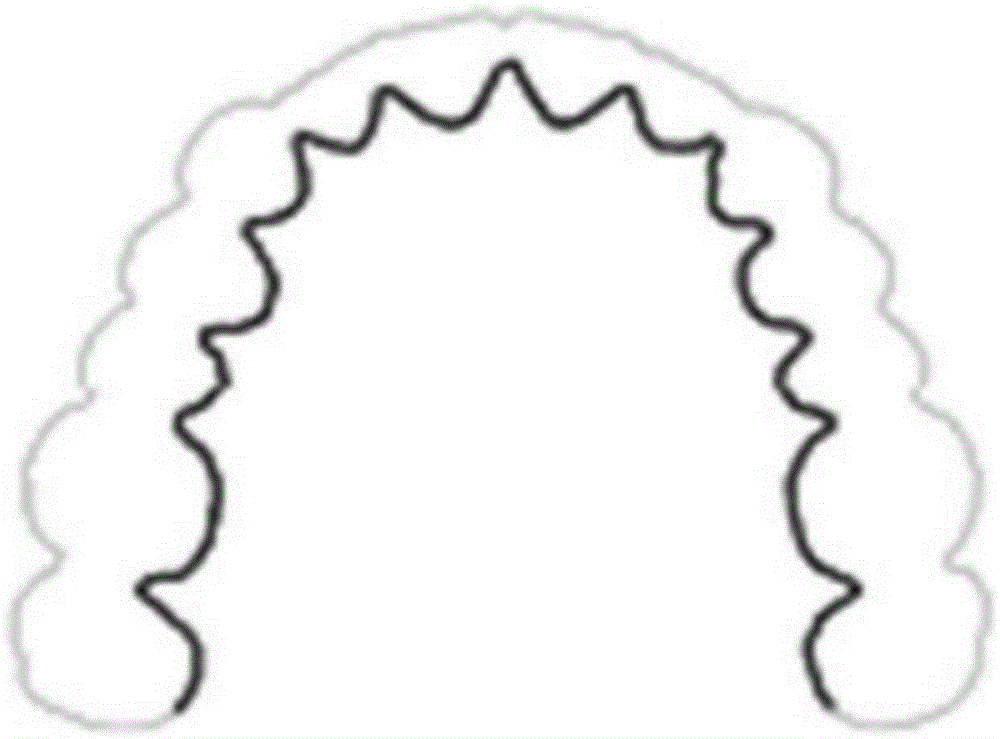

[0057] Step 1: Reconstruct the gingival margin contour of the three-dimensional dental model of the residual teeth of the edentulous patient and the sample;

[0058] First calculate the residual teeth of the patient with missing teeth and the vertex p of the jaw triangular mesh of the sample i The maxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com