Supersonic sand blasting gun

A sandblasting gun and supersonic technology, applied in the field of sandblasting gun structure design, can solve the problems of affecting the speed of sand particles, affecting the speed of airflow, and many components, so as to achieve the effect of improving wear resistance, reducing collision and reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

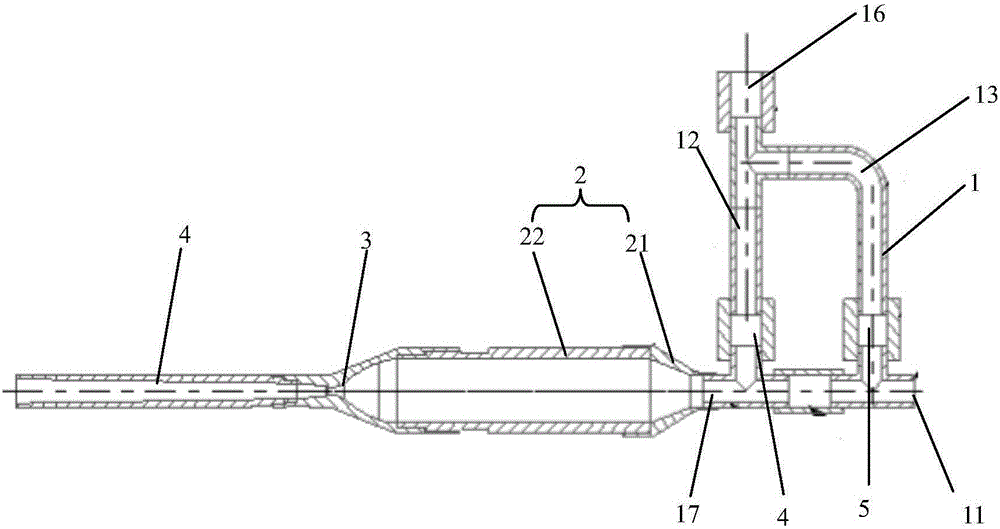

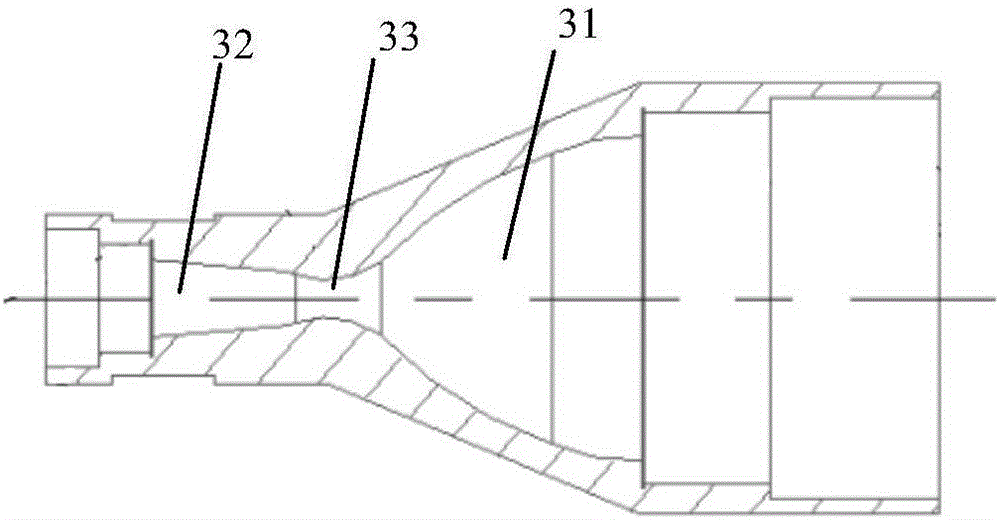

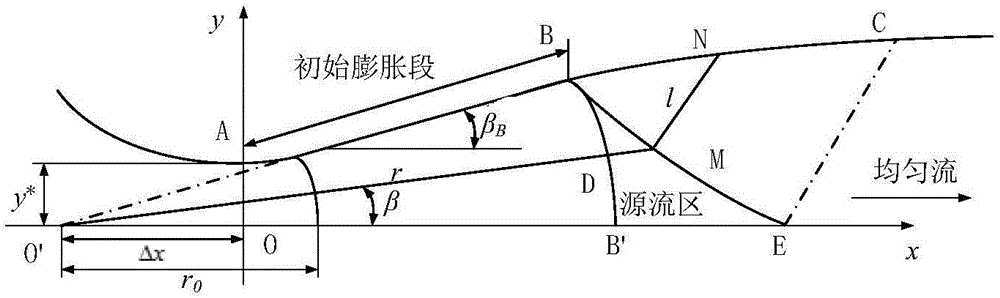

[0020] see figure 1 class figure 2 As shown, a supersonic sandblasting gun includes a sand inlet device 1, an expansion tube 2 connected to the sand outlet 17 of the sand inlet device 1, a Laval tube 3 connected to the expansion tube 2, and an acceleration tube 4 connected to the Laval tube 3 The expansion pipe 2 includes a gradually expanding transition pipe 21 connected to the sand outlet and a main body 22 (also called a sand mixing pipe) extending forward from the transition pipe 21, and the diameter of the main body 22 is larger than that of the outlet. Diameters of sand hole, Laval tube 3 and accelerating tube 4. The expansion tube 22 expands the diameter of the channel so as to adapt to the recommended contraction ratio of the Laval tube 3 (the ratio of the tube diameter before contraction to the tube diameter after contraction) so that the airflow in the tube can be decelerated and pressurized in the Laval tube 3 , to reserve appropriate potential energy; at the sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com