Dynamic balance high-speed main shaft device and carpet tufting machine with same

A high-speed main shaft and driving shaft technology, applied in the field of carpet tufting machines, can solve the problem that the working speed of carpet tufting machines cannot be greatly improved, and achieve the effects of low vibration, low noise, and stable operation of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

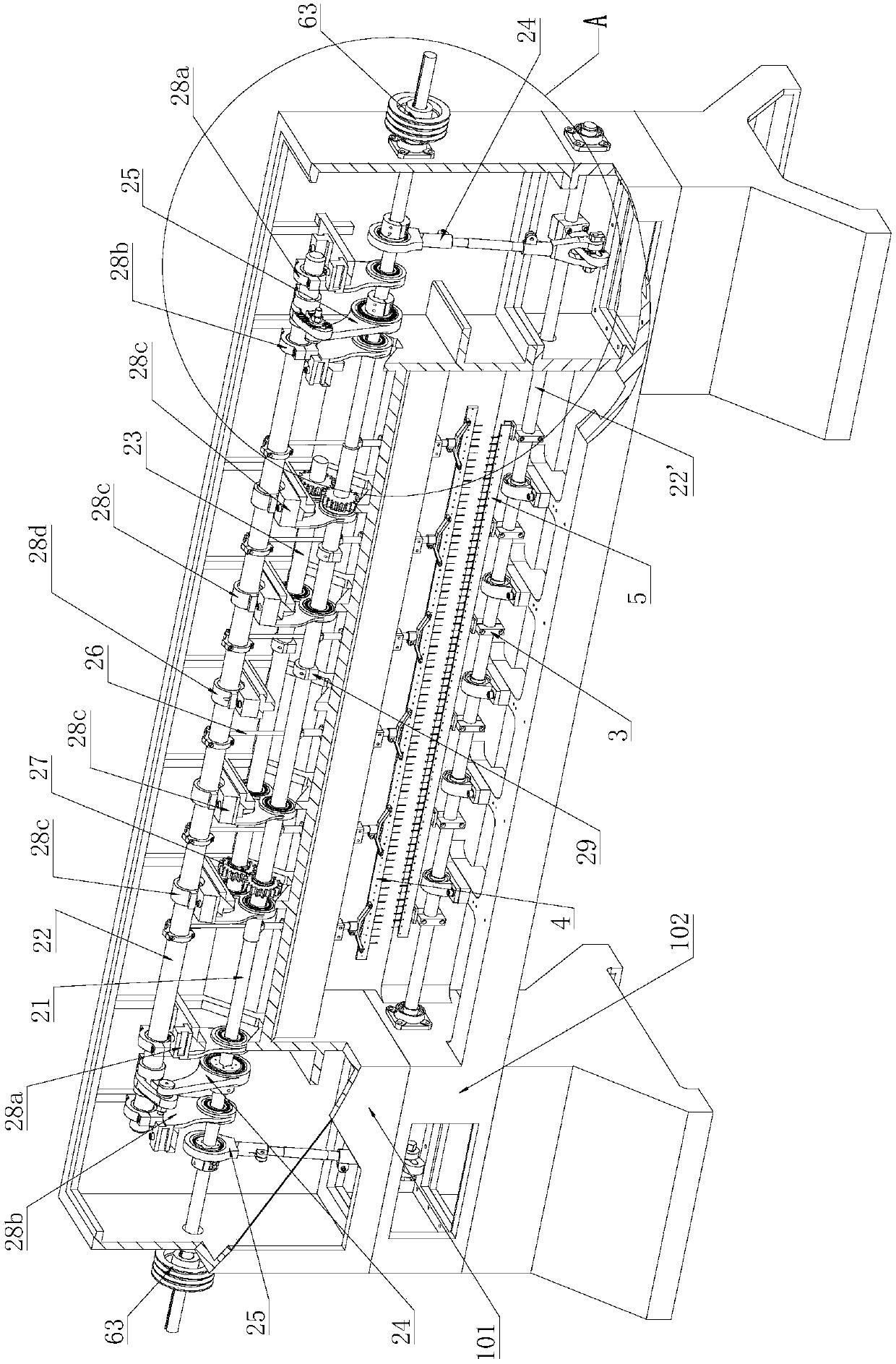

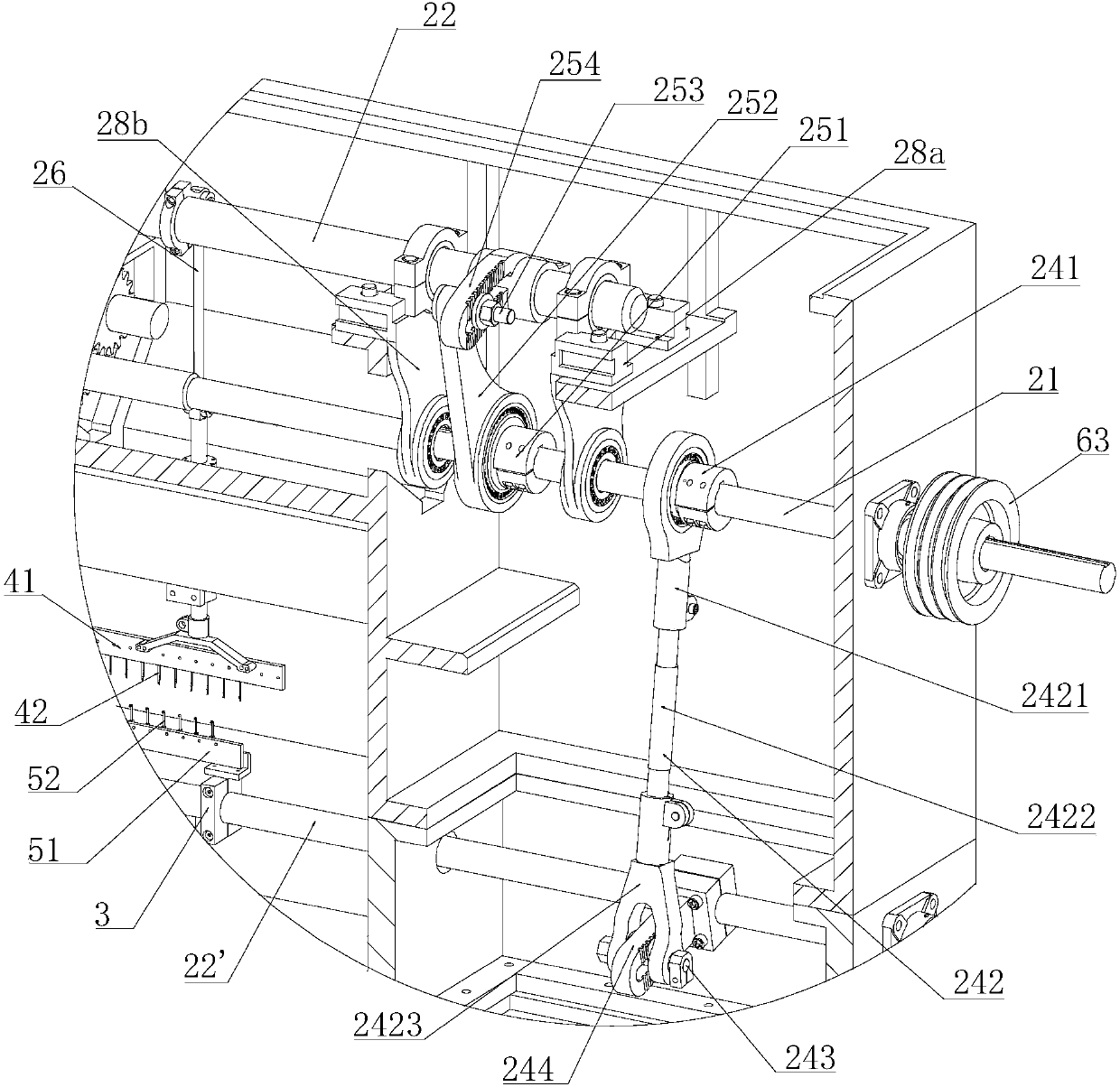

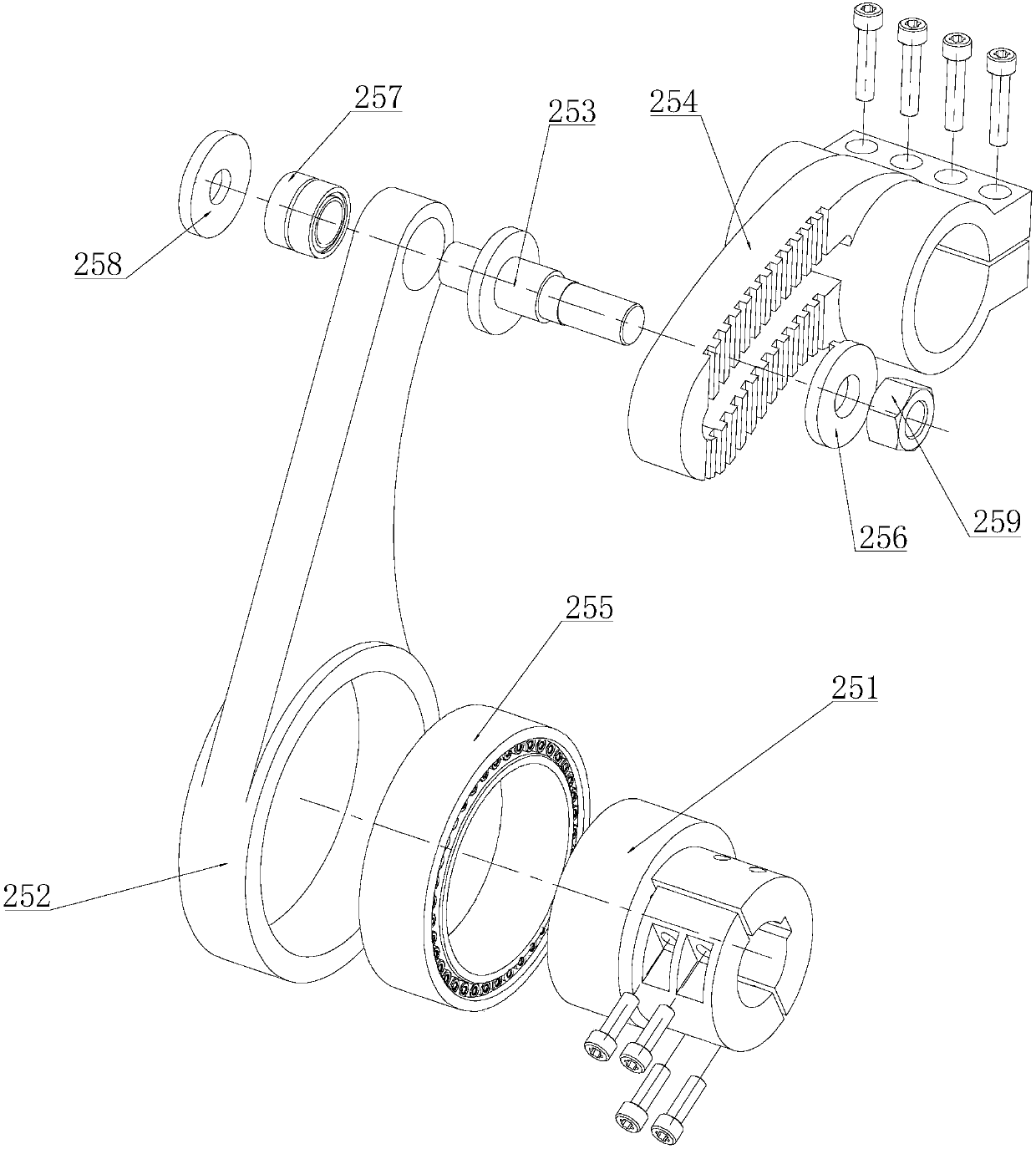

[0054] The invention provides a dynamic balance high-speed spindle device, such as figure 1 with figure 2 As shown, it includes a driving shaft 21, a first driven shaft 22, a synchronous shaft 23, a second driven shaft 22', a first crank connecting rod group 25, a second crank connecting rod group 24, a needle driving slider group 26, Gear set 27, shaft support 28 and eccentric weight 29. Wherein, the shaft support 28 is fixedly installed on the inner longitudinal beam of the upper box body 101 of the frame 10, and is used for supporting the driving shaft 21, the first driven shaft 22 and the synchronous shaft 23, and the shaft support 28 has a through hole , bearings are placed in the through hole; the driving shaft 21, the first driven shaft 22 and the synchronous shaft 23 all pass through the through hole on the shaft support 28 and are assembled on the shaft support 28 according to fit; the two ends of the driving shaft 21 After passing through the bearings fixed on the...

Embodiment 2

[0063] The present invention provides a kind of carpet tufting machine with this spindle device, as Figure 5 As shown, it includes a frame 10, a main motor 1, a first belt drive 6, a main shaft device 2, a swing lever 3, a needle part 4, a hook part 5, a second belt drive 15, a first reducer 7, and a third belt Transmission 16, the second speed reducer 8, the blanket roller assembly 9, the third speed reducer 11, the fourth belt drive 17, the cloth feed roller assembly 12, the yarn feed roller assembly 13 and the cloth roller 14.

[0064] Such as Figure 5 As shown, the rack 10 includes an upper box 101 above, a beam 102 in the middle and two bases 103 below, which are symmetrically arranged in the center. The frame 10 is used for installing other components.

[0065] Such as Figure 5 As shown, the main motor 1 and the first belt drive 6 each have two parts, symmetrically arranged on both sides of the frame 10, the main motor 1 is fixedly placed above the upper box 101 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com