Multi-stage decoupling conical cutter head for full-section tunnel boring machine

A tunnel boring machine, full-section technology, applied in tunnels, mining equipment, earthwork drilling, etc., can solve the problems of ineffective rock breaking, poor performance, difficult control of the circular truncated cutter head, etc., to improve the overall rock breaking efficiency, The effect of reducing rock breaking difficulty and ensuring driving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

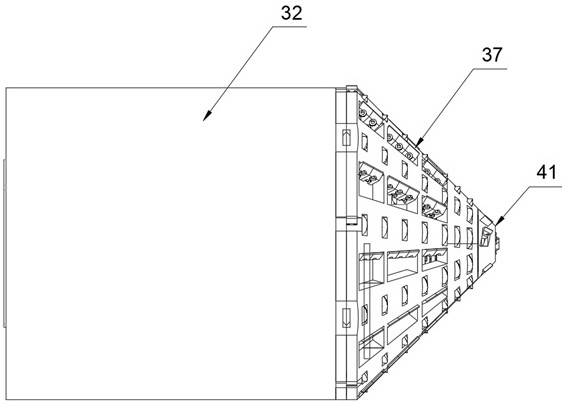

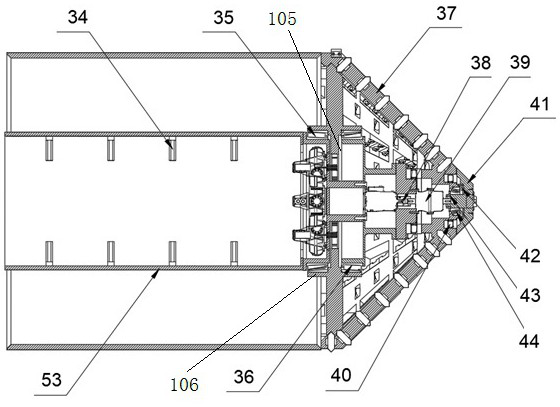

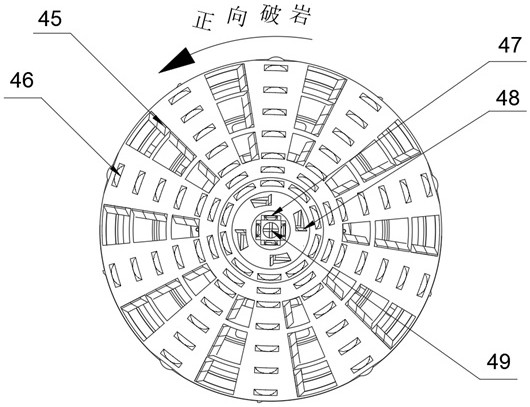

[0044] A multi-stage decoupling conical cutterhead for a full-section tunnel boring machine, comprising a circular truncated female cutterhead 37 and a circular truncated sub-cutter 41, the large diameter end of the circular truncated female cutterhead 37 being driven by the female cutterhead In cooperation with the main body 32 of the roadheader, the small diameter end of the circular truncated female cutter head 37 is rotatably connected to the circular cone shaped sub cutter head 41, and the large diameter end of the circular cone shaped sub cutter head 41 is connected to the main body of the roadheader through the sub cutter head drive unit. 32 swivel fit. The mother cutter head driving unit and the sub cutter head driving unit are all connected with the hydraulic control unit.

[0045] Specifically, it includes a circular truncated female cutter head 37 that is rotatably connected to the right end of the main body 32 of the roadheader, the circular truncated female cutter...

Embodiment 2

[0049] A multi-stage decoupling conical cutter head for a full-section tunnel boring machine, the female cutter head drive unit includes a first quantitative motor 2, a second quantitative motor 3, a third quantitative motor 4, and a fourth quantitative motor 5. At least one of the sub-cutter drive units includes a variable displacement motor 1 .

[0050] The hydraulic control unit includes a first shut-off valve 6, a second shut-off valve 7, a third shut-off valve 8, a fourth shut-off valve 9, a fifth shut-off valve 10, a sixth shut-off valve 11, a seventh shut-off valve 12, and an eighth shut-off valve. Stop valve 13, ninth stop valve 14, tenth stop valve 15, first three-phase asynchronous motor 16, second three-phase asynchronous motor 17, first variable pump 18, second variable pump 19, quantitative pump 20, first Check valve 21, second check valve 22, temperature sensor 23, three-position four-way proportional reversing valve 24, three-way pressure reducing valve 25, safe...

Embodiment 3

[0055] A multi-stage decoupling conical cutter head for a full-section tunnel boring machine, wherein a cylindrical boss 101 is provided in the center of one end of the circular truncated sub cutter head 41 with a large diameter, and a circular hole is opened inside the cylindrical boss 101. The inner wall of the hole is provided with a keyway for drivingly connecting with the output shaft of the sub-cutter drive unit. A third tapered roller bearing 44 is provided between the outer wall of the cylindrical boss 101 and the inner wall of the circular truncated female cutter head 37 , which facilitates the rotation of the circular truncated sub cutter head 41 .

[0056] Further, the outer ring of the third tapered roller bearing 44 is embedded in the center of the small diameter end of the circular truncated female cutter disc 37, and the small diameter end of the circular truncated female cutter disc 37 is connected with a bearing end cover through several bolts. 42. It is used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com