Hydraulic pump flow regulating device

A technology of flow regulating device and hydraulic pump, which is applied in the direction of fluid pressure actuating device, servo motor assembly, mechanical equipment, etc., can solve the problem of high cost, and achieve the effect of improving oil absorption capacity, reducing cost and increasing working speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

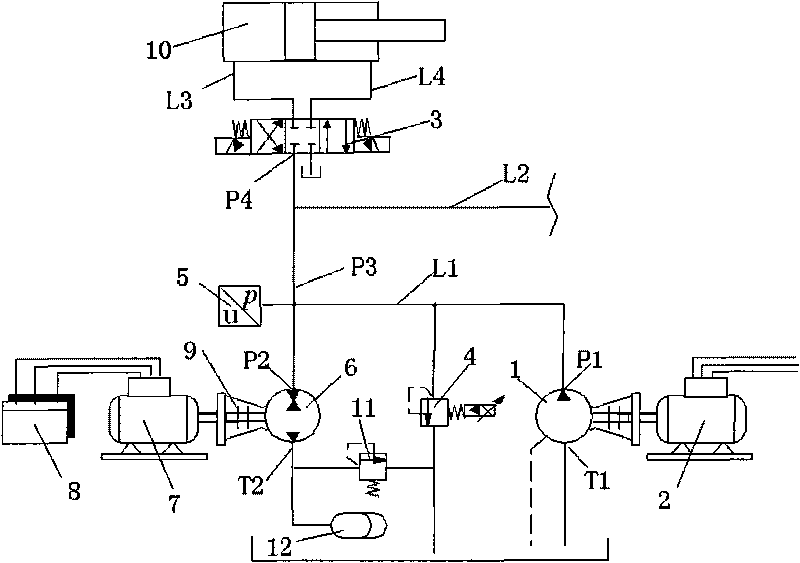

[0020] figure 1 It is the first embodiment of the present invention. The adjusting device of the hydraulic pump flow comprises a one-way rotary hydraulic pump 1, a power source 2, a control valve 3, an overflow valve 4, a pressure sensor 5 and a hydraulic actuator 10, and its composition is that the present invention is based on the existing hydraulic pump flow adjustment. In the system, a two-way rotating hydraulic pump 6, a motor 7, a motor speed controller 8, a shaft coupling 9, a safety valve 11 and an accumulator 12 are further added. Wherein, the power source 2 drives the one-way rotary hydraulic pump 1, the oil outlet P1 of the one-way rotary hydraulic pump 1 communicates with the first oil port P2 of the two-way rotary hydraulic pump 6 through the first hydraulic pipeline L1, and the total oil outlet P3 It communicates with the first hydraulic pipeline L1, which is the common oil outlet of two hydraulic pumps, the one-way rotary hydraulic pump 1 and the two-way rotar...

Embodiment 2

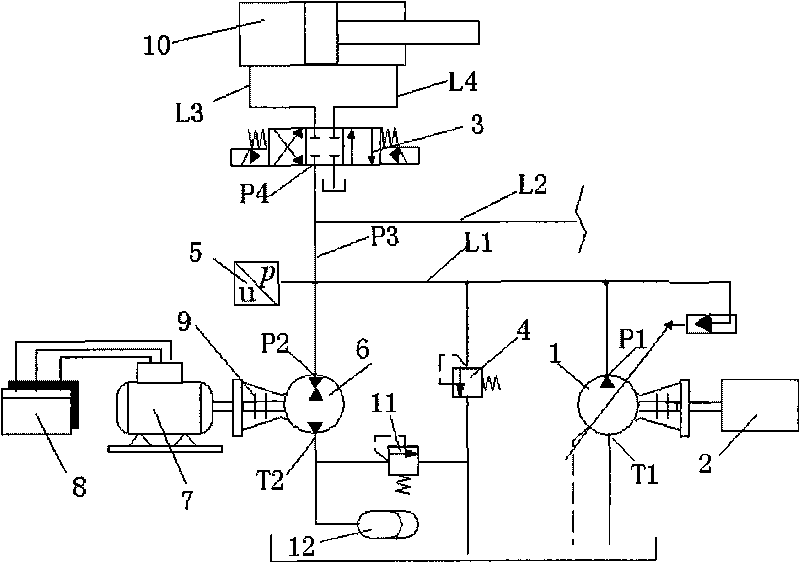

[0024] figure 2 It is the second embodiment of the present invention. The difference with the first embodiment is: 1) The selected one-way rotary hydraulic pump 1 is a mechanically adjusted constant power type variable hydraulic pump, its displacement is equal to that of the two-way rotary hydraulic pump 2, and its output flow It has a hyperbolic relationship with the pressure at the pump outlet P1, that is, the product of the two is a constant value, thus limiting the maximum output power of the one-way rotary hydraulic pump 1 . 2) The power source 2 adopts an internal combustion engine, driven by diesel or gasoline. In addition, the composition, connection relationship and working principle of the system are exactly the same as those of Embodiment 1, and it can be applied in hybrid-driven traveling machinery, such as excavators, loaders and tractors.

Embodiment 3

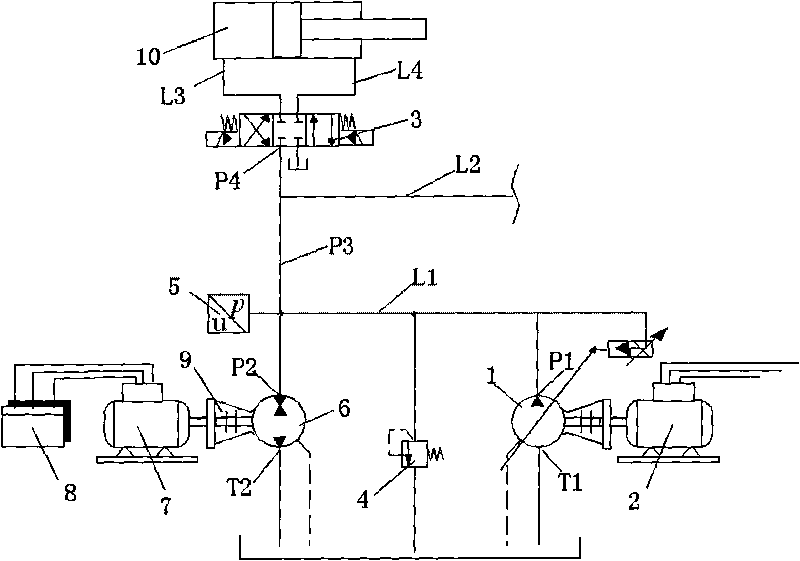

[0026] image 3 It is the third embodiment of the present invention. The differences from the first embodiment are as follows: 1) The selected one-way rotary hydraulic pump 1 is a constant pressure variable pump controlled by electronic proportion, which can be controlled continuously proportionally by changing the current signal of the proportional pilot valve integrated on it. The pressure value at the pump outlet. 2) The safety valve 11 and the accumulator 12 are removed, and the second oil port T2 of the two-way rotary hydraulic pump 6 communicates directly with the oil tank T. In addition, the composition, connection relationship and working principle of the system are exactly the same as those in Embodiment 1. The characteristic of the system is that it can continuously control the flow and pressure supplied to the hydraulic actuator 10 through the main oil outlet P3, which can be applied to injection molding machines, Presses, die-casting machines, balers and other in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com