Continuous extruding machine with cooling device outside extruding wheel

A technology of external cooling and extrusion wheel, which is applied in the direction of metal extrusion forming tools, metal extrusion, metal processing equipment, etc., can solve the problems of equipment parts such as corrosion, defects, and easy cracking of extrusion wheels, etc., to achieve increased Contact area, good cooling effect, effect of improving cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

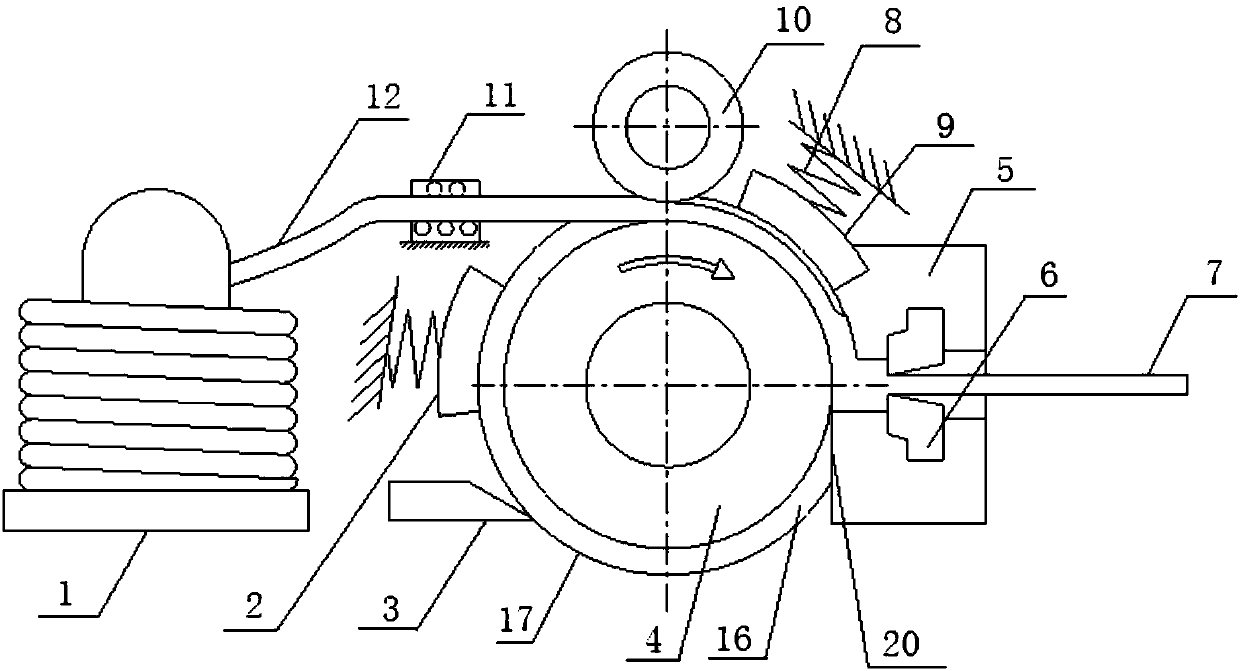

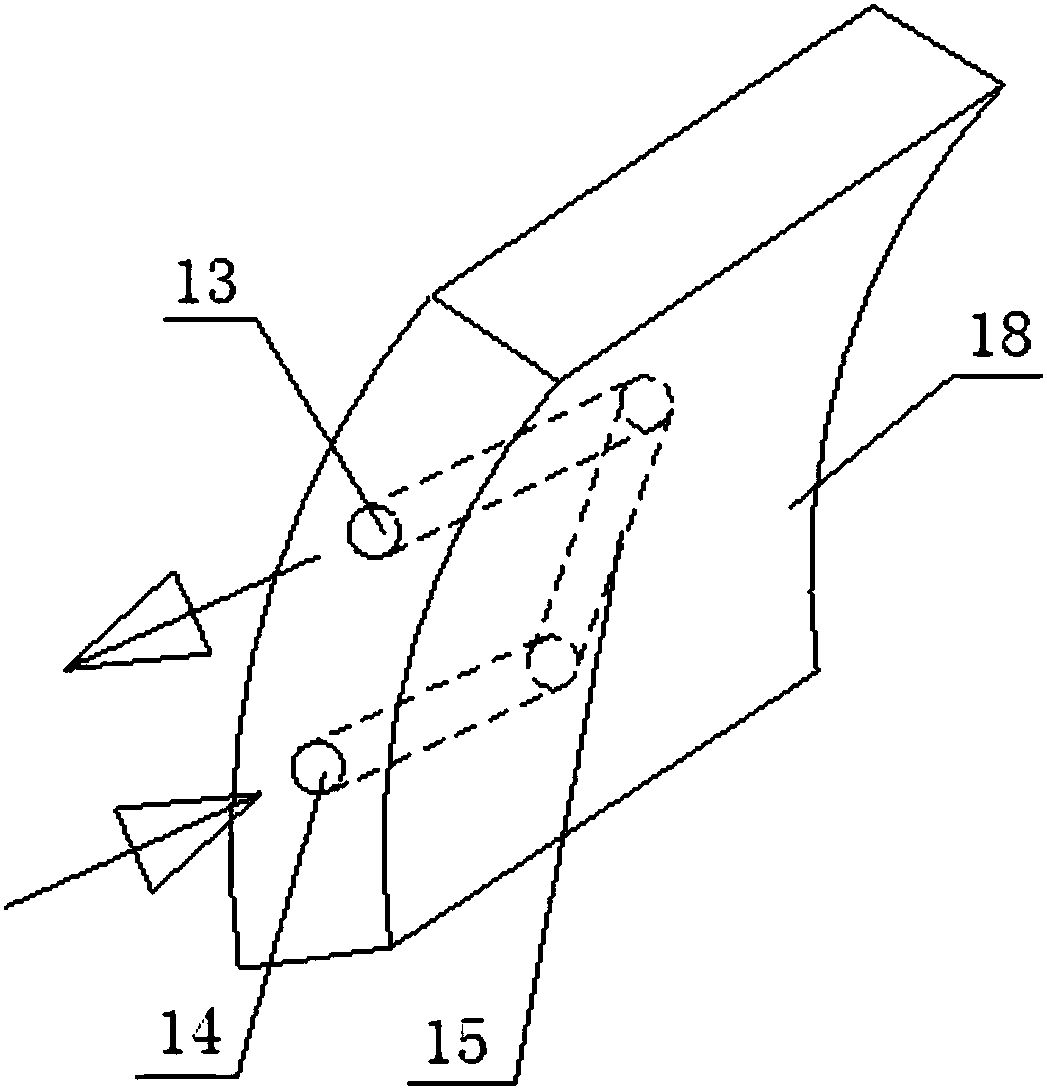

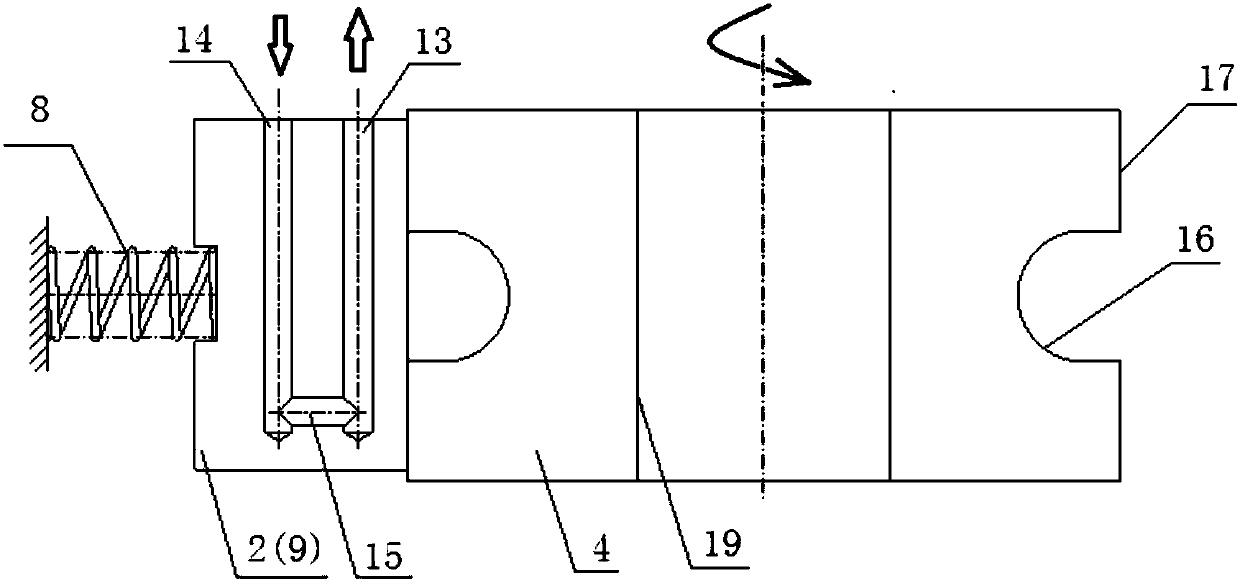

[0029] Such as figure 1 In the shown continuous extrusion machine with an external cooling device for the extrusion wheel, the rod material 12 is placed on the pay-off device 1, and the rod material 12 enters the extrusion wheel groove 16 through the compaction wheel 10 after passing through the pretreatment device 11, The rod material 12 enters the cavity 5 driven by the friction force of the groove 16 of the extrusion wheel, and is extruded into a product 7 through the mold 6 installed in the cavity 5. After the outer surface 17 of the extrusion wheel rotates out of the cavity 5, it passes through the The scraper 3 cleans up the extruded metal adhered to the outer surface 17 of the extrusion wheel, and keeps the outer surface 17 of the extrusion wheel smooth. The two groups of cooling blocks whose surface 17 is in close contact cool the extrusion wheel. The first cooling block 2 is installed between the compacting wheel 10 and the scraper 3, and the second cooling block 9 is...

Embodiment 2

[0035] The structure of the continuous extrusion machine with the external cooling device of the extrusion wheel in this embodiment is basically the same as that of Embodiment 1, the difference is that there is one group of cooling blocks, which are arranged at the position between the compaction wheel 10 and the scraper 3 place.

Embodiment 3

[0037] The structure of the continuous extrusion machine with the external cooling device of the extrusion wheel in this embodiment is basically the same as that of Embodiment 1, the difference is that there is one set of cooling blocks installed between the compaction wheel 10 and the cavity 5 The location of the cooling block, that is, the cooling block is installed in the shoe seat, can effectively use the space, increase the contact area between the cooling block and the extrusion wheel, and improve the cooling effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com