High-pressure high-speed axial piston pump piston pair four-axis force testing device

A technology of axial piston pump and testing device, which is applied in the field of hydraulic components, can solve the problems of low maximum speed and pressure, interference of support installation force, high cost, etc., and achieve high lubricating performance, reliable overall structure, and simple overall structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings.

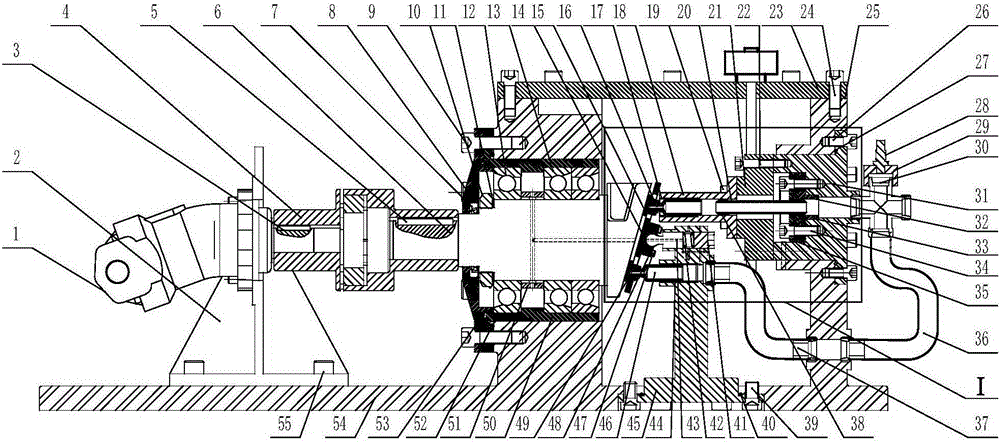

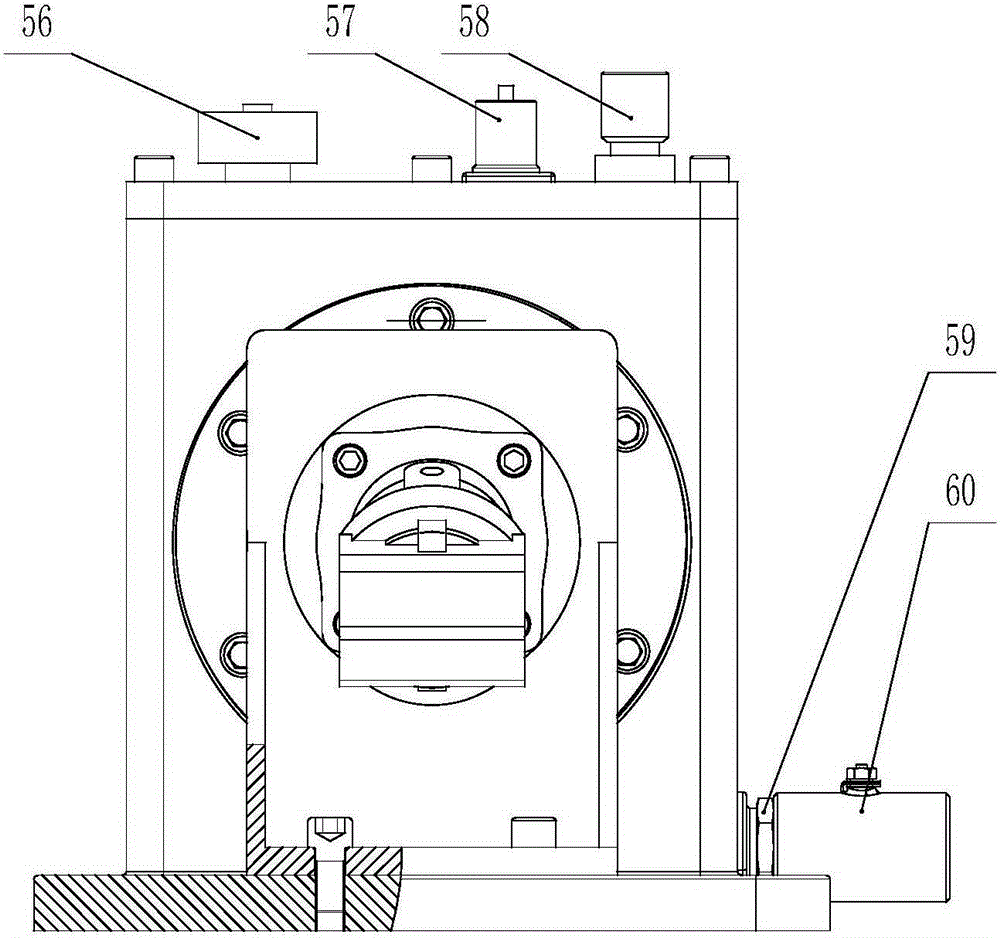

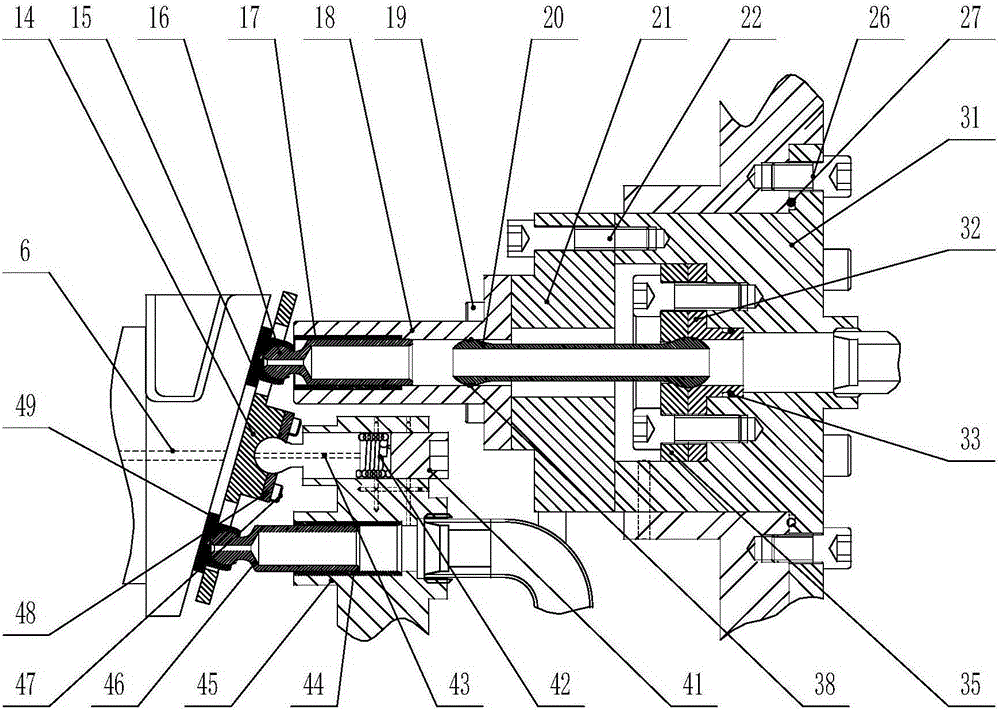

[0022] like figure 1 As shown, a high-pressure high-speed axial plunger pump plunger pair four-axis force test device includes: a transmission part, a support part, a plunger pair part to be tested, an auxiliary plunger pair part, a casing upper cover 23, an upper Cover screw 24, sealing gasket 25, pressure sensor 28, pressure sensor base 29, four-way joint 30, housing 54, liquid level switch 56, temperature sensor 57, air filter 58, straight joint 59 and oil drain stop valve 60; wherein, the transmission part is installed on the housing 54; the plunger chamber of the measured plunger sub-part and the plunger chamber of the auxiliary plunger sub-part are all connected to the four-way joint 30; the pressure sensor 28 is connected to the pressure sensor base 29 The four-way joint 30 is connected; a temperature sensor 57, a liquid level switch 56 and an air fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com