Novel high strength and high stability stamping retainer of cylinder roller bearing

A cylindrical roller bearing, high-stability technology, applied in the direction of bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of inability to meet the requirements of equipment use, unfavorable mass production and processing, complex processing technology, etc., to reduce processing. The effect of cost, cost reduction and reduction of processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings.

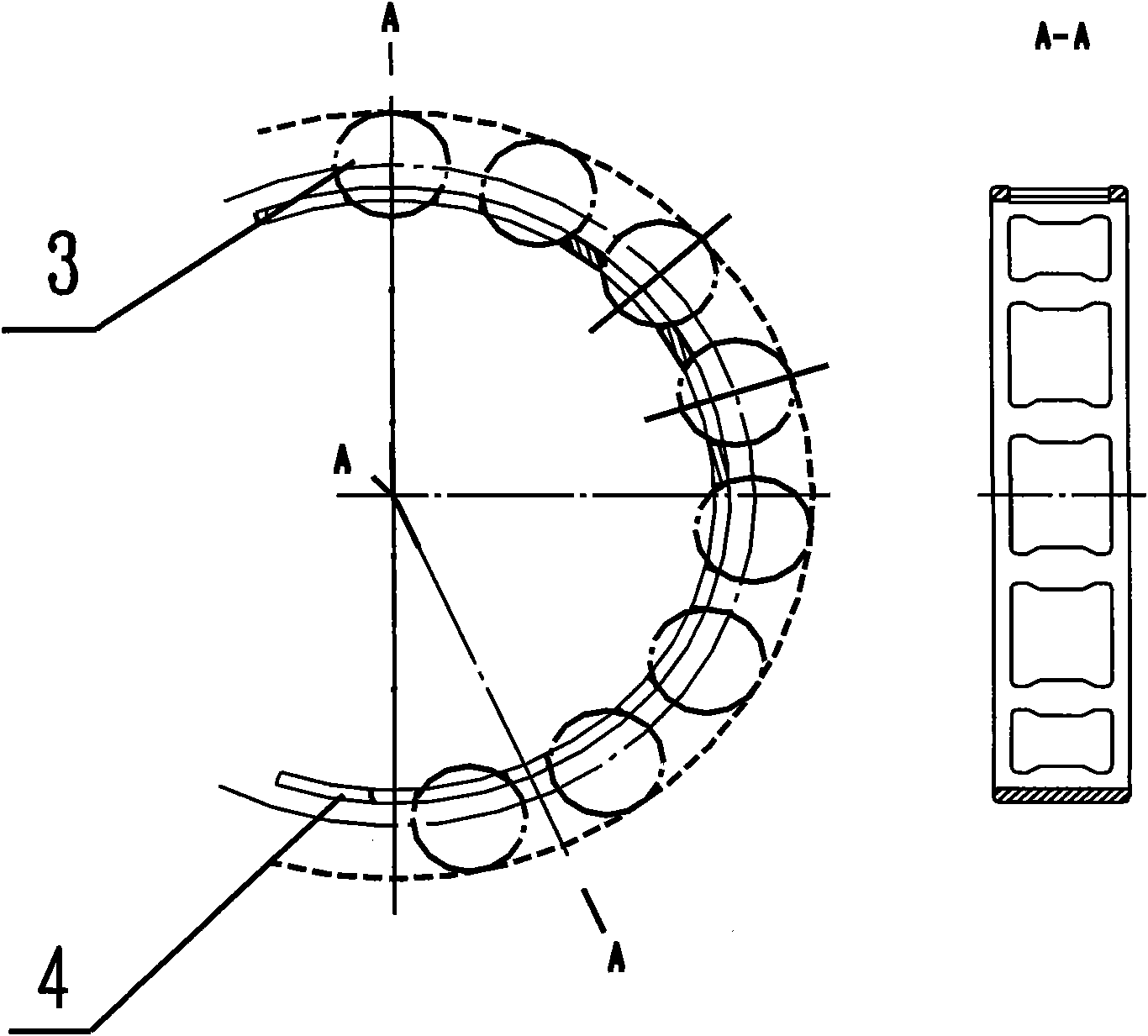

[0011] Such as figure 2 As shown, the stamping cage of the new high-strength and high-stability cylindrical roller bearing is made of a steel plate with a thickness of 1.5mm. The pocket hole is in the form of a square hole, its width is designed to be 0.985 times the diameter of the roller, and its length is designed to be 1.02 times the length of the roller.

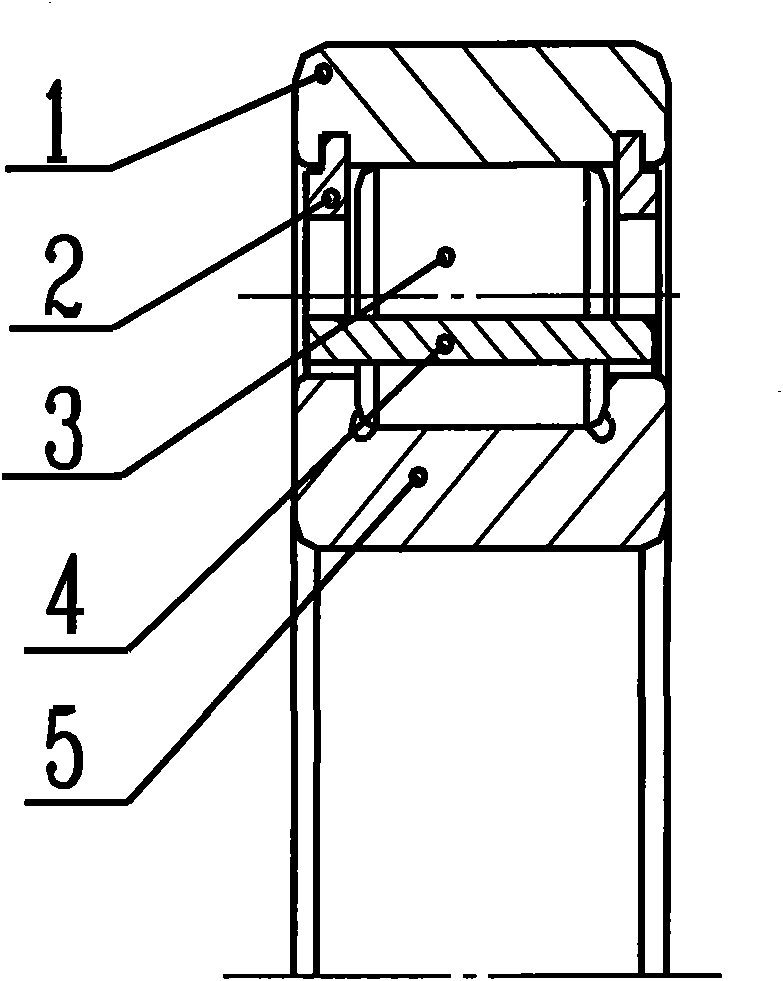

[0012] Apply the cage prepared above to figure 1 On the cylindrical roller bearing shown, the cylindrical roller bearing includes an outer ring 1 , a retaining ring 2 , cylindrical rollers 3 , a cage 4 and an inner ring 5 . The cylindrical rollers 3 are distributed on the raceway formed by the outer ring 1 and the inner ring 5 and are evenly separated by several pockets on the cage 4; The groove is in interference contact, so as to ensure that the outer ring 1 is not separated from other parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com