Suspension dehydrator

A dehydrator and suspension technology, which is used in spin dryers, washing devices, textiles and papermaking, etc., can solve problems such as low dehydration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

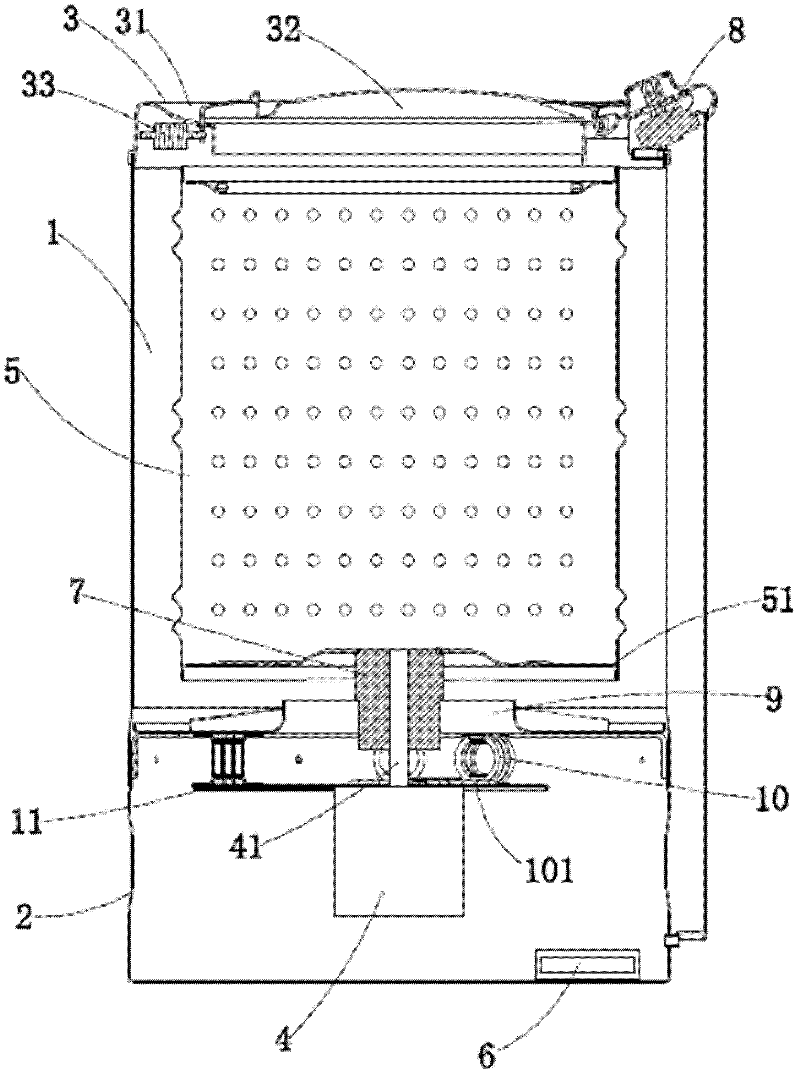

[0017] Such as figure 1 As shown, the suspension type dehydrator provided by the present invention includes a cover frame part 3, a barrel body 1, a rotating cage 5, a base 2 and a motor 4, the barrel body 1 is fixed on the base 2, and the water is conveniently collected and discharged, and the base 2 Electrical components 6 are installed inside, the cover frame part 3 is fixed on the upper end of the barrel body 1, a dehydration timer 8 is installed on the cover frame part 1 to cooperate with the electrical components 6, the motor 4 is located in the base 2, and the rotating cage 5 is located in the barrel body 1, the bottom plate 51 of the tumbler 5 is welded with a connecting bushing 7, the motor shaft 41 cooperates with the connecting bushing 7, the tumbler 5 is driven by the motor 4 to rotate at a high speed, the joint between the base 2 and the barrel body 1 A base end plate 13 is fixedly installed, and a motor mounting plate 11 is fixedly installed in the base 2. Severa...

Embodiment 2

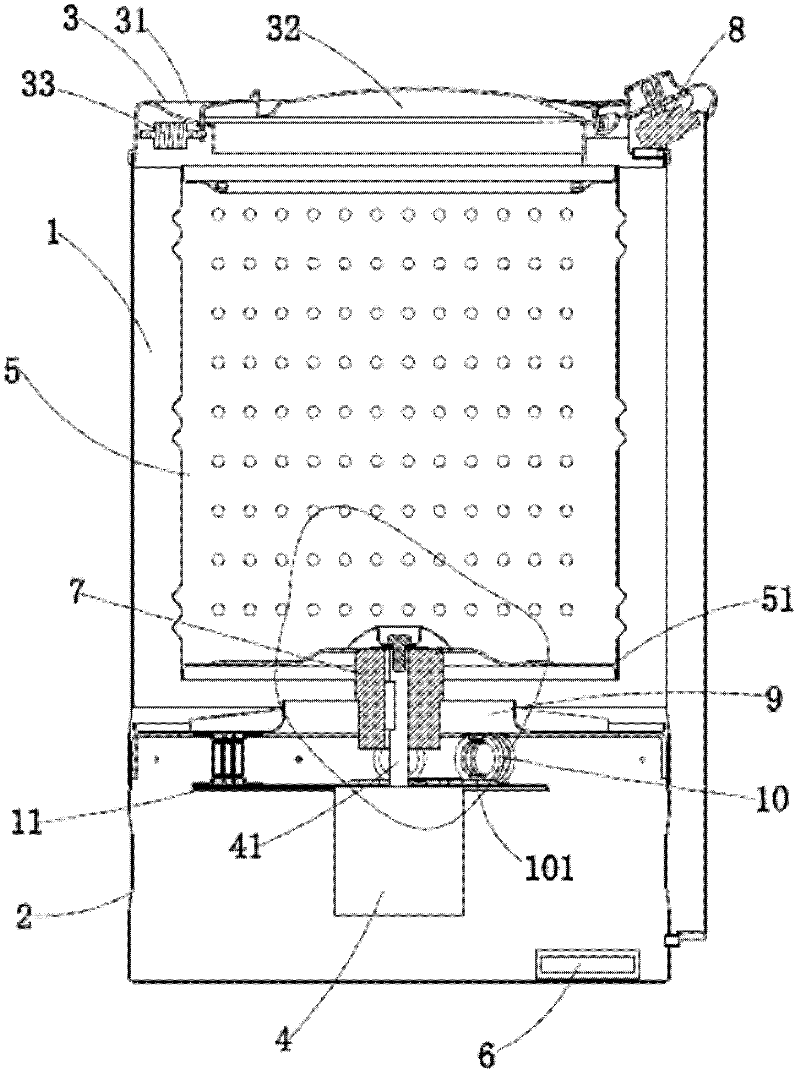

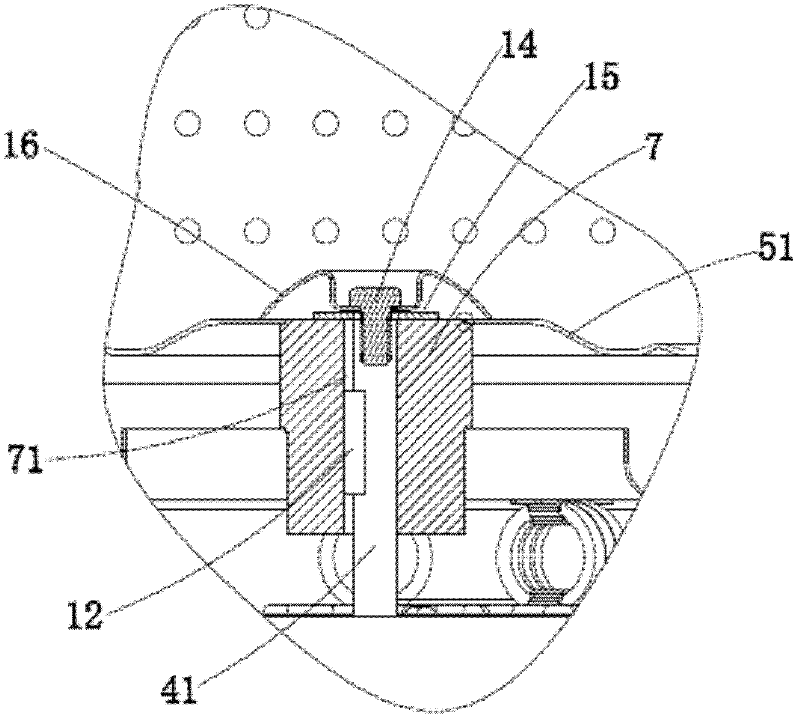

[0020] Such as figure 2 , image 3 As shown, the general structure of the suspension dehydrator provided in this embodiment is consistent with that of Embodiment 1, but in order to facilitate disassembly and maintenance, the linkage between the motor shaft 41 and the connecting sleeve 7 is a key fit structure, and the connecting sleeve 7 The inner wall is provided with a keyway 71, and the motor shaft 41 fixed with the key 12 penetrates the connecting bushing 7, and the key 12 on the motor shaft 41 cooperates with the keyway 71 on the inner wall of the connecting bushing 7; in order to protect the motor 4, the connecting bushing 7 A spacer element 15 is provided at the top of the inner hole, and the spacer element 15 is fixed to the motor shaft 41 by a fastener 14. The fastener 14 can be a screw or other fastening standard parts, and a mask is provided on the bottom plate of the cage 16 cooperates with spacer element 15.

Embodiment 3

[0022] Such as Figure 4 As shown, the general structure of the suspension dehydrator provided in this embodiment is consistent with that of Embodiment 1, but in order to strengthen the connection strength between the bottom plate 51 of the tumbler and the connecting sleeve 7, a lining plate is fixedly placed on the connecting sleeve 7 13. The lining plate 13 is welded with the connecting shaft sleeve 7, and also welded with the bottom plate 5 of the cage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com